automatic transmission FORD E-250 2008 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: E-250, Model: FORD E-250 2008Pages: 285, PDF Size: 2.81 MB

Page 184 of 285

D (Drive) without Overdrive

D (Drive) without Overdrive can be

activated by pressing the

transmission control switch (TCS)

on the end of the gearshift lever.

•This position allows for all forward gears except overdrive.

•The O/D OFF lamp will illuminate

in the instrument cluster.

•Provides engine braking.

•Use when driving conditions cause excessive shifting from O/D to

other gears. Examples: city traffic, hilly terrain, heavy loads, trailer

towing and when engine braking is required.

•To return to O/D (Overdrive), press the transmission control switch.

The O/D OFF lamp will not be illuminated.

•O/D (Overdrive) is automatically returned each time the key is turned

off.

3 (Third)

Transmission starts and operates in third gear only.

Used for improved traction on slippery roads. Selecting 3 (Third)

provides additional engine braking.

2 (Second)

Use 2 (Second) to start-up on slippery roads or to provide additional

engine braking on downgrades.

1 (First)

•Provides maximum engine braking.

•Allows upshifts by moving gearshift lever.

•The transmission will not downshift into 1 (First) at high speeds; it

will downshift to a lower gear and then shift into 1 (First) when the

vehicle reaches slower speeds.

Forced downshifts

•Allowed in D (Drive) with Overdrive or D (Drive) without Overdrive.

•Depress the accelerator to the floor.

•Allows transmission to select an appropriate gear.

O/D

ON/OFF

O/D

OFF

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Driving

184

ProCarManuals.com

Page 187 of 285

The RSS automatically turns on

when the gearshift lever is placed in

R (Reverse) and the ignition is on.

An RSS control allows the driver to

turn the RSS on and off. To turn the

RSS off, the ignition must be ON,

and the gear selector in R

(Reverse). An indicator light on the

control will illuminate when the system is turned off. If the indicator

light illuminates when the RSS is not turned off, it may indicate a failure

in the RSS. The RSS will remain off until either the RSS control is

pushed again or the ignition switch is recycled.

While receiving a warning, on some radios, the volume will be reduced to

a predetermined level. After the warning goes away, the radio will return

to the previous value.

Keep the RSS sensors (located on the rear bumper/fascia) free

from snow, ice and large accumulations of dirt (do not clean the

sensors with sharp objects). If the sensors are covered, it will

affect the accuracy of the RSS.

If your vehicle sustains damage to the rear bumper/fascia, leaving

it misaligned or bent, the sensing zone may be altered causing

inaccurate measurement of obstacles or false alarms.

VEHICLE USED AS A STATIONARY POWER SOURCE

Auxiliary equipment called power take-off or PTO, is often added to the

engine or transmission to operate utility equipment. Examples include a

wheel-lift for tow trucks, cranes, tools for construction or tire service and

pumping fluids. PTO applications draw auxiliary horsepower from the

powertrain, often while the vehicle is stationary. In this condition, there

is limited cooling air flow through the radiator and around the vehicle

that normally occurs when a vehicle is moving. The aftermarket PTO

system installer, having the most knowledge of the final application, is

responsible for determining whether additional chassis heat protection or

powertrain cooling is required, and alerting the user to the safe and

proper operation.

Your vehicle is qualified for use as a stationary power source, within

limits detailed in theFord Truck Body Builders Layout Book,found at

www.fleet.ford.com/truckbbas, and through the Ford Truck Body Builders

Advisory Service.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Driving

187

ProCarManuals.com

Page 210 of 285

WARNING:When a wheel is installed, always remove any

corrosion, dirt or foreign materials present on the mounting

surfaces of the wheel or the surface of the wheel hub, brake drum or

brake disc that contacts the wheel. Ensure that any fasteners that

attach the rotor to the hub are secured so they do not interfere with

the mounting surfaces of the wheel. Installing wheels without correct

metal-to-metal contact at the wheel mounting surfaces can cause the

wheel nuts to loosen and the wheel to come off while the vehicle is in

motion, resulting in loss of control.

