transmission FIAT TIPO 5DOORS STATION WAGON 2017 1.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: TIPO 5DOORS STATION WAGON, Model: FIAT TIPO 5DOORS STATION WAGON 2017 1.GPages: 264, PDF Size: 4.53 MB

Page 76 of 264

43) 44) 45) 46) 47)

TC (Traction Control)

SYSTEM

The system automatically operates in

the event of slipping, loss of grip on wet

roads (aquaplaning) and acceleration on

slippery, snowy or icy roads, etc. on

one or more drive wheels. Depending

on the slipping conditions, two different

control systems are activated:

if the slipping involves both drive

wheels, the system intervenes, reducing

the power transmitted by the engine;

if the slipping only involves one of the

drive wheels, the BLD (Brake Limited

Differential) function is activated,

automatically braking the wheel which

is slipping (the behaviour of a

self-locking differential is simulated).

This will increase the engine torque

transferred to the wheel which isn't

slipping. This function remains active

even if the "Systems partially disabled"

and "Systems disabled" modes are

selected (see description in the

following pages).

System intervention

The intervention of the system is

indicated by the flashing of the

warning light on the instrument

panel, to inform the driver that the

vehicle is in critical stability and grip

conditions.

48) 49) 50) 51) 52)

PBA (Panic Brake

Assist) SYSTEM

The PBA system is designed to improve

the vehicle’s braking capacity during

emergency braking.

The system detects emergency braking

by monitoring the speed and force with

which the brake pedal is pressed, and

consequently applies the optimal brake

pressure. This can reduce the braking

distance: the PBA system therefore

completes the ABS.

Maximum assistance from the PBA

system is obtained by pressing the

brake pedal very quickly. In addition, the

brake pedal should be pressed

continuously during braking, avoiding

intermittent presses, to get the most

out of the system. Do not reduce

pressure on the brake pedal until

braking is no longer necessary.

The PBA system is deactivated when

the brake pedal is released.

54) 54) 55)

HHC (Hill Hold Control)

SYSTEM

This is an integral part of the ESC

system and facilitates starting on

slopes, activating automatically in the

following cases:

uphill: vehicle stationary on a roadwith a gradient higher than 5%, engine

running, brake pressed and

transmission in neutral or gear other

than reverse engaged;

downhill: vehicle stationary on a road

with a gradient higher than 5%, engine

running, brake pressed and reverse

gear engaged.

When setting off, the ESC system

control unit maintains the braking

pressure on the wheels until the engine

torque necessary for starting is

reached, or in any case for a maximum

of 2 seconds, allowing your right foot to

be moved easily from the brake pedal

to the accelerator.

When two seconds have elapsed,

without starting, the system is

automatically deactivated, gradually

releasing the braking pressure. During

this release stage it is possible to hear a

typical mechanical brake release noise,

indicating the imminent movement of

the car.

56) 57)

ERM (Electronic Rollover

Mitigation) SYSTEM

The system monitors the tendency of

the wheels to rise from the ground if the

driver performs extreme manoeuvres

like quick steering to avoid an obstacle,

especially in poor road conditions.

74

SAFETY

Page 110 of 264

STARTING AND DRIVING

Let’s get to the core of the vehicle:

seeing how you can exploit all of its

potential to the full.

