FORD E SERIES 2016 4.G Owners Manual

Manufacturer: FORD, Model Year: 2016, Model line: E SERIES, Model: FORD E SERIES 2016 4.GPages: 319, PDF Size: 6.18 MB

Page 191 of 319

When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

•

Towing a trailer.

• Driving vehicles equipped with a

camper body.

• Driving vehicles with a load on the

cargo rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly

and seek service as soon as possible.

Tire Change Procedure WARNINGS

When one of the front wheels is off

the ground, the transmission alone

will not prevent your vehicle from

moving or slipping off the jack, even if the

transmission is in park (P) or neutral (N). To help prevent your vehicle from

moving when you change a tire, be

sure to place the transmission in park

(P) or neutral (N), set the parking brake,

and block (in both directions) the wheel

that is diagonally opposite (other side and

end of your vehicle) to the tire being

changed. Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured. Do not attempt to change a tire on

the side of the vehicle close to

moving traffic. Pull far enough off the

road to avoid the danger of being hit when

operating the jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one

provided as original equipment with your

vehicle, make sure the jack capacity is

adequate for the vehicle weight, including

any vehicle cargo or modifications. Note:

Passengers should not remain in your

vehicle when the vehicle is being jacked.

Removing the flat wheel and tire

1. Park on a level surface, set the parking

brake and activate the hazard flashers.

