lock FORD E SERIES 2008 4.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: E SERIES, Model: FORD E SERIES 2008 4.GPages: 280, PDF Size: 2.56 MB

Page 205 of 280

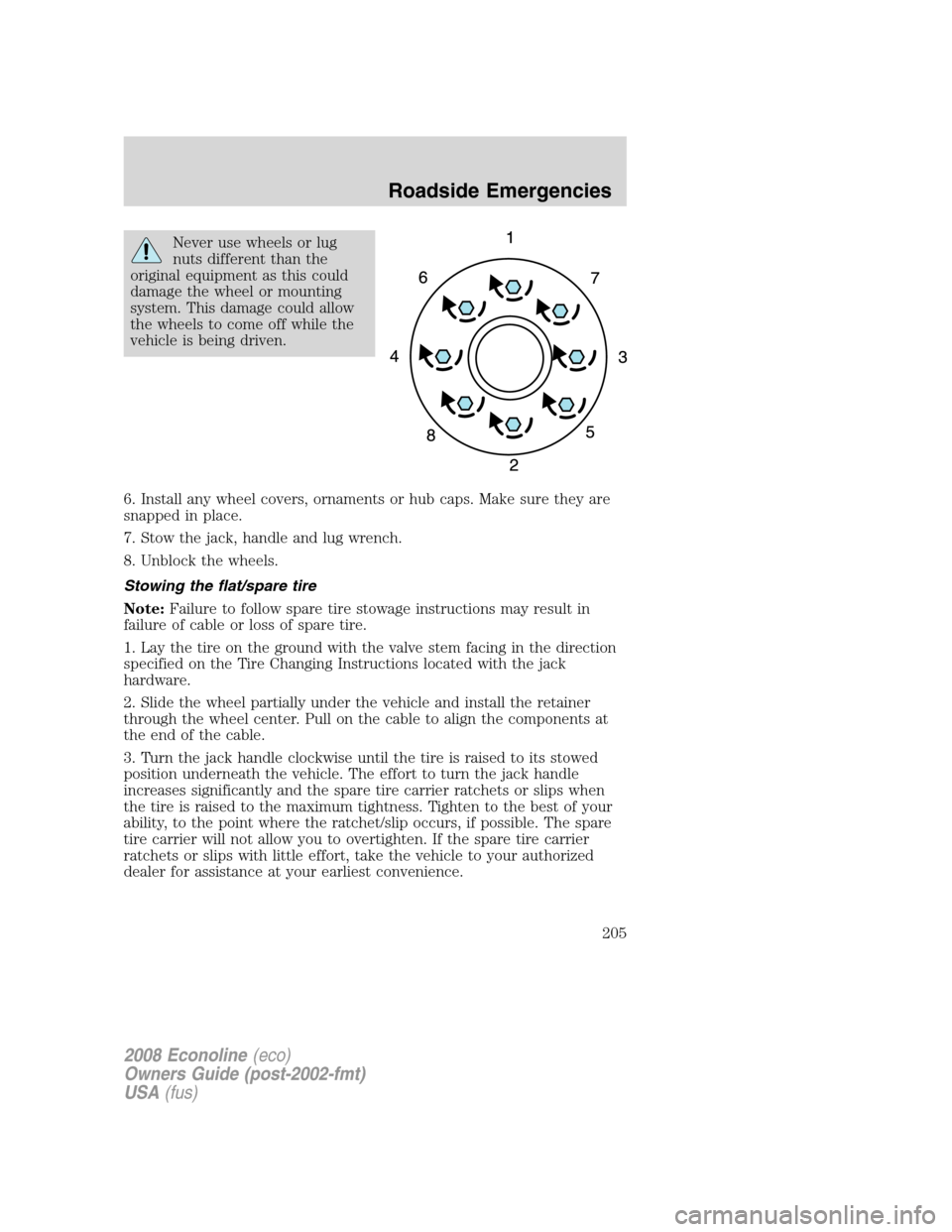

Never use wheels or lug

nuts different than the

original equipment as this could

damage the wheel or mounting

system. This damage could allow

the wheels to come off while the

vehicle is being driven.

