clock FORD E SERIES 2008 4.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: E SERIES, Model: FORD E SERIES 2008 4.GPages: 280, PDF Size: 2.56 MB

Page 44 of 280

Sealed beam

3. Rotate the bulb socket counterclockwise and remove.

4. Carefully pull the bulb straight out of the socket.

To complete installation, follow the removal procedures in reverse order.

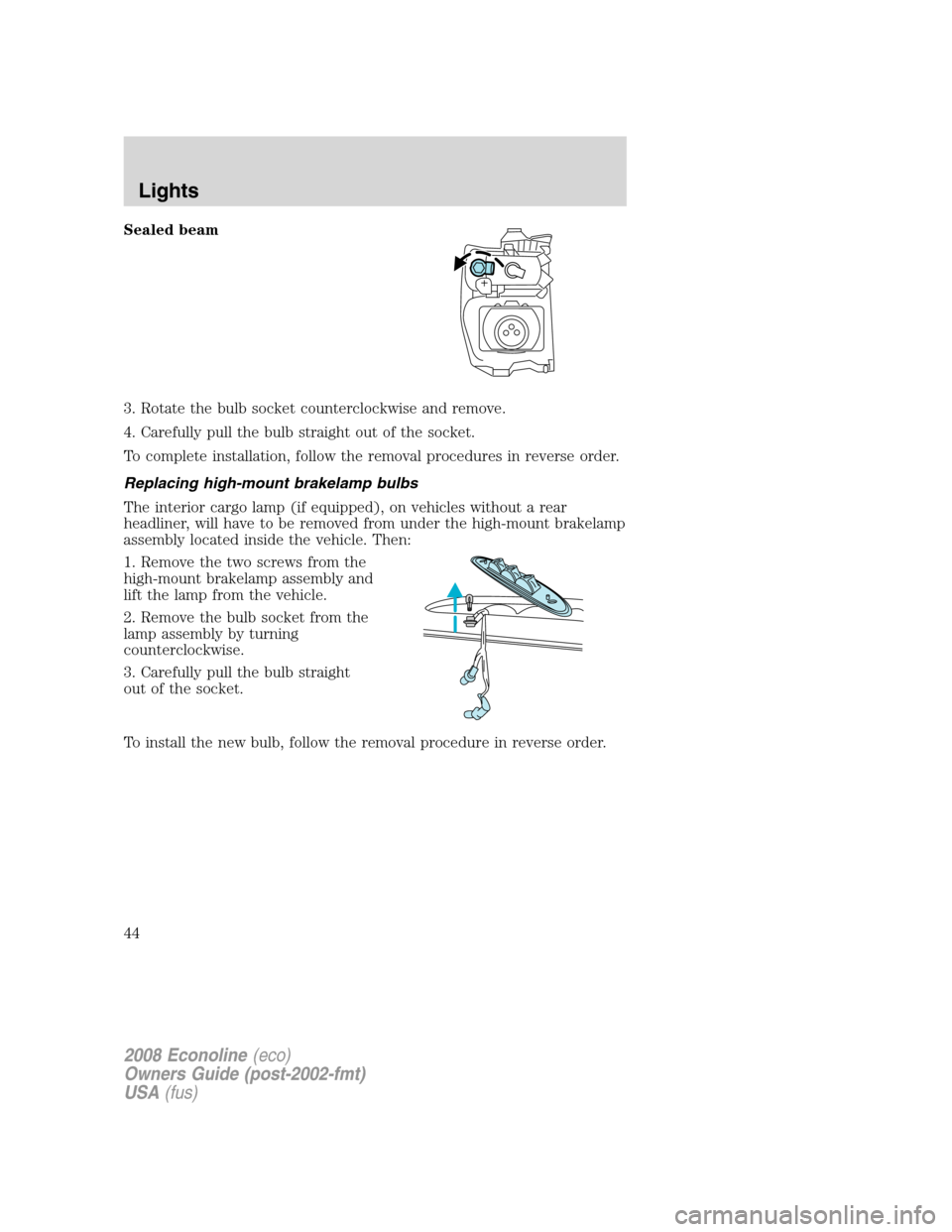

Replacing high-mount brakelamp bulbs

The interior cargo lamp (if equipped), on vehicles without a rear

headliner, will have to be removed from under the high-mount brakelamp

assembly located inside the vehicle. Then:

1. Remove the two screws from the

high-mount brakelamp assembly and

lift the lamp from the vehicle.

2. Remove the bulb socket from the

lamp assembly by turning

counterclockwise.

3. Carefully pull the bulb straight

out of the socket.