We’ll look at how to drive it safely in any

situation, so that it can be a welcome

companion, with our comfort and our

wallets in mind.STARTING THE ENGINE.......109

PARKING THE VEHICLE........110

PARKING BRAKE............110

USING THE TRANSMISSION. . . .111

STOP/START SYSTEM........111

SPEED LIMITER.............113

ELECTRONIC CRUISE CONTROL .114

ADAPTIVE CRUISE CONTROL

(ACC)....................116

PARKING SENSORS..........123

REAR VIEW CAMERA.........125

TOWING TRAILERS..........127

REFUELLING THE VEHICLE.....128

108

STARTING AND DRIVING

Page 113 of 264

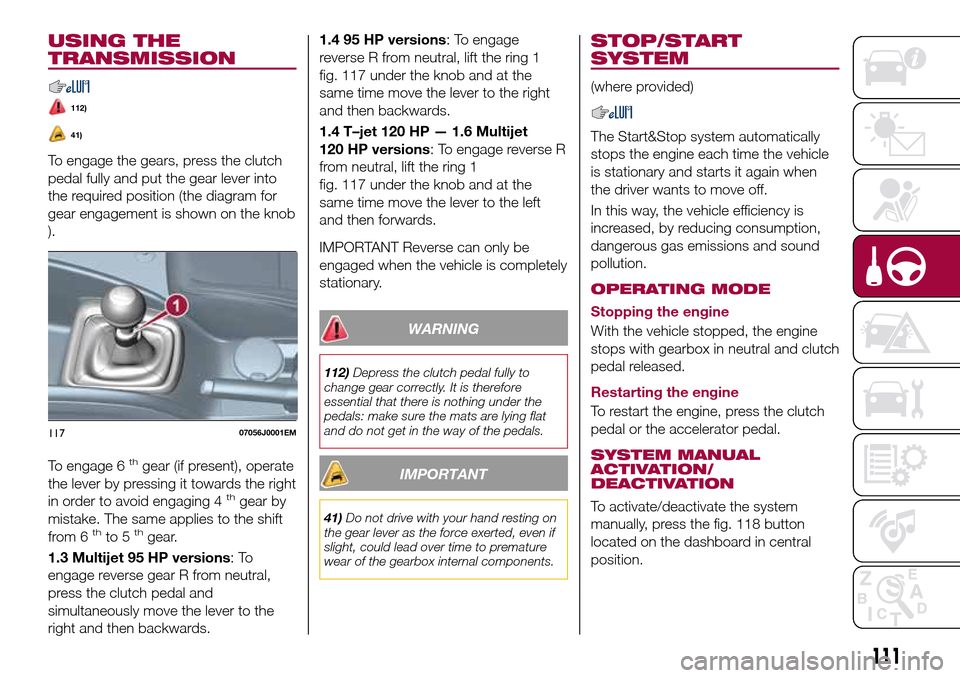

USING THE

TRANSMISSION

112)

41)

To engage the gears, press the clutch

pedal fully and put the gear lever into

the required position (the diagram for

gear engagement is shown on the knob

).

To engage 6

thgear (if present), operate

the lever by pressing it towards the right

in order to avoid engaging 4

thgear by

mistake. The same applies to the shift

from 6

thto 5thgear.

1.3 Multijet 95 HP versions:To

engage reverse gear R from neutral,

press the clutch pedal and

simultaneously move the lever to the

right and then backwards.1.4 95 HP versions: To engage

reverse R from neutral, lift the ring 1

fig. 117 under the knob and at the

same time move the lever to the right

and then backwards.

1.4 T–jet 120 HP — 1.6 Multijet

120 HP versions: To engage reverse R

from neutral, lift the ring 1

fig. 117 under the knob and at the

same time move the lever to the left

and then forwards.

IMPORTANT Reverse can only be

engaged when the vehicle is completely

stationary.

WARNING

112)Depress the clutch pedal fully to

change gear correctly. It is therefore

essential that there is nothing under the

pedals: make sure the mats are lying flat

and do not get in the way of the pedals.

IMPORTANT

41)Do not drive with your hand resting on

the gear lever as the force exerted, even if

slight, could lead over time to premature

wear of the gearbox internal components.

STOP/START

SYSTEM

(where provided)

The Start&Stop system automatically

stops the engine each time the vehicle

is stationary and starts it again when

the driver wants to move off.

In this way, the vehicle efficiency is

increased, by reducing consumption,

dangerous gas emissions and sound

pollution.

OPERATING MODE

Stopping the engine

With the vehicle stopped, the engine

stops with gearbox in neutral and clutch

pedal released.

Restarting the engine

To restart the engine, press the clutch

pedal or the accelerator pedal.

SYSTEM MANUAL

ACTIVATION/

DEACTIVATION

To activate/deactivate the system

manually, press the fig. 118 button

located on the dashboard in central

position.

