coolant temperature FIAT UNO 1983 Service Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 24 of 303

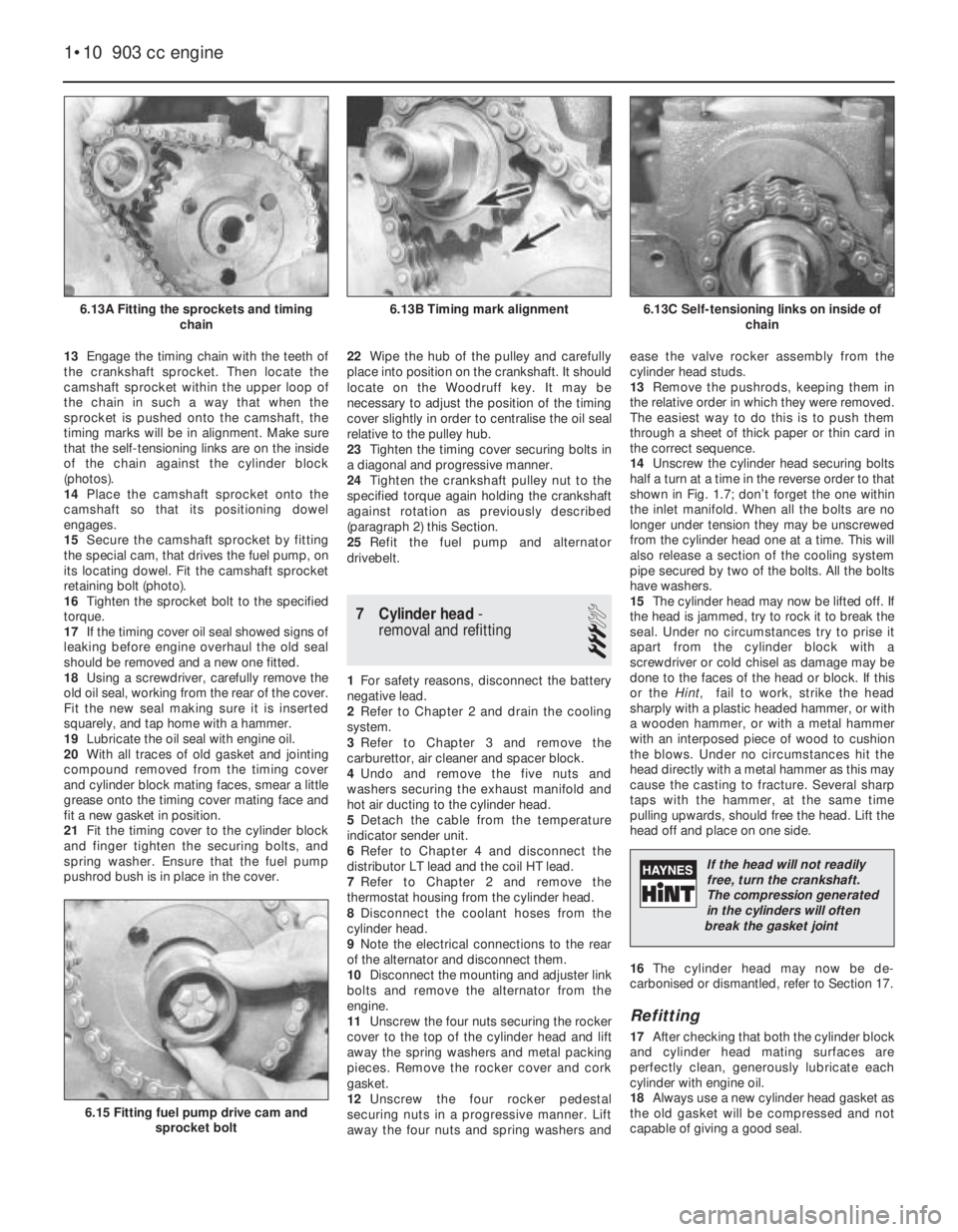

13Engage the timing chain with the teeth of

the crankshaft sprocket. Then locate the

camshaft sprocket within the upper loop of

the chain in such a way that when the

sprocket is pushed onto the camshaft, the

timing marks will be in alignment. Make sure

that the self-tensioning links are on the inside

of the chain against the cylinder block

(photos).

14Place the camshaft sprocket onto the

camshaft so that its positioning dowel

engages.

15Secure the camshaft sprocket by fitting

the special cam, that drives the fuel pump, on

its locating dowel. Fit the camshaft sprocket

retaining bolt (photo).

16Tighten the sprocket bolt to the specified

torque.

17If the timing cover oil seal showed signs of

leaking before engine overhaul the old seal

should be removed and a new one fitted.

18Using a screwdriver, carefully remove the

old oil seal, working from the rear of the cover.

Fit the new seal making sure it is inserted

squarely, and tap home with a hammer.

19Lubricate the oil seal with engine oil.

20With all traces of old gasket and jointing

compound removed from the timing cover

and cylinder block mating faces, smear a little

grease onto the timing cover mating face and

fit a new gasket in position.

21Fit the timing cover to the cylinder block

and finger tighten the securing bolts, and

spring washer. Ensure that the fuel pump

pushrod bush is in place in the cover.22Wipe the hub of the pulley and carefully

place into position on the crankshaft. It should

locate on the Woodruff key. It may be

necessary to adjust the position of the timing

cover slightly in order to centralise the oil seal

relative to the pulley hub.

23Tighten the timing cover securing bolts in

a diagonal and progressive manner.

24Tighten the crankshaft pulley nut to the

specified torque again holding the crankshaft

against rotation as previously described

(paragraph 2) this Section.

25Refit the fuel pump and alternator

drivebelt.

7 Cylinder head-

removal and refitting

3

1For safety reasons, disconnect the battery

negative lead.

2Refer to Chapter 2 and drain the cooling

system.

3Refer to Chapter 3 and remove the

carburettor, air cleaner and spacer block.

4Undo and remove the five nuts and

washers securing the exhaust manifold and

hot air ducting to the cylinder head.

5Detach the cable from the temperature

indicator sender unit.

6Refer to Chapter 4 and disconnect the

distributor LT lead and the coil HT lead.

7Refer to Chapter 2 and remove the

thermostat housing from the cylinder head.

8Disconnect the coolant hoses from the

cylinder head.

9Note the electrical connections to the rear

of the alternator and disconnect them.

10Disconnect the mounting and adjuster link

bolts and remove the alternator from the

engine.

11Unscrew the four nuts securing the rocker

cover to the top of the cylinder head and lift

away the spring washers and metal packing

pieces. Remove the rocker cover and cork

gasket.

12Unscrew the four rocker pedestal

securing nuts in a progressive manner. Lift

away the four nuts and spring washers andease the valve rocker assembly from the

cylinder head studs.

13Remove the pushrods, keeping them in

the relative order in which they were removed.

The easiest way to do this is to push them

through a sheet of thick paper or thin card in

the correct sequence.

