battery FORD E-450 2002 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2002, Model line: E-450, Model: FORD E-450 2002Pages: 256, PDF Size: 3.52 MB

Page 167 of 256

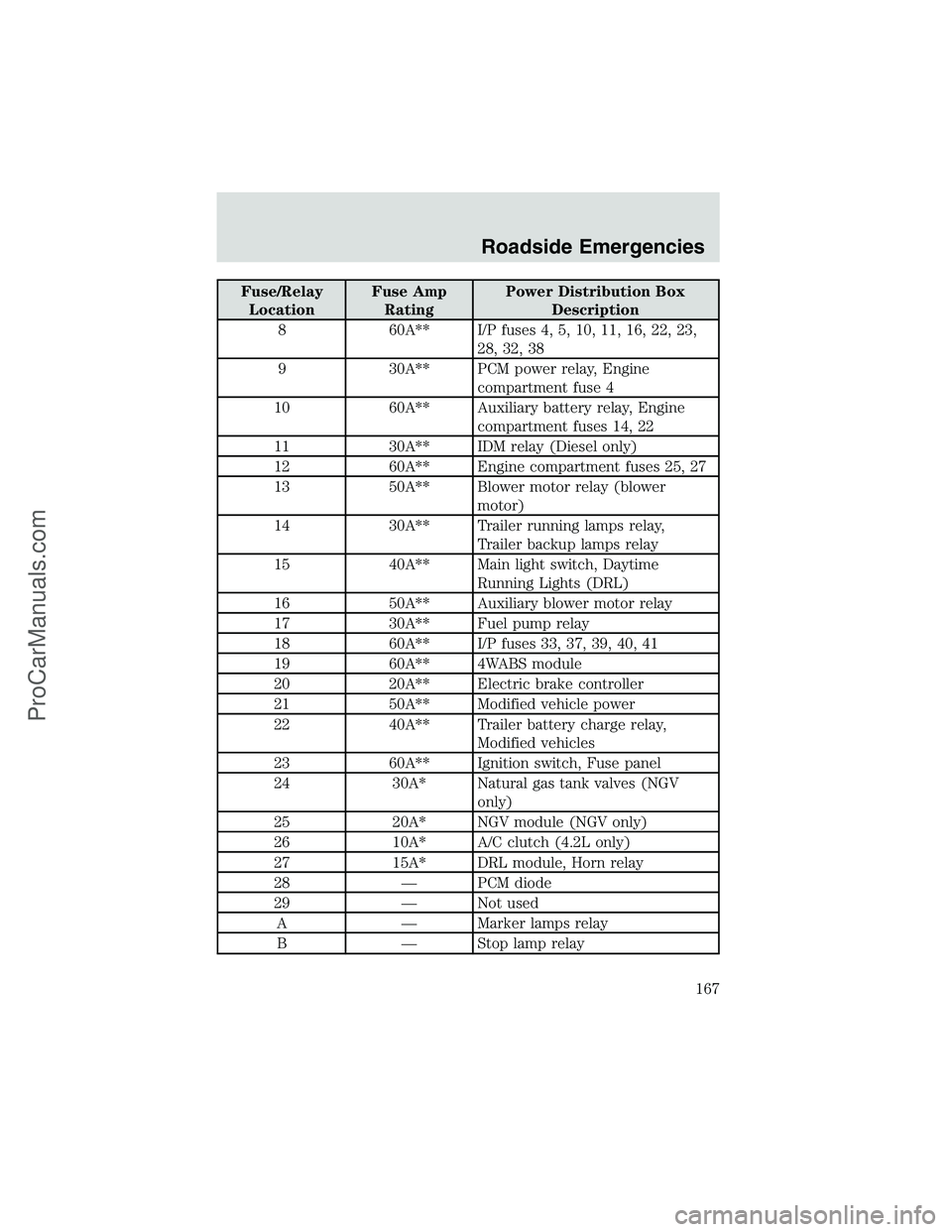

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

8 60A** I/P fuses 4, 5, 10, 11, 16, 22, 23,

28, 32, 38

9 30A** PCM power relay, Engine

compartment fuse 4

10 60A** Auxiliary battery relay, Engine

compartment fuses 14, 22

11 30A** IDM relay (Diesel only)

12 60A** Engine compartment fuses 25, 27

13 50A** Blower motor relay (blower

motor)

14 30A** Trailer running lamps relay,

Trailer backup lamps relay

15 40A** Main light switch, Daytime

Running Lights (DRL)