2. Place the transmission in park (P) and

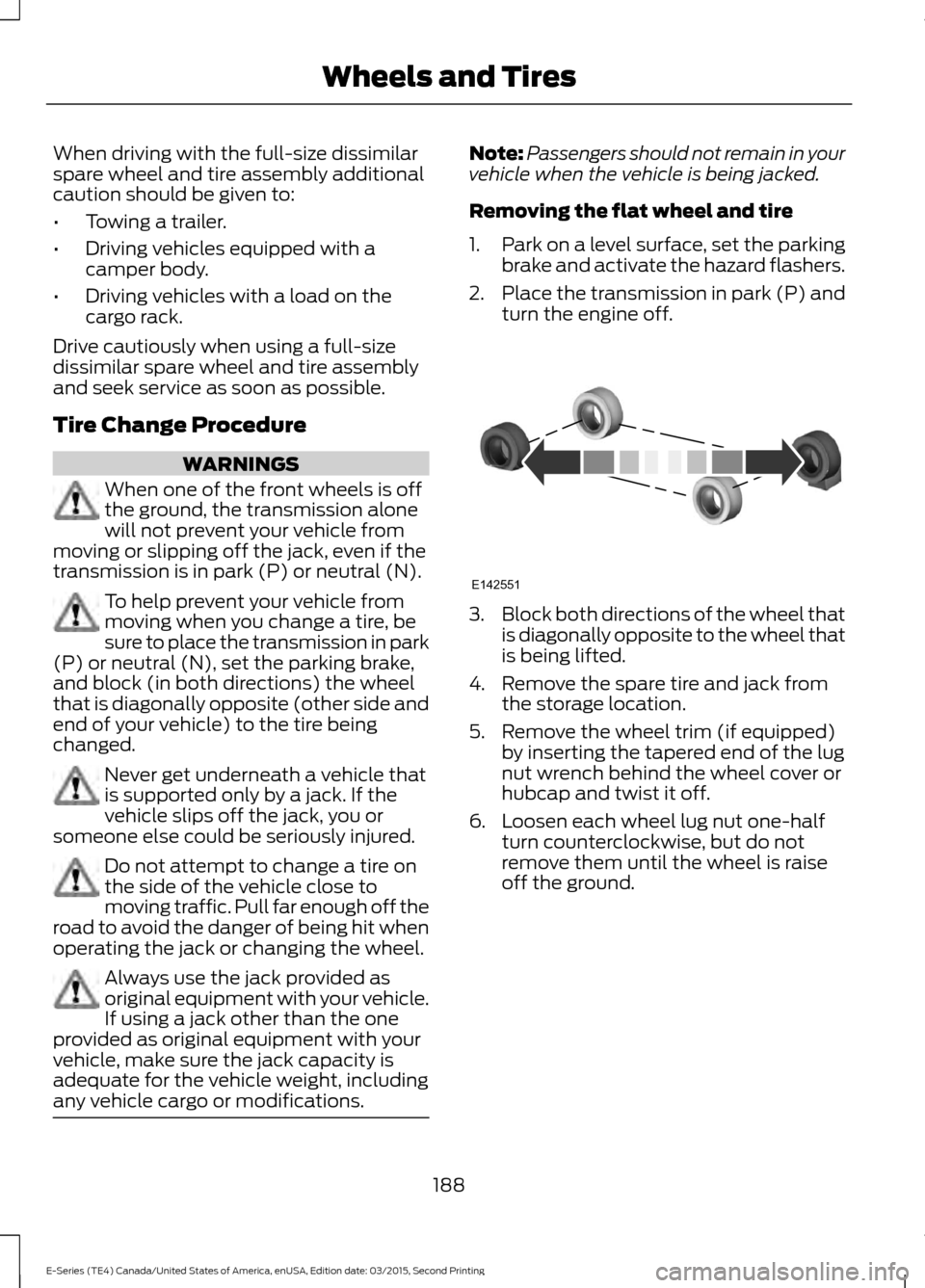

turn the engine off. 3.

Block both directions of the wheel that

is diagonally opposite to the wheel that

is being lifted.

4. Remove the spare tire and jack from the storage location.

5. Remove the wheel trim (if equipped) by inserting the tapered end of the lug

nut wrench behind the wheel cover or

hubcap and twist it off.

6. Loosen each wheel lug nut one-half turn counterclockwise, but do not

remove them until the wheel is raise

off the ground.