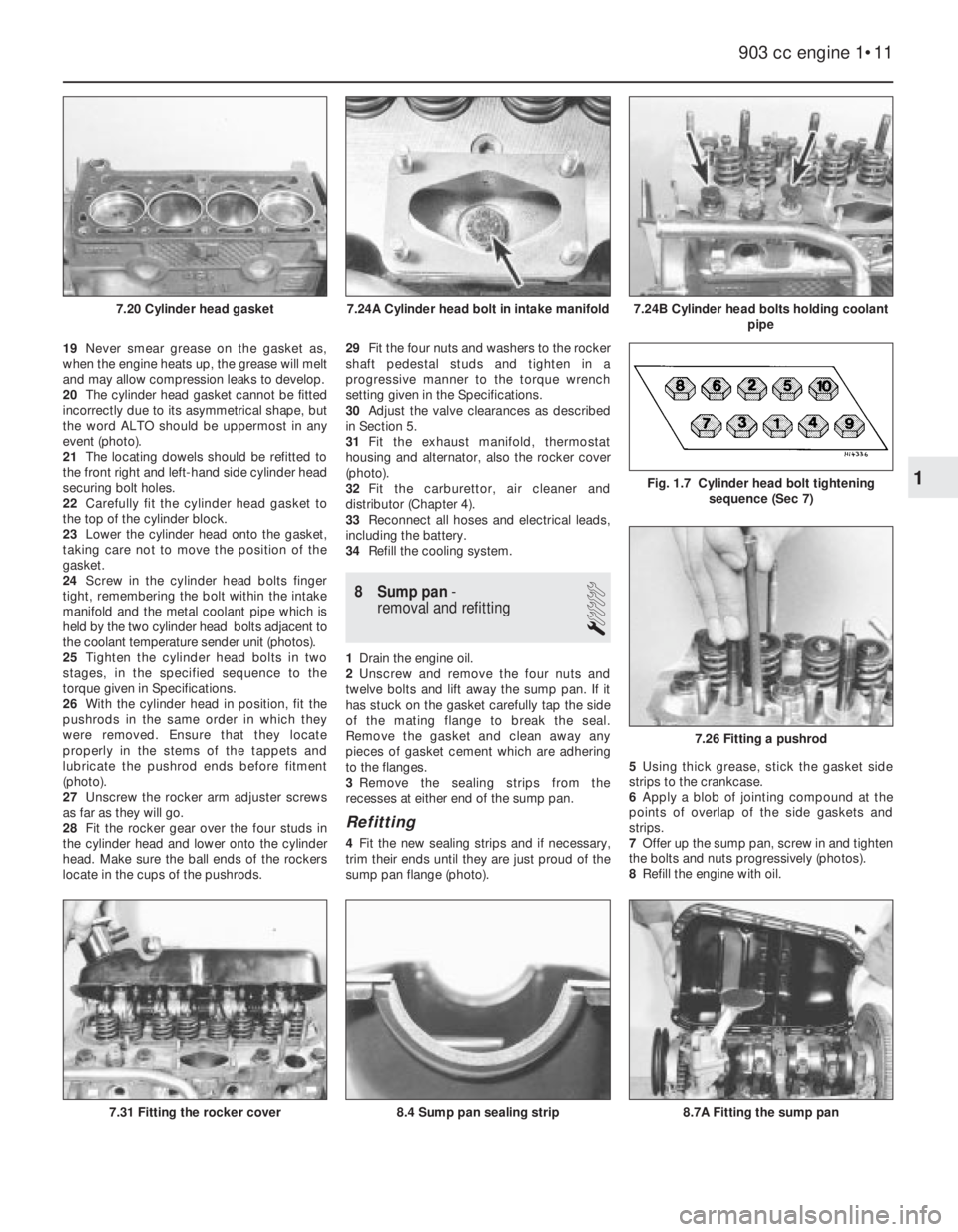

14Unscrew the cylinder head securing bolts

half a turn at a time in the reverse order to that

shown in Fig. 1.7; don’t forget the one within

the inlet manifold. When all the bolts are no

longer under tension they may be unscrewed

from the cylinder head one at a time. This will

also release a section of the cooling system

pipe secured by two of the bolts. All the bolts

have washers.

15The cylinder head may now be lifted off. If

the head is jammed, try to rock it to break the

seal. Under no circumstances try to prise it

apart from the cylinder block with a

screwdriver or cold chisel as damage may be

done to the faces of the head or block. If this

or the Hint, fail to work, strike the head

sharply with a plastic headed hammer, or with

a wooden hammer, or with a metal hammer

with an interposed piece of wood to cushion

the blows. Under no circumstances hit the

head directly with a metal hammer as this may

cause the casting to fracture. Several sharp

taps with the hammer, at the same time

pulling upwards, should free the head. Lift the

head off and place on one side.

16The cylinder head may now be de-

carbonised or dismantled, refer to Section 17.

Refitting

17After checking that both the cylinder block

and cylinder head mating surfaces are

perfectly clean, generously lubricate each

cylinder with engine oil.

18Always use a new cylinder head gasket as

the old gasket will be compressed and not

capable of giving a good seal.

1•10 903 cc engine

6.15 Fitting fuel pump drive cam and

sprocket bolt

6.13C Self-tensioning links on inside of

chain6.13B Timing mark alignment6.13A Fitting the sprockets and timing

chain

If the head will not readily

free, turn the crankshaft.

The compression generated

in the cylinders will often

break the gasket joint

Page 25 of 303

19Never smear grease on the gasket as,

when the engine heats up, the grease will melt

and may allow compression leaks to develop.

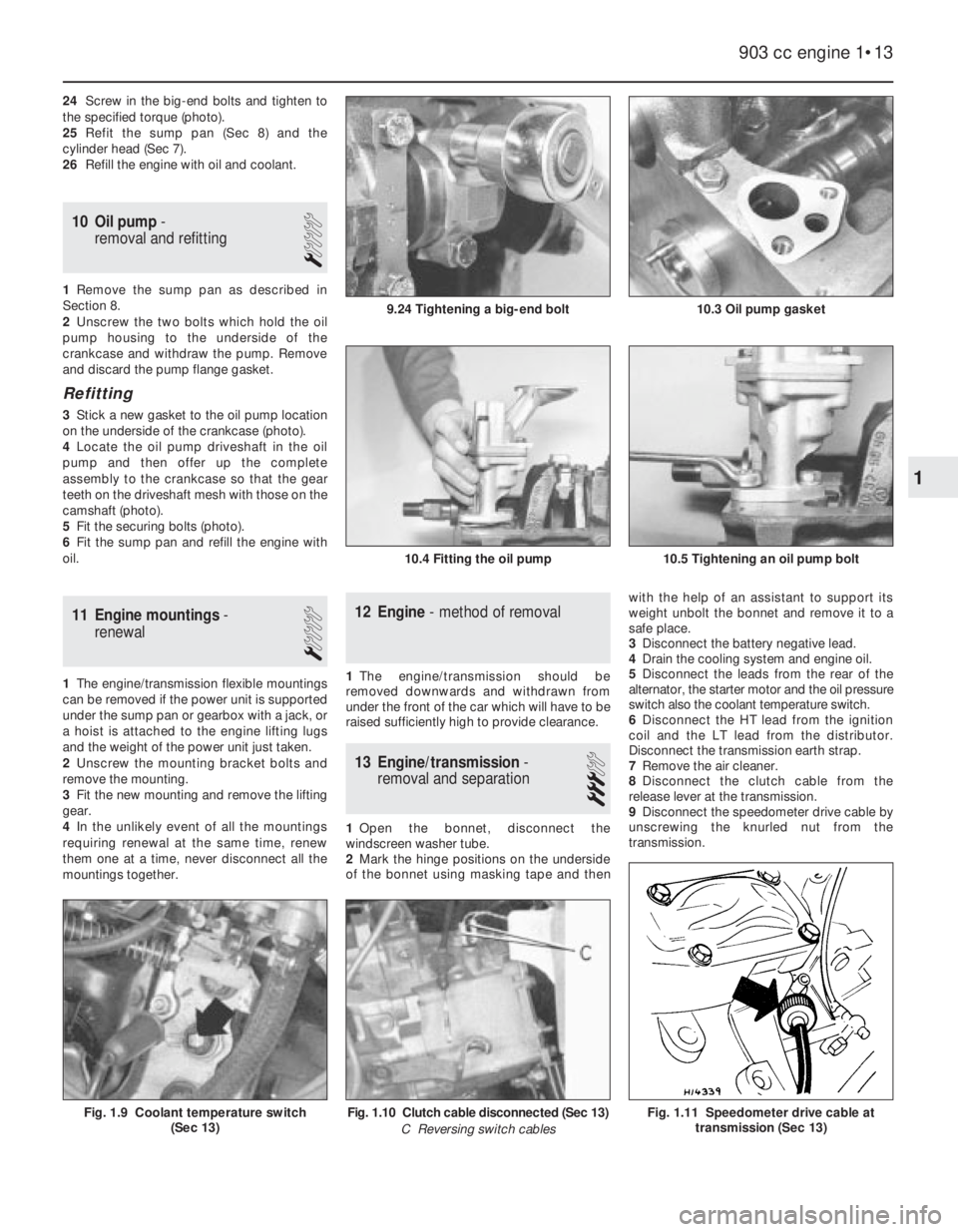

20The cylinder head gasket cannot be fitted

incorrectly due to its asymmetrical shape, but

the word ALTO should be uppermost in any

event (photo).

