brake light FORD E SERIES 2016 4.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: E SERIES, Model: FORD E SERIES 2016 4.GPages: 319, PDF Size: 6.18 MB

Page 107 of 319

•

Service your vehicle more frequently if

you tow a trailer. See your scheduled

maintenance information.

• If you use a rental trailer, follow the

instructions the rental agency gives

you.

See Load limits in the Load Carrying

chapter for load specification terms found

on the tire label and Safety Compliance

label and instructions on calculating your

vehicle's load.

Remember to account for the trailer

tongue weight as part of your vehicle load

when calculating the total vehicle weight.

Trailer Towing Connector When attaching the trailer wiring connector

to your vehicle, only use a proper fitting

connector that works with the vehicle and

trailer functions. Some seven-position

connectors may have the SAE J2863 logo,

which confirms that it is the proper wiring

connector and works correctly with your

vehicle.

Function

Color

Left turn signal and stop lamp

Yellow

Ground (-)

White

Electric brakes

Blue Function

Color

Right turn signal and stop

lamp

Green

Battery (+)

Orange

Running lights

Brown

Reverse lights

Grey

Hitches

Do not use a hitch that either clamps onto

the bumper or attaches to the axle. You

must distribute the load in your trailer so

that 10-15% of the total weight of the

trailer is on the tongue.

Weight-distributing Hitches WARNING

Do not adjust a weight-distributing

hitch to any position where the rear

bumper of the vehicle is higher than

it was before attaching the trailer. Doing

so will defeat the function of the

weight-distributing hitch, which may cause

unpredictable handling, and could result

in serious personal injury. When hooking-up a trailer using a

weight-distributing hitch, always use the

following procedure:

1. Park the loaded vehicle, without the

trailer, on a level surface.

2. Measure the height to the top of your vehicle's front wheel opening on the

fender. This is H1.

3. Attach the loaded trailer to your vehicle

without the weight-distributing bars

connected.

4. Measure the height to the top of your vehicle's front wheel opening on the

fender a second time. This is H2.

104

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing TowingE163167

Page 108 of 319

5. Install and adjust the tension in the

weight-distributing bars so that the

height of your vehicle's front wheel

opening on the fender is approximately

half the way down from H2, toward H1.

6. Check that the trailer is level or slightly

nose down toward your vehicle. If not,

adjust the ball height accordingly and

repeat Steps 2-6.

When the trailer is level or slightly nose

down toward the vehicle:

• Lock the bar tension adjuster in place.

• Check that the trailer tongue securely

attaches and locks onto the hitch.

• Install safety chains, lighting, and trailer

brake controls as required by law or the

trailer manufacturer.

Safety Chains

Note: Do not attach safety chains to the

bumper.

Always connect the safety chains to the

frame or hook retainers of your vehicle

hitch.

To connect the safety chains, cross the

chains under the trailer tongue and allow

enough slack for turning tight corners. Do

not allow the chains to drag on the ground.

Trailer Brakes WARNING

Do not connect a trailer's hydraulic

brake system directly to your

vehicle's brake system. Your vehicle

may not have enough braking power and

your chances of having a collision greatly

increase. Electric brakes and manual, automatic or

surge-type trailer brakes are safe if you

install them properly and adjust them to

the manufacturer's specifications. The

trailer brakes must meet local and federal

regulations.

The rating for the tow vehicle's braking

system operation is at the gross vehicle

weight rating, not the gross combined

weight rating.

Separate functioning brake systems

are required for safe control of towed

vehicles and trailers weighing more

than 1500 pounds (680 kilograms)

when loaded.