188

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Wheels and TiresE142551

Page 192 of 319

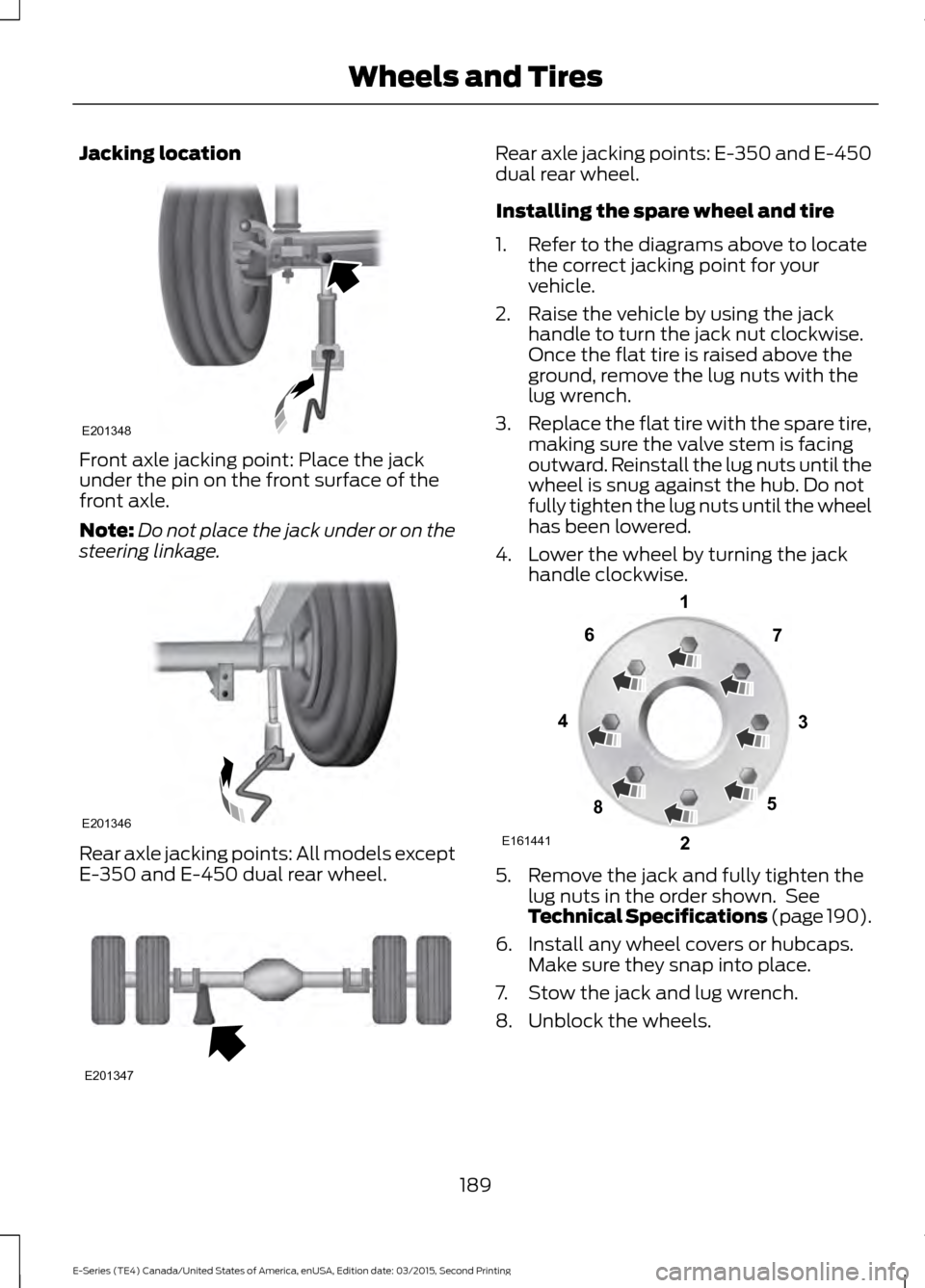

Jacking location

Front axle jacking point: Place the jack

under the pin on the front surface of the

front axle.

Note:

Do not place the jack under or on the

steering linkage. Rear axle jacking points: All models except

E-350 and E-450 dual rear wheel. Rear axle jacking points: E-350 and E-450

dual rear wheel.

Installing the spare wheel and tire

1. Refer to the diagrams above to locate

the correct jacking point for your

vehicle.

2. Raise the vehicle by using the jack handle to turn the jack nut clockwise.

Once the flat tire is raised above the

ground, remove the lug nuts with the

lug wrench.

3. Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward. Reinstall the lug nuts until the

wheel is snug against the hub. Do not

fully tighten the lug nuts until the wheel

has been lowered.

