light FIAT TIPO 5DOORS STATION WAGON 2017 1.G Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: TIPO 5DOORS STATION WAGON, Model: FIAT TIPO 5DOORS STATION WAGON 2017 1.GPages: 264, PDF Size: 4.53 MB

Page 125 of 264

44)The section of the bumper before the

sensor must not be covered with

adhesives, auxiliary headlights or any other

object.

45)Operation can be adversely affected by

any structural change made to the vehicle,

such as a modification to the front

geometry, tyre change, or a heavier load

than the standard load of the vehicle.

46)Incorrect repairs made on the front part

of the vehicle (e.g. bumper, chassis) may

alter the position of the radar sensor, and

adversely affect its operation. Go to a Fiat

Dealership for any operation of this type.

47)Do not tamper nor operate on the radar

sensor. In the event of a sensor failure,

contact a Fiat Dealership.

48)Do not wash with high-pressure jets in

the bumper lower area: in particular do not

operate on the system's electrical

connector.

49)Be careful in the case of repairs and

new paintings in the area around the

sensor (panel covering the sensor on the

left side of the bumper). In the event of a

frontal impact the sensor may automatically

deactivate and display a warning to indicate

that the sensor needs to be repaired. Even

without a malfunction warning, deactivate

the system operation if you think that the

position of the radar sensor has changed

(e.g. due to low-speed frontal impact as

during parking manoeuvres). In these

cases, go to a Fiat Dealership to have the

radar sensor realigned or replaced.PARKING SENSORS

(where provided)

SENSORS

123)

50) 51) 52)

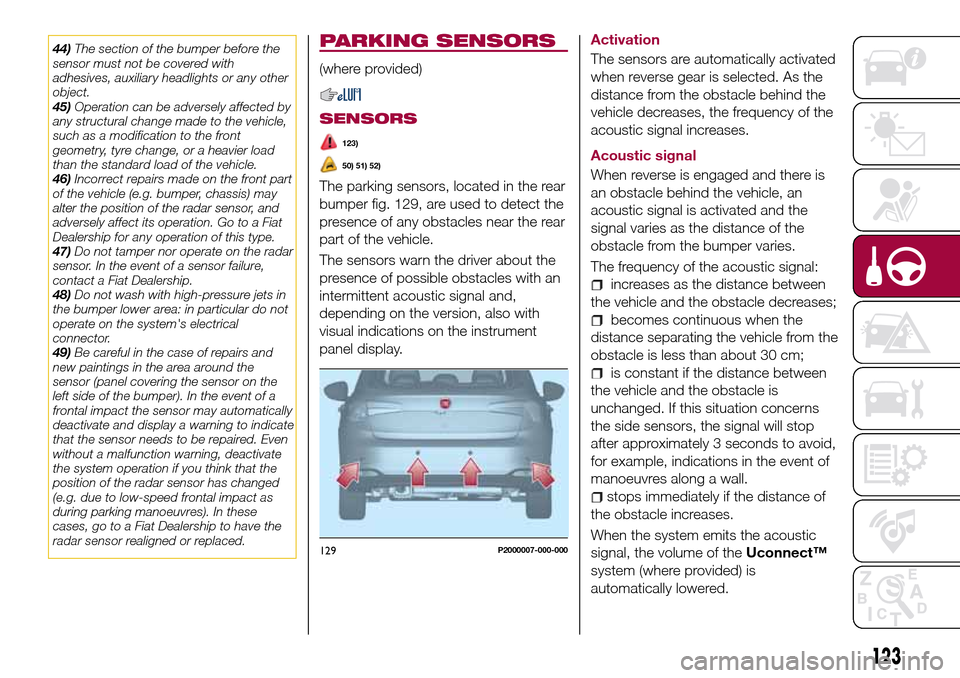

The parking sensors, located in the rear

bumper fig. 129, are used to detect the

presence of any obstacles near the rear

part of the vehicle.

The sensors warn the driver about the

presence of possible obstacles with an

intermittent acoustic signal and,

depending on the version, also with

visual indications on the instrument

panel display.Activation

The sensors are automatically activated

when reverse gear is selected. As the

distance from the obstacle behind the

vehicle decreases, the frequency of the

acoustic signal increases.

Acoustic signal

When reverse is engaged and there is

an obstacle behind the vehicle, an

acoustic signal is activated and the

signal varies as the distance of the

obstacle from the bumper varies.