21The locating dowels should be refitted to

the front right and left-hand side cylinder head

securing bolt holes.

22Carefully fit the cylinder head gasket to

the top of the cylinder block.

23Lower the cylinder head onto the gasket,

taking care not to move the position of the

gasket.

24Screw in the cylinder head bolts finger

tight, remembering the bolt within the intake

manifold and the metal coolant pipe which is

held by the two cylinder head bolts adjacent to

the coolant temperature sender unit (photos).

25Tighten the cylinder head bolts in two

stages, in the specified sequence to the

torque given in Specifications.

26With the cylinder head in position, fit the

pushrods in the same order in which they

were removed. Ensure that they locate

properly in the stems of the tappets and

lubricate the pushrod ends before fitment

(photo).

27Unscrew the rocker arm adjuster screws

as far as they will go.

28Fit the rocker gear over the four studs in

the cylinder head and lower onto the cylinder

head. Make sure the ball ends of the rockers

locate in the cups of the pushrods.29Fit the four nuts and washers to the rocker

shaft pedestal studs and tighten in a

progressive manner to the torque wrench

setting given in the Specifications.

30Adjust the valve clearances as described

in Section 5.

31Fit the exhaust manifold, thermostat

housing and alternator, also the rocker cover

(photo).

32Fit the carburettor, air cleaner and

distributor (Chapter 4).

33Reconnect all hoses and electrical leads,

including the battery.

34Refill the cooling system.

8 Sump pan-

removal and refitting

1

1Drain the engine oil.

2Unscrew and remove the four nuts and

twelve bolts and lift away the sump pan. If it

has stuck on the gasket carefully tap the side

of the mating flange to break the seal.

Remove the gasket and clean away any

pieces of gasket cement which are adhering

to the flanges.

3Remove the sealing strips from the

recesses at either end of the sump pan.

Refitting

4Fit the new sealing strips and if necessary,

trim their ends until they are just proud of the

sump pan flange (photo).5Using thick grease, stick the gasket side

strips to the crankcase.

6Apply a blob of jointing compound at the

points of overlap of the side gaskets and

strips.

7Offer up the sump pan, screw in and tighten

the bolts and nuts progressively (photos).

8Refill the engine with oil.

903 cc engine 1•11

7.24B Cylinder head bolts holding coolant

pipe7.24A Cylinder head bolt in intake manifold7.20 Cylinder head gasket

7.31 Fitting the rocker cover

7.26 Fitting a pushrod

Fig. 1.7 Cylinder head bolt tightening

sequence (Sec 7)1

8.4 Sump pan sealing strip8.7A Fitting the sump pan

Page 27 of 303

24Screw in the big-end bolts and tighten to

the specified torque (photo).

25Refit the sump pan (Sec 8) and the

cylinder head (Sec 7).

26Refill the engine with oil and coolant.

10 Oil pump-

removal and refitting

1

1Remove the sump pan as described in

Section 8.

2Unscrew the two bolts which hold the oil

pump housing to the underside of the

crankcase and withdraw the pump. Remove

and discard the pump flange gasket.

Refitting

3Stick a new gasket to the oil pump location

on the underside of the crankcase (photo).

4Locate the oil pump driveshaft in the oil

pump and then offer up the complete

assembly to the crankcase so that the gear

teeth on the driveshaft mesh with those on the

camshaft (photo).

5Fit the securing bolts (photo).

6Fit the sump pan and refill the engine with

oil.

11 Engine mountings-

renewal

1

1The engine/transmission flexible mountings

can be removed if the power unit is supported

under the sump pan or gearbox with a jack, or

a hoist is attached to the engine lifting lugs

and the weight of the power unit just taken.

2Unscrew the mounting bracket bolts and

remove the mounting.

3Fit the new mounting and remove the lifting

gear.

4In the unlikely event of all the mountings

requiring renewal at the same time, renew

them one at a time, never disconnect all the

mountings together.

12 Engine- method of removal

1The engine/transmission should be

removed downwards and withdrawn from

under the front of the car which will have to be

raised sufficiently high to provide clearance.

13 Engine/transmission-

removal and separation

3

1Open the bonnet, disconnect the

windscreen washer tube.

2Mark the hinge positions on the underside

of the bonnet using masking tape and thenwith the help of an assistant to support its

weight unbolt the bonnet and remove it to a

safe place.

3Disconnect the battery negative lead.

4Drain the cooling system and engine oil.

5Disconnect the leads from the rear of the

alternator, the starter motor and the oil pressure

switch also the coolant temperature switch.

6Disconnect the HT lead from the ignition

coil and the LT lead from the distributor.

Disconnect the transmission earth strap.

7Remove the air cleaner.

8Disconnect the clutch cable from the

release lever at the transmission.

9Disconnect the speedometer drive cable by

unscrewing the knurled nut from the

transmission.

903 cc engine 1•13

10.3 Oil pump gasket

10.4 Fitting the oil pump10.5 Tightening an oil pump bolt

9.24 Tightening a big-end bolt

Fig. 1.11 Speedometer drive cable at

transmission (Sec 13)Fig. 1.10 Clutch cable disconnected (Sec 13)

C Reversing switch cablesFig. 1.9 Coolant temperature switch

(Sec 13)

1

Page 37 of 303

removed and the weight of the car is again on

its roadwheels.

4Fill the cooling system.

5Fill the engine with oil.

6Replenish lost transmission oil.

7Reconnect the battery.

8Adjust the clutch pedal as described in

Chapter 5.

24 Engine- initial start-up after

overhaul or major repair

4

1Make sure that the battery is fully charged

and that all lubricants, coolant and fuel are

replenished.

2If the fuel system has been dismantled it will

require several revolutions of the engine on

the starter motor to pump the petrol up to the

carburettor.

3Turn the carburettor throttle speed screwthrough one complete turn to increase the idle

speed in order to offset the initial stiffness of

new engine internal components.

4As soon as the engine fires and runs, keep

it going at a fast idle speed and bring it up to

normal working temperature.

5As the engine warms up there will be odd

smells and some smoke from parts getting

hot and burning off oil deposits. The signs to

look for are leaks of water or oil which will be

obvious.

6Check also the exhaust pipe and manifold

connections as these do not always “find”

their exact gas tight position until the warmth

and vibration have acted on them and it is

almost certain that they will need tightening

further. This should be done, of course, with

the engine stopped.

7When normal running temperature has

been reached, adjust the engine idle speed as

described in Chapter 3.

8Stop the engine and wait a few minutes tosee if any lubricant or coolant is dripping out

when the engine is stationary.

9Road test the car to check that the timing is

correct and that the engine is giving the

necessary smoothness and power. Do not

race the engine - if new bearings and/or

pistons have been fitted it should be treated

as a new engine and run in at a reduced

speed for the first 500 km (300 miles).