16 50A** Auxiliary blower motor relay

17 30A** Fuel pump relay

18 60A** I/P fuses 33, 37, 39, 40, 41

19 60A** 4WABS module

20 20A** Electric brake controller

21 50A** Modified vehicle power

22 40A** Trailer battery charge relay,

Modified vehicles

23 60A** Ignition switch, Fuse panel

24 30A* Natural gas tank valves (NGV

only)

25 20A* NGV module (NGV only)

26 10A* A/C clutch (4.2L only)

27 15A* DRL module, Horn relay

28—PCM diode

29—Not used

A—Marker lamps relay

B—Stop lamp relay

Roadside Emergencies

167

ProCarManuals.com

Page 168 of 256

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

C—Trailer backup lamps relay

D—Trailer running lamps relay

E—Trailer battery charge relay

F—IDM relay (Diesel only), A/C

clutch relay (4.2L only)

G—PCM relay

H—Blower motor relay

J—Horn relay

K—Fuel pump relay

* Mini fuses ** Maxi fuses

Relays

Relays are located in the power distribution box and should be replaced

by qualified technicians.

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

The use of tire sealants is not recommended and may

compromise the integrity of your tires.

Spare tire information

The spare tire for your vehicle is stowed under the rear of your vehicle

(except cutaway and stripped chassis models).