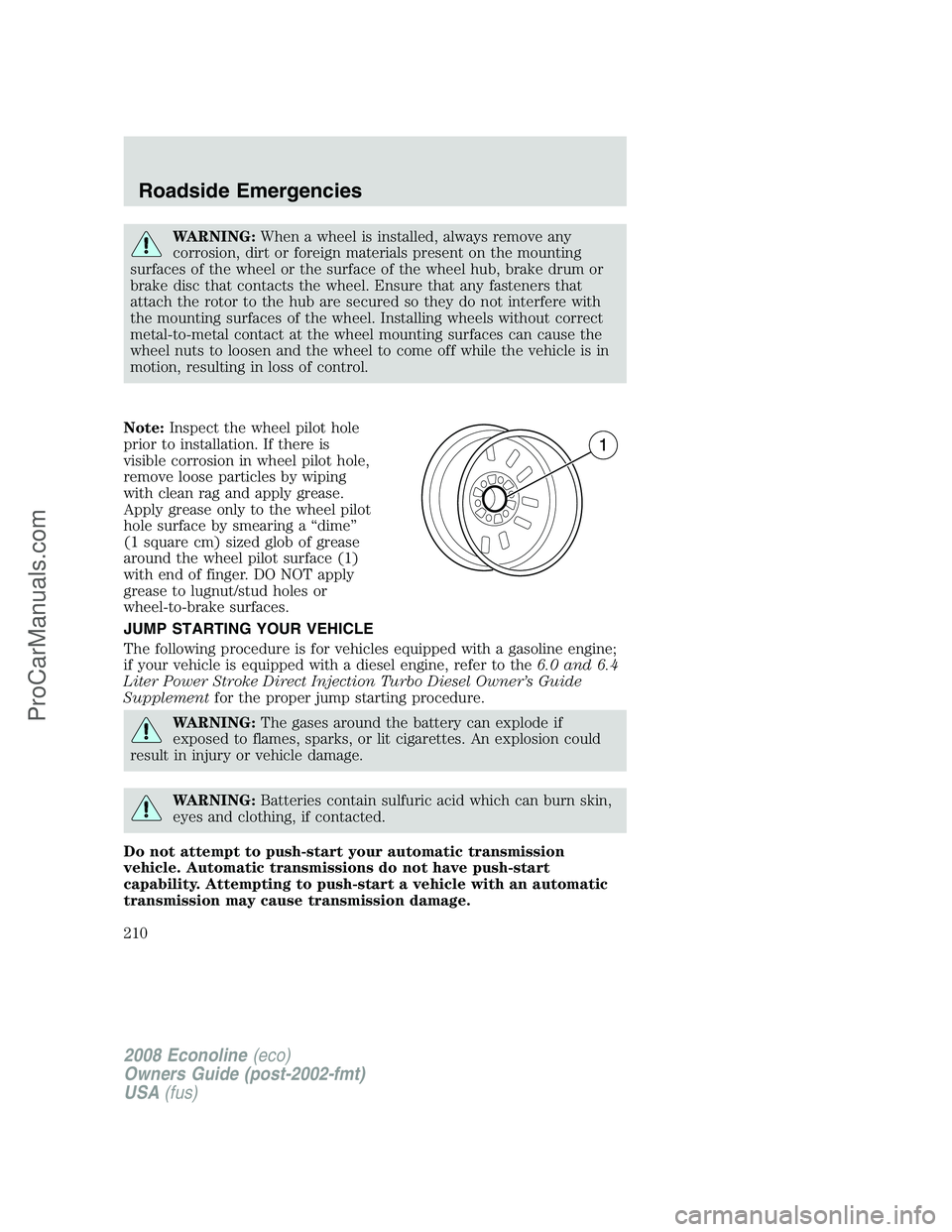

Note:Inspect the wheel pilot hole

prior to installation. If there is

visible corrosion in wheel pilot hole,

remove loose particles by wiping

with clean rag and apply grease.

Apply grease only to the wheel pilot

hole surface by smearing a “dime”

(1 square cm) sized glob of grease

around the wheel pilot surface (1)

with end of finger. DO NOT apply

grease to lugnut/stud holes or

wheel-to-brake surfaces.

JUMP STARTING YOUR VEHICLE

The following procedure is for vehicles equipped with a gasoline engine;

if your vehicle is equipped with a diesel engine, refer to the6.0 and 6.4

Liter Power Stroke Direct Injection Turbo Diesel Owner’s Guide

Supplementfor the proper jump starting procedure.

WARNING:The gases around the battery can explode if

exposed to flames, sparks, or lit cigarettes. An explosion could

result in injury or vehicle damage.