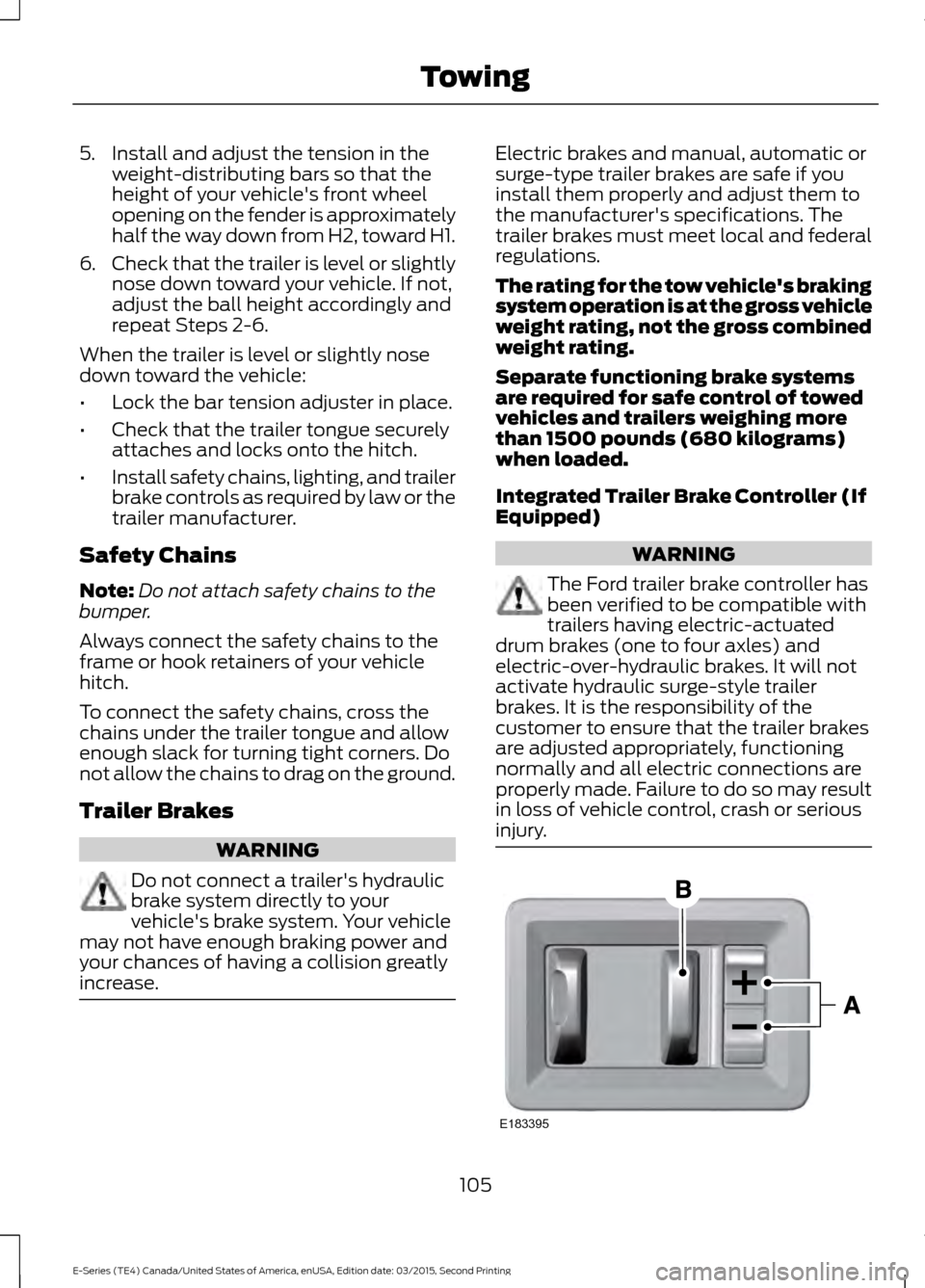

Integrated Trailer Brake Controller (If

Equipped)

WARNING

The Ford trailer brake controller has

been verified to be compatible with

trailers having electric-actuated

drum brakes (one to four axles) and

electric-over-hydraulic brakes. It will not

activate hydraulic surge-style trailer

brakes. It is the responsibility of the

customer to ensure that the trailer brakes

are adjusted appropriately, functioning

normally and all electric connections are

properly made. Failure to do so may result

in loss of vehicle control, crash or serious

injury. 105

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing TowingE183395

Page 111 of 319

•

Avoid towing in adverse weather

conditions. The trailer brake controller

does not provide anti-lock control of

the trailer wheels. Trailer wheels can

lock up on slippery surfaces, resulting

in reduced stability of trailer and tow

vehicle.

• The trailer brake controller is equipped

with a feature that reduces output at

vehicle speeds below 11 mph (18 km/h)

so trailer and vehicle braking is not jerky

or harsh. This feature is only available

when applying the brakes using your

vehicle's brake pedal, not the

controller.