Roadside Emergencies

168

ProCarManuals.com

Page 175 of 256

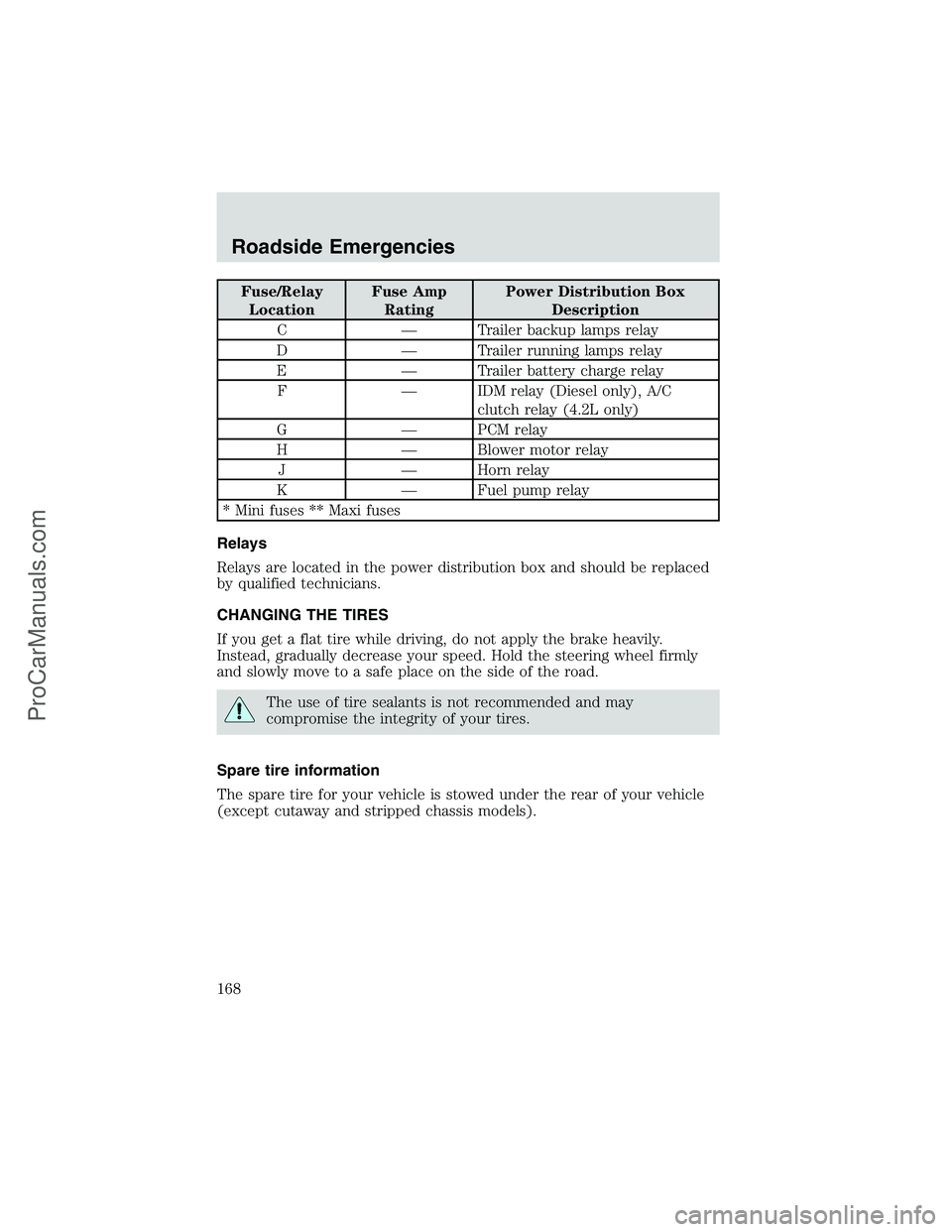

Model Bolt size Wheel lug nut torque*

Nm Lb-ft

E-150 1/2-20 135 100

E-250, E-350 and E-450 9/16-18 190 140

E-550 M14x1.5 200–225 150–165

* Torque specifications are for nut and bolt threads free of dirt and rust.

Do not use oil or grease on threads (E-550 vehicles, refer to following

Note). Use only Ford recommended replacement fasteners.

Note:For E-550 vehicles, on all

two-piece flat wheel nuts, apply

motor oil between the flat washer

and the nut. Do not apply motor oil

to the wheel nut threads or the

wheel stud threads.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic transmissions

do not have push-start capability; also, the catalytic converter may

become damaged.