WARNING:Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not attempt to push-start your automatic transmission

vehicle. Automatic transmissions do not have push-start

capability. Attempting to push-start a vehicle with an automatic

transmission may cause transmission damage.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

210

ProCarManuals.com

Page 211 of 285

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

automatic transmission must relearn its shift strategy. As a result, the

transmission may have firm and/or soft shifts. This operation is

considered normal and will not affect function or durability of the

transmission. Over time, the adaptive learning process will fully update

transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

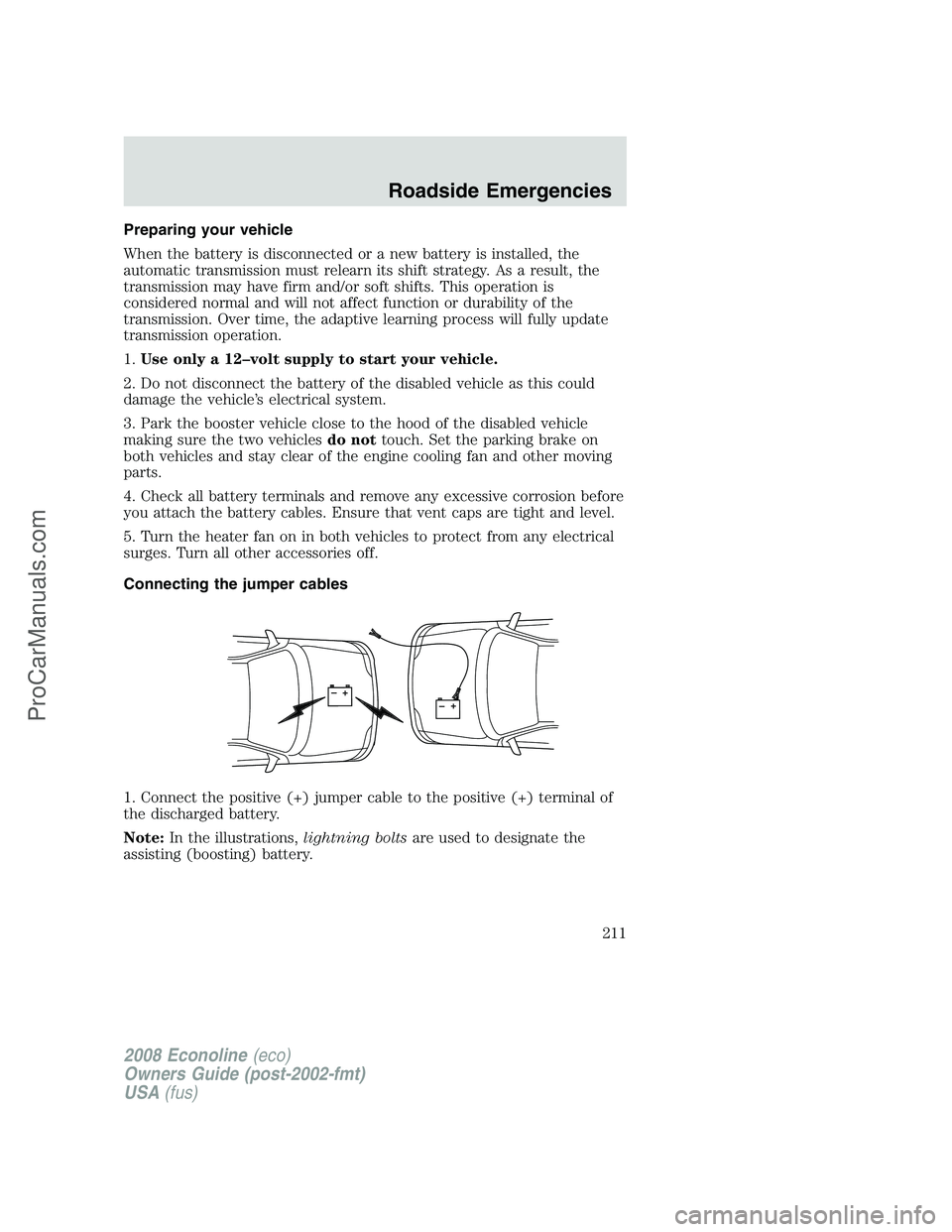

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

211

ProCarManuals.com

Page 235 of 285

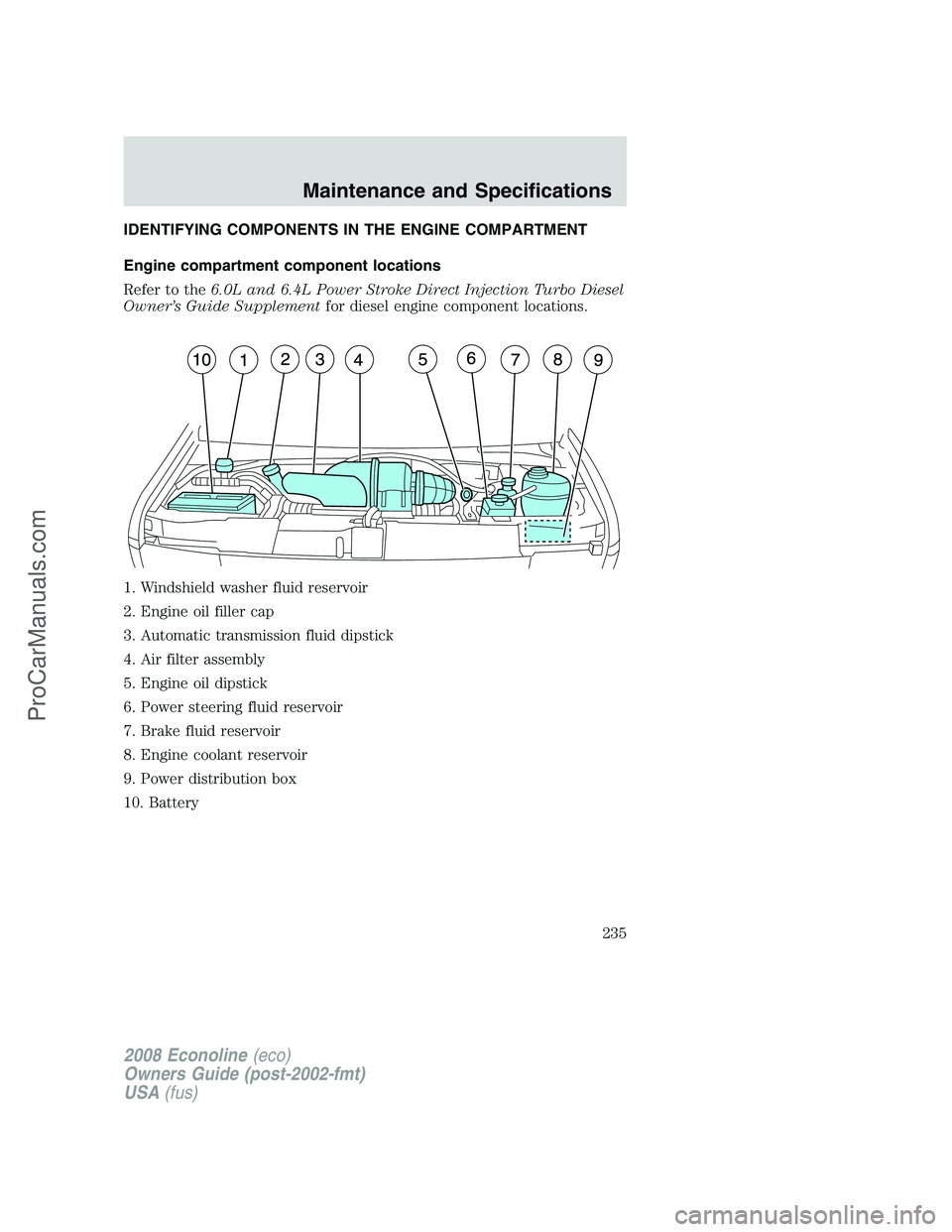

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

Engine compartment component locations

Refer to the6.0L and 6.4L Power Stroke Direct Injection Turbo Diesel

Owner’s Guide Supplementfor diesel engine component locations.

1. Windshield washer fluid reservoir

2. Engine oil filler cap

3. Automatic transmission fluid dipstick

4. Air filter assembly

5. Engine oil dipstick

6. Power steering fluid reservoir

7. Brake fluid reservoir

8. Engine coolant reservoir

9. Power distribution box

10. Battery

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

235

ProCarManuals.com

Page 241 of 285

It is recommended that the negative battery cable terminal be

disconnected from the battery if you plan to store your vehicle for an

extended period of time. This will minimize the discharge of your battery

during storage.

WARNING:Batteries normally produce explosive gases which

can cause personal injury. Therefore, do not allow flames, sparks

or lighted substances to come near the battery. When working near the

battery, always shield your face and protect your eyes. Always provide

proper ventilation.