To install the new bulb, follow the removal procedure in reverse order.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Lights

44

Page 45 of 280

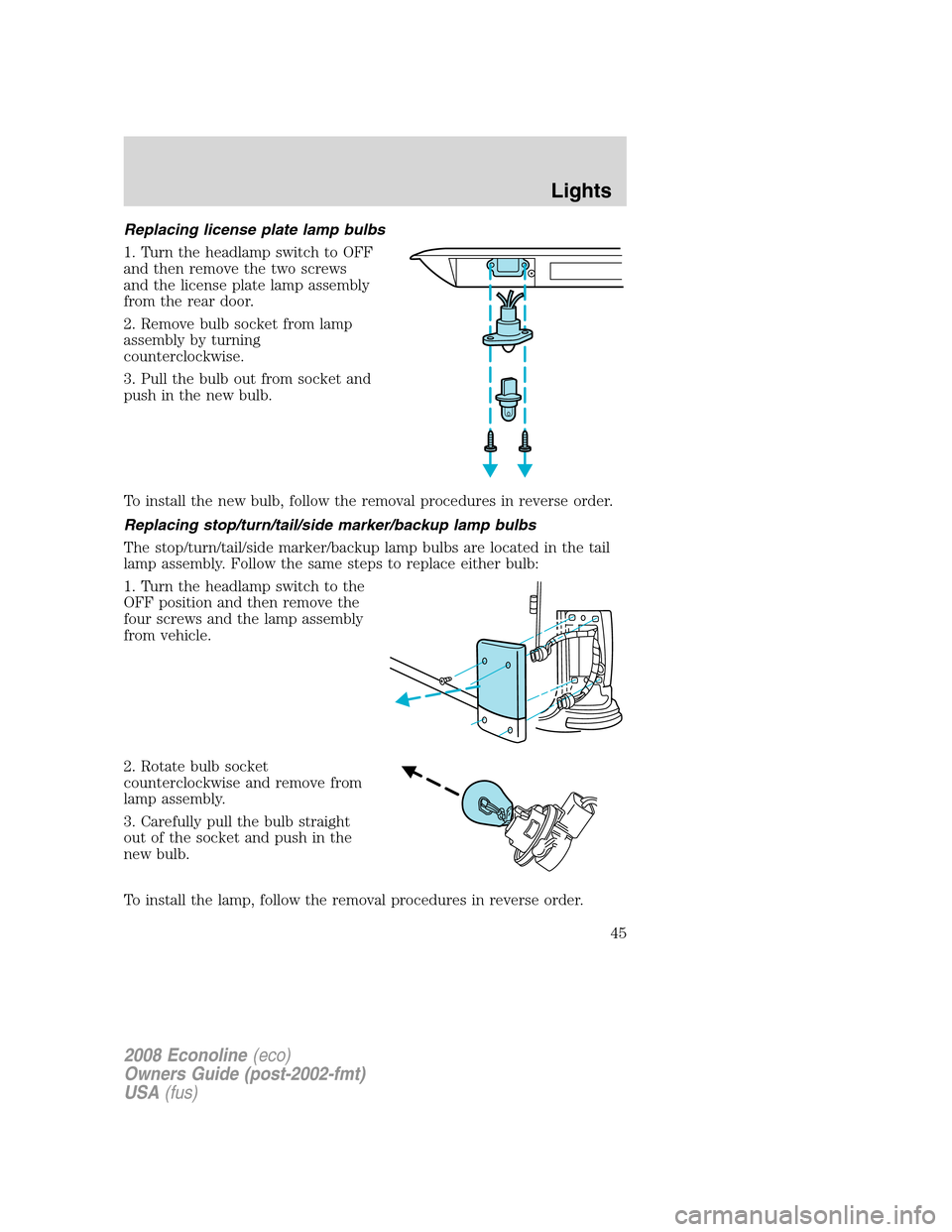

Replacing license plate lamp bulbs

1. Turn the headlamp switch to OFF

and then remove the two screws

and the license plate lamp assembly

from the rear door.

2. Remove bulb socket from lamp

assembly by turning

counterclockwise.

3. Pull the bulb out from socket and

push in the new bulb.

To install the new bulb, follow the removal procedures in reverse order.

Replacing stop/turn/tail/side marker/backup lamp bulbs

The stop/turn/tail/side marker/backup lamp bulbs are located in the tail

lamp assembly. Follow the same steps to replace either bulb:

1. Turn the headlamp switch to the

OFF position and then remove the

four screws and the lamp assembly

from vehicle.

2. Rotate bulb socket

counterclockwise and remove from

lamp assembly.

3. Carefully pull the bulb straight

out of the socket and push in the

new bulb.