10After the first 1500 km (900 miles) the

cylinder head bolts must be re-torqued in the

following way (engine cold).

11Remove the air cleaner and rocker cover.

Unscrew the first bolt (Fig. 1.7) through a

quarter turn and then tighten it to final stage 2

torque (see Specifications).

12Repeat on the remaining bolts, one at a

time.

13Check and adjust the valve clearances

(Section 5).

14Refit the rocker cover and air cleaner.

903 cc engine 1•23

26.4 Shim engraved mark26.2 Removing a shim from a cam follower25.4 Checking a valve clearance

1

Part 3: 1116 cc and 1301 cc engines

25 Valve clearances- checking

2

This should only be required if the valves

have been renewed or ground in, or at high

mileages when noise or poor engine

performance indicates that a check is

necessary.

It is important that each valve clearance is

set correct otherwise the timing will be

wrong and engine performance poor. If there

is no clearance at all, the valve and its seat

will soon burn. Always set the clearances

with the engine cold.

1Remove the camshaft cover. Jack-up a

front wheel and engage top gear so that by

turning the wheel, the crankshaft can be

rotated.

2Each valve clearance must be checked

when the high point of the cam is pointing

directly upward away from the cam follower.

3Check the clearances in the firing order

1-3-4-2, No. 1 cylinder being at the timing

belt end of the engine. This will minimise the

amount of crankshaft rotation required.4Insert the appropriate feeler blade

between the heel of the cam and the cam

follower shim of the first valve. If necessary

alter the thickness of the feeler blade until it

is a stiff, sliding fit. Record the thickness,

which will, of course, represent the valve

clearance for this particular valve (photo).

5Turn the crankshaft, check the second

valve clearance and record it.

6Repeat the operations on all the remaining

valves, recording their respective clearances.

7Remember that the clearance for inlet and

exhaust valves differs - see Specifications.

Counting from the timing cover end of the

engine, the valve sequence is:

Inlet 2-3-6-7

Exhaust 1-4-5-8

26 Valve clearances-

adjustment

3

1Check the valve clearances (Section 25).

2Clearances which are incorrect will mean

the particular shim will have to be changed.

To remove the shim, turn the crankshaft untilthe high point of the cam is pointing directly

upward. The cam follower will now have to

be depressed so that the shim can be

extracted. Special tools (A60642 and

A87001) are available from your Fiat dealer to

do the job, otherwise you will have to make

up a forked lever to locate on the rim of the

cam follower. This must allow room for the

shim to be prised out by means of the

cut-outs provided in the cam follower rim

(photo).

3Once the shim is extracted, establish its

thickness and change it for a thicker or

thinner one to bring the previously recorded

clearance within specification. For example,

if the measured valve clearance was 1.27

mm (0.05 in) too great, a shim thicker by this

amount will be required. Conversely, if the

clearance was 1.27 mm (0.05 in) too small, a

shim thinner by this amount will be required.

4Shims have their thickness (mm) engraved

on them; although the engraved side should

be fitted so as not to be visible, wear still

occurs and often obliterates the number. In

this case, measuring their thickness with a

metric micrometer is the only method to

establish their thickness (photo).

Page 41 of 303

2The big-end bearing shells can be renewed

without having to remove the cylinder head if

the caps are unbolted and the

piston/connecting rod pushed gently about

one inch up the bore (the crankpin being at its

lowest point). If these shells are worn,

however, the main bearing shells will almost

certainly be worn as well. In this case, the

engine should be removed for complete

overhaul including crankshaft removal.

3To remove the piston/connecting rods,

remove the cylinder head as described in

Section 29.

4Grip the oil pick-up pipe and twist or rock it

from its hole in the crankcase. It is an

interference fit in the hole.

5Unscrew the nuts from the big-end caps,

then remove the caps with their bearing

shells. The caps and their connecting rods are

numbered 1, 2, 3 and 4 from the timing cover

end of the engine. The numbers are adjacent

at the big-end cap joint and on the side of the

crankcase furthest from the auxiliary shaft.

6If the bearing shells are to be used again,

tape them to their respective big-end caps.

7Push each connecting rod/piston assembly

up the bore and out of the cylinder block.

There is one reservation; if a wear ridge has

developed at the top of the bores, remove this

by careful scraping before trying to remove

the piston/rod assemblies. The ridge will

otherwise prevent removal or break the piston

rings during the attempt.

8If the connecting rod bearing shells are to

be used again, tape the shells to their

respective rods.

9Dismantling the piston/connecting rod is

described in Section 18.

Refitting

10Fit the new shells into the connecting rod

and caps, ensuring the surfaces on which the

shells seat, are clean and dry.

11Check that the piston ring gaps are evenly

spaced at 120º intervals. Liberally oil the rings

and the cylinder bores.

12Fit a piston ring clamp to compress the

rings.