WARNING:When lifting a plastic-cased battery, excessive

pressure on the end walls could cause acid to flow through the

vent caps, resulting in personal injury and/or damage to the vehicle or

battery. Lift the battery with a battery carrier or with your hands on

opposite corners.

WARNING:Keep batteries out of reach of children. Batteries

contain sulfuric acid. Avoid contact with skin, eyes or clothing.

Shield your eyes when working near the battery to protect against

possible splashing of acid solution. In case of acid contact with skin or

eyes, flush immediately with water for a minimum of 15 minutes and

get prompt medical attention. If acid is swallowed, call a physician

immediately.

WARNING:Battery posts, terminals and related accessories

contain lead and lead compounds.Wash hands after handling.

For information on transmission operation after the battery has been

disconnected, refer toAutomatic transmission operationin the

Drivingchapter.

Auxiliary battery (if equipped)

Your vehicle may be equipped with a frame-mounted auxiliary battery

located on the passenger side frame rail, behind the front passenger

door. This auxiliary battery is connected to the auxiliary battery relay, so

it is not used to start the vehicle.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

241

ProCarManuals.com

Page 264 of 285

DRIVELINE UNIVERSAL JOINT AND SLIP YOKE

Your vehicle may be equipped with universal joints that require

lubrication. Refer to thescheduled maintenance informationfor

maintenance intervals. If the original universal joints are replaced with

universal joints equipped with grease fittings, lubrication will also be

necessary.

TRANSMISSION FLUID

Checking automatic transmission fluid (if equipped)

Refer to yourscheduled maintenance informationfor scheduled

intervals for fluid checks and changes. Your transmission does not

consume fluid. However, the fluid level should be checked if the

transmission is not working properly, i.e., if the transmission slips or

shifts slowly or if you notice some sign of fluid leakage.

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 km]). If your vehicle has been

operated for an extended period at high speeds, in city traffic during hot

weather or pulling a trailer, the vehicle should be turned off for about

30 minutes to allow fluid to cool before checking.

1. Drive the vehicle 20 miles (30 km) or until it reaches normal operating

temperature.

2. Park the vehicle on a level surface and engage the parking brake.

3. With the parking brake engaged and your foot on the brake pedal,

start the engine and move the gearshift lever through all of the gear

ranges. Allow sufficient time for each gear to engage.

4. Latch the gearshift lever in P (Park) and leave the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lint free rag. If

necessary, refer toIdentifying components in the engine compartment

in this chapter for the location of the dipstick.