• The controller interacts with the brake

control system and powertrain control

system of your vehicle to provide the

best performance on different road

conditions.

• Your vehicle's brake system and the

trailer brake system work

independently of each other. Changing

the gain setting on the controller does

not affect the operation of your

vehicle's brakes whether you attach a

trailer or not.

• When you switch the engine off, the

controller output is disabled and the

display and module shut down. The

controller module and display turn on

when you switch the ignition on.

• The trailer brake controller is only a

factory-installed or dealer-installed

item. Ford is not responsible for

warranty or performance of the

controller due to misuse or customer

installation. Trailer Lamps WARNING

Never connect any trailer lamp wiring

to the vehicle's tail lamp wiring; this

may damage the electrical system

resulting in fire. Contact your authorized

dealer as soon as possible for assistance

in proper trailer tow wiring installation.

Additional electrical equipment may be

required. Trailer lamps are required on most towed

vehicles. Make sure all running lights, brake

lights, direction indicators and hazard lights

are working.

Before Towing a Trailer

Practice turning, stopping and backing up

to get the feel of your vehicle-trailer

combination before starting on a trip.

When turning, make wider turns so the

trailer wheels clear curbs and other

obstacles.

When Towing a Trailer

•

Do not drive faster than 70 mph

(113 km/h) during the first 500 mi

(800 km).

• Do not make full-throttle starts.

• Check your hitch, electrical connections

and trailer wheel lug nuts thoroughly

after you have traveled 50 mi (80 km).

• When stopped in congested or heavy

traffic during hot weather, place the

gearshift in position P to aid engine and

transmission cooling and to help A/C

performance.

• Switch off the speed control with

heavy loads or in hilly terrain. The

speed control may turn off

automatically when you are towing on

long, steep grades.

108

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Towing

Page 116 of 319

•

Avoid using speed control in hilly

terrain.

• Do not rest your foot on the brake

pedal while driving.

• Avoid carrying unnecessary weight.

• Avoid adding particular accessories to

your vehicle (e.g. bug deflectors,

rollbars/light bars, running boards, ski

racks).

• Avoid driving with the wheels out of

alignment.

DRIVING THROUGH WATER WARNING

Do not drive through flowing or deep

water as you may lose control of your

vehicle.

Note:

Driving through standing water can

cause vehicle damage.

Note: Engine damage can occur if water

enters the air filter.

Before driving through standing water,

check the depth. Never drive through water

that is higher than the bottom of the wheel

hubs. When driving through standing water, drive

very slowly and do not stop your vehicle.

Your brake performance and traction may

be limited. After driving through water and

as soon as it is safe to do so:

•

Lightly press the brake pedal to dry the

brakes and to check that they work.

• Check that the horn works.

• Check that the exterior lights work.

• Turn the steering wheel to check that

the steering power assist works.

FLOOR MATS WARNINGS

Always use floor mats that are

designed to fit the foot well of your

vehicle. Only use floor mats that

leave the pedal area unobstructed. Only

use floor mats that are firmly secured to

retention posts so that they cannot slip out

of position and interfere with the pedals

or impair safe operation of your vehicle in

other ways. Pedals that cannot move freely can

cause loss of vehicle control and

increase the risk of serious personal

injury. Always make sure that the floor

mats are properly attached to the

retention posts in the carpet that are

supplied with your vehicle. Floor mats must

be properly secured to both retention posts

to make sure mats do not shift out of

position. Never place floor mats or any other

covering in the vehicle foot well that

cannot be properly secured to

prevent them from moving and interfering

with the pedals or the ability to control the

vehicle.