The frequency of the acoustic signal:

increases as the distance between

the vehicle and the obstacle decreases;

becomes continuous when the

distance separating the vehicle from the

obstacle is less than about 30 cm;

is constant if the distance between

the vehicle and the obstacle is

unchanged. If this situation concerns

the side sensors, the signal will stop

after approximately 3 seconds to avoid,

for example, indications in the event of

manoeuvres along a wall.

stops immediately if the distance of

the obstacle increases.

When the system emits the acoustic

signal, the volume of theUconnect™

system (where provided) is

automatically lowered.

129P2000007-000-000

123

Page 126 of 264

Detection distances

If several obstacles are detected by the

sensors, only the nearest one is

considered.

Indication on display

The indications regarding the Park

Assist system are shown only if the

"Acoustic signal and display" item in the

"Settings" menu of theUconnect™ 5"

or7" HDsystem (where provided) was

previously selected (for more

information, see the description in the

dedicated chapter).

The system indicates the presence of

an obstacle by displaying a single arc in

one of the possible areas, in

accordance with the distance of the

object and the position in relation to the

vehicle. If the obstacle is detected in the

rear central area, a single arc will be

displayed as the obstacle approaches,

first constant, then flashing, in addition

to an acoustic signal.

FAULT INDICATION

Parking sensor faults, if any, will be

indicated when reverse is engaged by

the switching on of the

symbol on

the instrument panel together with the

message on the display (see

description in the "Warning lights and

messages" paragraph, "Knowing the

instrument panel" chapter).

OPERATION WITH A

TRAILER

The operation of the sensors is

automatically deactivated when the

trailer's electrical connection is inserted

in the vehicle's tow hook socket.

Sensors are reactivated on removing

the trailer's electrical connection.

IMPORTANT NOTES

When parking, take the utmost care

over obstacles that may be above or

under the sensor. Objects close to the

vehicle are not detected under certain

circumstances and could therefore

cause damage to the vehicle or be

damaged.

Some conditions may influence the

performance of the parking system:

reduced sensor sensitivity and a

reduction in the parking assistance

system performance could be due to

the presence of: ice, snow, mud, paint,

etc. on the surface of the sensor;

the sensor may detect a

non-existent obstacle ("echo

interference") due to mechanical

interference, for example when washing

the vehicle, in rain (strong wind), hail;

the signals sent by the sensor can

also be altered by the presence of

ultrasonic systems (e.g. pneumatic

brake systems of trucks or pneumatic

drills) near the vehicle;

parking assistance system

performance can also be influenced by

the position of the sensors, for example

due to a change in the ride setting

(caused by wear to the shock

absorbers, suspension), or by changing

tyres, overloading the vehicle or fitting

specific trims that require the vehicle to

be lowered;

the presence of a tow hook without

trailer, which may interfere with the

correct operation of the parking

sensors;

the presence of adhesives on the

sensors. Therefore, take care not to

place adhesives on the sensors.

WARNING

123)Parking and other potentially

dangerous manoeuvres are, however,

always the driver’s responsibility. When

performing these operations, always make

sure that there are no other people

(especially children) or animals on the route

you want to take. The parking sensors are

an aid for the driver, but the driver must

never allow their attention to lapse during

potentially dangerous manoeuvres, even

those executed at low speeds.