6. Install the dipstick making sure it is fully seated in the filler tube.

7. Remove the dipstick and inspect the fluid level. The fluid should be in

the designated area for normal operating temperature or ambient

temperature.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

264

ProCarManuals.com

Page 267 of 285

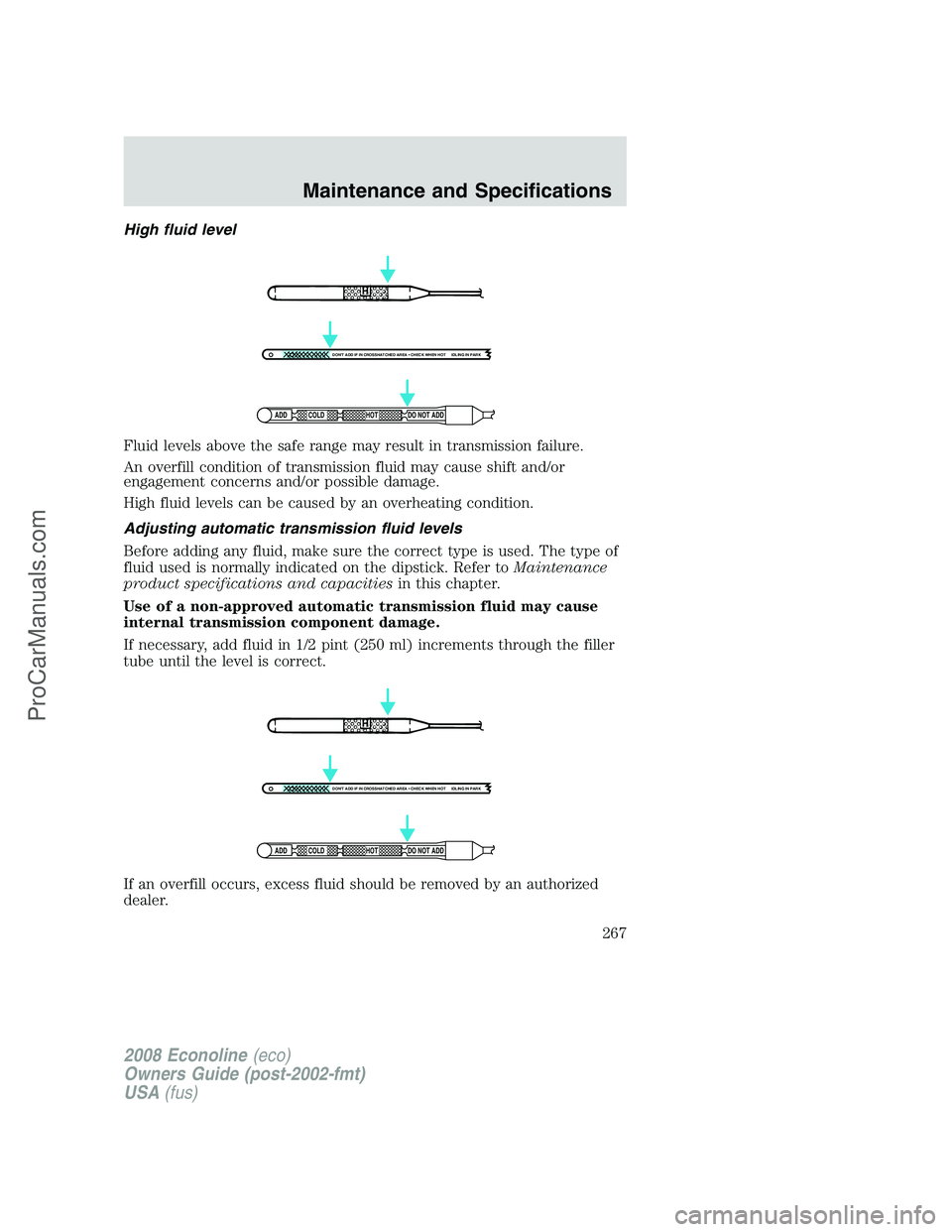

High fluid level

Fluid levels above the safe range may result in transmission failure.

An overfill condition of transmission fluid may cause shift and/or

engagement concerns and/or possible damage.

High fluid levels can be caused by an overheating condition.

Adjusting automatic transmission fluid levels

Before adding any fluid, make sure the correct type is used. The type of

fluid used is normally indicated on the dipstick. Refer toMaintenance

product specifications and capacitiesin this chapter.

Use of a non-approved automatic transmission fluid may cause

internal transmission component damage.

If necessary, add fluid in 1/2 pint (250 ml) increments through the filler

tube until the level is correct.

If an overfill occurs, excess fluid should be removed by an authorized

dealer.

DON'T ADD IF IN CROSSHATCHED AREA CHECK WHEN HOT IDLING IN PARK

ADD COLD HOT DO NOT ADD

DON'T ADD IF IN CROSSHATCHED AREA CHECK WHEN HOT IDLING IN PARK

ADD COLD HOT DO NOT ADD

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

267

ProCarManuals.com

Page 268 of 285

An overfill condition of transmission fluid may cause shift and/or

engagement concerns and/or possible damage.

Do not use supplemental transmission fluid additives, treatments or

cleaning agents. The use of these materials may affect transmission

operation and result in damage to internal transmission components.