13Insert the piston/connecting rod into the

cylinder bore, checking that the rod assembly

is correct for that particular bore. The cap and

rod matching numbers must be furthest away

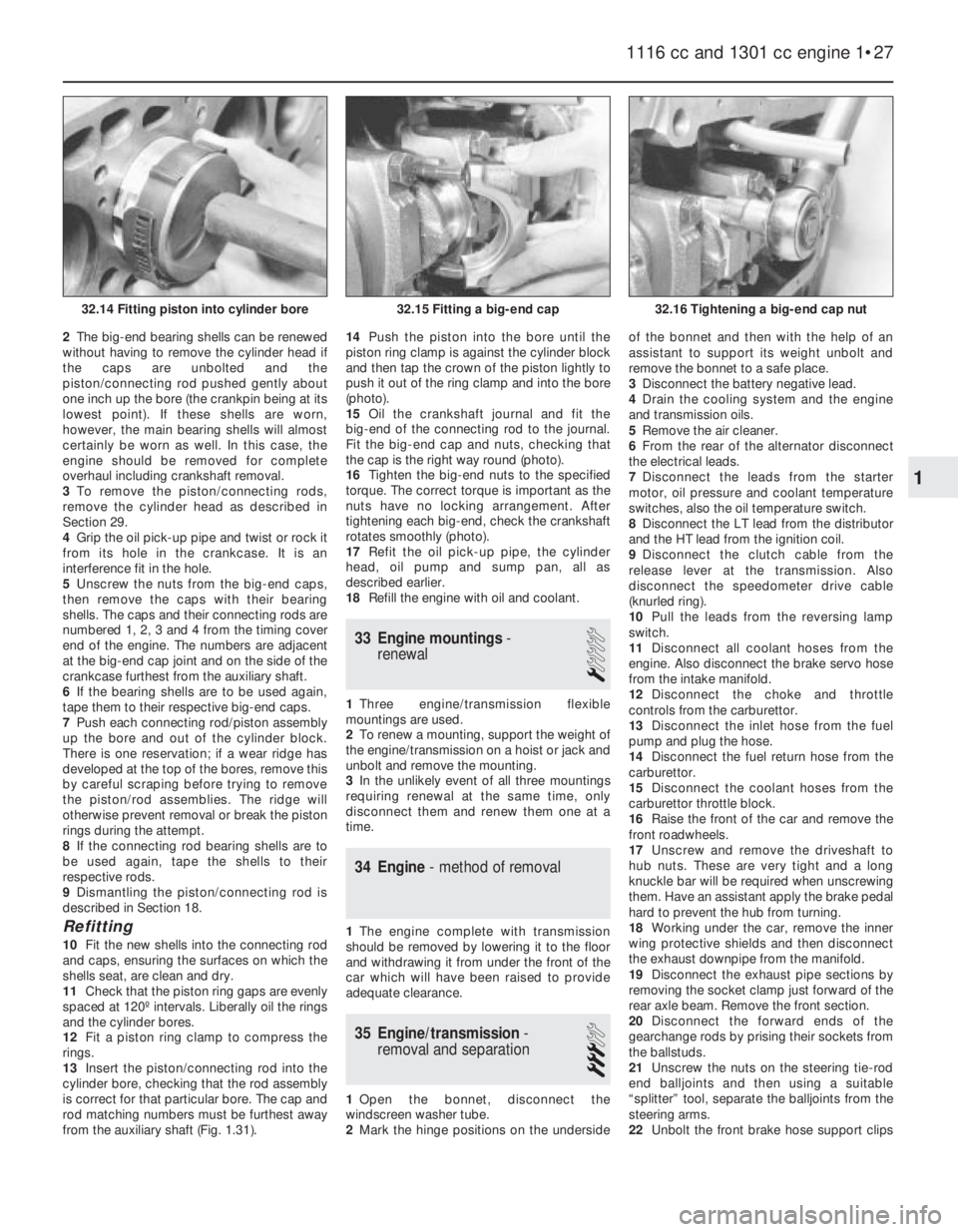

from the auxiliary shaft (Fig. 1.31).14Push the piston into the bore until the

piston ring clamp is against the cylinder block

and then tap the crown of the piston lightly to

push it out of the ring clamp and into the bore

(photo).

15Oil the crankshaft journal and fit the

big-end of the connecting rod to the journal.

Fit the big-end cap and nuts, checking that

the cap is the right way round (photo).

16Tighten the big-end nuts to the specified

torque. The correct torque is important as the

nuts have no locking arrangement. After

tightening each big-end, check the crankshaft

rotates smoothly (photo).

17Refit the oil pick-up pipe, the cylinder

head, oil pump and sump pan, all as

described earlier.

18Refill the engine with oil and coolant.

33 Engine mountings-

renewal

1

1Three engine/transmission flexible

mountings are used.

2To renew a mounting, support the weight of

the engine/transmission on a hoist or jack and

unbolt and remove the mounting.

3In the unlikely event of all three mountings

requiring renewal at the same time, only

disconnect them and renew them one at a

time.

34 Engine- method of removal

1The engine complete with transmission

should be removed by lowering it to the floor

and withdrawing it from under the front of the

car which will have been raised to provide

adequate clearance.

35 Engine/transmission-

removal and separation

3

1Open the bonnet, disconnect the

windscreen washer tube.

2Mark the hinge positions on the undersideof the bonnet and then with the help of an

assistant to support its weight unbolt and

remove the bonnet to a safe place.

3Disconnect the battery negative lead.

4Drain the cooling system and the engine

and transmission oils.

5Remove the air cleaner.

6From the rear of the alternator disconnect

the electrical leads.

7Disconnect the leads from the starter

motor, oil pressure and coolant temperature

switches, also the oil temperature switch.

8Disconnect the LT lead from the distributor

and the HT lead from the ignition coil.

9Disconnect the clutch cable from the

release lever at the transmission. Also

disconnect the speedometer drive cable

(knurled ring).

10Pull the leads from the reversing lamp

switch.

11Disconnect all coolant hoses from the

engine. Also disconnect the brake servo hose

from the intake manifold.

12Disconnect the choke and throttle

controls from the carburettor.

13Disconnect the inlet hose from the fuel

pump and plug the hose.

14Disconnect the fuel return hose from the

carburettor.

15Disconnect the coolant hoses from the

carburettor throttle block.

16Raise the front of the car and remove the

front roadwheels.

17Unscrew and remove the driveshaft to

hub nuts. These are very tight and a long

knuckle bar will be required when unscrewing

them. Have an assistant apply the brake pedal

hard to prevent the hub from turning.

18Working under the car, remove the inner

wing protective shields and then disconnect

the exhaust downpipe from the manifold.

19Disconnect the exhaust pipe sections by

removing the socket clamp just forward of the

rear axle beam. Remove the front section.

20Disconnect the forward ends of the

gearchange rods by prising their sockets from

the ballstuds.

21Unscrew the nuts on the steering tie-rod

end balljoints and then using a suitable

“splitter” tool, separate the balljoints from the

steering arms.

22Unbolt the front brake hose support clips

1116 cc and 1301 cc engine 1•27

32.16 Tightening a big-end cap nut32.15 Fitting a big-end cap32.14 Fitting piston into cylinder bore

1

Page 48 of 303

to the engine. Also reconnect the brake servo

hose to the intake manifold (photos).

22Reconnect the leads to the reversing lamp

switch. Reconnect the transmission earth lead

(photos).

23Reconnect the clutch cable and adjust as

described in Chapter 5.

24Reconnect the speedometer drive cable

to the transmission and tighten the knurled

retaining ring.

25Reconnect the low tension lead to the

distributor and the high tension lead to the

ignition coil.

26Reconnnect the electrical leads to thestarter motor, the oil pressure and

temperature switches and the coolant

temperature switch.

27Connect the leads to the alternator.

28Refit the air cleaner.

29Refill the cooling system. Refill the engine

with oil.

30Reconnect the battery.

31Refit the bonnet and connect the

windscreen washer tube.

32Fit the inner wing protective shields

(photo).

45 Engine- initial start-up after

major overhaul

4

1If new bearings and rings have been fitted,

it is likely that the engine will be stiff to turn so

make sure the battery is well charged.

2Switch on the ignition and check that

appropriate warning lights come on.

3Start up the engine. If it refuses to start,

refer to the “Fault Finding” Section in the

Reference section of this Manual.

4Watch the oil pressure warning light and

alternator charging indicator light. If there is

no charge or if the oil pressure warning light

does not go out after a second or two, havinghad time to fill the new oil filter, switch off and

recheck.

5If the warning lights go out, set the engine

to run on fast idle and check the engine for

leaks.

6Check the coolant level; it will probably go

down as air locks are filled.

7Keep the engine running at a fast idle and

bring it up to normal working temperature. As

the engine warms up, there will be some odd

smells and smoke from parts getting hot and

burning off oil deposits.

8When the engine running temperature has

been reached, adjust the idling speed, as

described in Chapter 3. Check and, if

necessary, adjust the ignition timing using a

stroboscope (see Chapter 4).

9Stop the engine and wait a few minutes;

check to see if there are any coolant or oil

leaks.

10Road test the car to check that the engine

is running with the correct smoothness and

power. If it does not, refer to “Fault finding” in

the Reference section of this Manual. Do not

race the engine. If new bearings and/or

pistons and rings have been fitted, it should

be treated as a new engine and run it at

reduced speed for at east 800 km (500 miles).

11After 800 km (500 miles) change the

engine oil and filter.

1•34 1116 cc and 1301 cc engine

44.32 Inner wing protective shield44.26B Coolant temperature switch44.26A Oil pressure warning switch

44.22B Transmission earth lead

44.22A Reversing lamp switch on

transmission44.21B Brake servo hose at manifold44.21A Heater hose at manifold

Page 51 of 303

2

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . “No loss” with radiator and integral expansion tank. Electric cooling

fan, belt-driven coolant pump, thermostat on cylinder head

General

Radiator fan cuts in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 to 94ºC (194 to 201ºF)

Radiator fan switches off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 to 89ºC (185 to 192ºF)

Thermostat opens:

903 cc engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 to 89ºC (185 to 192ºF)

1116 cc and 1301 cc engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 to 87ºC (181 to 188.6ºF)

Fully open:

903 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100ºC (212ºF)

1116 cc and 1301 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95ºC (203ºF)

Expansion tank pressure cap rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.78 bar (11 lbf/in2)

Coolant

Capacity:

903 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6 litre (8.1 pint)

1116 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 litre (10.6 pint)

1301 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2 litre (10.9 pint)

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ethylene glycol based antifreeze