124

STARTING AND DRIVING

Page 128 of 264

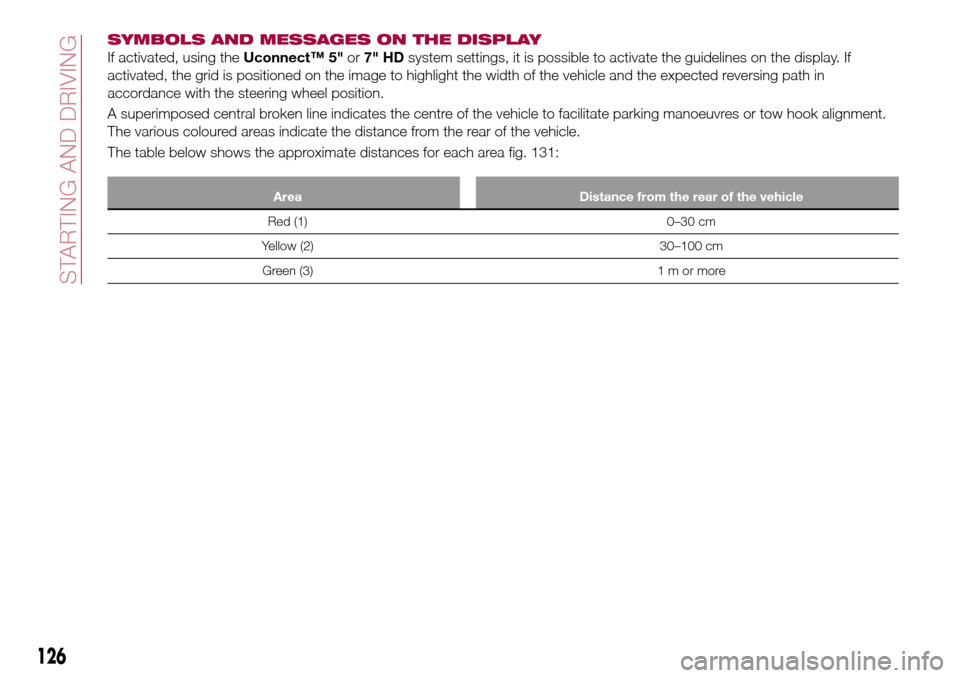

SYMBOLS AND MESSAGES ON THE DISPLAY

If activated, using theUconnect™ 5"or7" HDsystem settings, it is possible to activate the guidelines on the display. If

activated, the grid is positioned on the image to highlight the width of the vehicle and the expected reversing path in

accordance with the steering wheel position.

A superimposed central broken line indicates the centre of the vehicle to facilitate parking manoeuvres or tow hook alignment.

The various coloured areas indicate the distance from the rear of the vehicle.

The table below shows the approximate distances for each area fig. 131:

Area Distance from the rear of the vehicle

Red (1) 0–30 cm

Yellow (2) 30–100 cm

Green (3) 1 m or more

126

STARTING AND DRIVING

Page 130 of 264

Do not exceed the speed limits specific

to each country you are driving in, in the

case of vehicles towing trailers. In any

case, the top speed must not exceed

100 km/h.

Any electric brake must be powered

directly by the battery through a cable

with a cross-section of no less than

2.5 mm

2.

In addition to the electrical branches,

the vehicle electrical system can only be

connected to the supply cable for an

electric brake and to the cable for an

internal light for the trailer, not

exceeding 15 W. For connections, use

the preset control unit with a battery

cable with section not less than 2.5 mm

2.

IMPORTANT The use of auxiliary loads

other than external lights (e.g. electric

brake) must take place with engine

running.

INSTALLING A TOW

HOOK

To install a tow hook contact a Fiat

Dealership.

WARNING

125)The ABS with which the car is

equipped will not control the braking

system of the trailer. Particular caution is

required on slippery roads.

126)Never modify the braking system of

the vehicle to control the trailer brake. The

trailer braking system must be fully

independent of the car’s hydraulic system.

REFUELLING THE

VEHICLE

127) 128) 129)

Before refuelling, make sure that the

fuel type is correct.

Also stop the engine before refuelling.

PETROL ENGINES

Only use 95 R.O.N. unleaded petrol (EN

228 specifications).

DIESEL ENGINES

54)

Only use Diesel for motor vehicles

(EN590 specification).

When using or parking the vehicle for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available Diesel. In this case, it is

also advisable to keep the tank over

50% full.

REFUELLING CAPACITY

To ensure that you fill the tank

completely, top up twice after the first

click of the fuel supply gun.

Further top-ups could cause faults in

the fuel feeding system.