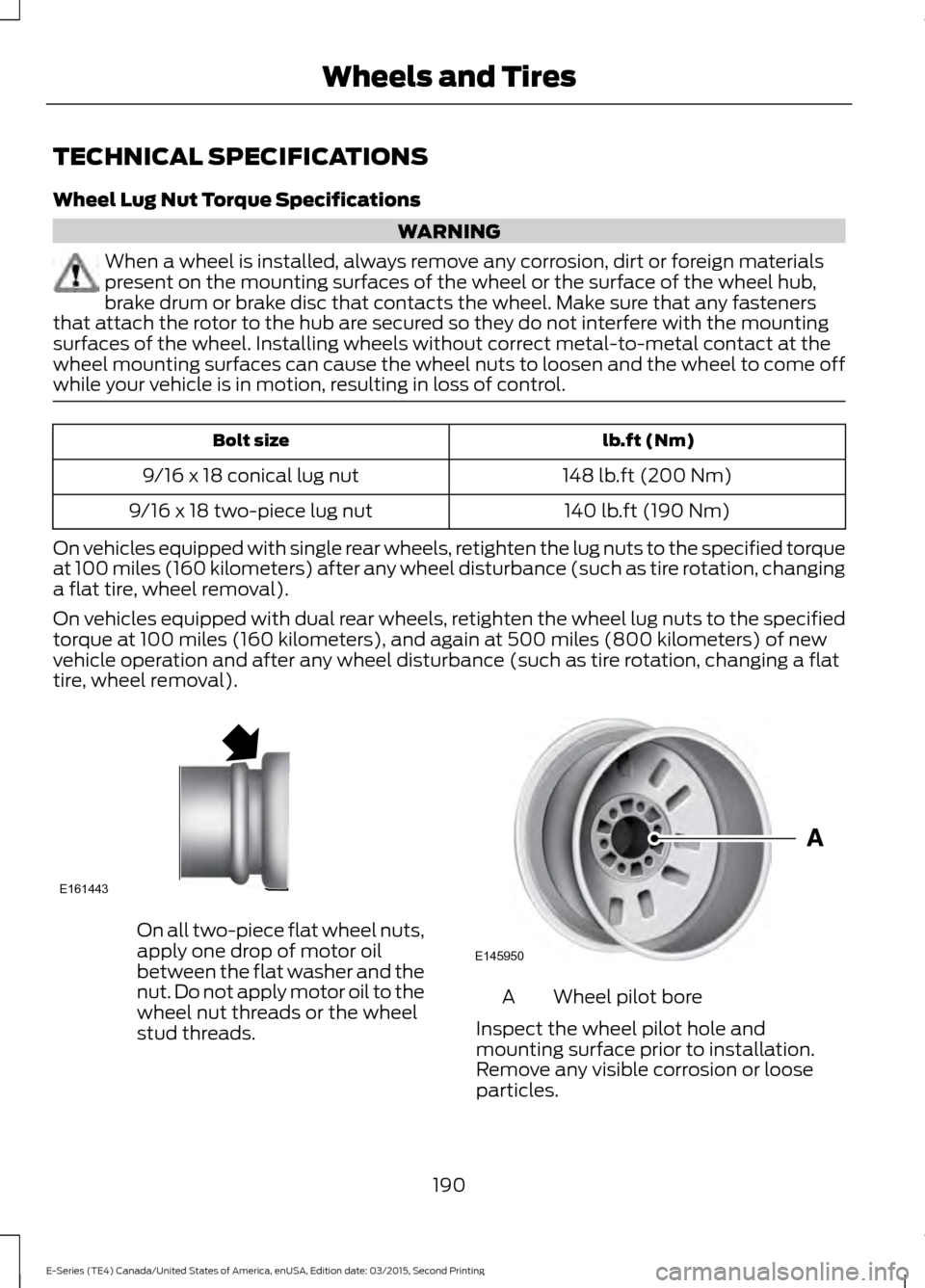

4. Lower the wheel by turning the jack handle clockwise. 5. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page 190).

6. Install any wheel covers or hubcaps. Make sure they snap into place.

7. Stow the jack and lug wrench.

8. Unblock the wheels.

189

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Wheels and TiresE201348 E201346 E201347 E161441

13

4

27

6

5

8

Page 193 of 319

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign materials

present on the mounting surfaces of the wheel or the surface of the wheel hub,

brake drum or brake disc that contacts the wheel. Make sure that any fasteners

that attach the rotor to the hub are secured so they do not interfere with the mounting

surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off

while your vehicle is in motion, resulting in loss of control. lb.ft (Nm)

Bolt size

148 lb.ft (200 Nm)

9/16 x 18 conical lug nut

140 lb.ft (190 Nm)

9/16 x 18 two-piece lug nut

On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque

at 100 miles (160 kilometers) after any wheel disturbance (such as tire rotation, changing

a flat tire, wheel removal).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts to the specified

torque at 100 miles (160 kilometers), and again at 500 miles (800 kilometers) of new

vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat

tire, wheel removal). On all two-piece flat wheel nuts,

apply one drop of motor oil

between the flat washer and the

nut. Do not apply motor oil to the

wheel nut threads or the wheel

stud threads.

Wheel pilot bore

A

Inspect the wheel pilot hole and

mounting surface prior to installation.

Remove any visible corrosion or loose

particles.

190

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Wheels and TiresE161443 E145950

Page 194 of 319

ENGINE SPECIFICATIONS - 5.4L V8

5.4L V8

Engine

330

Cubic inches

Minimum 87 octane or E85

Required fuel

1-3-7-2-6-5-4-8

Firing order

Coil on plug

Ignition system

0.051 — 0.057 in. (1.29 — 1.45 mm)