Torque wrench settingsNm lbf ft

Temperature sender switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 36

Coolant pump mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 25

Alternator adjuster and mountings nuts . . . . . . . . . . . . . . . . . . . . . . . . . 49 36

Chapter 2 Cooling and heating systems

For modifications, and information applicable to later models, see Supplement at end of manual

Coolant mixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Coolant pump - removal, overhaul and refitting . . . . . . . . . . . . . . . . 9

Cooling system - draining, flushing and refilling . . . . . . . . . . . . . . . . 2

Cooling system sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Description and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Drivebelt - tensioning and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fault finding - cooling and heating . . . . . . . . . . . . See end of ChapterHeater - dismantling, overhaul and reassembly . . . . . . . . . . . . . . . . 13

Heater unit - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Heating and ventilation system - description . . . . . . . . . . . . . . . . . . 11

Radiator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Radiator fan thermostatic switch - removal, checking and refitting . 5

Radiator fan - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 6

Thermostat - removal, testing and refitting . . . . . . . . . . . . . . . . . . . . 4

2•1

Specifications Contents

1 Description and

maintenance

1

1The cooling system consists of a

front-mounted radiator with built-in expansion

tank, a coolant pump (belt-driven from the

crankshaft pulley) and a thermostatically-

controlled electric cooling fan.

2In order to assist rapid warm-up, athermostat is located in a housing at the

left-hand end of the cylinder head. The hose

connections to the thermostat housing vary

according to model.

3The heater is supplied with coolant from the

engine and incorporates a matrix and blower

with the necessary controls.

4The throttle valve plate block of the

carburettor is coolant-heated as a means of

improving fuel atomisation.

5Maintenance is minimal as in theory no

coolant should ever be lost from theexpansion tank. Regularly check that the

coolant level is between 50.0 and 70.0 mm

(1.97 and 2.8 in) above the MIN mark on the

tank with the engine cold. The need for

regular topping up will indicate a leak

somewhere in the system. If one cannot be

found suspect an internal leak in the engine

although this is usually confirmed by a rise in

the engine oil level and water on the dipstick

(photo). Any topping-up should be done using

an antifreeze mixture (see Section 3), not plain

water.

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 52 of 303

6Avoid unscrewing the expansion tank cap

when the engine is hot, but if this must be

done, cover the cap with a cloth to avoid

scalding by escaping steam.

7Periodically, check the condition of all

coolant hoses and tighten the clips.

2 Cooling system- draining,

flushing and refilling

1

1Set the heater temperature lever to

maximum.

2Unscrew the cap from the expansion tank.

3Disconnect the radiator bottom hose and

unscrew the cylinder block drain plug (1116

cc and 1301 cc engines) and allow the coolant

to drain. Refer to photo 29.21B, page 64.

4If the system is in good condition with no

sign of rust or dirt in the drained coolant, then

it may be refilled immediately. If the system

has been neglected and the antifreeze has notbeen regularly renewed and there is evidence

of rust and sediment in the drained liquid then

flush the system through with a cold water

hose.

5If the radiator should appear to be clogged,

it may be necessary to remove it (Section 7)

invert it and reverse flush it using a cold water

hose. If, after a reasonable period the water

still does not run clear, the radiator should be

flushed with a good proprietary cleaning

system. Extensive damage should be repaired

by a specialist or the unit exchanged for a

new or reconditioned radiator.

6Reconnect the bottom hose and screw in

the drain plug.

7Remove the plug (B) (Fig. 2.2) from the

bleed hole in the heater hose.

8Remove the plug (D) (Fig. 2.3) from the

bleed hole in the expansion tank.

9Pour antifreeze mixture slowly into the filler

neck of the expansion tank until it is seen to

come out of the expansion tank plug hole.

Screw in the plug.

10Add further coolant until it is seen todribble out of the hole in the heater hose.

Screw in the plug.

11Top up the expansion tank to the

specified level and screw on the tank cap.

12Start the engine and run it until the cooling

fan cuts in. Switch off, allow to cool and top

up if necessary to the specified mark on the

expansion tank.

3 Coolant mixtures

1In cold climates, antifreeze is needed for

two reasons. In extreme cases, if the coolant

in the engine freezes solid it could crack the

cylinder block or head. But also in cold

weather, with the circulation restricted by the

thermostat, and any warm water that is

getting to the radiator being at the top, the

bottom of the radiator could freeze, and so

block circulation completely, making the

coolant trapped in the engine boil.

2The antifreeze should be mixed in the

proportions advocated by the makers,

according to the climate. There are two levels

of protection. The first cuts risk of damage, as

the antifreeze goes mushy before freezing.

The second, valid all year round, is the

corrosion protection it offers - see below. The

normal proportion in a temperate climate to

provide maximum protection against freezing

and corrosion is 50% antifreeze and

50% water.

3Use only ethylene glycol based antifreeze

and preferably soft water.

4Antifreeze should be left in through the

summer. It has an important secondary

function, to act as an inhibitor against

corrosion. In the cooling system are many

different metals, in particular the aluminium of

the cylinder head. In contact with the coolant

this sets up electrolytic corrosion,

accentuated by any dirt in the system. This

corrosion can be catastrophically fast.

5After about two years, the effectiveness of

the antifreeze’s inhibitor is used up. It must

then be discarded, and the system refilled

with new coolant.

6In warm climates free from frost, an

2•2 Cooling and heating systems

Fig. 2.3 Plug (D) in expansion tank (Sec 2)Fig. 2.2 Plug (B) in heater hose (Sec 2)

1.5 Expansion tank cap

Fig. 2.1 Cooling system on 903 cc engine (Sec 1)

Page 53 of 303

inhibitor should be used. Again, a reputable

make giving full protection must be chosen

and renewed every two years. Inhibitors with

dyes are useful for finding leaks, and on some

makes the dye shows when the inhibiting

ability is finished.