128

STARTING AND DRIVING

Page 133 of 264

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere with

our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the national or

international universal freephone

number to search for the nearest Fiat

Dealership.HAZARD WARNING LIGHTS.....132

BULB REPLACEMENT........132

REPLACING FUSES..........142

CHANGING A WHEEL.........148

FIX&GO AUTOMATIC KIT.......152

JUMP STARTING............155

FUEL CUT-OFF SYSTEM.......157

TOWING THE VEHICLE........159

131

Page 134 of 264

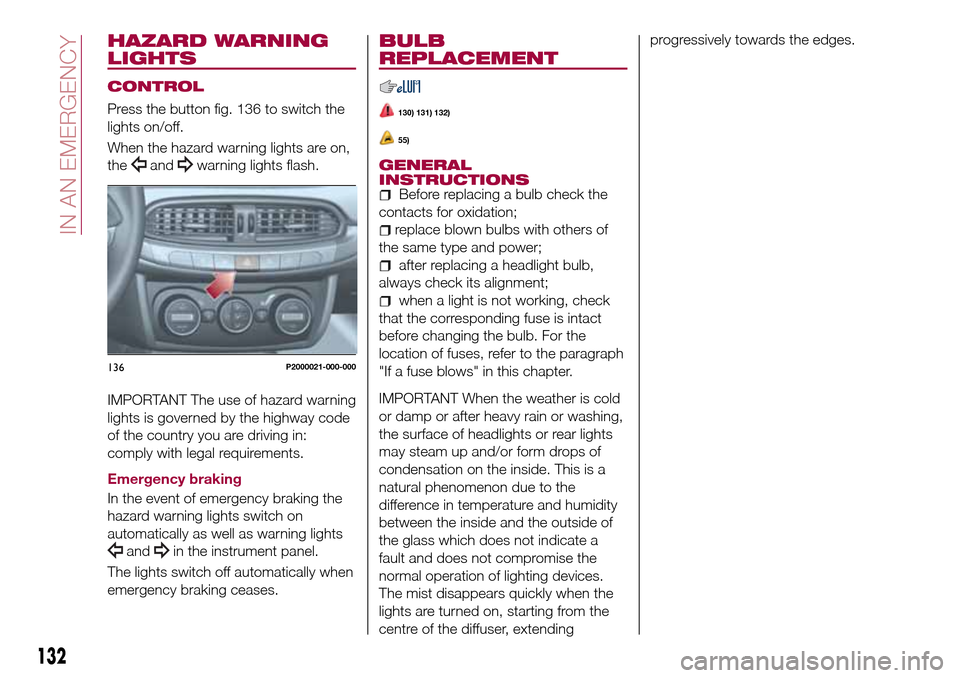

HAZARD WARNING

LIGHTS

CONTROL

Press the button fig. 136 to switch the

lights on/off.

When the hazard warning lights are on,

the

andwarning lights flash.

IMPORTANT The use of hazard warning

lights is governed by the highway code

of the country you are driving in:

comply with legal requirements.

Emergency braking

In the event of emergency braking the

hazard warning lights switch on

automatically as well as warning lights

andin the instrument panel.

The lights switch off automatically when

emergency braking ceases.

BULB

REPLACEMENT

130) 131) 132)

55)

GENERAL

INSTRUCTIONS

Before replacing a bulb check the

contacts for oxidation;

replace blown bulbs with others of

the same type and power;

after replacing a headlight bulb,

always check its alignment;

when a light is not working, check

that the corresponding fuse is intact

before changing the bulb. For the

location of fuses, refer to the paragraph

"If a fuse blows" in this chapter.

IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights

may steam up and/or form drops of

condensation on the inside. This is a

natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside of

the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from the

centre of the diffuser, extendingprogressively towards the edges.

