battery FORD E-450 2008 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: E-450, Model: FORD E-450 2008Pages: 285, PDF Size: 2.81 MB

Page 199 of 285

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

27 10A* PCM KAPWR, Canister vent

(gasoline engine only)

28 — Not used

A — Fuel pump relay

B — Horn relay

C — Trailer back-up lamps relay

D — Trailer running lamps relay

E — Trailer battery charge relay

F — IDM relay (diesel only), IVD

(gasoline only)

G — PCM relay

H — Blower motor relay

J — Accessory delay relay

K — Start relay

* Mini fuses ** Maxi fuses

Relay modules

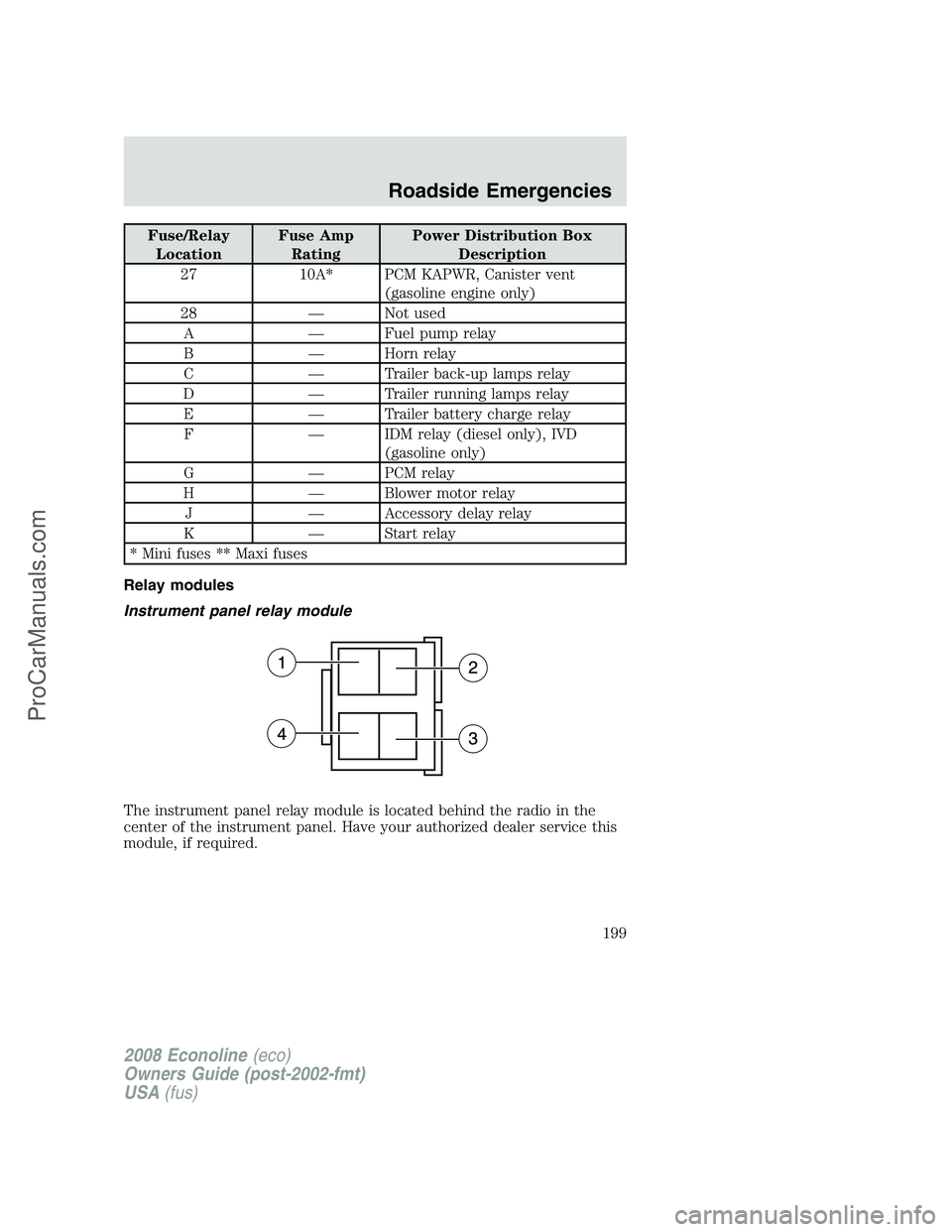

Instrument panel relay module

The instrument panel relay module is located behind the radio in the

center of the instrument panel. Have your authorized dealer service this

module, if required.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

199

ProCarManuals.com

Page 200 of 285

The relays are coded as follows:

Relay location Description

1 Interior lamps

2 Open

3 Open

4 Battery saver

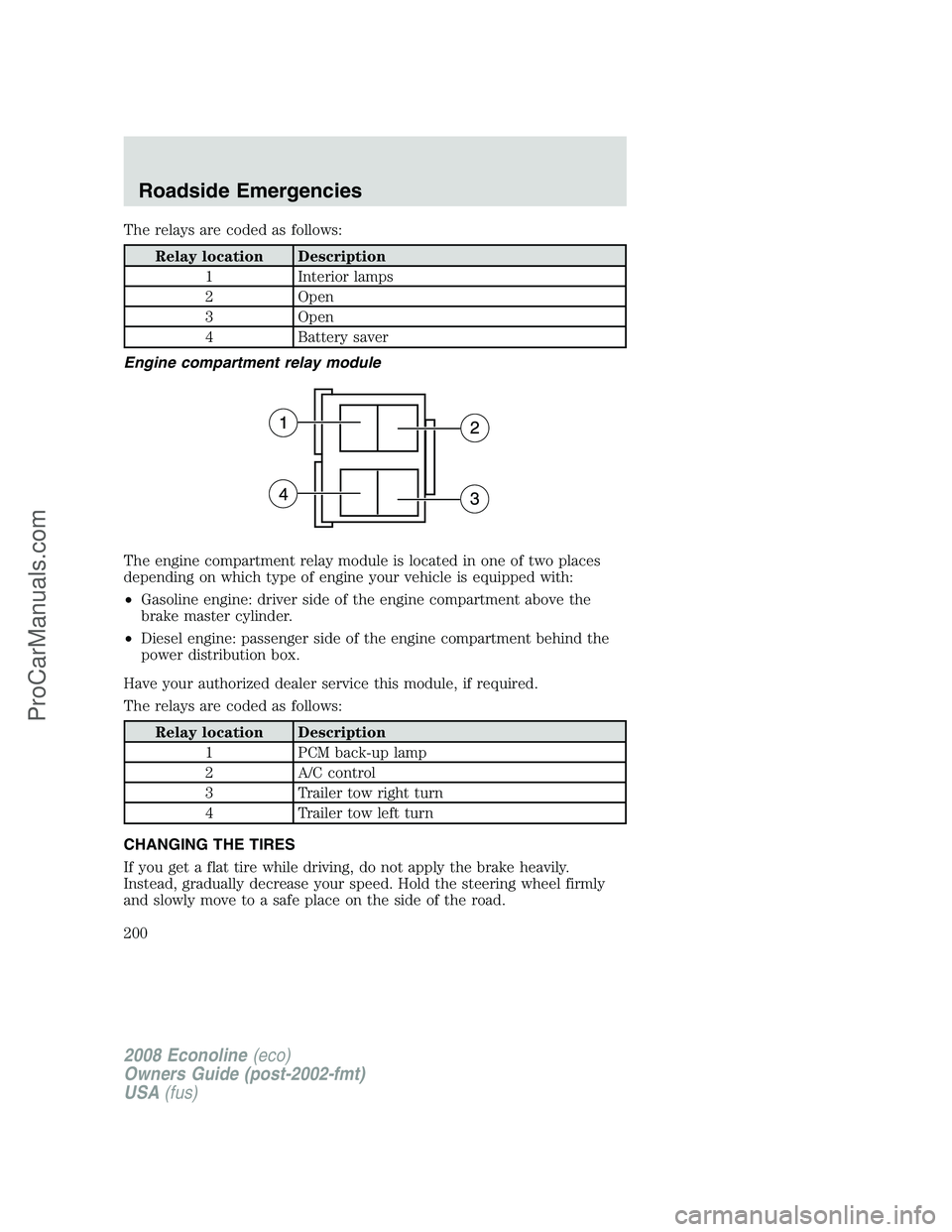

Engine compartment relay module

The engine compartment relay module is located in one of two places

depending on which type of engine your vehicle is equipped with:

•Gasoline engine: driver side of the engine compartment above the

brake master cylinder.

•Diesel engine: passenger side of the engine compartment behind the

power distribution box.

Have your authorized dealer service this module, if required.

The relays are coded as follows:

Relay location Description

1 PCM back-up lamp

2 A/C control

3 Trailer tow right turn

4 Trailer tow left turn

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

200

ProCarManuals.com

Page 210 of 285

WARNING:When a wheel is installed, always remove any

corrosion, dirt or foreign materials present on the mounting

surfaces of the wheel or the surface of the wheel hub, brake drum or

brake disc that contacts the wheel. Ensure that any fasteners that

attach the rotor to the hub are secured so they do not interfere with

the mounting surfaces of the wheel. Installing wheels without correct

metal-to-metal contact at the wheel mounting surfaces can cause the

wheel nuts to loosen and the wheel to come off while the vehicle is in

motion, resulting in loss of control.

