dashboard FIAT TIPO 5DOORS STATION WAGON 2017 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: TIPO 5DOORS STATION WAGON, Model: FIAT TIPO 5DOORS STATION WAGON 2017 1.GPages: 264, PDF Size: 4.53 MB

Page 148 of 264

UNDER DASHBOARD CONTROL UNIT

fig. 166

USERSFUSE AMPERE

Front door unlocking (driver side) 1 7.5

Front door unlocking (passenger side) 2 7.5

Rear door unlocking (left) 3 7.5

Rear door unlocking (right) 4 7.5

LUGGAGE COMPARTMENT FUSE BOX

fig. 169

USERSFUSE AMPERE

Rear 12 V socket F97 15

Driver's front seat heater F99 10

Passenger side front seat heater F92 10

Driver's front seat lumbar adjustment F90 10

WARNING

134)If the replaced fuse blows again, contact a Fiat Dealership.

135)Never replace a fuse with another with a higher amp rating; DANGER OF FIRE

136)If a fuse NOT indicated in this or the previous page is used, contact a Fiat Dealership.

137)Before replacing a fuse, make sure that the ignition device is at STOP, that the key, if mechanical, has been removed and that all devices

are switched off and/or disconnected.

146

IN AN EMERGENCY

Page 155 of 264

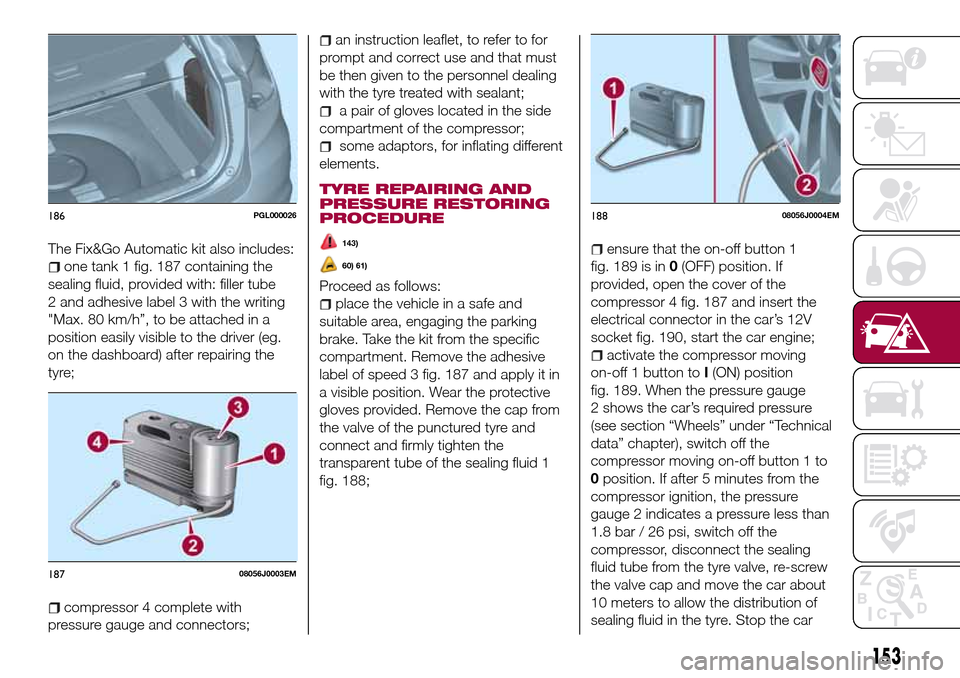

The Fix&Go Automatic kit also includes:

one tank 1 fig. 187 containing the

sealing fluid, provided with: filler tube

2 and adhesive label 3 with the writing

"Max. 80 km/h”, to be attached in a

position easily visible to the driver (eg.

on the dashboard) after repairing the

tyre;

compressor 4 complete with

pressure gauge and connectors;

an instruction leaflet, to refer to for

prompt and correct use and that must

be then given to the personnel dealing

with the tyre treated with sealant;

a pair of gloves located in the side

compartment of the compressor;

some adaptors, for inflating different

elements.