11707056J0001EM

111

Page 158 of 264

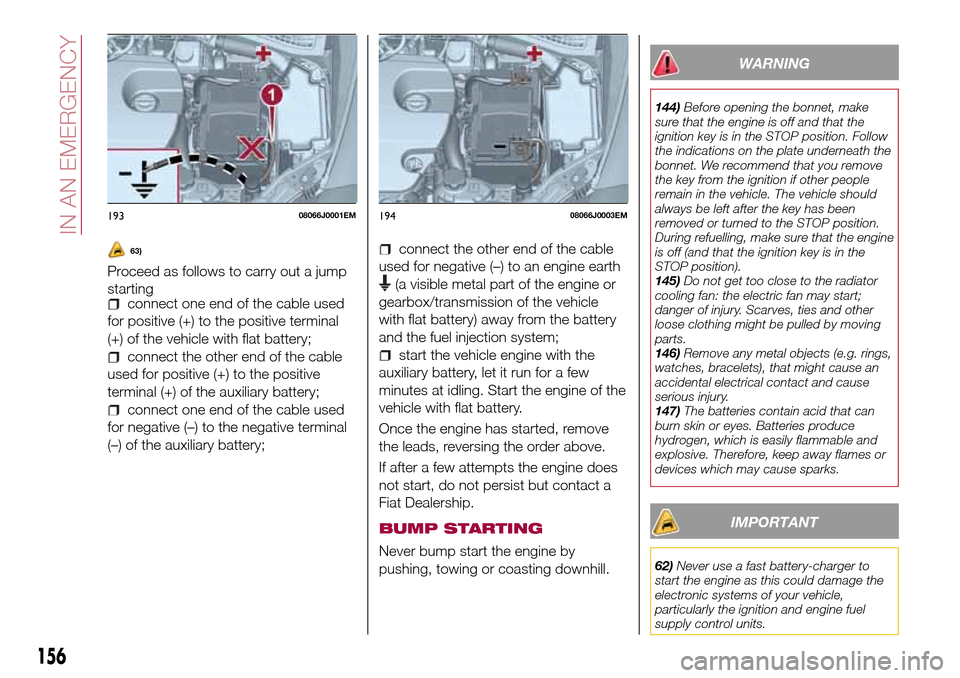

63)

Proceed as follows to carry out a jump

starting

connect one end of the cable used

for positive (+) to the positive terminal

(+) of the vehicle with flat battery;

connect the other end of the cable

used for positive (+) to the positive

terminal (+) of the auxiliary battery;

connect one end of the cable used

for negative (–) to the negative terminal

(–) of the auxiliary battery;

connect the other end of the cable

used for negative (–) to an engine earth

(a visible metal part of the engine or

gearbox/transmission of the vehicle

with flat battery) away from the battery

and the fuel injection system;

start the vehicle engine with the

auxiliary battery, let it run for a few

minutes at idling. Start the engine of the

vehicle with flat battery.

Once the engine has started, remove

the leads, reversing the order above.

If after a few attempts the engine does

not start, do not persist but contact a

Fiat Dealership.

BUMP STARTING

Never bump start the engine by

pushing, towing or coasting downhill.

WARNING

144)Before opening the bonnet, make

sure that the engine is off and that the

ignition key is in the STOP position. Follow

the indications on the plate underneath the

bonnet. We recommend that you remove

the key from the ignition if other people

remain in the vehicle. The vehicle should

always be left after the key has been

removed or turned to the STOP position.

During refuelling, make sure that the engine

is off (and that the ignition key is in the

STOP position).

145)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Scarves, ties and other

loose clothing might be pulled by moving

parts.

146)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

147)The batteries contain acid that can

burn skin or eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Therefore, keep away flames or

devices which may cause sparks.

IMPORTANT

62)Never use a fast battery-charger to

start the engine as this could damage the

electronic systems of your vehicle,

particularly the ignition and engine fuel

supply control units.

19308066J0001EM19408066J0003EM

156

IN AN EMERGENCY

Page 161 of 264

TOWING THE

VEHICLE

ATTACHING THE TOW

RING

149) 150) 151)

The tow hook provided is located in the

tool box inside the luggage

compartment.