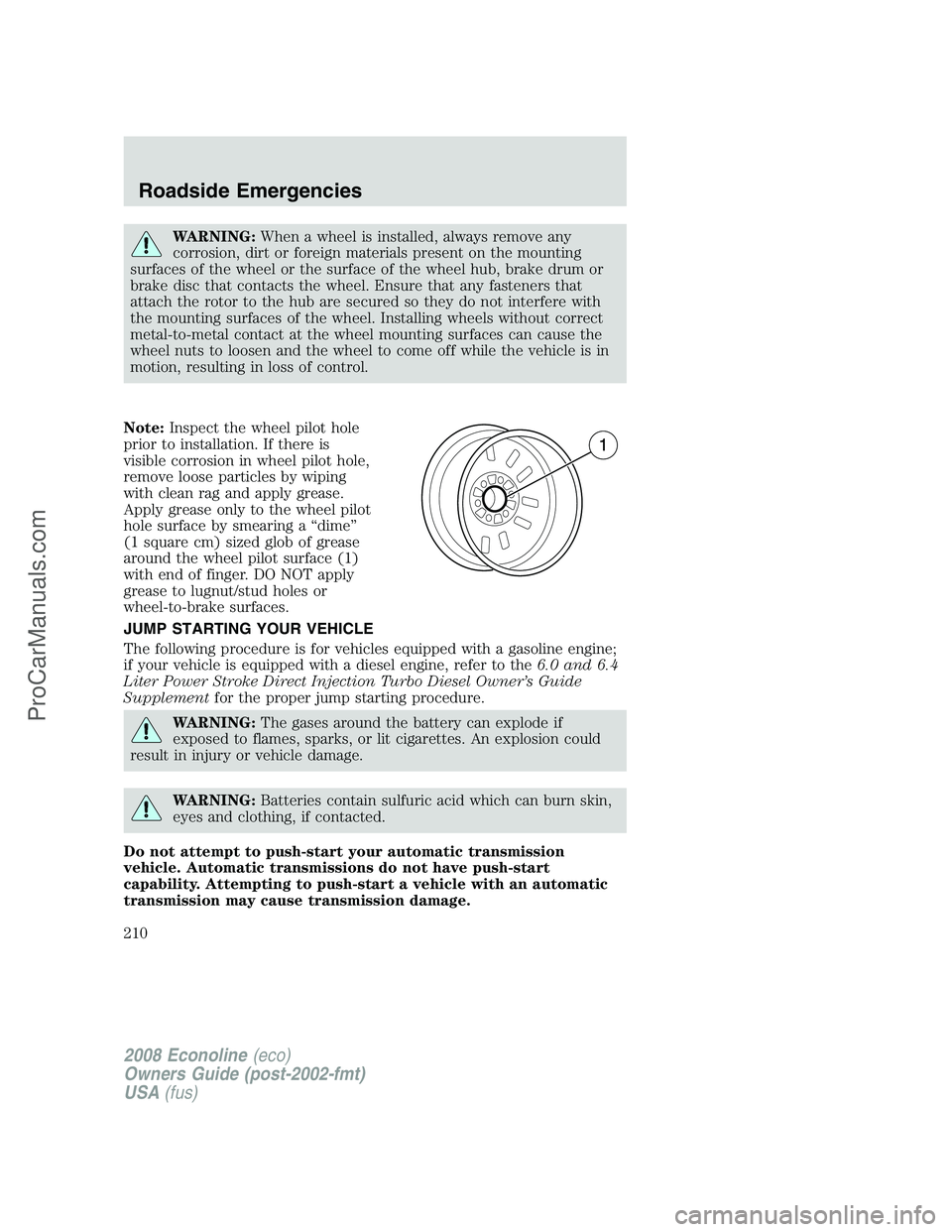

Note:Inspect the wheel pilot hole

prior to installation. If there is

visible corrosion in wheel pilot hole,

remove loose particles by wiping

with clean rag and apply grease.

Apply grease only to the wheel pilot

hole surface by smearing a “dime”

(1 square cm) sized glob of grease

around the wheel pilot surface (1)

with end of finger. DO NOT apply

grease to lugnut/stud holes or

wheel-to-brake surfaces.

JUMP STARTING YOUR VEHICLE

The following procedure is for vehicles equipped with a gasoline engine;

if your vehicle is equipped with a diesel engine, refer to the6.0 and 6.4

Liter Power Stroke Direct Injection Turbo Diesel Owner’s Guide

Supplementfor the proper jump starting procedure.

WARNING:The gases around the battery can explode if

exposed to flames, sparks, or lit cigarettes. An explosion could

result in injury or vehicle damage.

WARNING:Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not attempt to push-start your automatic transmission

vehicle. Automatic transmissions do not have push-start

capability. Attempting to push-start a vehicle with an automatic

transmission may cause transmission damage.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