113

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Driving HintsE176913

Page 136 of 319

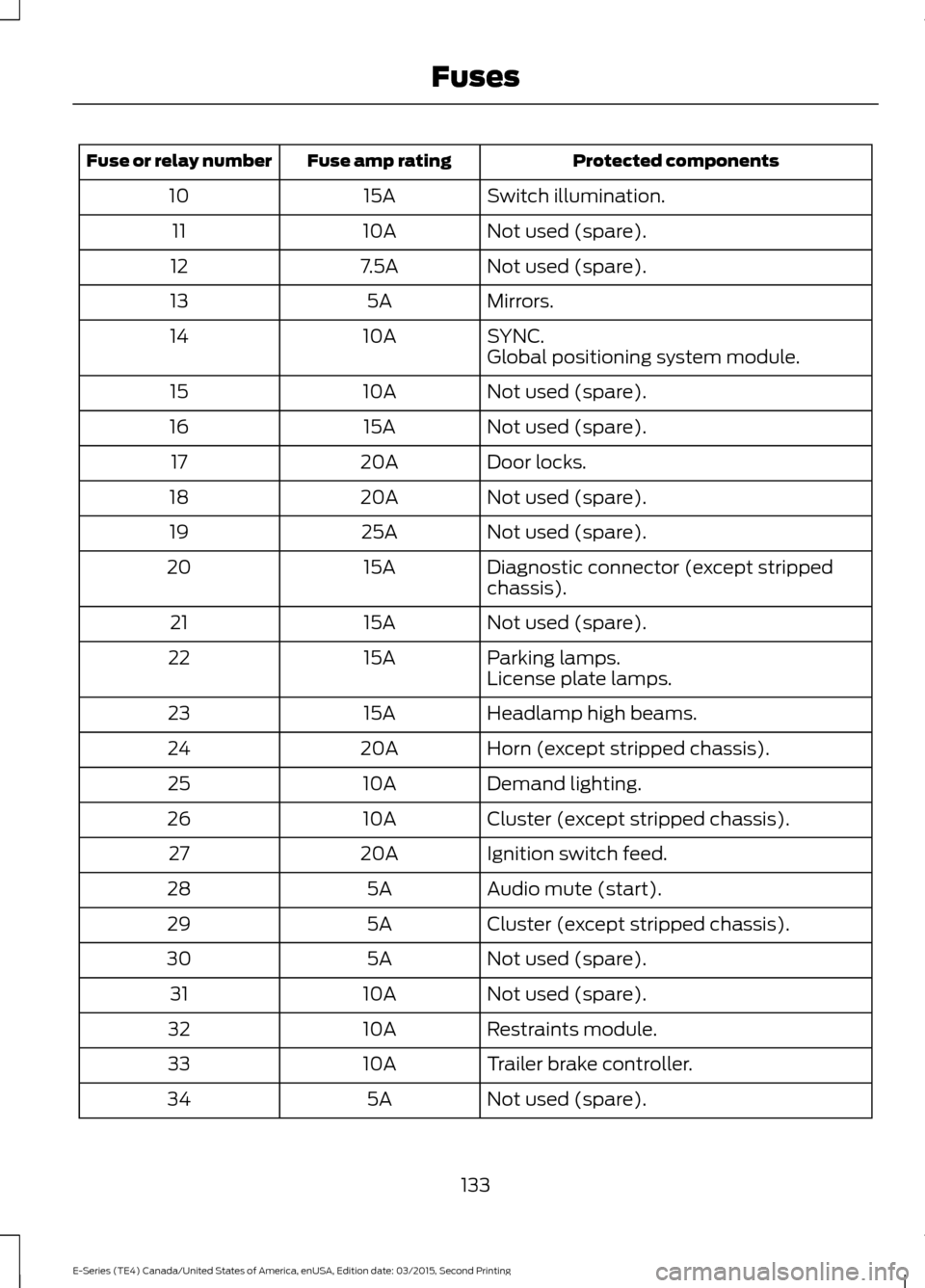

Protected components

Fuse amp rating

Fuse or relay number

Switch illumination.

15A

10

Not used (spare).

10A

11

Not used (spare).

7.5A

12

Mirrors.

5A

13

SYNC.

10A

14

Global positioning system module.

Not used (spare).

10A

15

Not used (spare).

15A

16

Door locks.

20A

17

Not used (spare).

20A

18

Not used (spare).

25A

19

Diagnostic connector (except stripped

chassis).

15A

20

Not used (spare).

15A

21

Parking lamps.

15A

22

License plate lamps.

Headlamp high beams.

15A

23

Horn (except stripped chassis).

20A

24

Demand lighting.

10A

25

Cluster (except stripped chassis).

10A

26

Ignition switch feed.

20A

27

Audio mute (start).

5A

28

Cluster (except stripped chassis).

5A

29

Not used (spare).

5A

30

Not used (spare).

10A

31

Restraints module.