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

Roadside Emergencies

175

ProCarManuals.com

Page 176 of 256

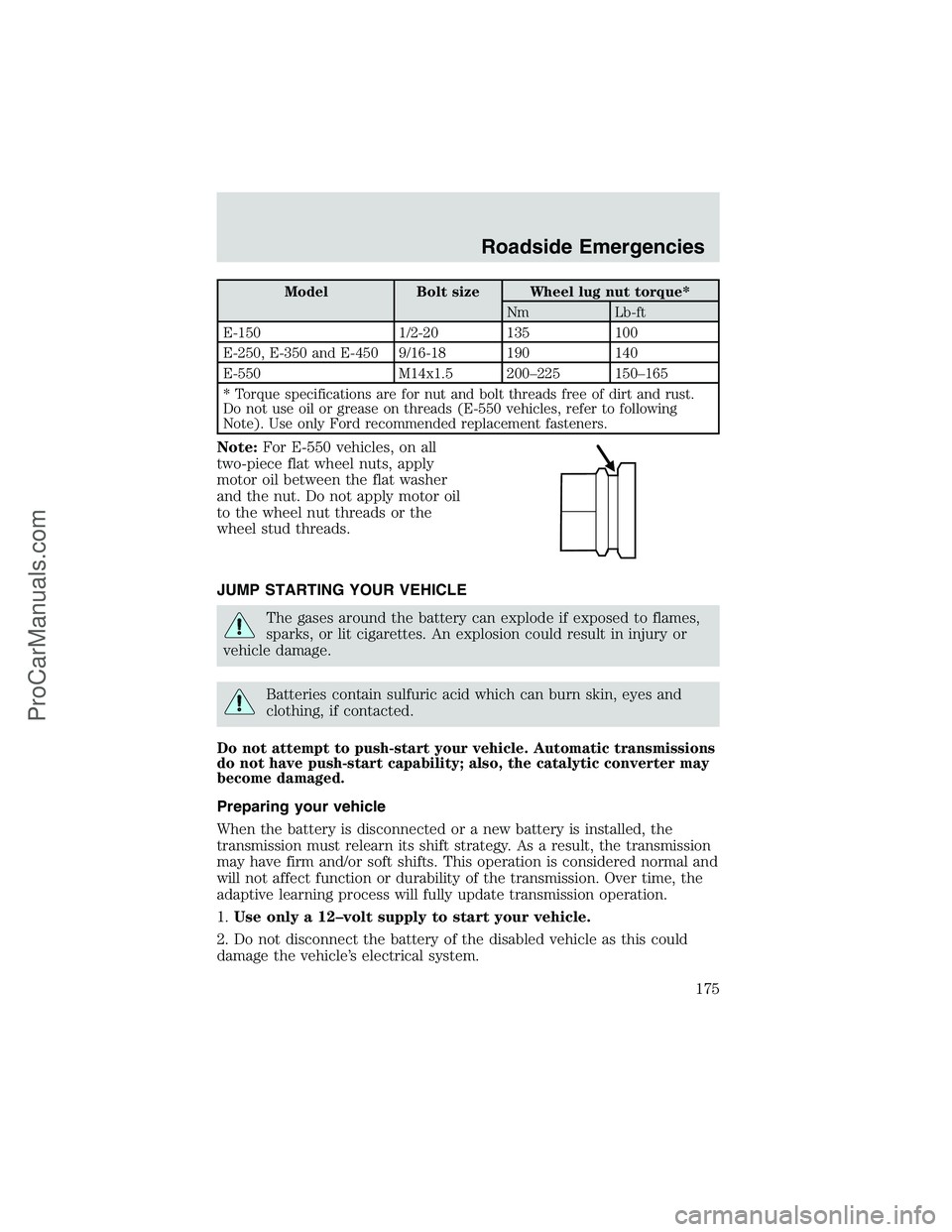

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

1. Connect the positive (+) booster cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