6. Install any wheel covers, ornaments or hub caps. Make sure they are

snapped in place.

7. Stow the jack, handle and lug wrench.

8. Unblock the wheels.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located with the jack

hardware.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your authorized

dealer for assistance at your earliest convenience.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

205

Page 206 of 280

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, as per yourscheduled maintenance

information),or at any time that the spare tire is disturbed through

service of other components.

6. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.

WHEEL LUG NUT TORQUE SPECIFICATIONS

On vehicles equipped with single rear wheels, retighten the lug nuts to

the specified torque at 100 miles (160 km) after any wheel disturbance

(tire rotation, changing a flat tire, wheel removal, etc.).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts

to the specified torque at 100 miles (160 km), and again at 500 miles

(800 km) of new vehicle operation and after any wheel disturbance (tire

rotation, changing a flat tire, wheel removal, etc.).

Bolt size and wheel

lug nut typeWheel lug nut torque*

lb.ft. N•m

9/16 x 18 conical lug

nut150 200

9/16 x 18 two-piece

lug nut140 190

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

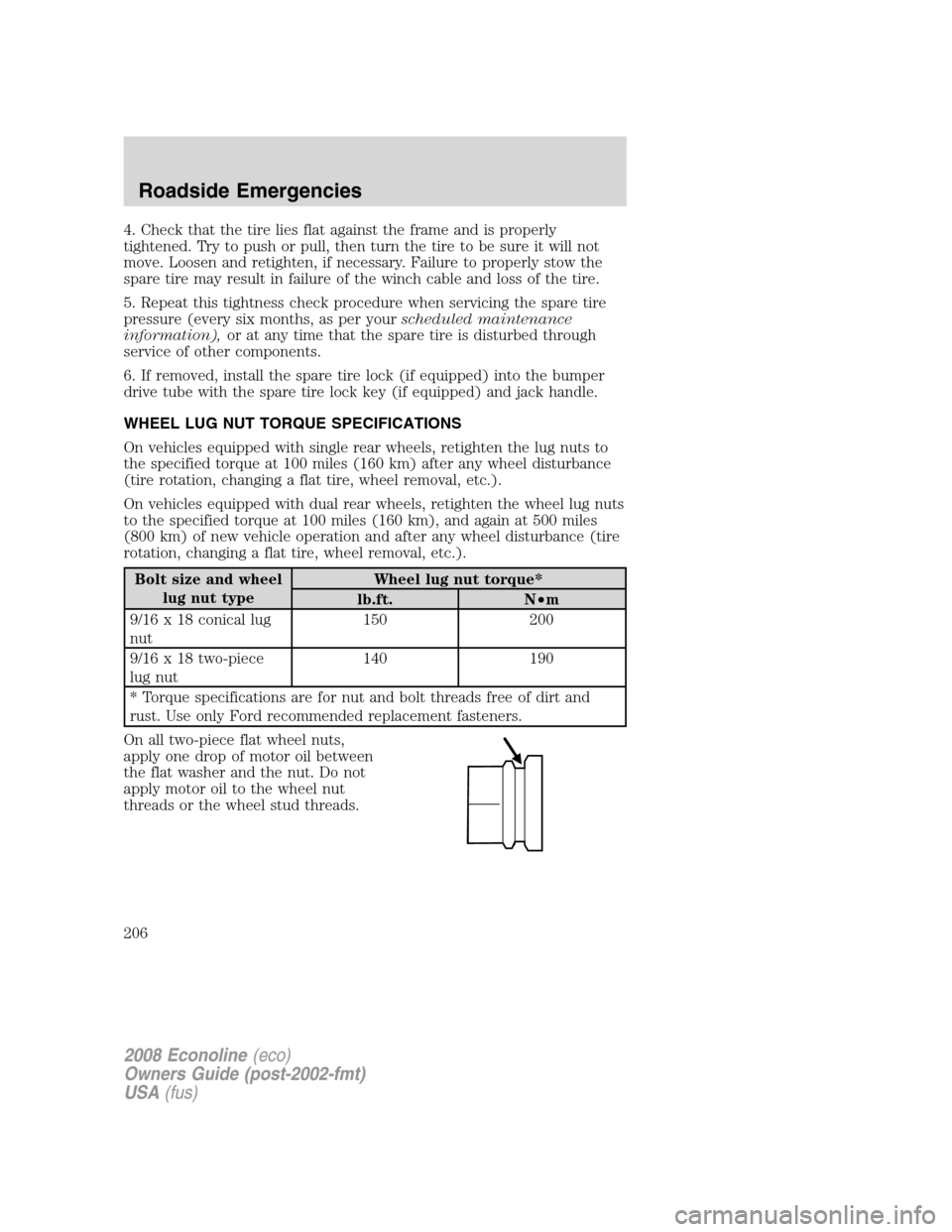

On all two-piece flat wheel nuts,

apply one drop of motor oil between

the flat washer and the nut. Do not

apply motor oil to the wheel nut

threads or the wheel stud threads.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

206

Page 223 of 280

•After polishing chrome bumpers, apply a coating of Motorcraft

Premium Liquid Wax (ZC-53-A), available from your authorized dealer,

or an equivalent quality product to help protect from environmental

effects.

WAXING

•Wash the vehicle first.

•Do not use waxes that contain abrasives; use Motorcraft Premium

Liquid Wax (ZC-53-A), which is available from your authorized dealer,