4 Thermostat-

removal, testing and refitting

1

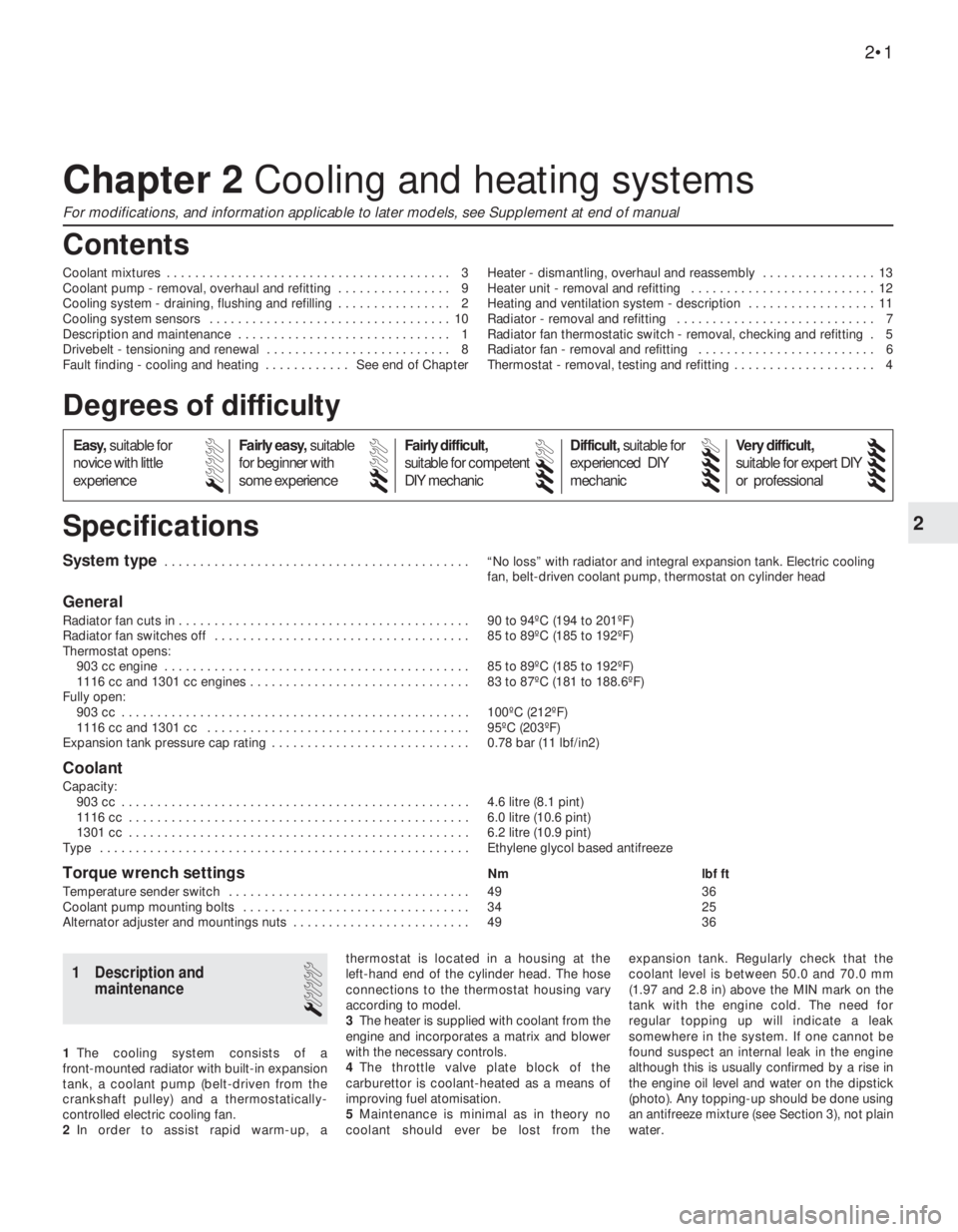

1The thermostat assembly is mounted on the

flywheel end of the cylinder block.

2Unfortunately, the thermostat/housing is a

complete unit and failure of the thermostat will

necessitate the purchase of the complete

component (photo).

3If the thermostat/housing is removed from

the engine, it can be suspended in water and

the water heated to check out its opening

temperature. Movement of the thermostat

valve can be observed to some extent

through the openings in the housing.

4When refitting, always use a new gasket at

its mounting face (photo).

5 Radiator fan thermostatic

switch- removal, checking

and refitting

1

1Drain the cooling system.

2If the thermostatic switch is being removed

because the fan is not operating and the

switch is suspect, check the fan fuse first,

before removing the switch.3To remove the switch, disconnect the leads

from the terminals and unscrew the switch.

4Connect a test bulb and battery across the

switch terminals and then immerse the

sensing part of the switch in a container of

water. Heat the water and, using a

thermometer, check the temperature of the

water when the bulb lights up, indicating the

switch is functioning. The switch should

operate at approximately 194ºF (90ºC). Allow

the water to cool and check that the switch

cuts out at 185ºF (85ºC). Renew a faulty

switch.

5Refitting of the switch is the reverse of the

removal procedure. Always fit a new O-ring on

the switch.

6 Radiator fan-

removal and refitting

1

1Disconnect the electrical leads from the

radiator fan motor.

2Unbolt the fan mounting struts from the

radiator and lift the complete assembly away.

3Refitting is a reversal of removal.

7 Radiator-

removal and refitting

1

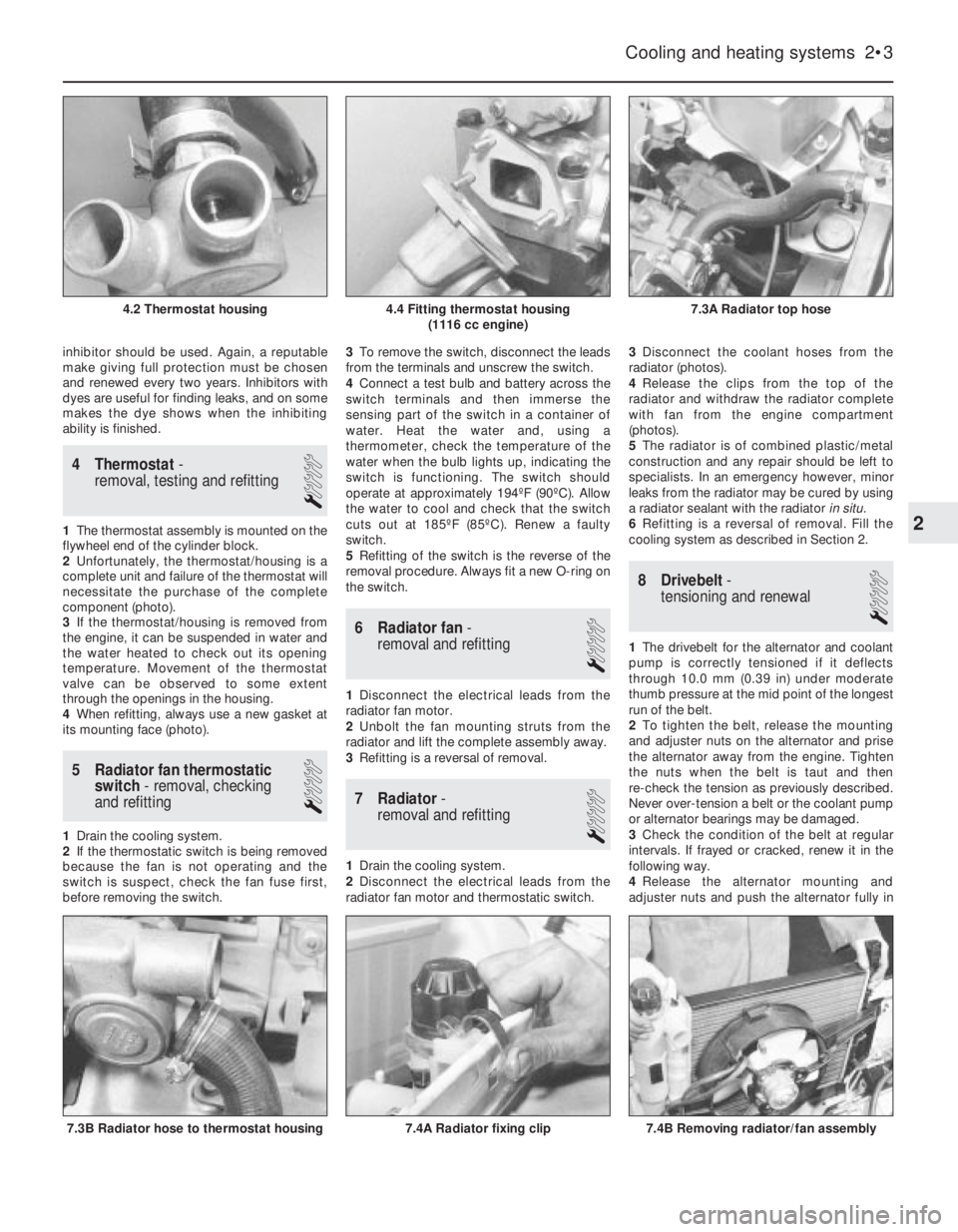

1Drain the cooling system.

2Disconnect the electrical leads from the

radiator fan motor and thermostatic switch.3Disconnect the coolant hoses from the

radiator (photos).

4Release the clips from the top of the

radiator and withdraw the radiator complete

with fan from the engine compartment

(photos).

5The radiator is of combined plastic/metal

construction and any repair should be left to

specialists. In an emergency however, minor

leaks from the radiator may be cured by using

a radiator sealant with the radiator in situ.

6Refitting is a reversal of removal. Fill the

cooling system as described in Section 2.