+–+–

+–+–

Roadside Emergencies

176

ProCarManuals.com

Page 177 of 256

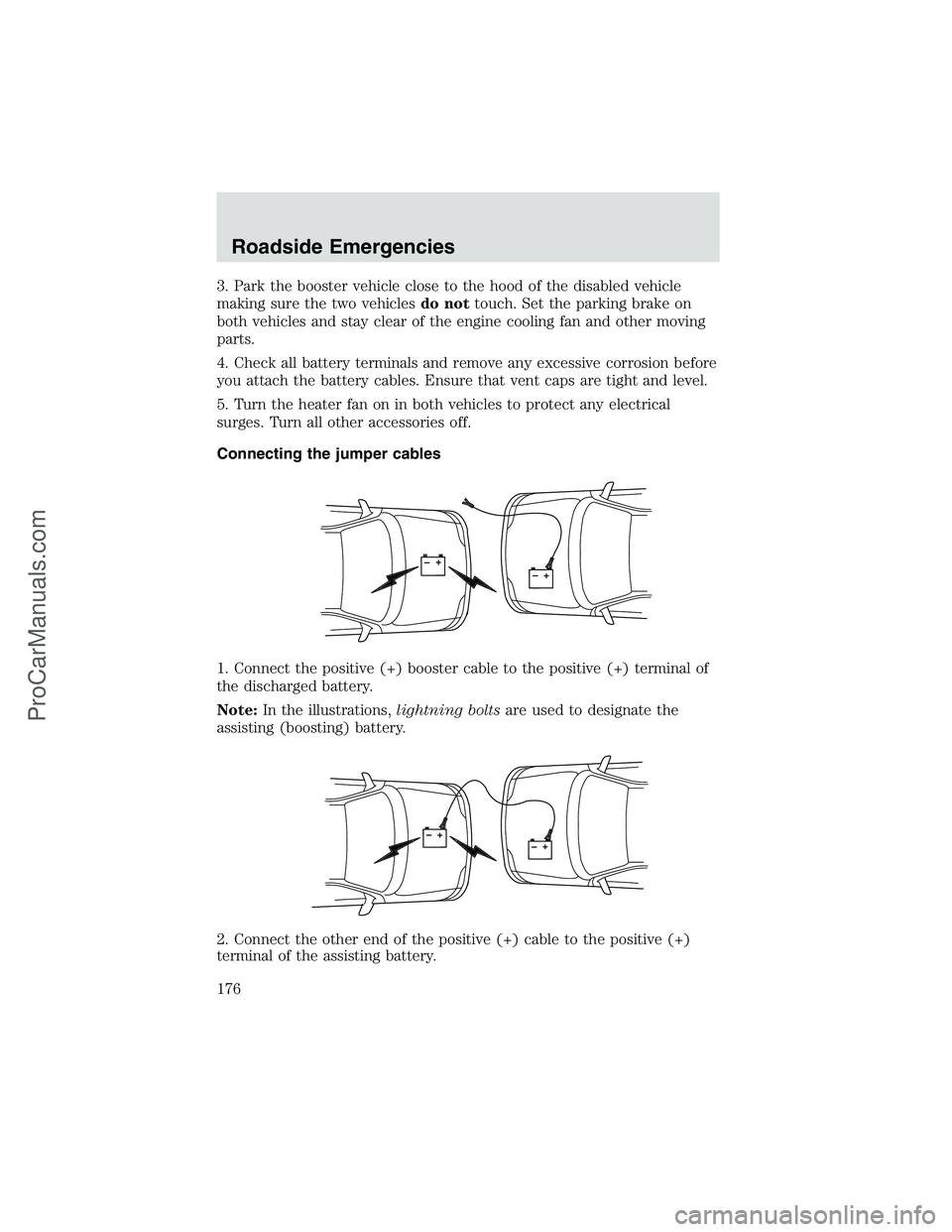

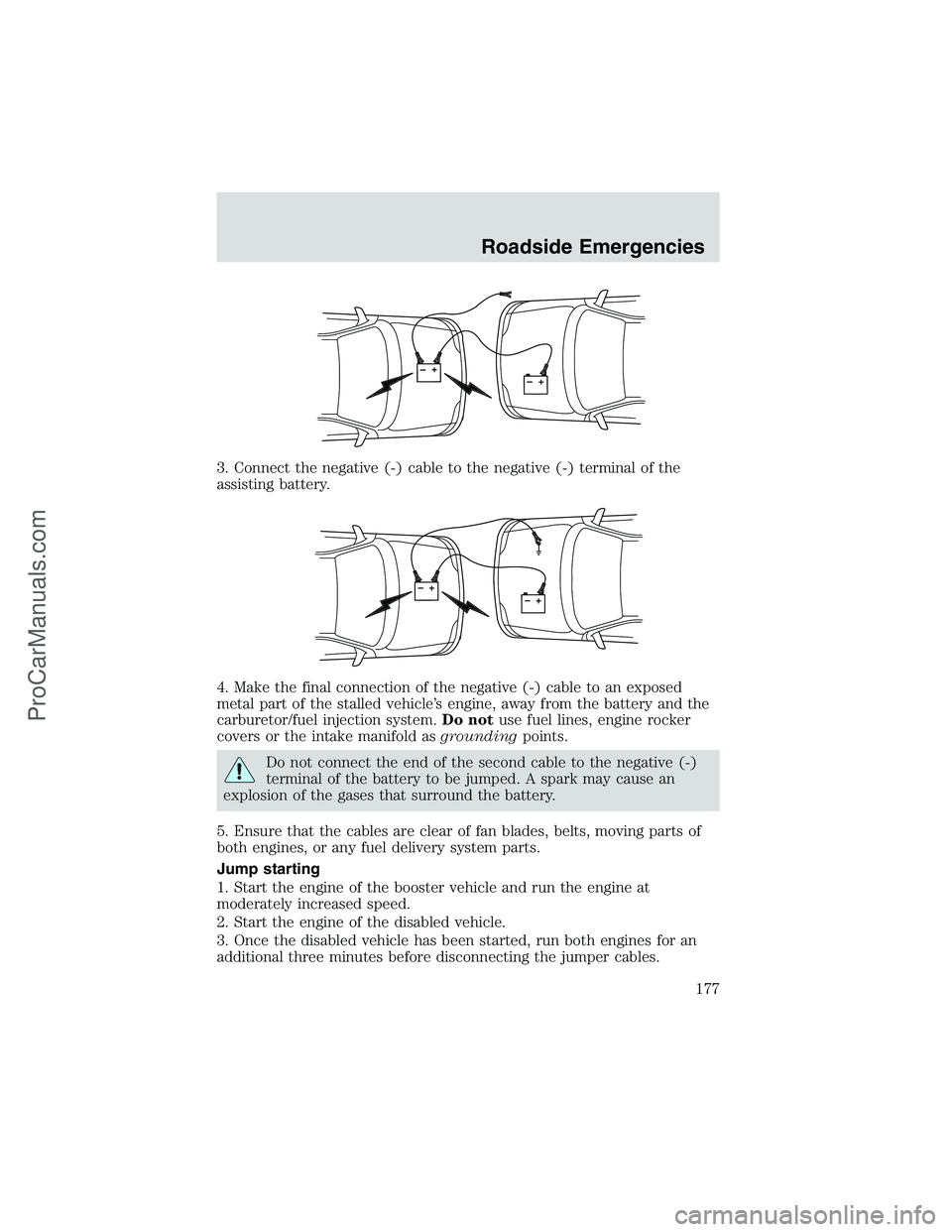

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle’s engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