To install the lamp, follow the removal procedures in reverse order.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Lights

45

Page 70 of 280

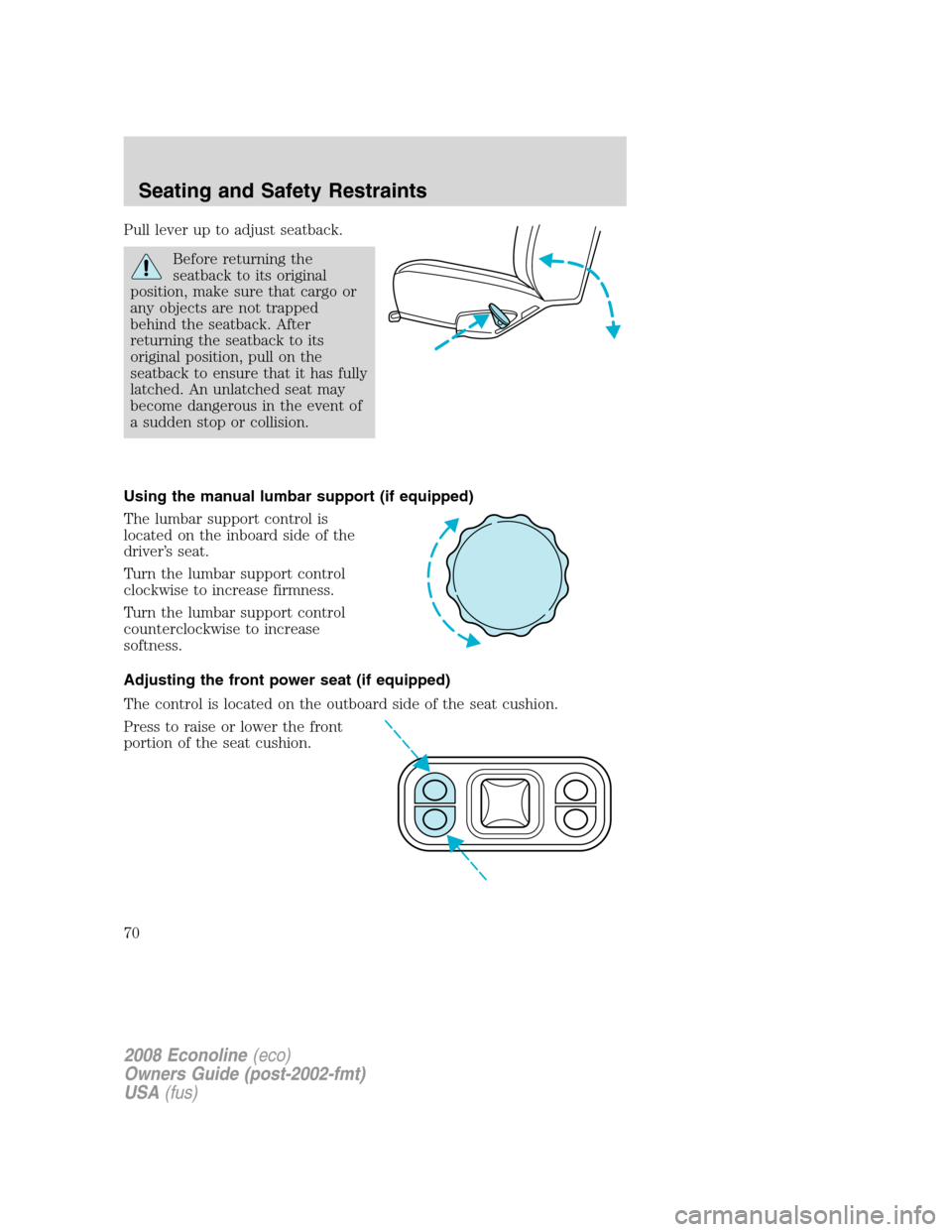

Pull lever up to adjust seatback.

Before returning the

seatback to its original

position, make sure that cargo or

any objects are not trapped

behind the seatback. After

returning the seatback to its

original position, pull on the

seatback to ensure that it has fully

latched. An unlatched seat may

become dangerous in the event of

a sudden stop or collision.

Using the manual lumbar support (if equipped)

The lumbar support control is

located on the inboard side of the

driver’s seat.

Turn the lumbar support control

clockwise to increase firmness.

Turn the lumbar support control

counterclockwise to increase

softness.

Adjusting the front power seat (if equipped)

The control is located on the outboard side of the seat cushion.

Press to raise or lower the front

portion of the seat cushion.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Seating and Safety Restraints

70

Page 139 of 280

3. Press and hold the brake pedal for two (2) seconds, then release.

4. Turn the ignition to OFF/LOCK (DO NOTremove the key.)

5. Cycle the ignition from OFF/LOCK to RUN three (3) times ending in

RUN.DO NOTstart the engine.

If reset mode has been entered successfully, the horn will sound once,

the TPMS indicator will flash and the message center will displayTRAIN

LF TIRE.

If after repeated attempts to enter reset mode, the horn does not sound,

the TPMS indicator does not flash and the message center does not

display TRAIN LF TIRE, seek service from your authorized dealer.