or an equivalent quality product.

•Do not allow paint sealant to come in contact with any non-body

(low-gloss black) colored trim, such as grained door handles, roof

racks, bumpers, side moldings, mirror housings or the windshield cowl

area. The paint sealant will “gray” or stain the parts over time.

•Do not allow paint sealant to come in contact with the sliding door

electrical contact switches. Paint sealant or other contaminants could

interfere with the proper operation of the power locks or radio

speakers. If necessary, clean the contacts with Motorcraft Bug and Tar

Remover (ZC-42) to remove any sealant. Do not use any abrasives on

the contact surfaces.

PAINT CHIPS

Your authorized dealer has touch-up paint to match your vehicle’s color.

Take your color code (printed on a sticker in the driver’s door jamb) to

your authorized dealer to ensure you get the correct color.

•Remove particles such as bird droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout before repairing paint chips.

•Always read the instructions before using the products.

ALUMINUM WHEELS AND WHEEL COVERS

Aluminum wheels and wheel covers are coated with a clearcoat paint

finish. In order to maintain their shine:

•Clean weekly with Motorcraft Wheel and Tire Cleaner (ZC-37-A),

which is available from your authorized dealer. Heavy dirt and brake

dust accumulation may require agitation with a sponge. Rinse

thoroughly with a strong stream of water.

•Never apply any cleaning chemical to hot or warm wheel rims or

covers.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Cleaning

223

Page 224 of 280

•Some automatic car washes may cause damage to the finish on your

wheel rims or covers. Chemical-strength cleaners, or cleaning

chemicals, in combination with brush agitation to remove brake dust

and dirt, could wear away the clearcoat finish over time.

•Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

•To remove tar and grease, use Motorcraft Bug and Tar Remover

(ZC-42), available from your authorized dealer.