10A

32

Trailer brake controller.

10A

33

Not used (spare).

5A

34

133

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Fuses

Page 142 of 319

To reset the oil life monitoring system do

the following:

1.

Switch the ignition on. Do not start the

engine.

2. Fully press the accelerator and brake pedals at the same time.

3. Keep the accelerator and brake pedals

fully pressed.

4. After three seconds, a message displays confirming the reset procedure

is in progress.

5. After 25 seconds, a message displays confirming the reset procedure is

complete.

6. Release the accelerator and brake pedals.

7. Switch the ignition off.

ENGINE COOLANT CHECK WARNINGS

Do not add engine coolant when the

engine is hot. Steam and scalding

liquids released from a hot cooling

system can burn you badly. Also, spilling

coolant on hot engine parts can burn you. Do not put engine coolant in the

windshield washer fluid container. If

sprayed on the windshield, engine

coolant could make it difficult to see

through the windshield. To reduce the risk of personal injury,

make sure the engine is cool before

unscrewing the coolant pressure

relief cap. The cooling system is under

pressure. Steam and hot liquid can come

out forcefully when you loosen the cap

slightly. Do not add coolant further than the

MAX mark. Checking the Engine Coolant

When the engine is cold, check the

concentration and level of the engine

coolant at the intervals listed in the

scheduled maintenance information. See

Scheduled Maintenance (page 268).

Note: Make sure that the coolant level is

between the MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the MAX mark.

Note: If the level is at the MIN mark, below

the MIN mark, or empty, add coolant

immediately. See

Adding Engine Coolant

in this chapter.

Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C).

Note: For best results, coolant

concentration should be tested with a

refractometer such as Robinair® Coolant

and Battery Refractometer 75240. We do

not recommend the use of hydrometers or

coolant test strips for measuring coolant

concentrations.

Note: Automotive fluids are not

interchangeable. Do not use engine coolant,

antifreeze or windshield washer fluid outside

of its specified function and vehicle location.

Adding Engine Coolant

Note: Do not use stop leak pellets, cooling

system sealants or additives as they can

cause damage to the engine cooling or

heating systems. Your warranty may not

cover these damages.

139

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Maintenance

Page 149 of 319

WARNINGS

Batteries normally produce explosive

gases which can cause personal

injury. Therefore, do not allow

flames, sparks or lighted substances to

come near the battery. When working near

the battery, always shield your face and

protect your eyes. Always provide proper

ventilation. When lifting a plastic-cased battery,

excessive pressure on the end walls

could cause acid to flow through the

vent caps, resulting in personal injury

and/or damage to the vehicle or battery.

Lift the battery with a battery carrier or

with your hands on opposite corners. Keep batteries out of reach of

children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or

clothing. Shield your eyes when working

near the battery to protect against possible

splashing of acid solution. In case of acid

contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Battery posts, terminals and related

accessories contain lead and lead

compounds. Wash hands after

handling. Note:

If your vehicle battery has a cover,

make sure it is reinstalled after the battery

has been cleaned or replaced.

Note: Electrical or electronic accessories

or components added to the vehicle by the

dealer or the owner may adversely affect

battery performance and durability.

Your vehicle is fitted with a Motorcraft®

maintenance-free battery which normally

does not require additional water during

its life of service. For longer, trouble-free operation, keep the

top of the battery clean and dry. Also,

make certain the battery cables are always

tightly fastened to the battery terminals.

If you see any corrosion on the battery or

terminals, remove the cables from the

terminals and clean with a wire brush. You

can neutralize the acid with a solution of

baking soda and water.

Always dispose of automotive batteries in

a responsible manner. Follow your local

authorized standards for disposal. Call your

local authorized recycling center to find

out more about recycling automotive

batteries.

Reconnecting the Battery

Because your vehicle

’s engine is

electronically controlled by a computer,

some control conditions are maintained

by power from the battery. When the

battery is disconnected or a new battery

is installed, the engine must relearn its idle

and fuel trim strategy for optimum

driveability and performance. Flexible fuel

vehicles (FFV) must also relearn the

ethanol content of the fuel for optimum

driveability and performance.

To begin this process.

1. Switch off all accessories and start the

engine.

2. Run the engine until it reaches normal operating temperature.

3. Allow the engine to idle for at least one

minute.