TPMS reset sequence

The TPMS system needs to be reset starting with the left front tire in

the following clockwise order:

1. Left front tire

2. Right front tire

3. Right rear tire

4. Left rear tire

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

139

Page 201 of 280

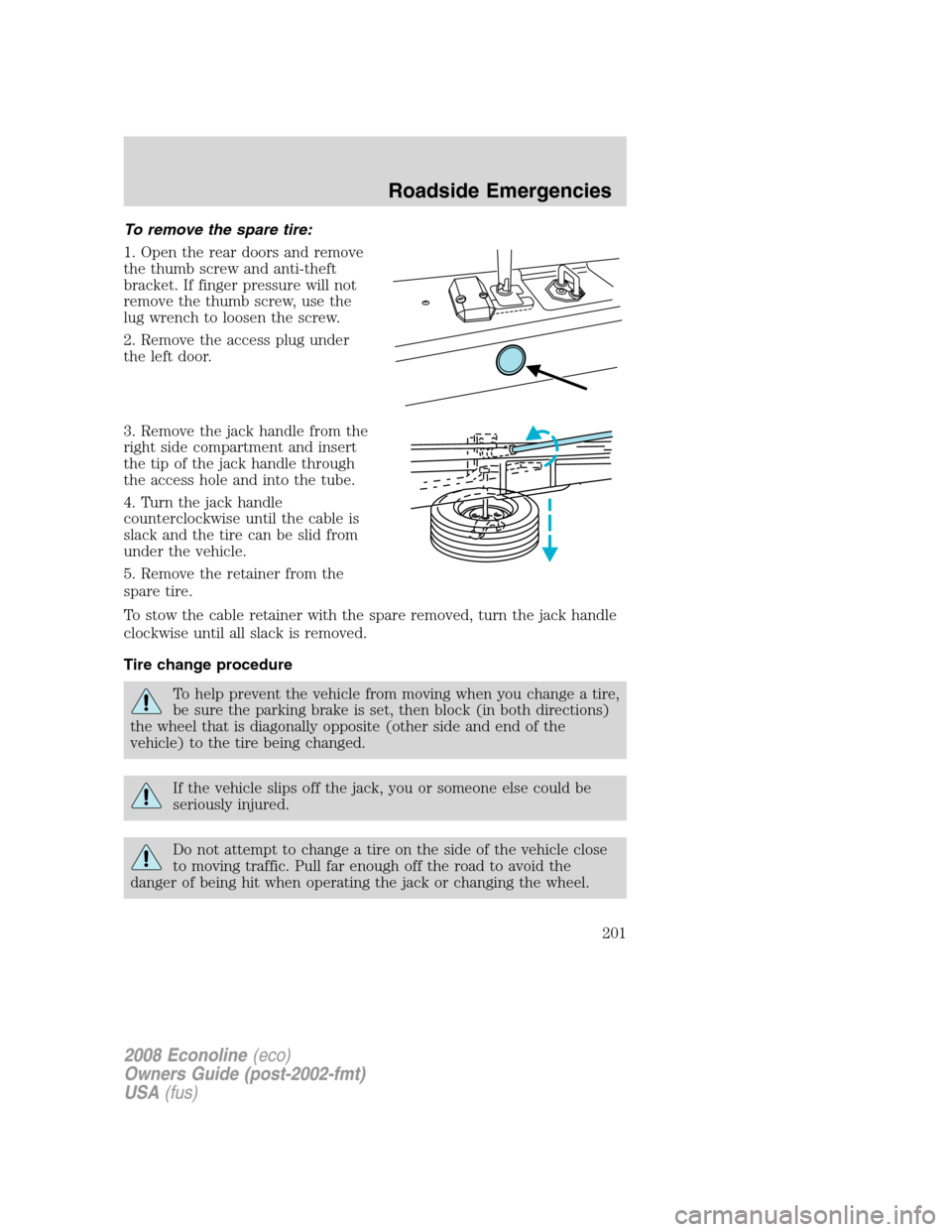

To remove the spare tire:

1. Open the rear doors and remove

the thumb screw and anti-theft

bracket. If finger pressure will not

remove the thumb screw, use the

lug wrench to loosen the screw.

2. Remove the access plug under

the left door.

3. Remove the jack handle from the

right side compartment and insert

the tip of the jack handle through

the access hole and into the tube.

4. Turn the jack handle

counterclockwise until the cable is

slack and the tire can be slid from

under the vehicle.

5. Remove the retainer from the

spare tire.

To stow the cable retainer with the spare removed, turn the jack handle

clockwise until all slack is removed.