210

ProCarManuals.com

Page 211 of 285

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

automatic transmission must relearn its shift strategy. As a result, the

transmission may have firm and/or soft shifts. This operation is

considered normal and will not affect function or durability of the

transmission. Over time, the adaptive learning process will fully update

transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

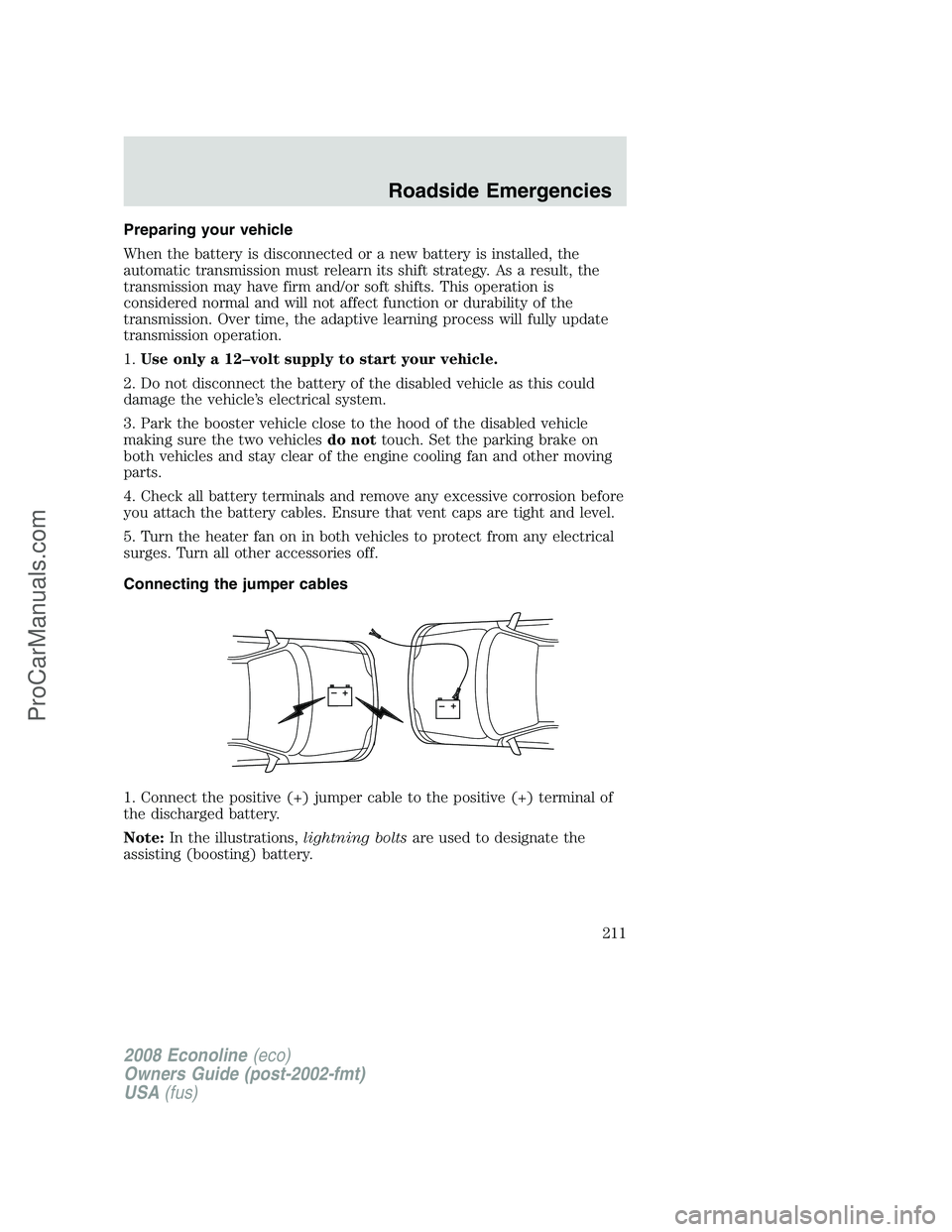

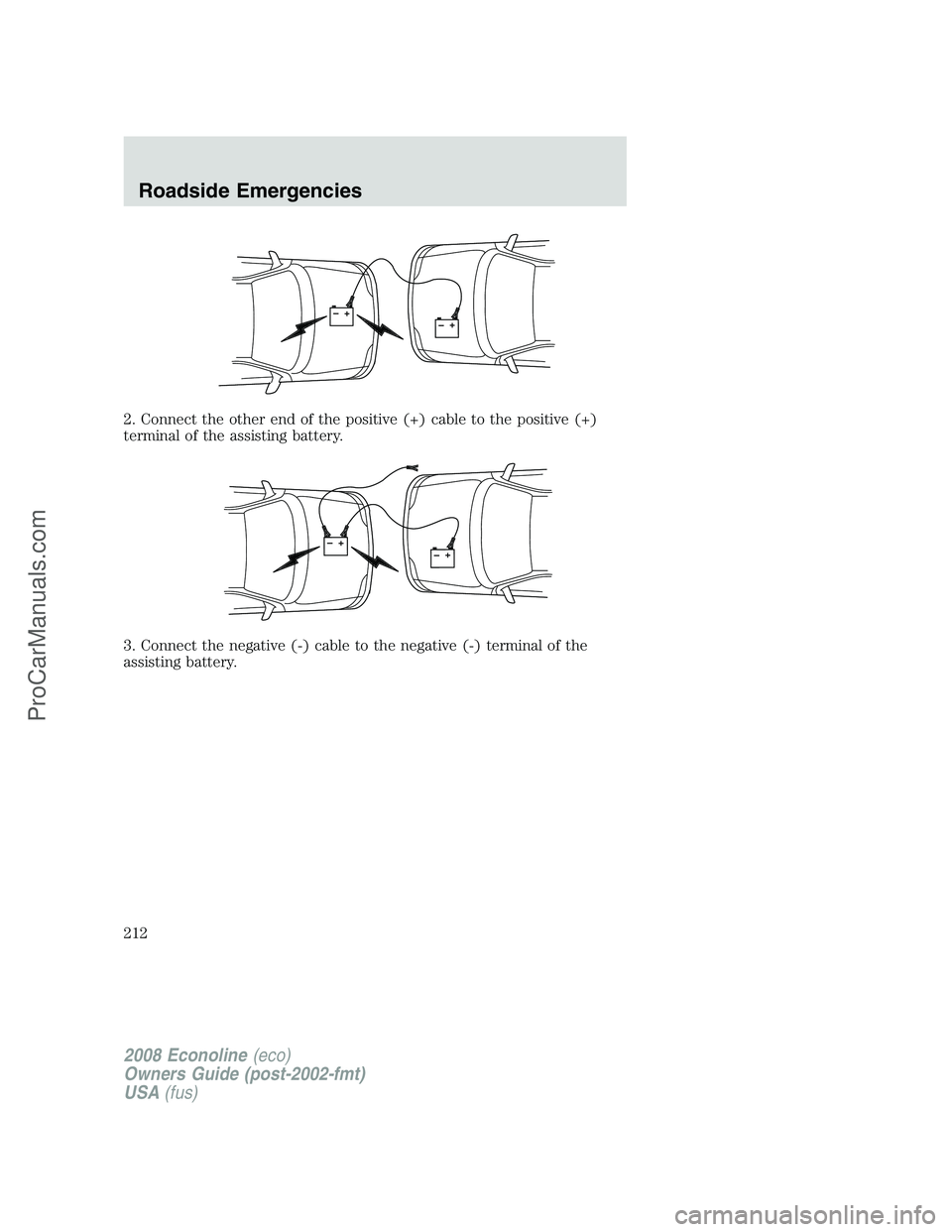

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

211

ProCarManuals.com

Page 212 of 285

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

+–+–

+–+–

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

212

ProCarManuals.com

Page 213 of 285

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle’s engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

WARNING:Do not connect the end of the second cable to the

negative (-) terminal of the battery to be jumped. A spark may

cause an explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

+–+–

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

213

ProCarManuals.com

Page 214 of 285

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

+–+–

+–+–

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

214

ProCarManuals.com

Page 215 of 285

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

215

ProCarManuals.com

Page 233 of 285

SERVICE RECOMMENDATIONS

To help you service your vehicle, we providescheduled maintenance

informationwhich makes tracking routine service easy.

If your vehicle requires professional service, your authorized dealer can

provide the necessary parts and service. Check yourWarranty

Guide/Customer Information Guideto find out which parts and

services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

•Do not work on a hot engine.

•Make sure that nothing gets caught in moving parts.

•Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

•Keep all open flames and other burning (cigarettes) material away

from the battery and all fuel related parts.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

233

ProCarManuals.com

Page 235 of 285

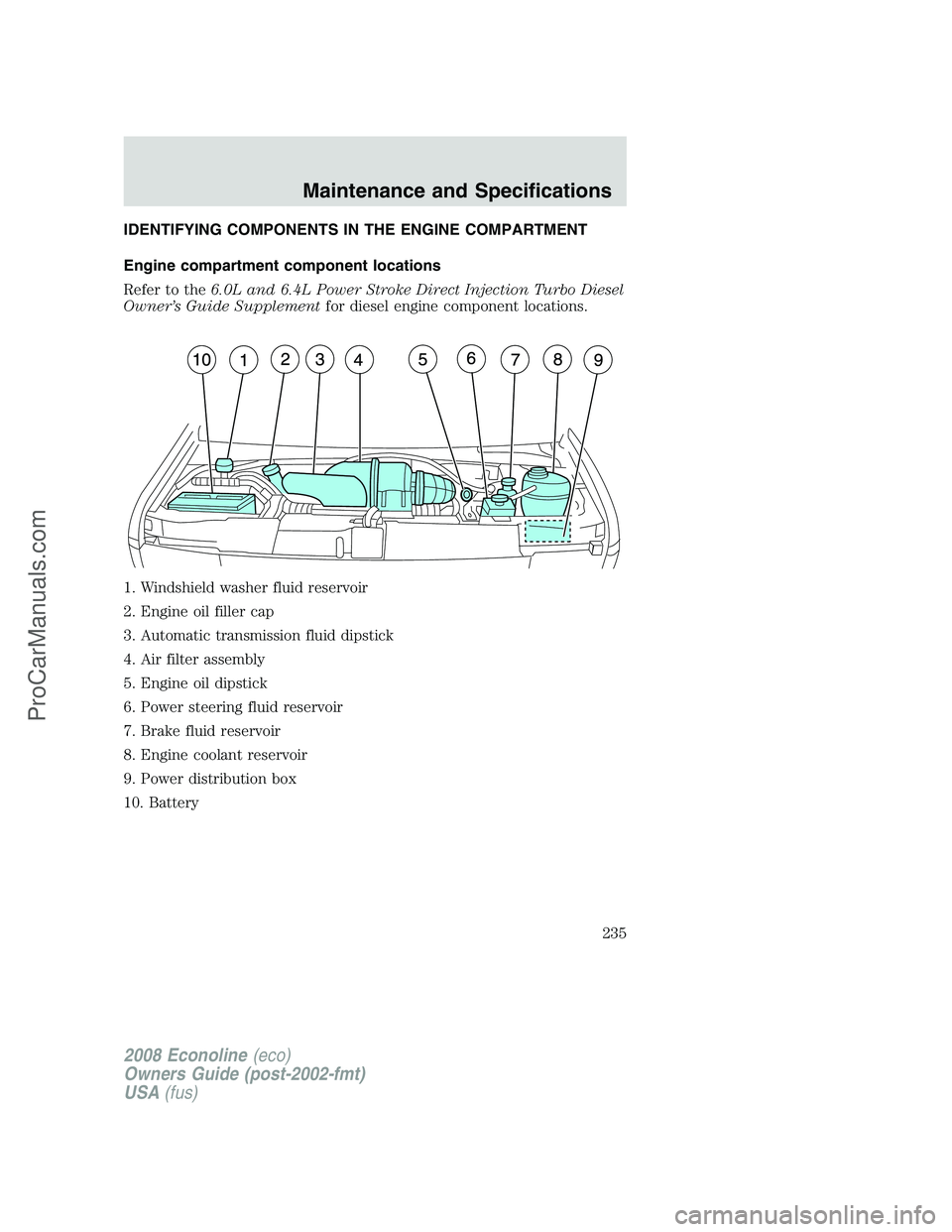

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

Engine compartment component locations

Refer to the6.0L and 6.4L Power Stroke Direct Injection Turbo Diesel

Owner’s Guide Supplementfor diesel engine component locations.

1. Windshield washer fluid reservoir

2. Engine oil filler cap

3. Automatic transmission fluid dipstick

4. Air filter assembly

5. Engine oil dipstick

6. Power steering fluid reservoir

7. Brake fluid reservoir

8. Engine coolant reservoir

9. Power distribution box

10. Battery

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

235

ProCarManuals.com