+–+–

+–+–

Roadside Emergencies

177

ProCarManuals.com

Page 178 of 256

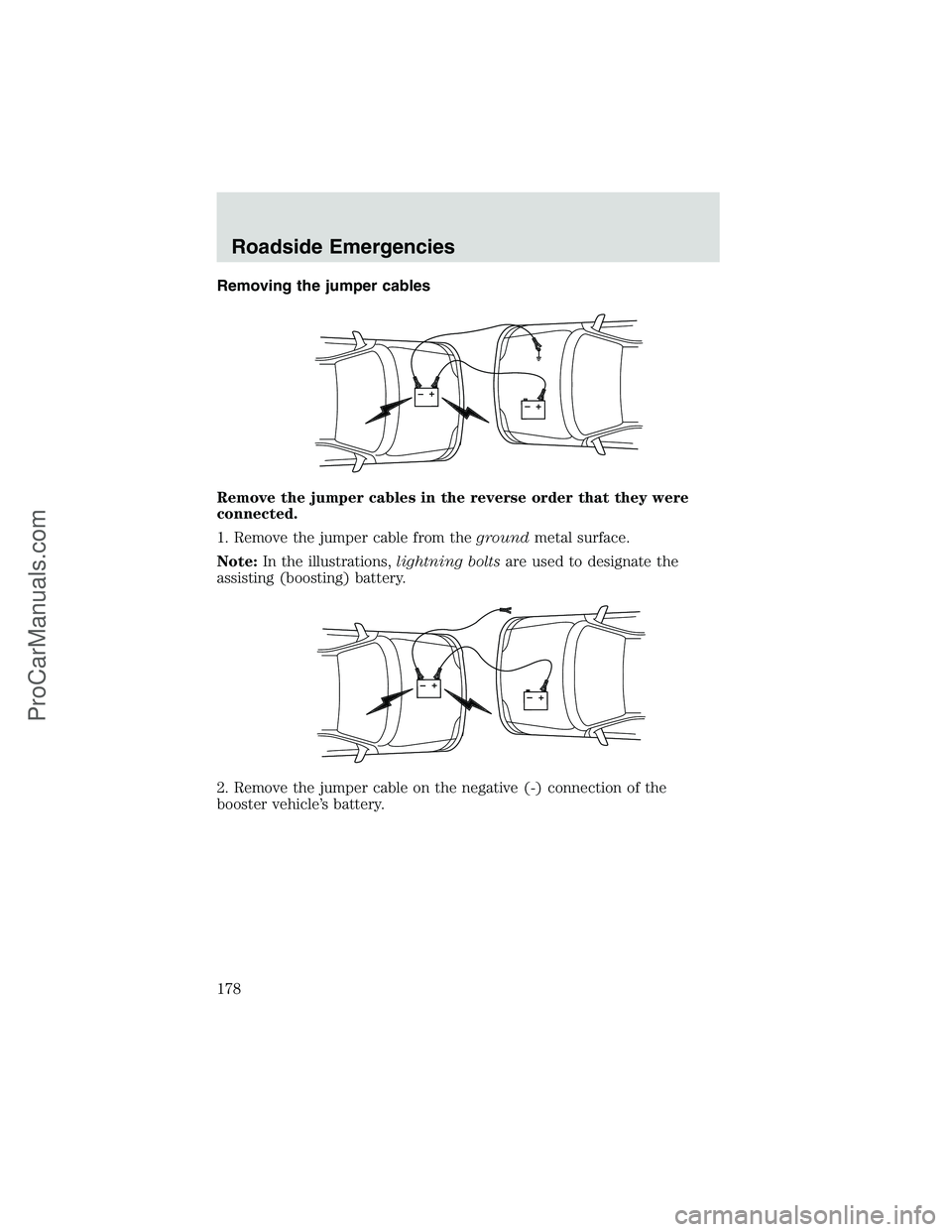

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

+–+–

+–+–

Roadside Emergencies

178

ProCarManuals.com

Page 179 of 256

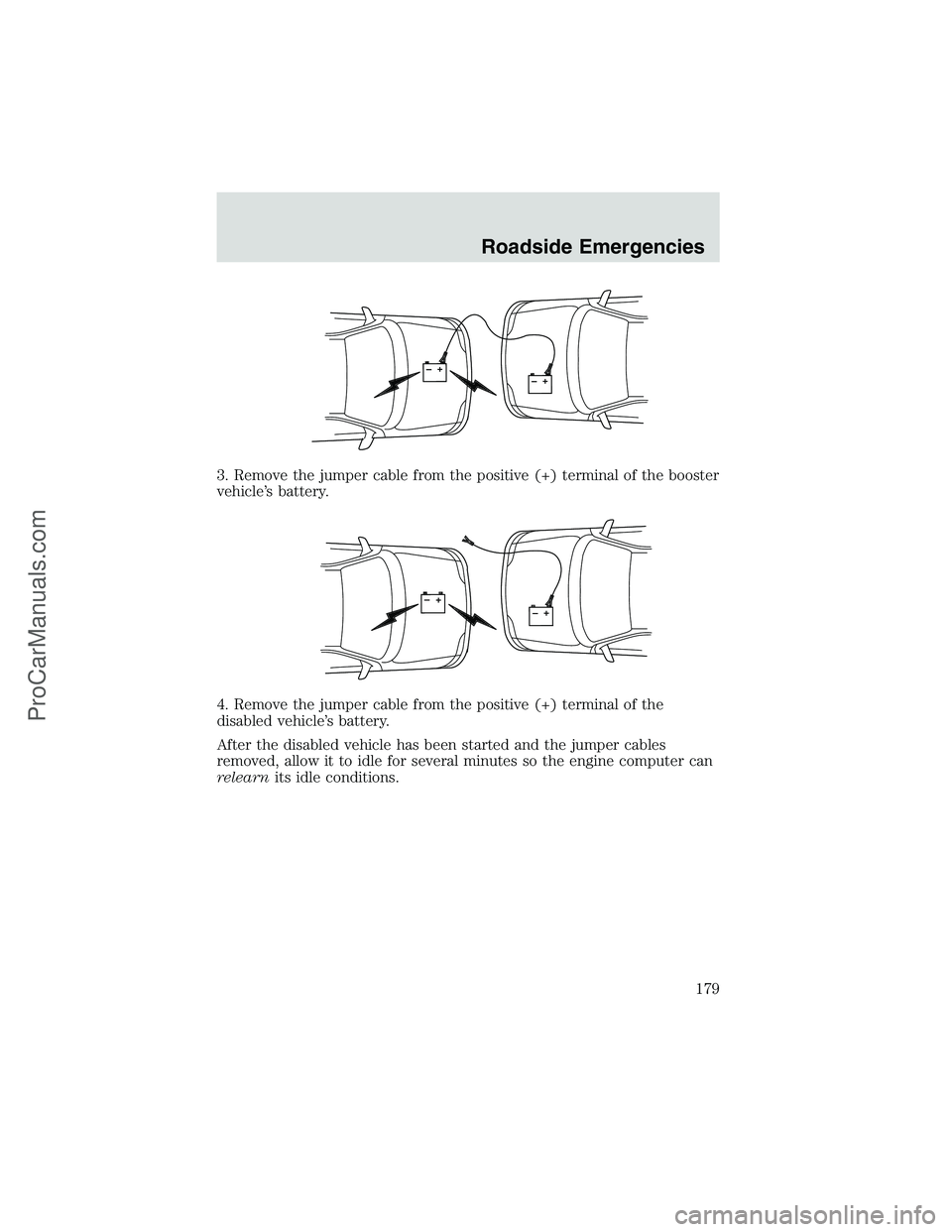

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

Roadside Emergencies

179

ProCarManuals.com

Page 198 of 256

SERVICE RECOMMENDATIONS

To help you service your vehicle:

•We highlight do-it-yourself items in the engine compartment for easy

location.

•We provide a scheduled maintenance guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

the necessary parts and service. Check yourWarranty Guide/Owner

Information Guideto find out which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

•Do not work on a hot engine.

•When the engine is running, make sure that loose clothing, jewelry or

long hair does not get caught up in moving parts.

•Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

•Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must“relearn”its idle

conditions before your vehicle will drive properly, as explained in the

Batterysection of this chapter.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Note:Do not start your engine with the air cleaner removed and do not

remove it while the engine is running.