4. Turn the A/C on and allow the engine to idle for at least one minute.

5. Fully press the foot brake. Release the parking brake. Shift the gearshift lever

to Drive (D) and allow the engine to

idle for at least one minute.

6. Drive the vehicle for approximately 10 mi (16 km) to complete the

relearning process.

146

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Maintenance

Page 156 of 319

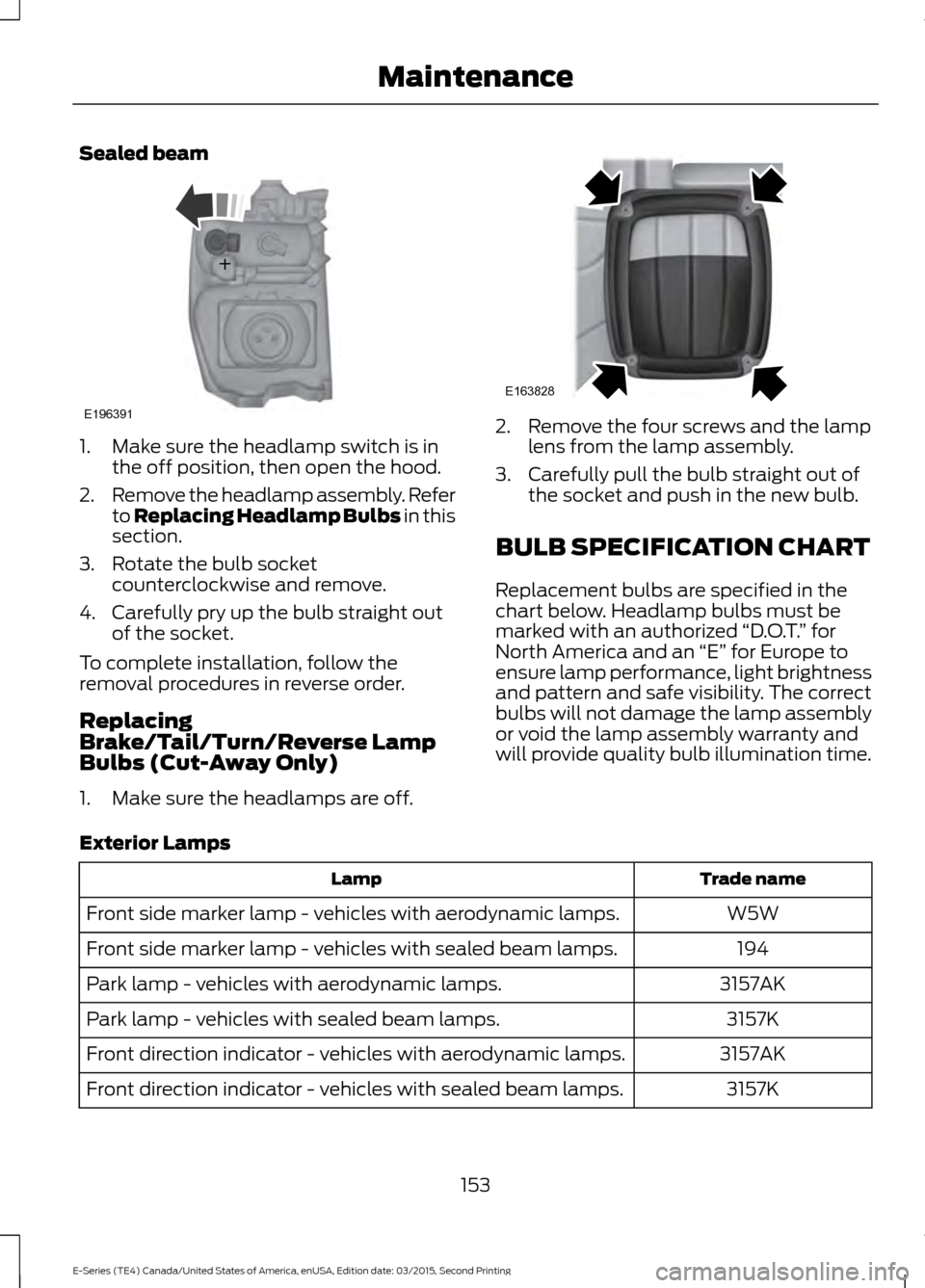

Sealed beam

1. Make sure the headlamp switch is in

the off position, then open the hood.