Spark plug gap

9.0:1

Compression ratio

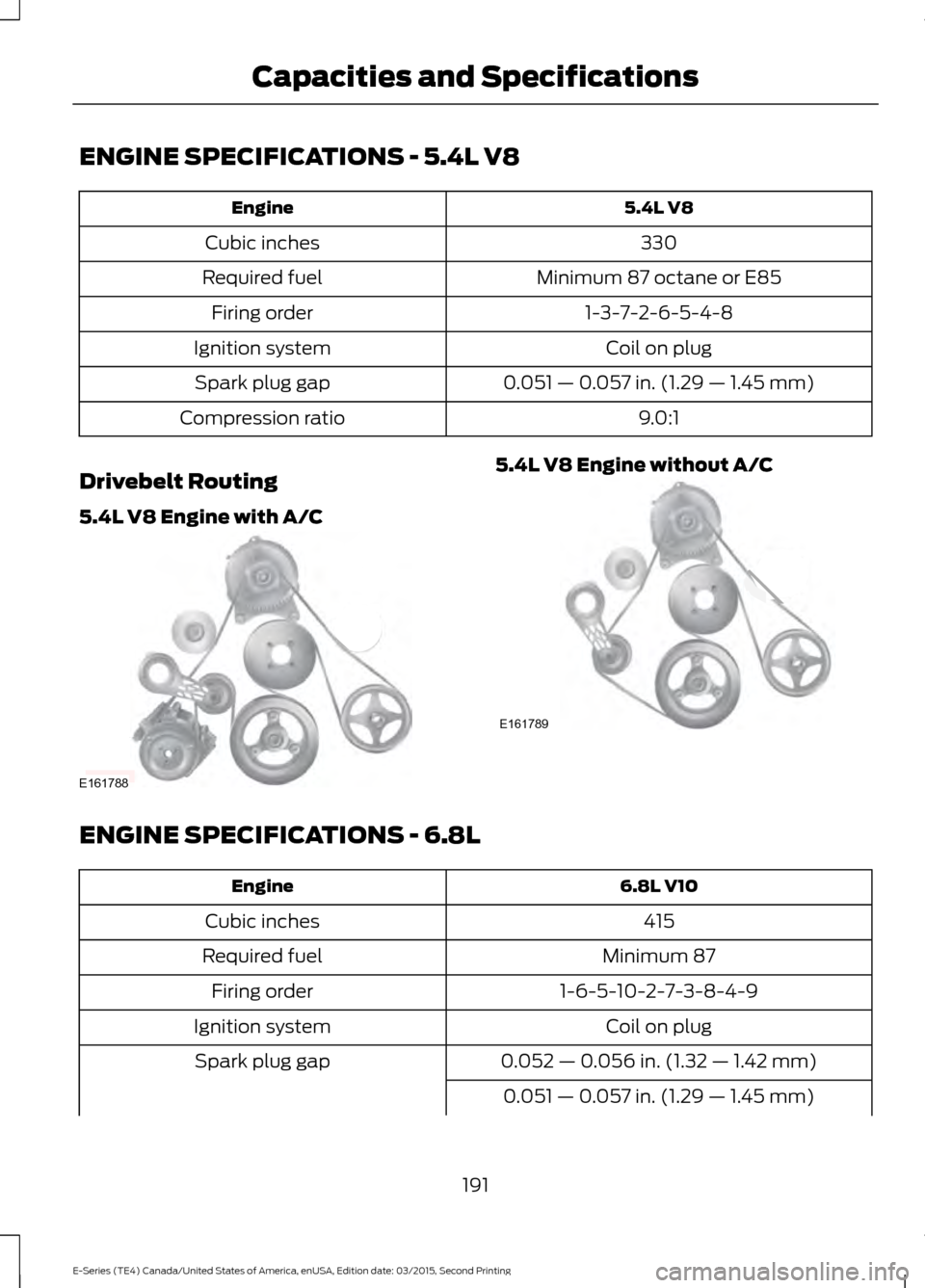

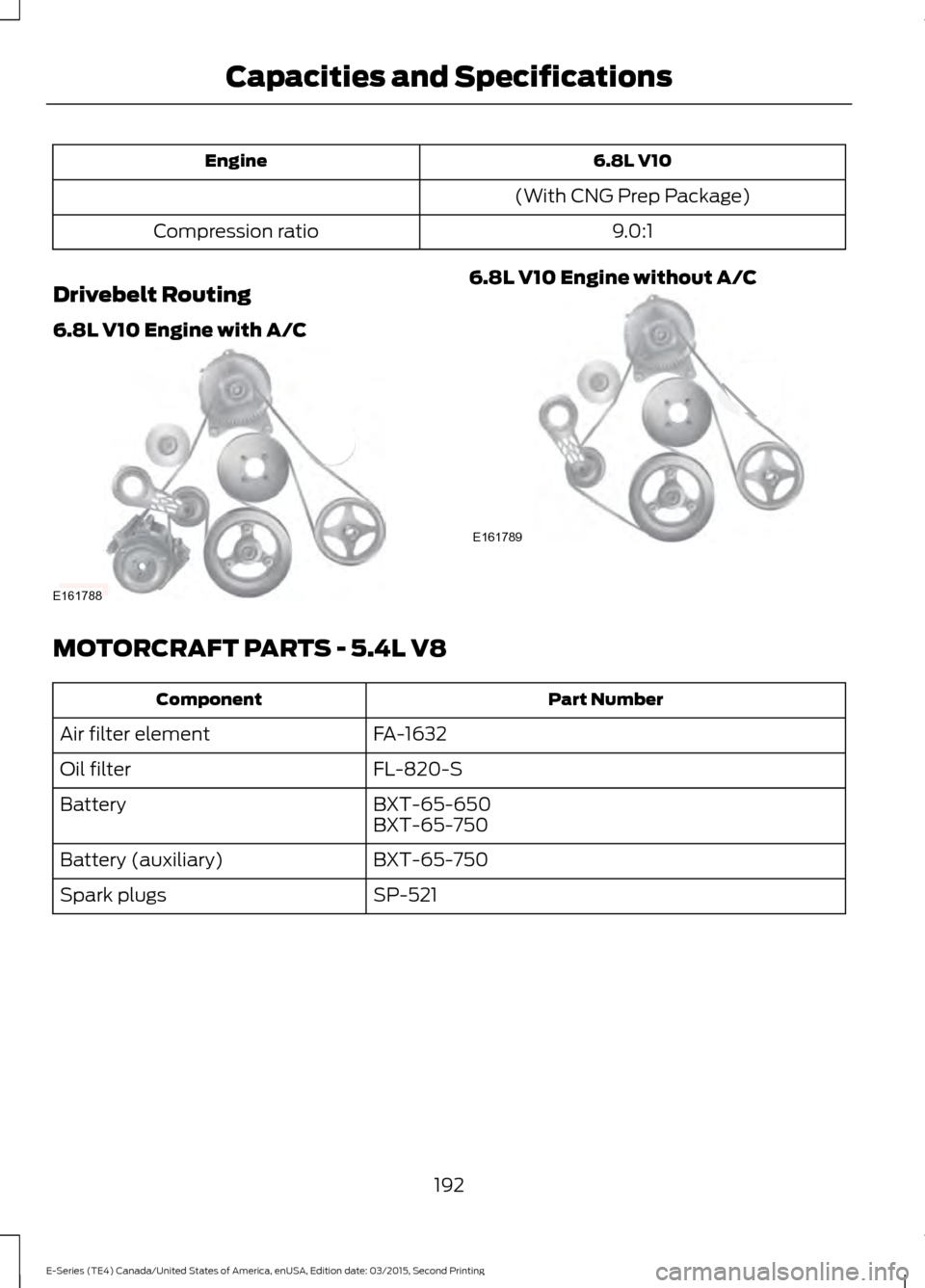

Drivebelt Routing

5.4L V8 Engine with A/C 5.4L V8 Engine without A/C

ENGINE SPECIFICATIONS - 6.8L

6.8L V10

Engine

415

Cubic inches

Minimum 87

Required fuel

1-6-5-10-2-7-3-8-4-9

Firing order

Coil on plug

Ignition system

0.052 — 0.056 in. (1.32 — 1.42 mm)

Spark plug gap

0.051 — 0.057 in. (1.29 — 1.45 mm)

191

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Capacities and SpecificationsE161788 E161789

Page 195 of 319

6.8L V10

Engine

(With CNG Prep Package)9.0:1

Compression ratio

Drivebelt Routing

6.8L V10 Engine with A/C 6.8L V10 Engine without A/C

MOTORCRAFT PARTS - 5.4L V8

Part Number

Component

FA-1632

Air filter element

FL-820-S

Oil filter

BXT-65-650

Battery

BXT-65-750

BXT-65-750

Battery (auxiliary)