Maintenance and Specifications

198

ProCarManuals.com

Page 200 of 256

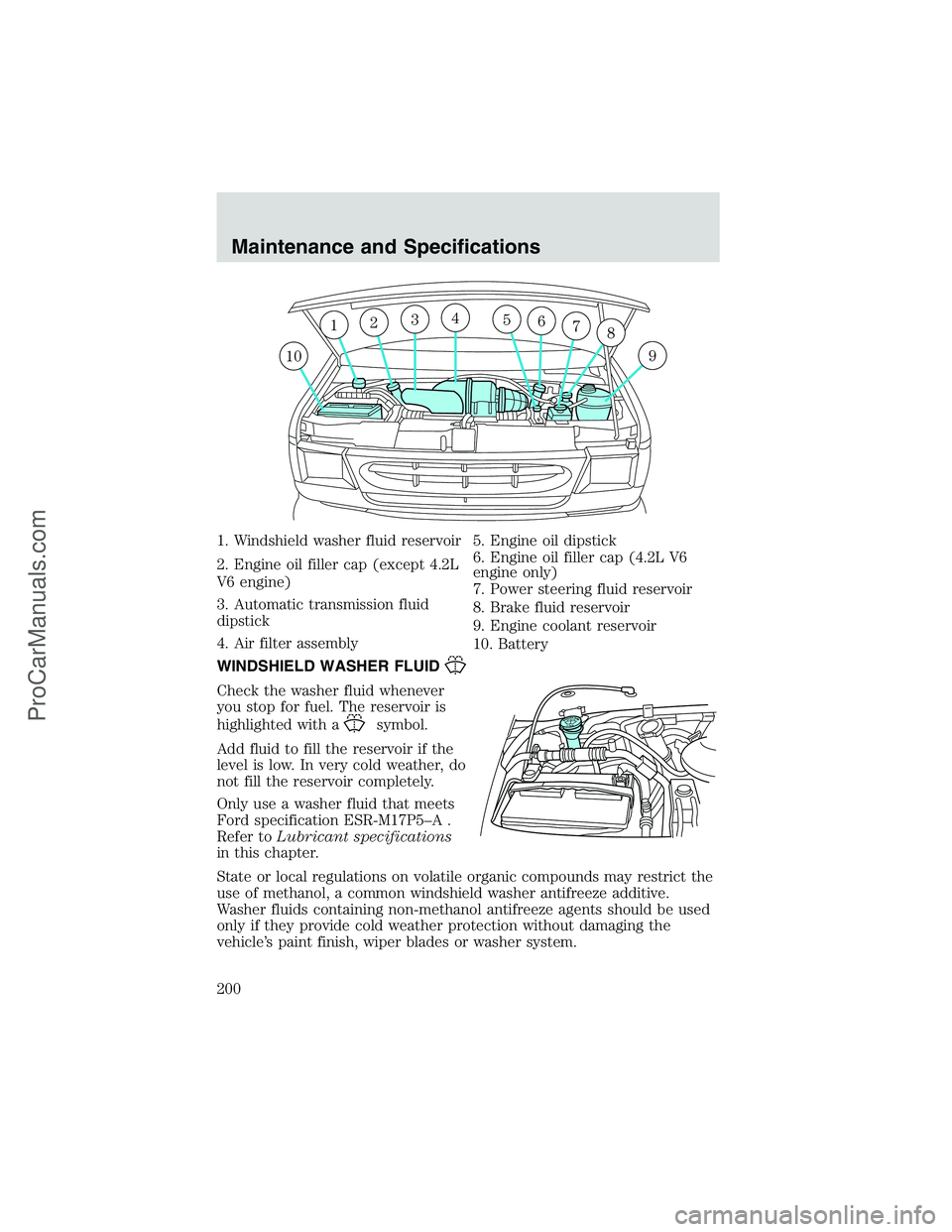

1. Windshield washer fluid reservoir

2. Engine oil filler cap (except 4.2L

V6 engine)

3. Automatic transmission fluid

dipstick

4. Air filter assembly5. Engine oil dipstick

6. Engine oil filler cap (4.2L V6

engine only)

7. Power steering fluid reservoir

8. Brake fluid reservoir

9. Engine coolant reservoir

10. Battery

WINDSHIELD WASHER FLUID

Check the washer fluid whenever

you stop for fuel. The reservoir is

highlighted with a

symbol.

Add fluid to fill the reservoir if the

level is low. In very cold weather, do

not fill the reservoir completely.

Only use a washer fluid that meets

Ford specification ESR-M17P5–A.

Refer toLubricant specifications

in this chapter.

State or local regulations on volatile organic compounds may restrict the

use of methanol, a common windshield washer antifreeze additive.

Washer fluids containing non-methanol antifreeze agents should be used

only if they provide cold weather protection without damaging the

vehicle’s paint finish, wiper blades or washer system.

12345678

910

Maintenance and Specifications

200

ProCarManuals.com

Page 204 of 256

BATTERY

Your vehicle is equipped with a

Motorcraft maintenance-free battery

which normally does not require

additional water during its life of

service.

However, for severe usage or in high temperature climates and for frame

mounted batteries, check the battery electrolyte level. Refer to the

scheduled maintenance guide for the service interval schedules.

Keep the electrolyte level in each cell up to the“level indicator”.

Do not overfill the battery cells.

If the electrolyte level in the battery is low, you can add plain tap water

to the battery, as long as you do not use hard water (water with a high

mineral or alkali content). If possible, however, try to only fill the battery

cells with distilled water. If the battery needs water often, have the

charging system checked.

If your battery has a cover/shield, make sure it is reinstalled

after the battery has been cleaned or replaced.

For longer, trouble-free operation, keep the top of the battery clean and

dry. Also, make certain the battery cables are always tightly fastened to

the battery terminals.

If you see any corrosion on the battery or terminals, remove the cables

from the terminals and clean with a wire brush. You can neutralize the

acid with a solution of baking soda and water.

When the battery is disconnected or a new battery installed, the

transmission must learn its adaptive strategy. As a result of this, the

transmission may shift firmly. This operation is considered normal and

will fully update transmission operation to its optimum shift feel.

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

Maintenance and Specifications

204

ProCarManuals.com