2. Remove the headlamp assembly. Refer

to Replacing Headlamp Bulbs in this

section.

3. Rotate the bulb socket counterclockwise and remove.

4. Carefully pry up the bulb straight out of the socket.

To complete installation, follow the

removal procedures in reverse order.

Replacing

Brake/Tail/Turn/Reverse Lamp

Bulbs (Cut-Away Only)

1. Make sure the headlamps are off. 2. Remove the four screws and the lamp

lens from the lamp assembly.

3. Carefully pull the bulb straight out of the socket and push in the new bulb.

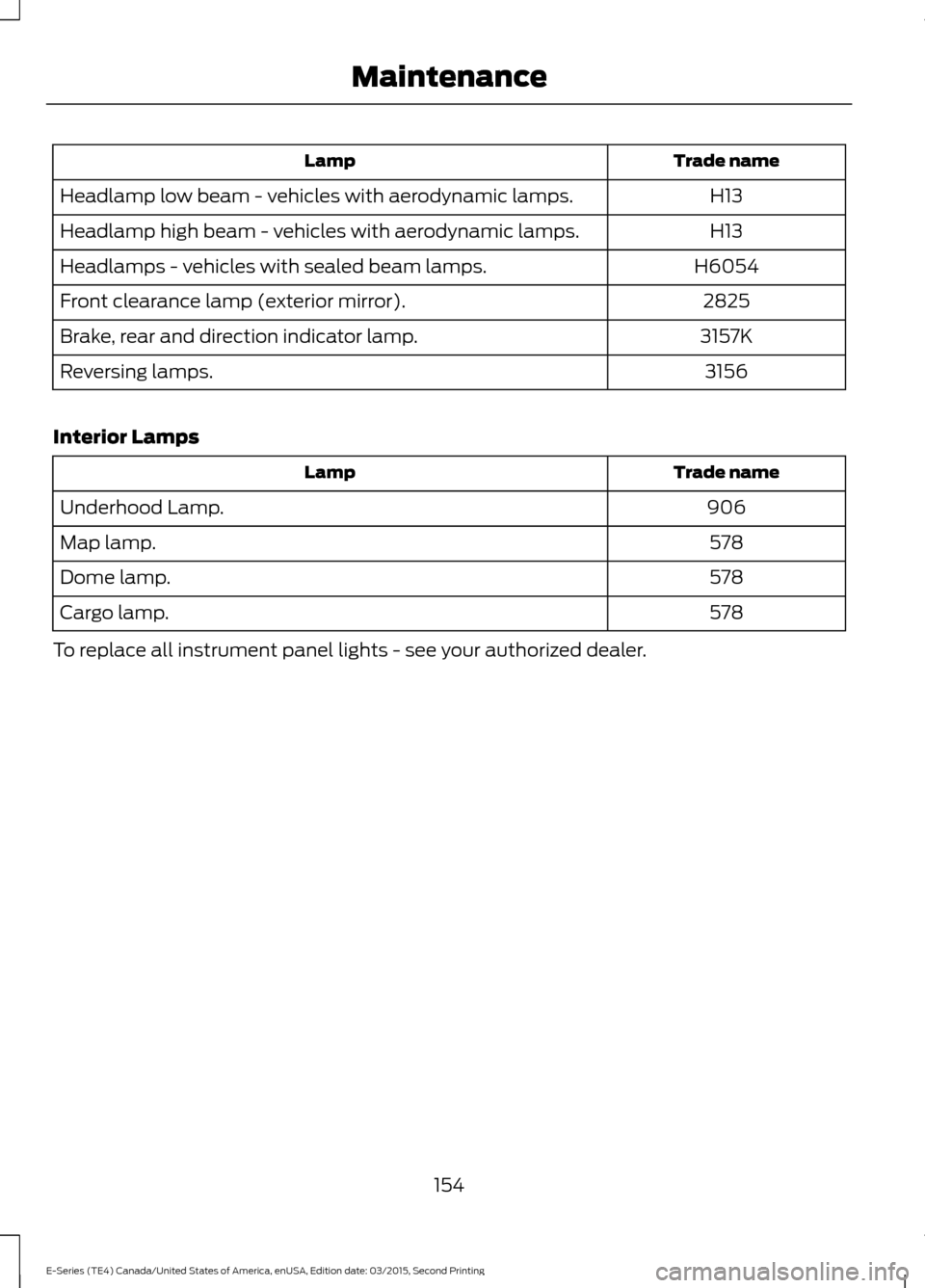

BULB SPECIFICATION CHART

Replacement bulbs are specified in the

chart below. Headlamp bulbs must be

marked with an authorized “D.O.T.” for

North America and an “E” for Europe to

ensure lamp performance, light brightness

and pattern and safe visibility. The correct

bulbs will not damage the lamp assembly

or void the lamp assembly warranty and

will provide quality bulb illumination time.

Exterior Lamps Trade name

Lamp

W5W

Front side marker lamp - vehicles with aerodynamic lamps.

194

Front side marker lamp - vehicles with sealed beam lamps.

3157AK

Park lamp - vehicles with aerodynamic lamps.

3157K

Park lamp - vehicles with sealed beam lamps.

3157AK

Front direction indicator - vehicles with aerodynamic lamps.

3157K

Front direction indicator - vehicles with sealed beam lamps.

153

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing MaintenanceE196391 E163828

Page 157 of 319

Trade name

Lamp

H13

Headlamp low beam - vehicles with aerodynamic lamps.

H13

Headlamp high beam - vehicles with aerodynamic lamps.

H6054

Headlamps - vehicles with sealed beam lamps.

2825

Front clearance lamp (exterior mirror).

3157K

Brake, rear and direction indicator lamp.

3156

Reversing lamps.

Interior Lamps Trade name

Lamp

906

Underhood Lamp.

578

Map lamp.

578

Dome lamp.

578

Cargo lamp.

To replace all instrument panel lights - see your authorized dealer.

154

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Maintenance

Page 164 of 319

Note:

Industrial-strength or heavy-duty

cleaners in combination with brush agitation

to remove brake dust and dirt, could wear

away the clear coat finish over a period time.

Note: Do not use hydrofluoric acid-based

or high caustic-based wheel cleaners, steel

wool, fuels or strong household detergents.