Tire change procedure

To help prevent the vehicle from moving when you change a tire,

be sure the parking brake is set, then block (in both directions)

the wheel that is diagonally opposite (other side and end of the

vehicle) to the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

Do not attempt to change a tire on the side of the vehicle close

to moving traffic. Pull far enough off the road to avoid the

danger of being hit when operating the jack or changing the wheel.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

201

Page 202 of 280

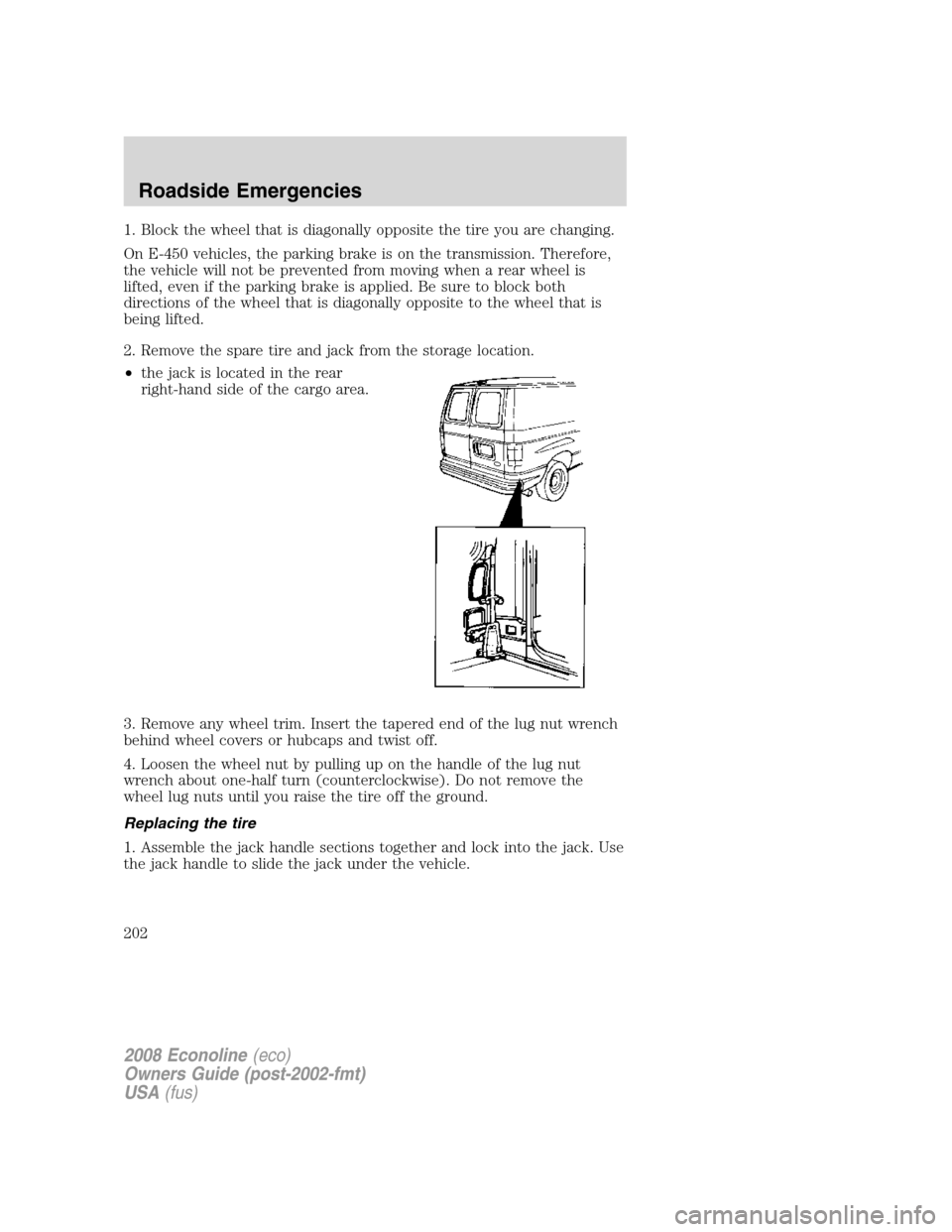

1. Block the wheel that is diagonally opposite the tire you are changing.

On E-450 vehicles, the parking brake is on the transmission. Therefore,

the vehicle will not be prevented from moving when a rear wheel is

lifted, even if the parking brake is applied. Be sure to block both

directions of the wheel that is diagonally opposite to the wheel that is

being lifted.

2. Remove the spare tire and jack from the storage location.

•the jack is located in the rear

right-hand side of the cargo area.

3. Remove any wheel trim. Insert the tapered end of the lug nut wrench

behind wheel covers or hubcaps and twist off.

4. Loosen the wheel nut by pulling up on the handle of the lug nut

wrench about one-half turn (counterclockwise). Do not remove the

wheel lug nuts until you raise the tire off the ground.