TYRE REPAIRING AND

PRESSURE RESTORING

PROCEDURE

143)

60) 61)

Proceed as follows:

place the vehicle in a safe and

suitable area, engaging the parking

brake. Take the kit from the specific

compartment. Remove the adhesive

label of speed 3 fig. 187 and apply it in

a visible position. Wear the protective

gloves provided. Remove the cap from

the valve of the punctured tyre and

connect and firmly tighten the

transparent tube of the sealing fluid 1

fig. 188;

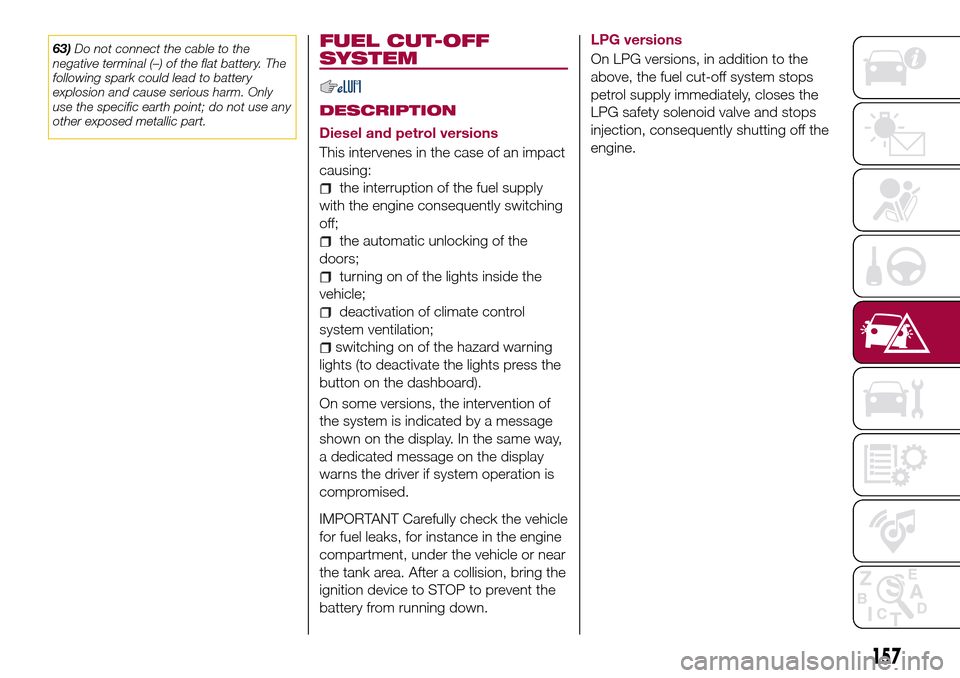

ensure that the on-off button 1

fig. 189 is in0(OFF) position. If

provided, open the cover of the

compressor 4 fig. 187 and insert the

electrical connector in the car’s 12V

socket fig. 190, start the car engine;

activate the compressor moving

on-off 1 button toI(ON) position

fig. 189. When the pressure gauge

2 shows the car’s required pressure

(see section “Wheels” under “Technical

data” chapter), switch off the

compressor moving on-off button 1 to

0position. If after 5 minutes from the

compressor ignition, the pressure

gauge 2 indicates a pressure less than

1.8 bar / 26 psi, switch off the

compressor, disconnect the sealing

fluid tube from the tyre valve, re-screw

the valve cap and move the car about

10 meters to allow the distribution of

sealing fluid in the tyre. Stop the car

186PGL000026

18708056J0003EM

18808056J0004EM

153

Page 159 of 264

63)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.FUEL CUT-OFF

SYSTEM

DESCRIPTION

Diesel and petrol versions

This intervenes in the case of an impact

causing:

the interruption of the fuel supply

with the engine consequently switching

off;

the automatic unlocking of the

doors;

turning on of the lights inside the

vehicle;

deactivation of climate control

system ventilation;

switching on of the hazard warning

lights (to deactivate the lights press the

button on the dashboard).

On some versions, the intervention of

the system is indicated by a message

shown on the display. In the same way,

a dedicated message on the display

warns the driver if system operation is

compromised.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or near

the tank area. After a collision, bring the

ignition device to STOP to prevent the

battery from running down.

LPG versions

On LPG versions, in addition to the

above, the fuel cut-off system stops

petrol supply immediately, closes the

LPG safety solenoid valve and stops

injection, consequently shutting off the

engine.

157

Page 187 of 264

INTERIOR

172) 173) 174)

Periodically check the cleanliness of the

interior, beneath the mats, which could

cause oxidation of the sheet metal.

SEATS AND FABRIC

PARTS

Remove dust with a soft brush or a

vacuum cleaner. It is advisable to use a

moist brush on when cleaning

non-fabric upholstery. Rub the seats

with a sponge moistened with a

solution of water and neutral detergent.

LEATHER SEATS(where provided)

Remove the dry dirt with a chamois or

slightly damp cloth, without exerting too

much pressure.

Remove any liquid or grease stains

using an absorbent dry cloth, without

rubbing. Then clean with a soft cloth or

buckskin cloth dampened with water

and mild soap. If the stain persists, use

specific products and observe the

instructions carefully.

IMPORTANT Never use alcohol. Make

sure that the cleaning products used

contain no alcohol or alcohol

derivatives, even in small quantities.PLASTIC AND COATED

PARTS

81)

Clean interior plastic parts with a damp

cloth (if possible made from microfibre),

and a solution of water and neutral,

non-abrasive detergent.