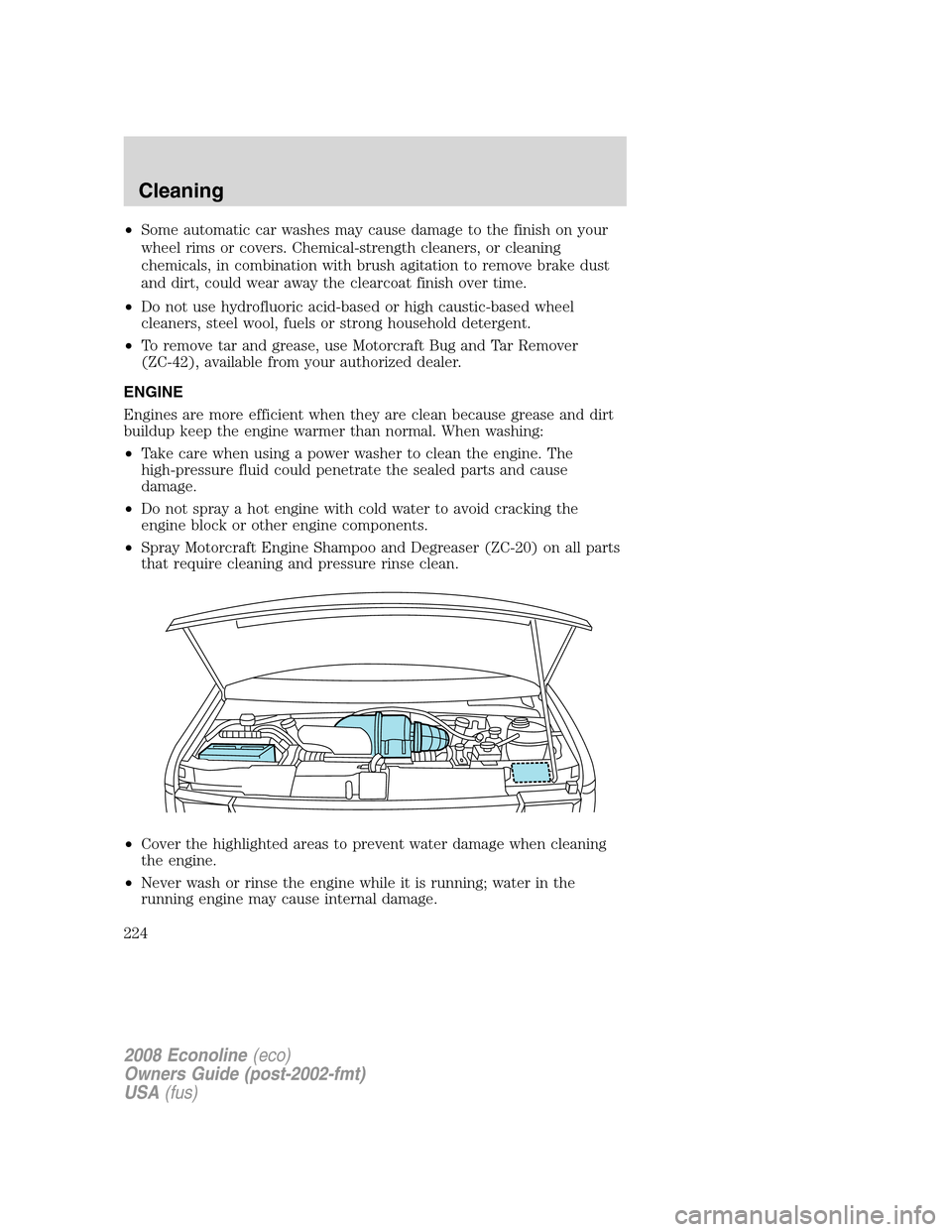

ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

•Cover the highlighted areas to prevent water damage when cleaning

the engine.

•Never wash or rinse the engine while it is running; water in the

running engine may cause internal damage.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Cleaning

224

Page 229 of 280

SERVICE RECOMMENDATIONS

To help you service your vehicle, we providescheduled maintenance

informationwhich makes tracking routine service easy.

If your vehicle requires professional service, your authorized dealer can

provide the necessary parts and service. Check yourWarranty Guideto

find out which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

•Do not work on a hot engine.

•Make sure that nothing gets caught in moving parts.

•Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

•Keep all open flames and other burning (cigarettes) material away

from the battery and all fuel related parts.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and shift to P (Park).

2. Block the wheels.

To reduce the risk of vehicle damage and/or personal burn

injuries, do not start your engine with the air cleaner removed

and do not remove it while the engine is running.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