8 Drivebelt-

tensioning and renewal

1

1The drivebelt for the alternator and coolant

pump is correctly tensioned if it deflects

through 10.0 mm (0.39 in) under moderate

thumb pressure at the mid point of the longest

run of the belt.

2To tighten the belt, release the mounting

and adjuster nuts on the alternator and prise

the alternator away from the engine. Tighten

the nuts when the belt is taut and then

re-check the tension as previously described.

Never over-tension a belt or the coolant pump

or alternator bearings may be damaged.

3Check the condition of the belt at regular

intervals. If frayed or cracked, renew it in the

following way.

4Release the alternator mounting and

adjuster nuts and push the alternator fully in

Cooling and heating systems 2•3

7.3A Radiator top hose4.4 Fitting thermostat housing

(1116 cc engine)4.2 Thermostat housing

7.4B Removing radiator/fan assembly7.4A Radiator fixing clip7.3B Radiator hose to thermostat housing

2

Page 55 of 303

fluid. They are “sealed”. Liquid will get in, but

a thorough clean will be impracticable, and it

will be impossible to get new grease in.

17Check all the parts, get a new gland, two

new grommets, (1116 cc and 1301 cc) and a

new gasket. Scrape all deposits out of the

housing and off the impeller.

18To reassemble, start by inserting the new

grommets (1116 cc and 1301 cc) in the

grooves by each bearing. Fit the circlip to the

shaft, then the shouldered ring, bearings and

spacer. Fit the shaft and bearing assembly

into the cover. Fit the stop screw. Press on

the pulley.

19Fit the new gland (seal), seating it in its

location in the cover. Press the impeller onto

the shaft. The impeller must be put on part

way, and then the housing held in place to see

how far the impeller must go down the shaft

to give the correct clearance, which is 0.8 to

1.3 mm (0.03 to 0.05 in) as shown in Figs. 2.4

and 2.5.

20The impeller clearance can be checked

through the coolant passage in the side of the

pump.

21Refitting is a reversal of the removal

process, but use a new flange gasket and

tension the drivebelt as described in Section 8

(photo).

22Refill the cooling system.

10 Cooling system sensors

1A coolant temperature sender switch is

located in the cylinder head (above No. 1

spark plug) on 903 cc engines and adjacent to

No. 2 spark plug on 1116 cc and 1301 cc

engines.

2The switch operates the coolant

temperature gauge and an excessive

temperature warning lamp.

3On some models, a level sensor is screwed

into the side of the expansion tank. This

sensor consists of a pair of reed switches

within a capsule which are kept closed by the

strong magnetic flux generated by the

hydrostatic force inspired by the action of the

coolant against the float.

4If the coolant level drops then the magneticflux is weakened and the switches open.

5In the event of a fault developing, before

assuming that the cause is the sensor, check

all connecting wiring.

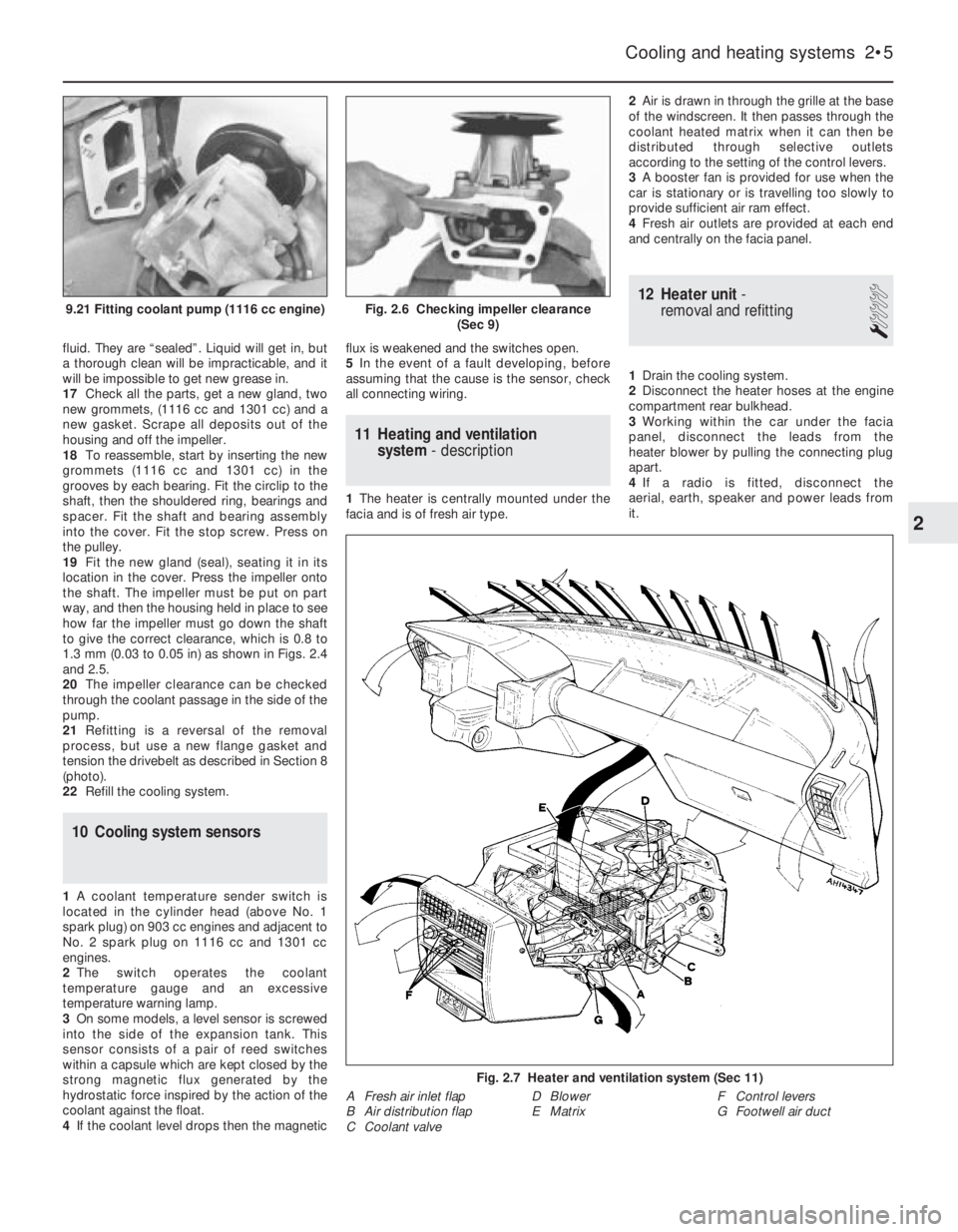

11 Heating and ventilation

system- description

1The heater is centrally mounted under the

facia and is of fresh air type.2Air is drawn in through the grille at the base

of the windscreen. It then passes through the

coolant heated matrix when it can then be

distributed through selective outlets

according to the setting of the control levers.

3A booster fan is provided for use when the

car is stationary or is travelling too slowly to

provide sufficient air ram effect.

4Fresh air outlets are provided at each end

and centrally on the facia panel.

12 Heater unit-

removal and refitting

1

1Drain the cooling system.

2Disconnect the heater hoses at the engine

compartment rear bulkhead.

3Working within the car under the facia

panel, disconnect the leads from the

heater blower by pulling the connecting plug

apart.

4If a radio is fitted, disconnect the

aerial, earth, speaker and power leads from

it.

Cooling and heating systems 2•5

Fig. 2.6 Checking impeller clearance

(Sec 9)9.21 Fitting coolant pump (1116 cc engine)

Fig. 2.7 Heater and ventilation system (Sec 11)

A Fresh air inlet flap

B Air distribution flap

C Coolant valveD Blower

E MatrixF Control levers

G Footwell air duct

2