136P2000021-000-000

132

IN AN EMERGENCY

Page 136 of 264

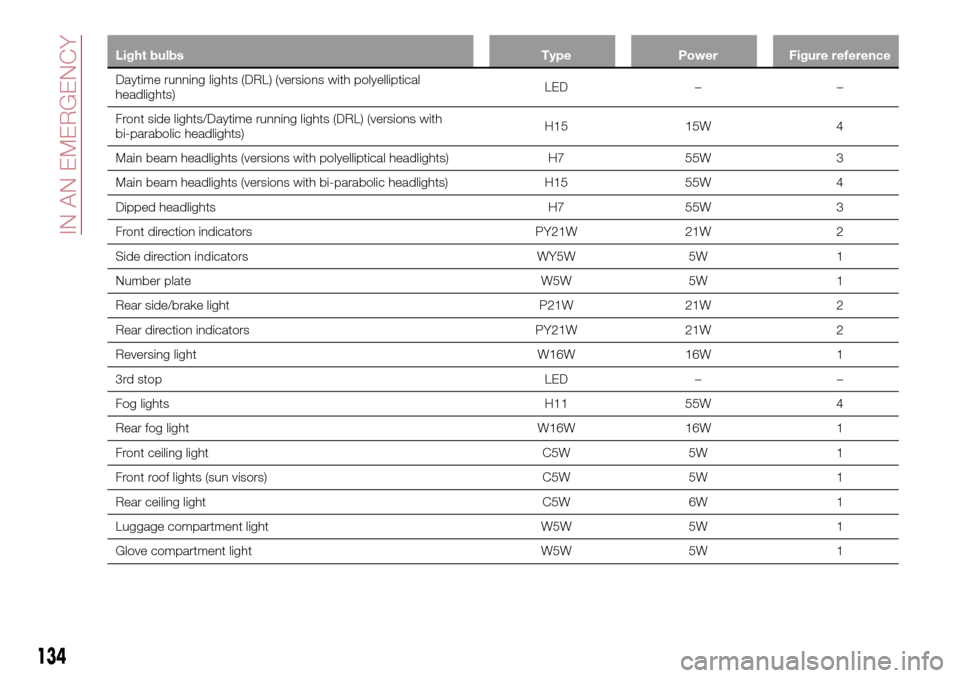

Light bulbs Type Power Figure reference

Daytime running lights (DRL) (versions with polyelliptical

headlights)LED – –

Front side lights/Daytime running lights (DRL) (versions with

bi-parabolic headlights)H15 15W 4

Main beam headlights (versions with polyelliptical headlights) H7 55W 3

Main beam headlights (versions with bi-parabolic headlights) H15 55W 4

Dipped headlights H7 55W 3

Front direction indicators PY21W 21W 2

Side direction indicators WY5W 5W 1

Number plate W5W 5W 1

Rear side/brake light P21W 21W 2

Rear direction indicators PY21W 21W 2

Reversing light W16W 16W 1

3rd stop LED – –

Fog lights H11 55W 4

Rear fog light W16W 16W 1

Front ceiling light C5W 5W 1

Front roof lights (sun visors) C5W 5W 1

Rear ceiling light C5W 6W 1

Luggage compartment light W5W 5W 1

Glove compartment light W5W 5W 1

134

IN AN EMERGENCY

Page 137 of 264

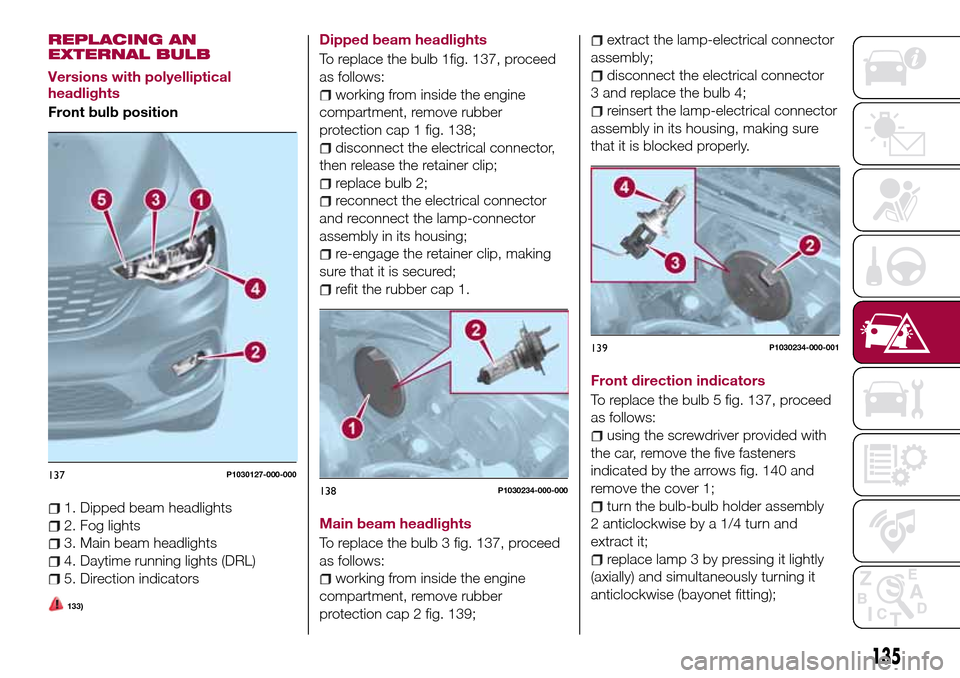

REPLACING AN

EXTERNAL BULB

Versions with polyelliptical

headlights

Front bulb position

1. Dipped beam headlights

2. Fog lights

3. Main beam headlights

4. Daytime running lights (DRL)

5. Direction indicators

133)

Dipped beam headlights

To replace the bulb 1fig. 137, proceed

as follows:

working from inside the engine

compartment, remove rubber

protection cap 1 fig. 138;

disconnect the electrical connector,

then release the retainer clip;

replace bulb 2;

reconnect the electrical connector

and reconnect the lamp-connector

assembly in its housing;

re-engage the retainer clip, making

sure that it is secured;

refit the rubber cap 1.