Replacing the tire

1. Assemble the jack handle sections together and lock into the jack. Use

the jack handle to slide the jack under the vehicle.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

202

Page 204 of 280

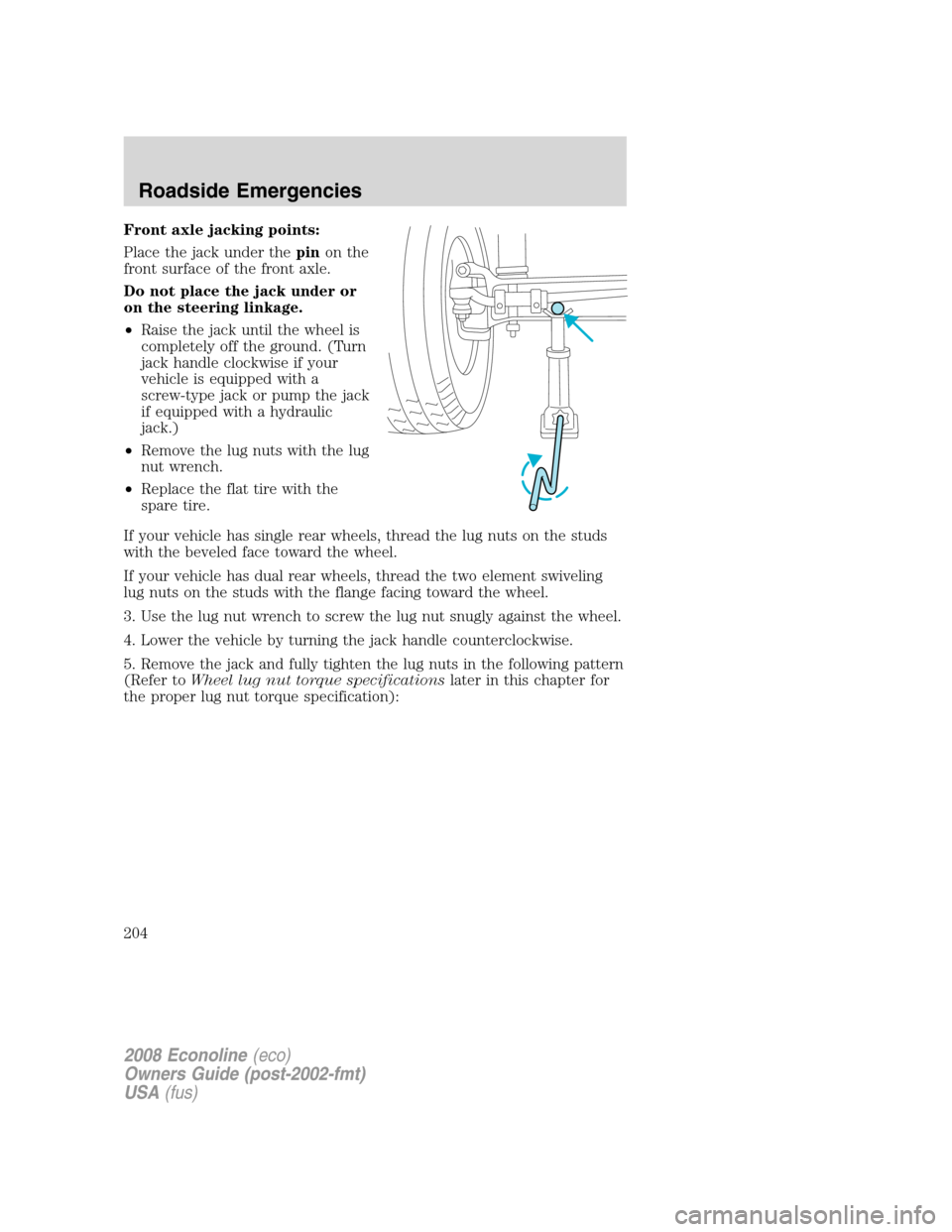

Front axle jacking points:

Place the jack under thepinon the

front surface of the front axle.

Do not place the jack under or

on the steering linkage.

•Raise the jack until the wheel is

completely off the ground. (Turn

jack handle clockwise if your

vehicle is equipped with a

screw-type jack or pump the jack

if equipped with a hydraulic

jack.)

•Remove the lug nuts with the lug

nut wrench.

•Replace the flat tire with the

spare tire.

If your vehicle has single rear wheels, thread the lug nuts on the studs

with the beveled face toward the wheel.

If your vehicle has dual rear wheels, thread the two element swiveling

lug nuts on the studs with the flange facing toward the wheel.