SP-521

Spark plugs

192

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Capacities and SpecificationsE161788 E161789

Page 196 of 319

Part Number

Component

FT-180

Torqshift automatic transmission

internal bottom-pan filter

WW-2005

Windshield wiper blade

We recommend Motorcraft replacement parts available at your Ford dealer or at

fordparts.com for scheduled maintenance. These parts meet or exceed Ford Motor

Company ’s specifications and are engineered for your vehicle. Use of other parts may

impact vehicle performance, emissions and durability. Your warranty may be void for any

damage related to use of other parts.

If a Motorcraft oil filter is not available, use an oil filter that meets industry performance

specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the

appropriate intervals. See Scheduled Maintenance (page 268).

193

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Capacities and Specifications

Page 197 of 319

MOTORCRAFT PARTS - 6.8L

Part Number

Component

FA-1632

Air filter element

FL-820-S

Oil filter

BXT-65-650

Battery

BXT-65-750

BXT-65-750

Battery (auxiliary)

SP-521

Spark plugs

FT-180

Torqshift automatic transmission

internal bottom-pan filter

WW-2005

Windshield wiper blade

We recommend Motorcraft replacement parts available at your Ford dealer or at

fordparts.com for scheduled maintenance. These parts meet or exceed Ford Motor

Company ’s specifications and are engineered for your vehicle. Use of other parts may

impact vehicle performance, emissions and durability. Your warranty may be void for any

damage related to use of other parts.

If a Motorcraft oil filter is not available, use an oil filter that meets industry performance

specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the

appropriate intervals. See Scheduled Maintenance (page 268).

194

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Capacities and Specifications