Main beam headlights

To replace the bulb 3 fig. 137, proceed

as follows:

working from inside the engine

compartment, remove rubber

protection cap 2 fig. 139;

extract the lamp-electrical connector

assembly;

disconnect the electrical connector

3 and replace the bulb 4;

reinsert the lamp-electrical connector

assembly in its housing, making sure

that it is blocked properly.

Front direction indicators

To replace the bulb 5 fig. 137, proceed

as follows:

using the screwdriver provided with

the car, remove the five fasteners

indicated by the arrows fig. 140 and

remove the cover 1;

turn the bulb-bulb holder assembly

2 anticlockwise by a 1/4 turn and

extract it;

replace lamp 3 by pressing it lightly

(axially) and simultaneously turning it

anticlockwise (bayonet fitting);

137P1030127-000-000

138P1030234-000-000

139P1030234-000-001

135

Page 138 of 264

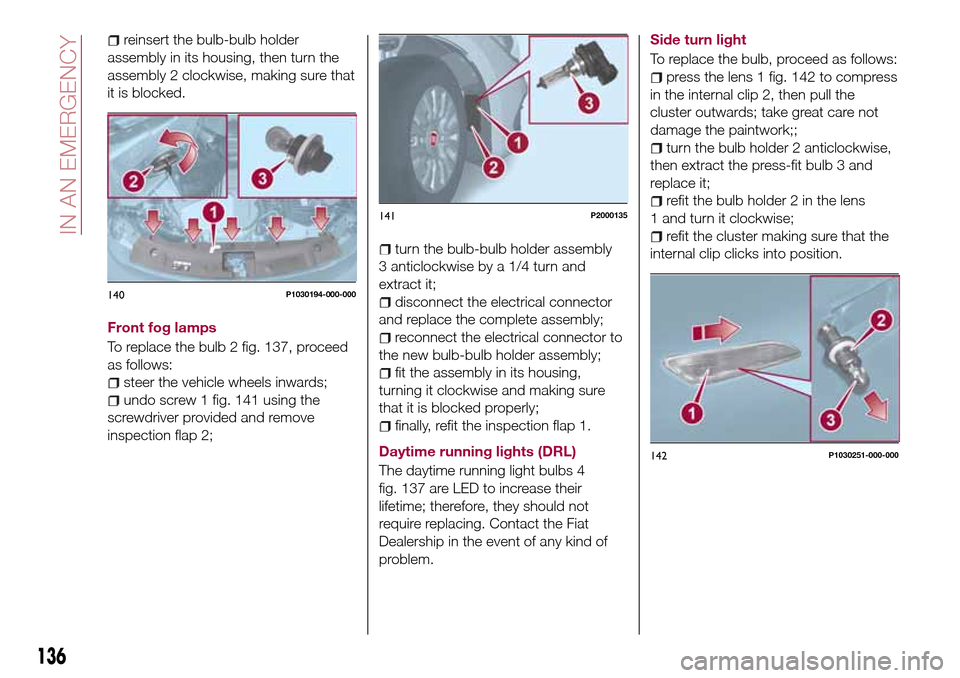

reinsert the bulb-bulb holder

assembly in its housing, then turn the

assembly 2 clockwise, making sure that

it is blocked.

Front fog lamps

To replace the bulb 2 fig. 137, proceed

as follows:

steer the vehicle wheels inwards;

undo screw 1 fig. 141 using the

screwdriver provided and remove

inspection flap 2;

turn the bulb-bulb holder assembly

3 anticlockwise by a 1/4 turn and

extract it;

disconnect the electrical connector

and replace the complete assembly;

reconnect the electrical connector to

the new bulb-bulb holder assembly;

fit the assembly in its housing,

turning it clockwise and making sure

that it is blocked properly;

finally, refit the inspection flap 1.