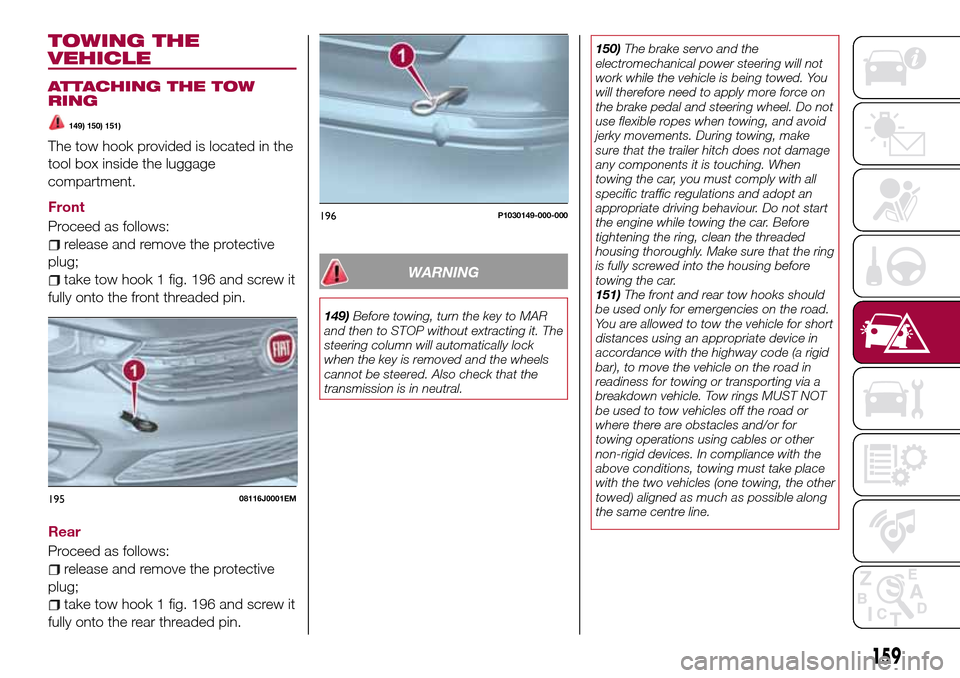

Front

Proceed as follows:

release and remove the protective

plug;

take tow hook 1 fig. 196 and screw it

fully onto the front threaded pin.

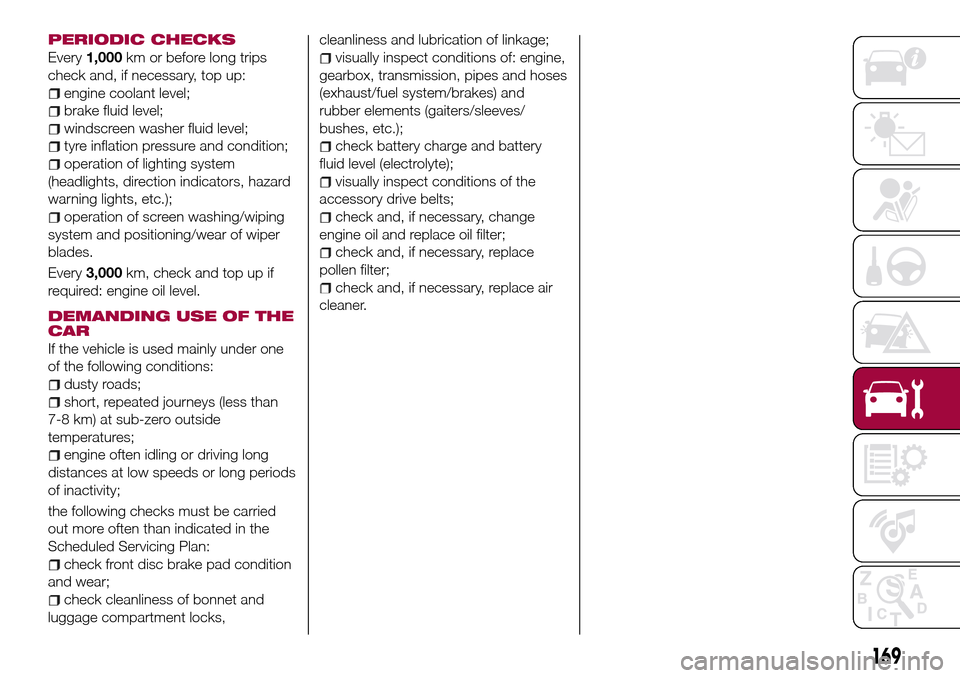

Rear

Proceed as follows:

release and remove the protective

plug;

take tow hook 1 fig. 196 and screw it

fully onto the rear threaded pin.

WARNING

149)Before towing, turn the key to MAR

and then to STOP without extracting it. The

steering column will automatically lock

when the key is removed and the wheels

cannot be steered. Also check that the

transmission is in neutral.150)The brake servo and the

electromechanical power steering will not

work while the vehicle is being towed. You

will therefore need to apply more force on

the brake pedal and steering wheel. Do not

use flexible ropes when towing, and avoid

jerky movements. During towing, make

sure that the trailer hitch does not damage

any components it is touching. When

towing the car, you must comply with all

specific traffic regulations and adopt an

appropriate driving behaviour. Do not start

the engine while towing the car. Before

tightening the ring, clean the threaded

housing thoroughly. Make sure that the ring

is fully screwed into the housing before

towing the car.

151)The front and rear tow hooks should

be used only for emergencies on the road.

You are allowed to tow the vehicle for short

distances using an appropriate device in

accordance with the highway code (a rigid

bar), to move the vehicle on the road in

readiness for towing or transporting via a

breakdown vehicle. Tow rings MUST NOT

be used to tow vehicles off the road or

where there are obstacles and/or for

towing operations using cables or other

non-rigid devices. In compliance with the

above conditions, towing must take place

with the two vehicles (one towing, the other

towed) aligned as much as possible along

the same centre line.

19508116J0001EM

196P1030149-000-000

159

Page 171 of 264

PERIODIC CHECKS

Every1,000km or before long trips

check and, if necessary, top up:

engine coolant level;

brake fluid level;

windscreen washer fluid level;

tyre inflation pressure and condition;

operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.);

operation of screen washing/wiping

system and positioning/wear of wiper

blades.

Every3,000km, check and top up if

required: engine oil level.

DEMANDING USE OF THE

CAR

If the vehicle is used mainly under one

of the following conditions:

dusty roads;

short, repeated journeys (less than

7-8 km) at sub-zero outside

temperatures;

engine often idling or driving long

distances at low speeds or long periods

of inactivity;

the following checks must be carried

out more often than indicated in the

Scheduled Servicing Plan:

check front disc brake pad condition

and wear;

check cleanliness of bonnet and

luggage compartment locks,cleanliness and lubrication of linkage;

visually inspect conditions of: engine,

gearbox, transmission, pipes and hoses

(exhaust/fuel system/brakes) and

rubber elements (gaiters/sleeves/

bushes, etc.);

check battery charge and battery

fluid level (electrolyte);

visually inspect conditions of the

accessory drive belts;

check and, if necessary, change

engine oil and replace oil filter;

check and, if necessary, replace

pollen filter;

check and, if necessary, replace air

cleaner.