229

Page 232 of 280

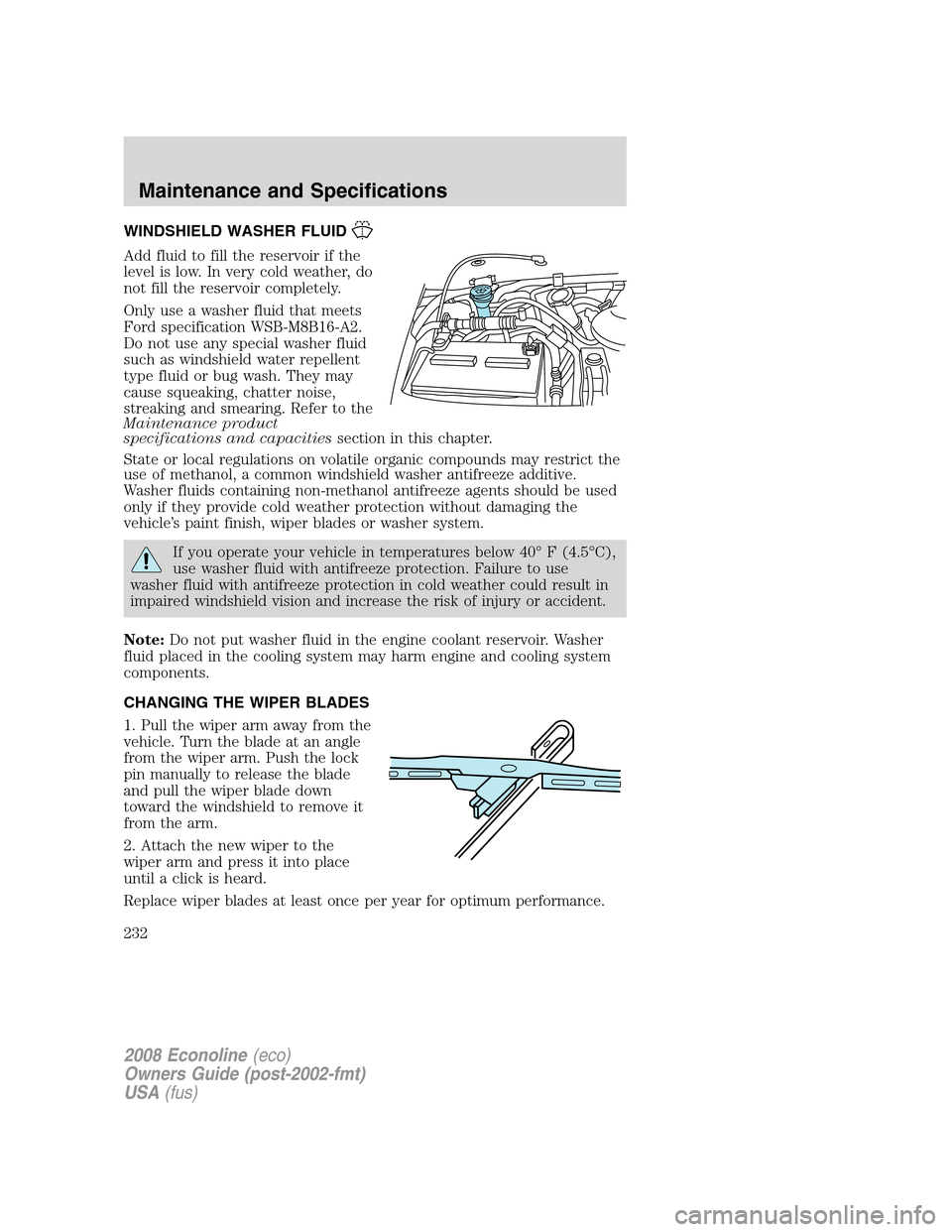

WINDSHIELD WASHER FLUID

Add fluid to fill the reservoir if the

level is low. In very cold weather, do

not fill the reservoir completely.

Only use a washer fluid that meets

Ford specification WSB-M8B16-A2.

Do not use any special washer fluid

such as windshield water repellent

type fluid or bug wash. They may

cause squeaking, chatter noise,

streaking and smearing. Refer to the

Maintenance product

specifications and capacitiessection in this chapter.

State or local regulations on volatile organic compounds may restrict the

use of methanol, a common windshield washer antifreeze additive.

Washer fluids containing non-methanol antifreeze agents should be used

only if they provide cold weather protection without damaging the

vehicle’s paint finish, wiper blades or washer system.

If you operate your vehicle in temperatures below 40° F (4.5°C),

use washer fluid with antifreeze protection. Failure to use

washer fluid with antifreeze protection in cold weather could result in

impaired windshield vision and increase the risk of injury or accident.