3. Use the lug nut wrench to screw the lug nut snugly against the wheel.

4. Lower the vehicle by turning the jack handle counterclockwise.

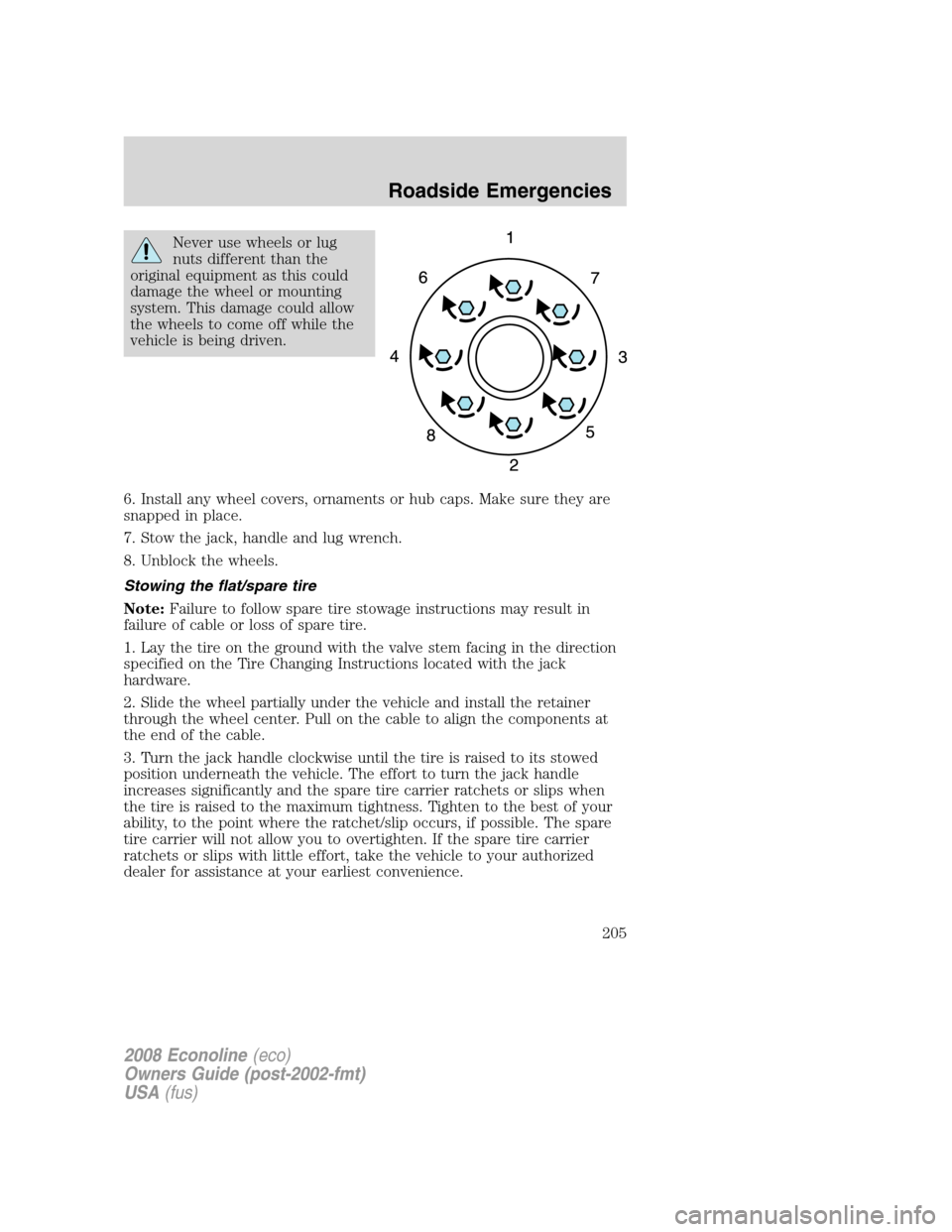

5. Remove the jack and fully tighten the lug nuts in the following pattern

(Refer toWheel lug nut torque specificationslater in this chapter for

the proper lug nut torque specification):

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

204

Page 205 of 280

Never use wheels or lug

nuts different than the

original equipment as this could

damage the wheel or mounting

system. This damage could allow

the wheels to come off while the

vehicle is being driven.

6. Install any wheel covers, ornaments or hub caps. Make sure they are

snapped in place.