169

Page 201 of 264

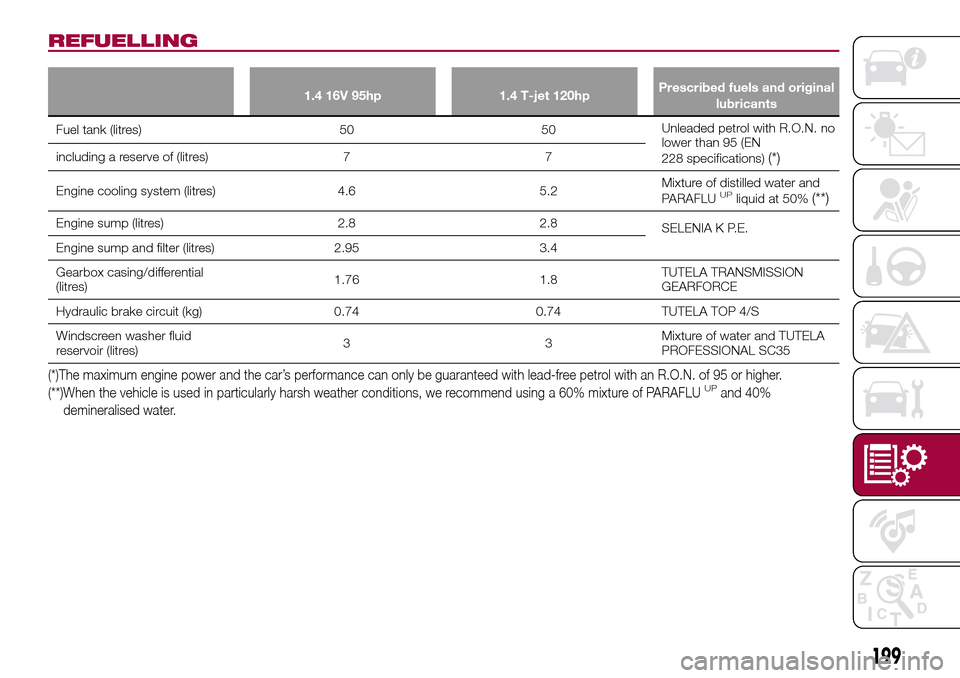

REFUELLING

1.4 16V 95hp 1.4 T-jet 120hpPrescribed fuels and original

lubricants

Fuel tank (litres) 50 50Unleaded petrol with R.O.N. no

lower than 95 (EN

228 specifications)

(*)including a reserve of (litres) 7 7

Engine cooling system (litres) 4.6 5.2Mixture of distilled water and

PARAFLU

UPliquid at 50%(**)

Engine sump (litres) 2.8 2.8

SELENIA K P.E.

Engine sump and filter (litres) 2.95 3.4

Gearbox casing/differential

(litres)1.76 1.8TUTELA TRANSMISSION

GEARFORCE

Hydraulic brake circuit (kg) 0.74 0.74 TUTELA TOP 4/S

Windscreen washer fluid

reservoir (litres)33Mixture of water and TUTELA

PROFESSIONAL SC35

(*)The maximum engine power and the car’s performance can only be guaranteed with lead-free petrol with an R.O.N. of 95 or higher.

(**)When the vehicle is used in particularly harsh weather conditions, we recommend using a 60% mixture of PARAFLUUPand 40%

demineralised water.