Note:Do not put washer fluid in the engine coolant reservoir. Washer

fluid placed in the cooling system may harm engine and cooling system

components.

CHANGING THE WIPER BLADES

1. Pull the wiper arm away from the

vehicle. Turn the blade at an angle

from the wiper arm. Push the lock

pin manually to release the blade

and pull the wiper blade down

toward the windshield to remove it

from the arm.

2. Attach the new wiper to the

wiper arm and press it into place

until a click is heard.

Replace wiper blades at least once per year for optimum performance.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

232

Page 234 of 280

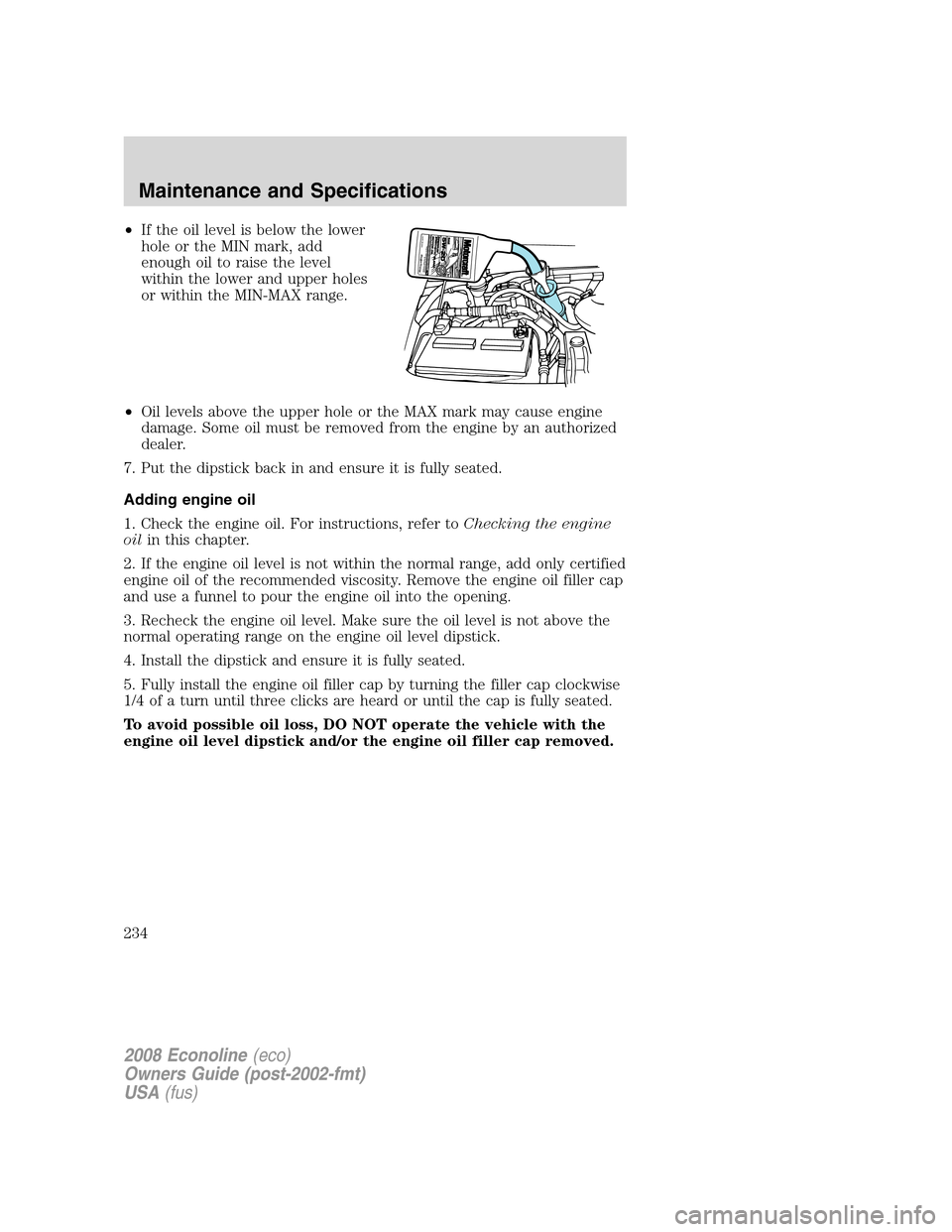

•If the oil level is below the lower

hole or the MIN mark, add

enough oil to raise the level

within the lower and upper holes

or within the MIN-MAX range.