7. Stow the jack, handle and lug wrench.

8. Unblock the wheels.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located with the jack

hardware.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your authorized

dealer for assistance at your earliest convenience.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

205

Page 234 of 280

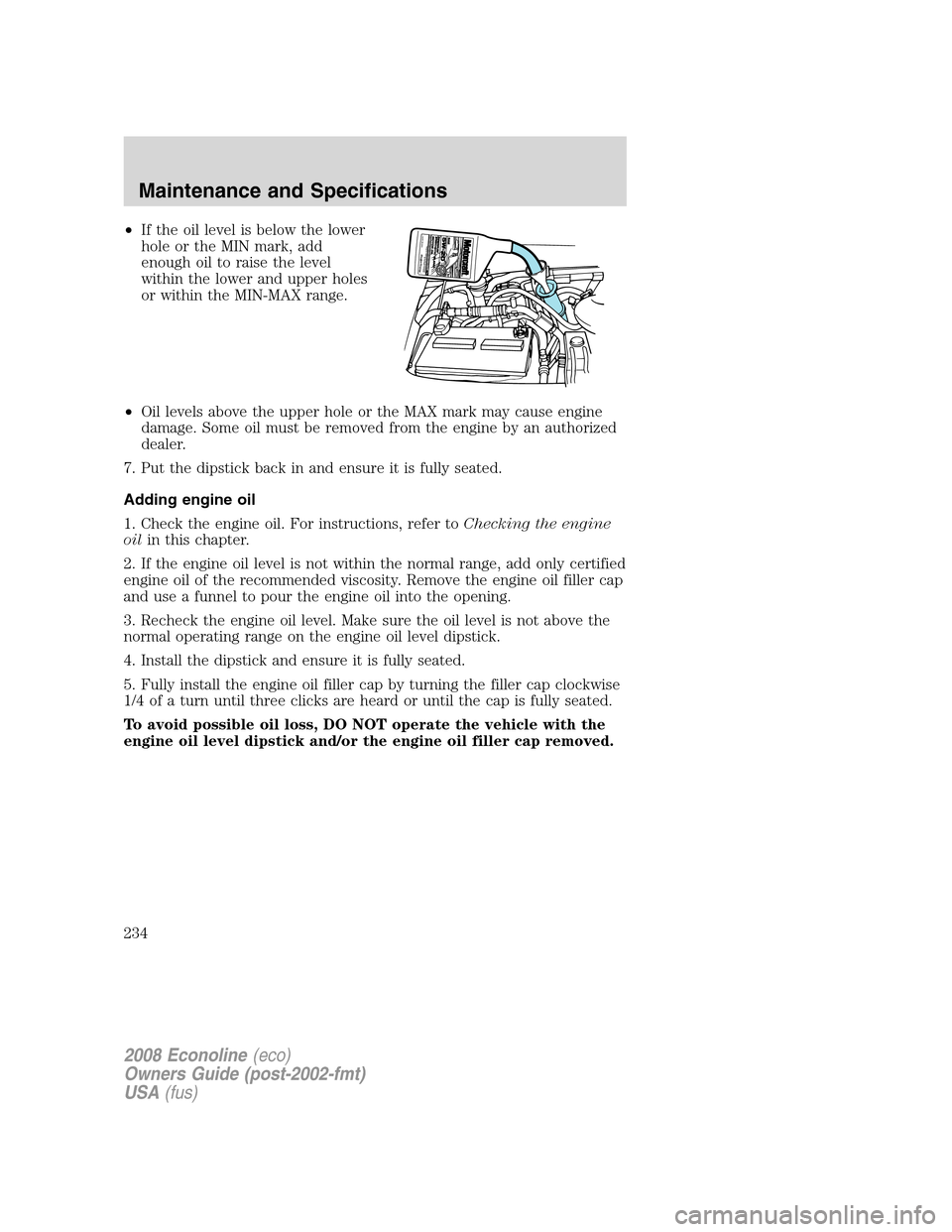

•If the oil level is below the lower

hole or the MIN mark, add

enough oil to raise the level

within the lower and upper holes

or within the MIN-MAX range.

•Oil levels above the upper hole or the MAX mark may cause engine

damage. Some oil must be removed from the engine by an authorized

dealer.

7. Put the dipstick back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

normal operating range on the engine oil level dipstick.

4. Install the dipstick and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until three clicks are heard or until the cap is fully seated.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level dipstick and/or the engine oil filler cap removed.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

234

Page 238 of 280

If the battery has been disconnected or a new battery has been installed,

the clock and radio settings must be reset once the battery is

reconnected.

•Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

intervals listed inscheduled maintenance information.The coolant

concentration should be maintained at 50/50 coolant and distilled water,

which equates to a freeze point of -34°F (-36°C). Coolant concentration

testing is possible with a hydrometer or antifreeze tester (such as the

Rotunda Battery and Antifreeze Tester, 014–R1060). The level of coolant

should be maintained at the “FULL COLD” level or within the “COLD

FILL RANGE” in the coolant reservoir. If the level falls below, add

coolant per the instructions in theAdding engine coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

60%, the engine parts could become damaged or not work properly.A

50–50 mixture of coolant and water provides the following:

•Freeze protection down to -34°F (-36°C).

•Boiling protection up to 265°F (129°C).

•Protection against rust and other forms of corrosion.

•Enables calibrated gauges to work properly.

LEAD

RETURN

RECYCLE

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

238