Page 198 of 319

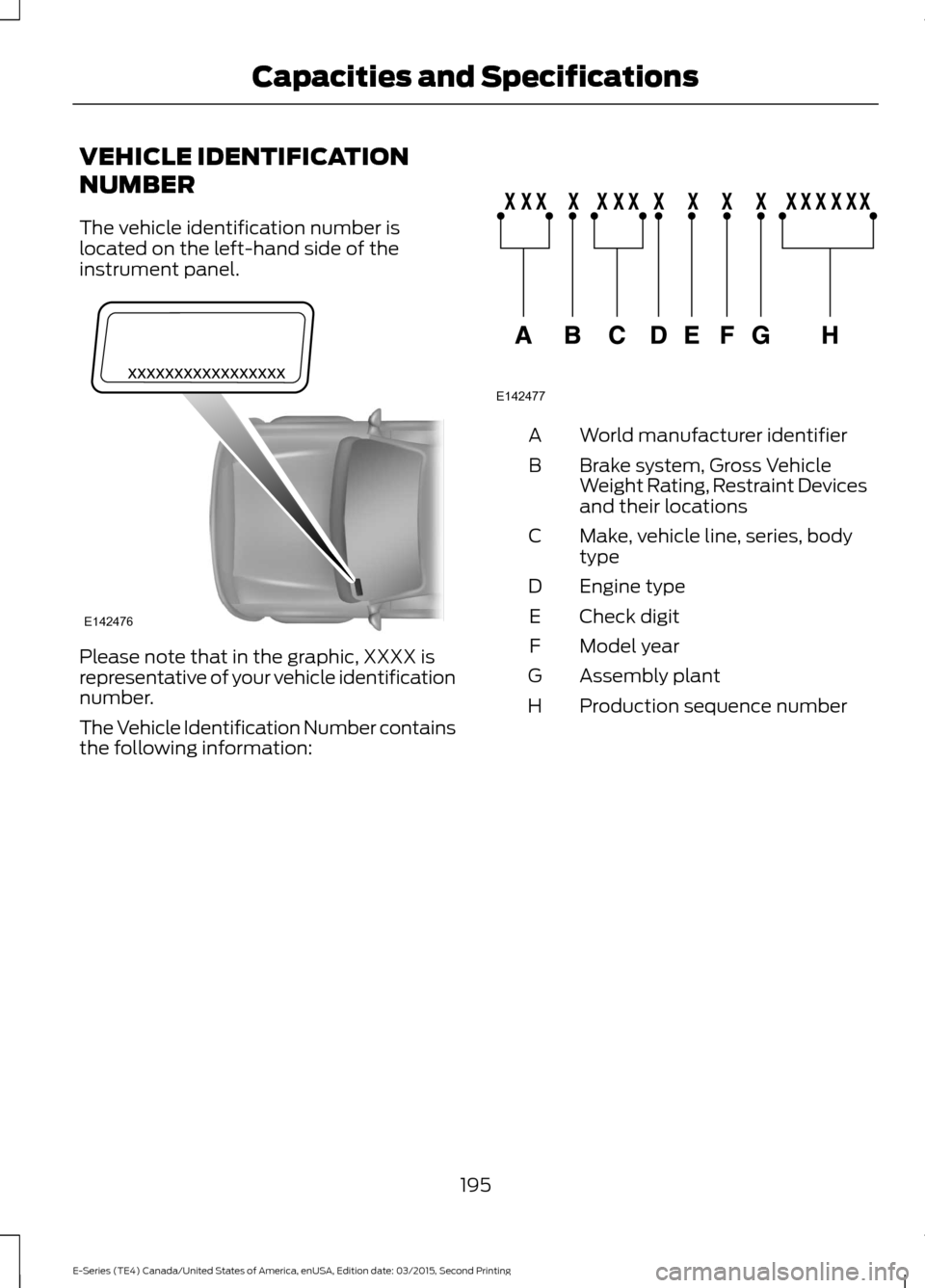

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number is

located on the left-hand side of the

instrument panel.

Please note that in the graphic, XXXX is

representative of your vehicle identification

number.

The Vehicle Identification Number contains

the following information: World manufacturer identifier

A

Brake system, Gross Vehicle

Weight Rating, Restraint Devices

and their locations

B

Make, vehicle line, series, body

type

C

Engine type

D

Check digit

E

Model year

F

Assembly plant

G

Production sequence number

H

195

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Capacities and SpecificationsE142476 E142477

Page 199 of 319

VEHICLE CERTIFICATION

LABEL

The National Highway Traffic Safety

Administration Regulations require that a

Safety Compliance Certification Label be

affixed to a vehicle and prescribe where

the Safety Compliance Certification Label

may be located. The Safety Compliance

Certification Label shall be affixed to either

the door hinge pillar, the door latch post,

or the edge of the door near the door latch,

next to the driver's seating position.

TRANSMISSION CODE

DESIGNATION The transmission code is on the Safety

Compliance Certification Label. The

following table shows the transmission

code along with the transmission

description.

Code

Description

T

Five-speed automatic transmission 5R110W

P

Six-speed automatic transmission 6R140

196

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Capacities and SpecificationsE167469 E167814

Page 200 of 319

CAPACITIES AND SPECIFICATIONS - 5.4L V8

WARNING

The air conditioning refrigerant system contains refrigerant R-134a under high

pressure. Opening the air conditioning refrigerant system can cause personal injury.

Have the air conditioning refrigerant system serviced only by qualified personnel.

Capacity

Item

6.0 qt (5.7 L)

Engine oil (with oil filter)

28.7 qt (27.2 L)

Engine coolant

30.7 qt (29.1 L)

Engine coolant - with auxiliary rear heat

Between MIN/MAX on brake fluid reservoir

Brake fluid

Between MIN/MAX on power steering fluidreservoir

Power steering fluid

18.7 qt (17.7 L)*

Automatic transmission fluid

6.6 pt (3.1L)**

Dana Limited Slip Axle fluid

M70FF (M267FF)

E-350

9.7 pt (4.6L)**

Dana Limited Slip Axle fluid

M70HD (M273HD)

E-450

6.6 pt (3.1L)**

Dana conventional axle fluid

M70FF (M267FF)

E-350

9.7 pt (4.6L)**

Dana conventional axle fluid

M70HD (M273HD)

E-450

Fill as required

Windshield washer fluid

40 gal (151 L)

Fuel tank

55 gal (208 L)

Fuel tank

(Optional or E-Super Duty)

1.9 lb (0.85 kg)

A/C refrigerant

197

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 03/2015, Second Printing Capacities and Specifications