•Oil levels above the upper hole or the MAX mark may cause engine

damage. Some oil must be removed from the engine by an authorized

dealer.

7. Put the dipstick back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

normal operating range on the engine oil level dipstick.

4. Install the dipstick and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until three clicks are heard or until the cap is fully seated.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level dipstick and/or the engine oil filler cap removed.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

234

Page 238 of 280

If the battery has been disconnected or a new battery has been installed,

the clock and radio settings must be reset once the battery is

reconnected.

•Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

intervals listed inscheduled maintenance information.The coolant

concentration should be maintained at 50/50 coolant and distilled water,

which equates to a freeze point of -34°F (-36°C). Coolant concentration

testing is possible with a hydrometer or antifreeze tester (such as the

Rotunda Battery and Antifreeze Tester, 014–R1060). The level of coolant

should be maintained at the “FULL COLD” level or within the “COLD

FILL RANGE” in the coolant reservoir. If the level falls below, add

coolant per the instructions in theAdding engine coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

60%, the engine parts could become damaged or not work properly.A

50–50 mixture of coolant and water provides the following:

•Freeze protection down to -34°F (-36°C).

•Boiling protection up to 265°F (129°C).

•Protection against rust and other forms of corrosion.

•Enables calibrated gauges to work properly.

LEAD

RETURN

RECYCLE

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

238

Page 241 of 280

coolant degas system with a pressurized cap, or if it is necessary to

remove the coolant pressure relief cap on the radiator of a vehicle with

an overflow system, follow these steps to add engine coolant.

To reduce the risk of personal injury, make sure the engine is

cool before unscrewing the coolant pressure relief cap. The

cooling system is under pressure; steam and hot liquid can come out

forcefully when the cap is loosened slightly.

Add the proper mixture of coolant and water to the cooling system by

following these steps:

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (a translucent plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

5. Fill the coolant reservoir slowly with the proper coolant mixture, to

within the “COLD FILL RANGE” or the “FULL COLD” level on the

reservoir. If you removed the radiator cap in an overflow system, fill the

radiator until the coolant is visible and radiator is almost full.

6. Replace the cap. Turn until tightly installed. Cap must be tightly

installed to prevent coolant loss.

After any coolant has been added, check the coolant concentration (refer

toChecking engine coolant). If the concentration is not 50/50

(protection to –34°F/–36°C), drain some coolant and adjust the

concentration. It may take several drains and additions to obtain a 50/50

coolant concentration.

Whenever coolant has been added, the coolant level in the coolant

reservoir should be checked the next few times you drive the vehicle. If

necessary, add enough 50/50 concentration of engine coolant and

distilled water to bring the liquid level to the proper level.

If you have to add more than 1.0 quart (1.0 liter) of engine coolant per

month, have your authorized dealer check the engine cooling system.

Your cooling system may have a leak. Operating an engine with a low

level of coolant can result in engine overheating and possible engine

damage.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

241

Page 247 of 280

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a 1/4 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/4 of a turn until it

stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/4 of a turn until it clicks at least once.

If the check fuel cap light

or a “check fuel cap” message comes on,

the fuel filler cap may not be properly installed. The light or message can

come on after several driving events after you’ve refueled your vehicle.

At the next opportunity, safely pull off of the road, remove the fuel filler

cap, align the cap properly and reinstall it. The check fuel cap

light

or “check fuel cap” message may not reset immediately; it may

take several driving cycles for the check fuel cap light

or “check fuel

cap” message to turn off. A driving cycle consists of an engine start-up

(after four or more hours with the engine off) followed by city and

highway driving.

Continuing to drive with the check fuel cap light

or “check fuel cap”

message on may cause the

light to turn on as well.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If the fuel filler cap is

venting vapor or if you hear a hissing sound, wait until it stops

before completely removing the fuel filler cap. Otherwise, fuel may

spray out and injure you or others.

2008 Econoline(eco)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

247