199

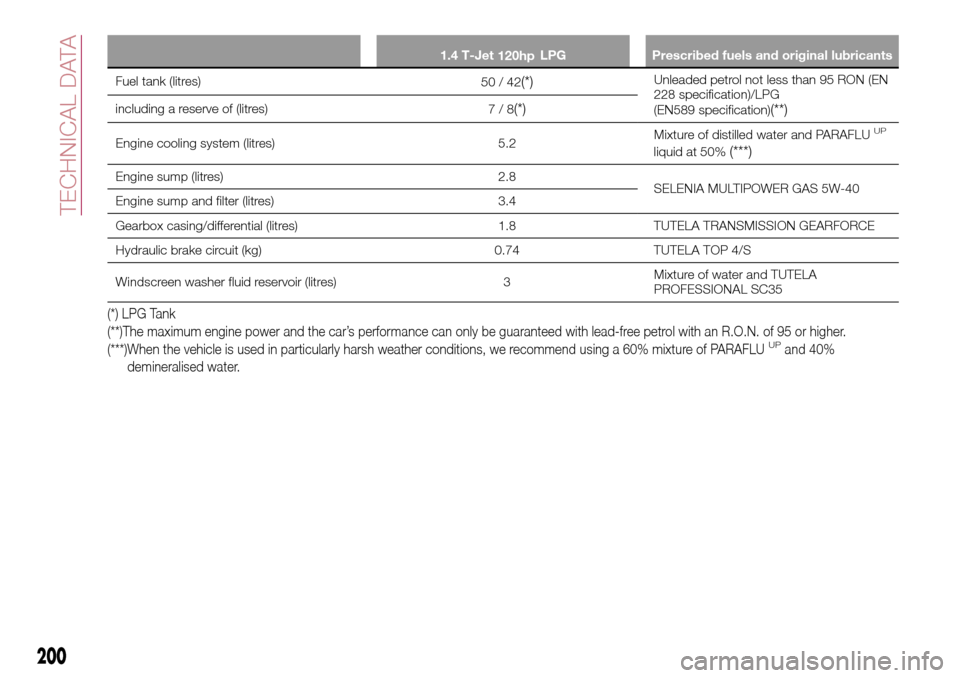

Page 202 of 264

1.4 T-Jet LPG Prescribed fuels and original lubricants

Fuel tank (litres)

50/42(*)Unleaded petrol not less than 95 RON (EN

228 specification)/LPG

(EN589 specification)

(**)including a reserve of (litres)

7/8(*)

Engine cooling system (litres) 5.2Mixture of distilled water and PARAFLUUP

liquid at 50%(***)

Engine sump (litres) 2.8

SELENIA MULTIPOWER GAS 5W-40

Engine sump and filter (litres) 3.4

Gearbox casing/differential (litres) 1.8 TUTELA TRANSMISSION GEARFORCE

Hydraulic brake circuit (kg) 0.74 TUTELA TOP 4/S

Windscreen washer fluid reservoir (litres) 3Mixture of water and TUTELA

PROFESSIONAL SC35

(*) LPG Tank

(**)The maximum engine power and the car’s performance can only be guaranteed with lead-free petrol with an R.O.N. of 95 or higher.

(***)When the vehicle is used in particularly harsh weather conditions, we recommend using a 60% mixture of PARAFLU

UPand 40%

demineralised water.

200

TECHNICAL DATA

120hp

Page 203 of 264

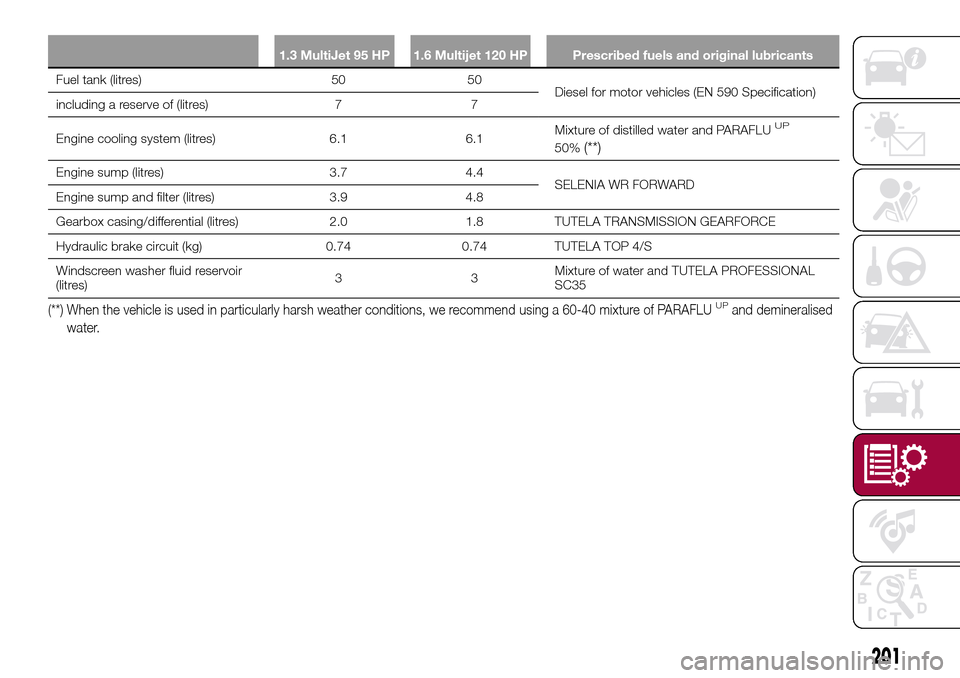

1.3 MultiJet 95 HP 1.6 Multijet 120 HP Prescribed fuels and original lubricants

Fuel tank (litres) 50 50

Diesel for motor vehicles (EN 590 Specification)

including a reserve of (litres) 7 7

Engine cooling system (litres) 6.1 6.1Mixture of distilled water and PARAFLU

UP

50%(**)