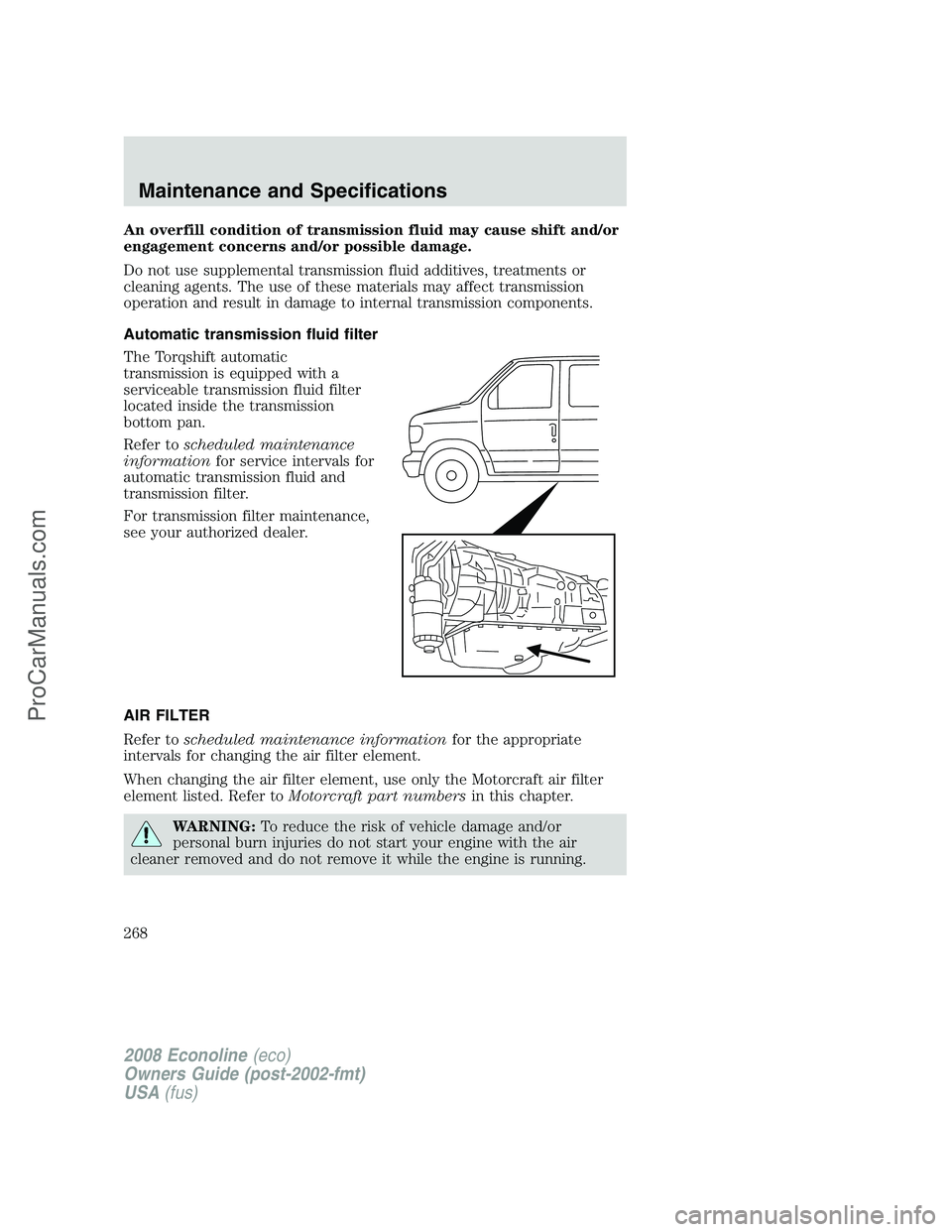

Automatic transmission fluid filter

The Torqshift automatic

transmission is equipped with a

serviceable transmission fluid filter

located inside the transmission

bottom pan.

Refer toscheduled maintenance

informationfor service intervals for

automatic transmission fluid and

transmission filter.

For transmission filter maintenance,

see your authorized dealer.

AIR FILTER

Refer toscheduled maintenance informationfor the appropriate

intervals for changing the air filter element.

When changing the air filter element, use only the Motorcraft air filter

element listed. Refer toMotorcraft part numbersin this chapter.

WARNING:To reduce the risk of vehicle damage and/or

personal burn injuries do not start your engine with the air

cleaner removed and do not remove it while the engine is running.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