Note: If you intend parking your vehicle for

an extended period after cleaning the

wheels with a wheel cleaner, drive your

vehicle for a few minutes before doing so.

This will reduce the risk of increased

corrosion of the brake discs.

Alloy wheels and wheel covers are coated

with a clear coat paint finish. To maintain

their condition we recommend that you:

• Clean the wheels weekly using

Motorcraft Wheel and Tire Cleaner.

Apply using manufacturer's

instructions.

• Use a sponge to remove heavy

deposits of dirt and brake dust

accumulation.

• Rinse thoroughly with a strong stream

of water when you have completed the

cleaning process.

• To remove tar and grease, use

Motorcraft Bug and Tar Remover.

VEHICLE STORAGE

If you plan on storing your vehicle for 30

days or more, read the following

maintenance recommendations to make

sure your vehicle stays in good operating

condition.

We engineer and test all motor vehicles

and their components for reliable, regular

driving. Under various conditions,

long-term storage may lead to degraded

engine performance or failure unless you

use specific precautions to preserve engine

components. General

•

Store all vehicles in a dry, ventilated

place.

• Protect from sunlight, if possible.

• If vehicles are stored outside, they

require regular maintenance to protect

against rust and damage.

Body

• Wash your vehicle thoroughly to

remove dirt, grease, oil, tar or mud from

exterior surfaces, rear-wheel housing

and the underside of front fenders.

• Periodically wash your vehicle if it is

stored in exposed locations.

• Touch-up exposed or primed metal to

prevent rust.

• Cover chrome and stainless steel parts

with a thick coat of auto wax to prevent

discoloration. Re-wax as necessary

when you wash your vehicle.

• Lubricate all hood, door and luggage

compartment hinges and latches with

a light grade oil.

• Cover interior trim to prevent fading.

• Keep all rubber parts free from oil and

solvents.

Engine

• Change the engine oil and filter prior to

storage because used engine oil

contains contaminates which may

cause engine damage.

• Start the engine every 15 days for a

minimum of 15 minutes. Run at fast idle

with the climate controls set to defrost

until the engine reaches normal

operating temperature.

161

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Vehicle Care