Daytime running lights (DRL)

The daytime running light bulbs 4

fig. 137 are LED to increase their

lifetime; therefore, they should not

require replacing. Contact the Fiat

Dealership in the event of any kind of

problem.Side turn light

To replace the bulb, proceed as follows:

press the lens 1 fig. 142 to compress

in the internal clip 2, then pull the

cluster outwards; take great care not

damage the paintwork;;

turn the bulb holder 2 anticlockwise,

then extract the press-fit bulb 3 and

replace it;

refit the bulb holder 2 in the lens

1 and turn it clockwise;

refit the cluster making sure that the

internal clip clicks into position.

140P1030194-000-000

141P2000135

142P1030251-000-000

136

IN AN EMERGENCY

Page 139 of 264

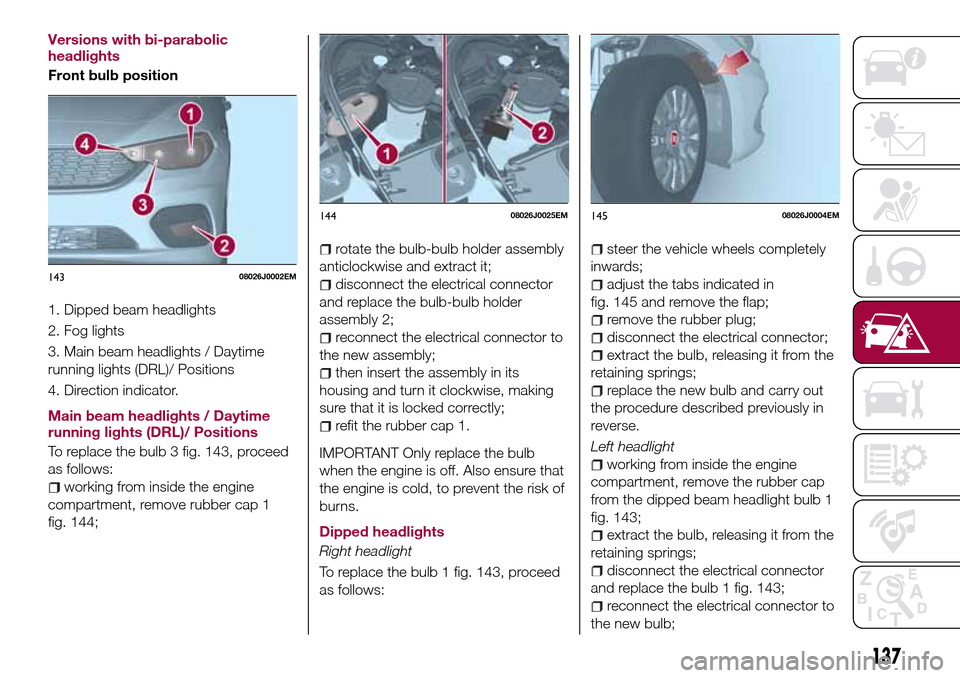

Versions with bi-parabolic

headlights

Front bulb position

1. Dipped beam headlights

2. Fog lights

3. Main beam headlights / Daytime

running lights (DRL)/ Positions

4. Direction indicator.

Main beam headlights / Daytime

running lights (DRL)/ Positions

To replace the bulb 3 fig. 143, proceed

as follows:

working from inside the engine

compartment, remove rubber cap 1

fig. 144;

rotate the bulb-bulb holder assembly

anticlockwise and extract it;

disconnect the electrical connector

and replace the bulb-bulb holder

assembly 2;

reconnect the electrical connector to

the new assembly;

then insert the assembly in its

housing and turn it clockwise, making

sure that it is locked correctly;

refit the rubber cap 1.

IMPORTANT Only replace the bulb

when the engine is off. Also ensure that

the engine is cold, to prevent the risk of

burns.

Dipped headlights

Right headlight

To replace the bulb 1 fig. 143, proceed

as follows:

steer the vehicle wheels completely

inwards;

adjust the tabs indicated in

fig. 145 and remove the flap;

remove the rubber plug;

disconnect the electrical connector;

extract the bulb, releasing it from the

retaining springs;

replace the new bulb and carry out

the procedure described previously in

reverse.

Left headlight

working from inside the engine

compartment, remove the rubber cap

from the dipped beam headlight bulb 1

fig. 143;

extract the bulb, releasing it from the

retaining springs;

disconnect the electrical connector

and replace the bulb 1 fig. 143;

reconnect the electrical connector to

the new bulb;

14308026J0002EM

14408026J0025EM14508026J0004EM

137