268

ProCarManuals.com

Page 270 of 285

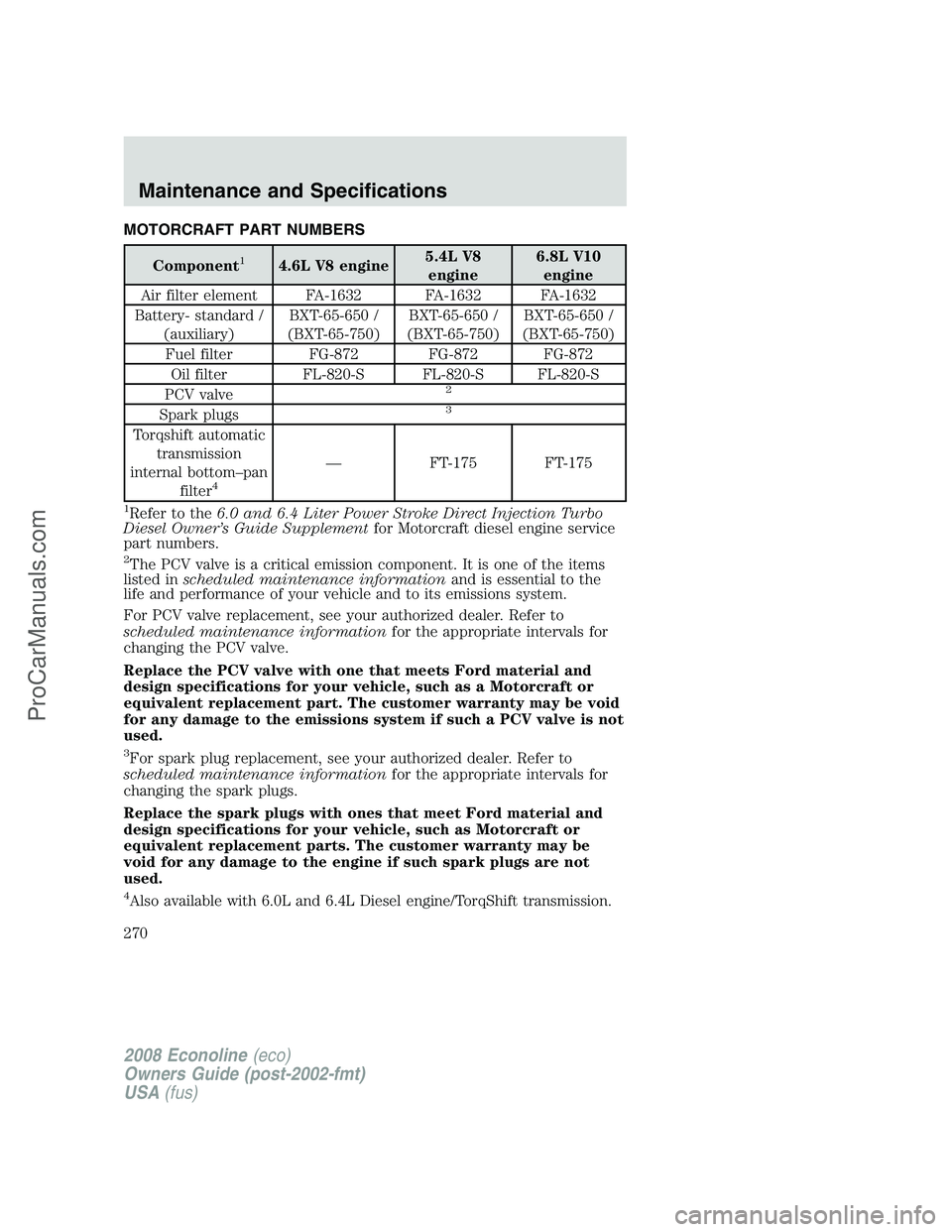

MOTORCRAFT PART NUMBERS

Component14.6L V8 engine5.4L V8

engine6.8L V10

engine

Air filter element FA-1632 FA-1632 FA-1632

Battery- standard /

(auxiliary)BXT-65-650 /

(BXT-65-750)BXT-65-650 /

(BXT-65-750)BXT-65-650 /

(BXT-65-750)

Fuel filter FG-872 FG-872 FG-872

Oil filter FL-820-S FL-820-S FL-820-S

PCV valve

2

Spark plugs3

Torqshift automatic

transmission

internal bottom–pan

filter

4

— FT-175 FT-175

1Refer to the6.0 and 6.4 Liter Power Stroke Direct Injection Turbo

Diesel Owner’s Guide Supplementfor Motorcraft diesel engine service

part numbers.

2The PCV valve is a critical emission component. It is one of the items

listed inscheduled maintenance informationand is essential to the

life and performance of your vehicle and to its emissions system.

For PCV valve replacement, see your authorized dealer. Refer to

scheduled maintenance informationfor the appropriate intervals for

changing the PCV valve.

Replace the PCV valve with one that meets Ford material and

design specifications for your vehicle, such as a Motorcraft or

equivalent replacement part. The customer warranty may be void

for any damage to the emissions system if such a PCV valve is not

used.

3For spark plug replacement, see your authorized dealer. Refer to

scheduled maintenance informationfor the appropriate intervals for

changing the spark plugs.

Replace the spark plugs with ones that meet Ford material and

design specifications for your vehicle, such as Motorcraft or

equivalent replacement parts. The customer warranty may be

void for any damage to the engine if such spark plugs are not

used.

4Also available with 6.0L and 6.4L Diesel engine/TorqShift transmission.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

270

ProCarManuals.com