Engine sump (litres) 3.7 4.4

SELENIA WR FORWARD

Engine sump and filter (litres) 3.9 4.8

Gearbox casing/differential (litres) 2.0 1.8 TUTELA TRANSMISSION GEARFORCE

Hydraulic brake circuit (kg) 0.74 0.74 TUTELA TOP 4/S

Windscreen washer fluid reservoir

(litres)33Mixture of water and TUTELA PROFESSIONAL

SC35

(**) When the vehicle is used in particularly harsh weather conditions, we recommend using a 60-40 mixture of PARAFLUUPand demineralised

water.

201

Page 205 of 264

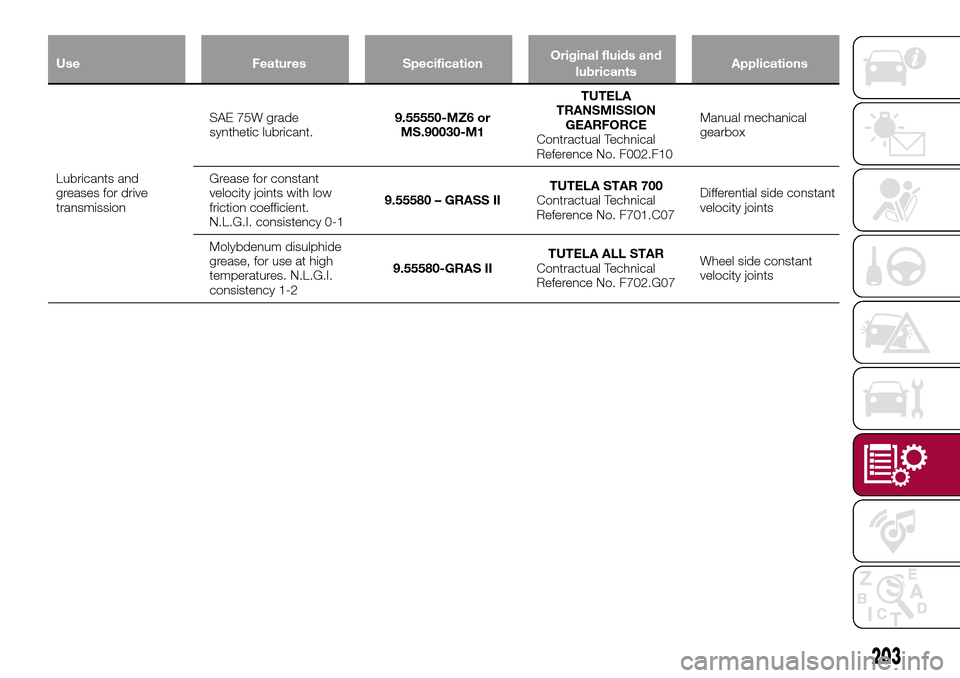

Use Features SpecificationOriginal fluids and

lubricantsApplications

Lubricants and

greases for drive

transmissionSAE 75W grade

synthetic lubricant.9.55550-MZ6 or

MS.90030-M1TUTELA

TRANSMISSION

GEARFORCE

Contractual Technical

Reference No. F002.F10Manual mechanical

gearbox

Grease for constant

velocity joints with low

friction coefficient.

N.L.G.I. consistency 0-19.55580 – GRASS IITUTELA STAR 700

Contractual Technical

Reference No. F701.C07Differential side constant

velocity joints

Molybdenum disulphide

grease, for use at high

temperatures. N.L.G.I.

consistency 1-29.55580-GRAS IITUTELA ALL STAR

Contractual Technical

Reference No. F702.G07Wheel side constant

velocity joints

203