To clean oily or persistent stains, use

specific products free from solvents and

designed to maintain the original

appearance and colour of the

components.

Remove any dust using a microfibre

cloth, if necessary moistened with

water. The use of paper tissues is not

recommended as these may leave

residues.

GENUINE LEATHER

PARTS

(where provided)

Use only water and mild soap to clean

these parts. Never use alcohol or

alcohol-based products.

Before using a specific product for

cleaning interiors, make sure that it

does not contain alcohol and/or alcohol

based substances.

WARNING

172)Never use flammable products, such

as petrol ether or rectified petrol to clean

the inside of the car. The electrostatic

charges which are generated by rubbing

during the cleaning operation may cause a

fire.

173)Do not keep aerosol cans in the car:

they might explode. Aerosol cans must not

be exposed to a temperature exceeding

50°C. When the vehicle is exposed to

sunlight, the internal temperature can

greatly exceed this value.

174)There must be no obstacles on the

floor underneath the pedals; make sure

that mats are always flat and do not

interfere with the pedals.

IMPORTANT

81)Never use alcohol, petrols and

derivatives to clean the dashboard and

instrument panel lens.

185

Page 189 of 264

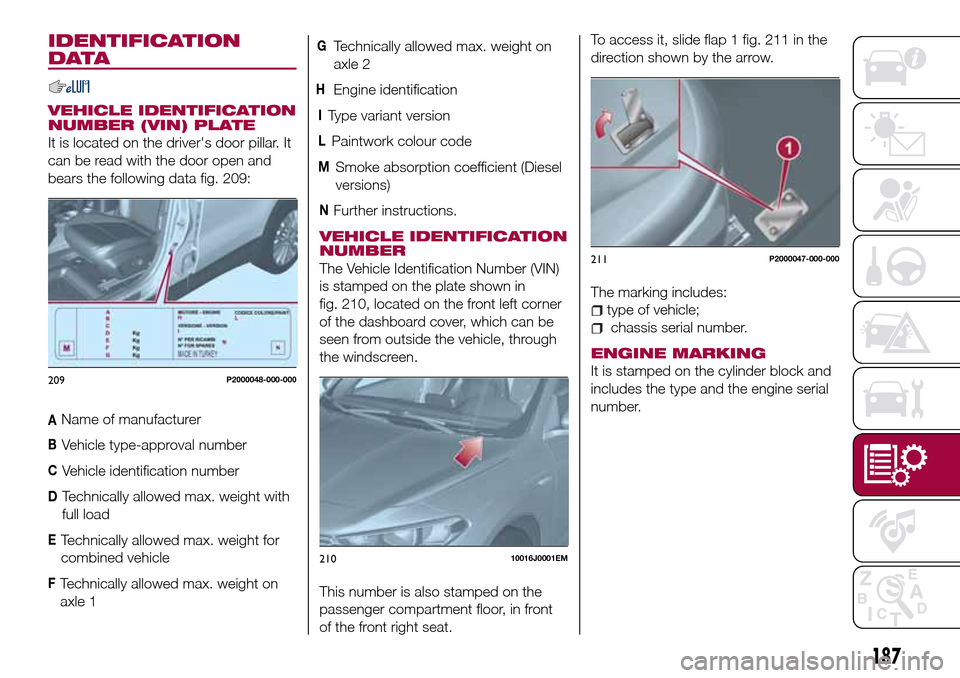

IDENTIFICATION

DATA

VEHICLE IDENTIFICATION

NUMBER (VIN) PLATE

It is located on the driver's door pillar. It

can be read with the door open and

bears the following data fig. 209:

AName of manufacturer

BVehicle type-approval number

CVehicle identification number

DTechnically allowed max. weight with

full load

ETechnically allowed max. weight for

combined vehicle

FTechnically allowed max. weight on

axle 1

GTechnically allowed max. weight on

axle 2

HEngine identification

IType variant version

LPaintwork colour code

MSmoke absorption coefficient (Diesel

versions)

NFurther instructions.

VEHICLE IDENTIFICATION

NUMBER

The Vehicle Identification Number (VIN)

is stamped on the plate shown in

fig. 210, located on the front left corner

of the dashboard cover, which can be

seen from outside the vehicle, through

the windscreen.

This number is also stamped on the

passenger compartment floor, in front

of the front right seat.To access it, slide flap 1 fig. 211 in the

direction shown by the arrow.

The marking includes:

type of vehicle;

chassis serial number.

ENGINE MARKING

It is stamped on the cylinder block and

includes the type and the engine serial

number.209P2000048-000-000

21010016J0001EM

211P2000047-000-000

187