ignition FORD E SERIES 2022 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2022, Model line: E SERIES, Model: FORD E SERIES 2022Pages: 300, PDF Size: 3.18 MB

Page 143 of 300

TOWING THE VEHICLE ON

FOUR WHEELS

Emergency Towing

WARNING: If your vehicle has a

steering wheel lock make sure the

ignition is in the accessory or on position

when being towed.

You can flat-tow (all wheels on the

ground, regardless of the powertrain or

transmission configuration) your disabled

vehicle (without access to wheel dollies

or vehicle transport trailer) under the

following conditions:

• Your vehicle is facing forward so you

tow it in a forward direction.

• You shift into Neutral (N). If you cannot

shift into Neutral (N), you may need to

override the transmission. See

Transmission

(page 96).

• Maximum speed is 35 mph (56 km/h).

• Maximum distance is

50 mi (80 km).

Recreational Towing

Note: Put your climate control system in

recirculated air mode to prevent exhaust

fumes from entering the vehicle. See

Climate Control

(page 74).

Follow these guidelines if you have a need

for recreational (RV) towing. An example

of recreational towing would be towing

your vehicle behind a motorhome. These

guidelines are to make sure you do not

damage the transmission during towing.

Do not tow your vehicle with any wheels

on the ground, as vehicle or transmission

damage may occur. It is recommended to

tow your vehicle with all four wheels off

the ground, for example when using a

vehicle transport trailer. Otherwise, you

cannot tow your vehicle.

140

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Towing

Page 162 of 300

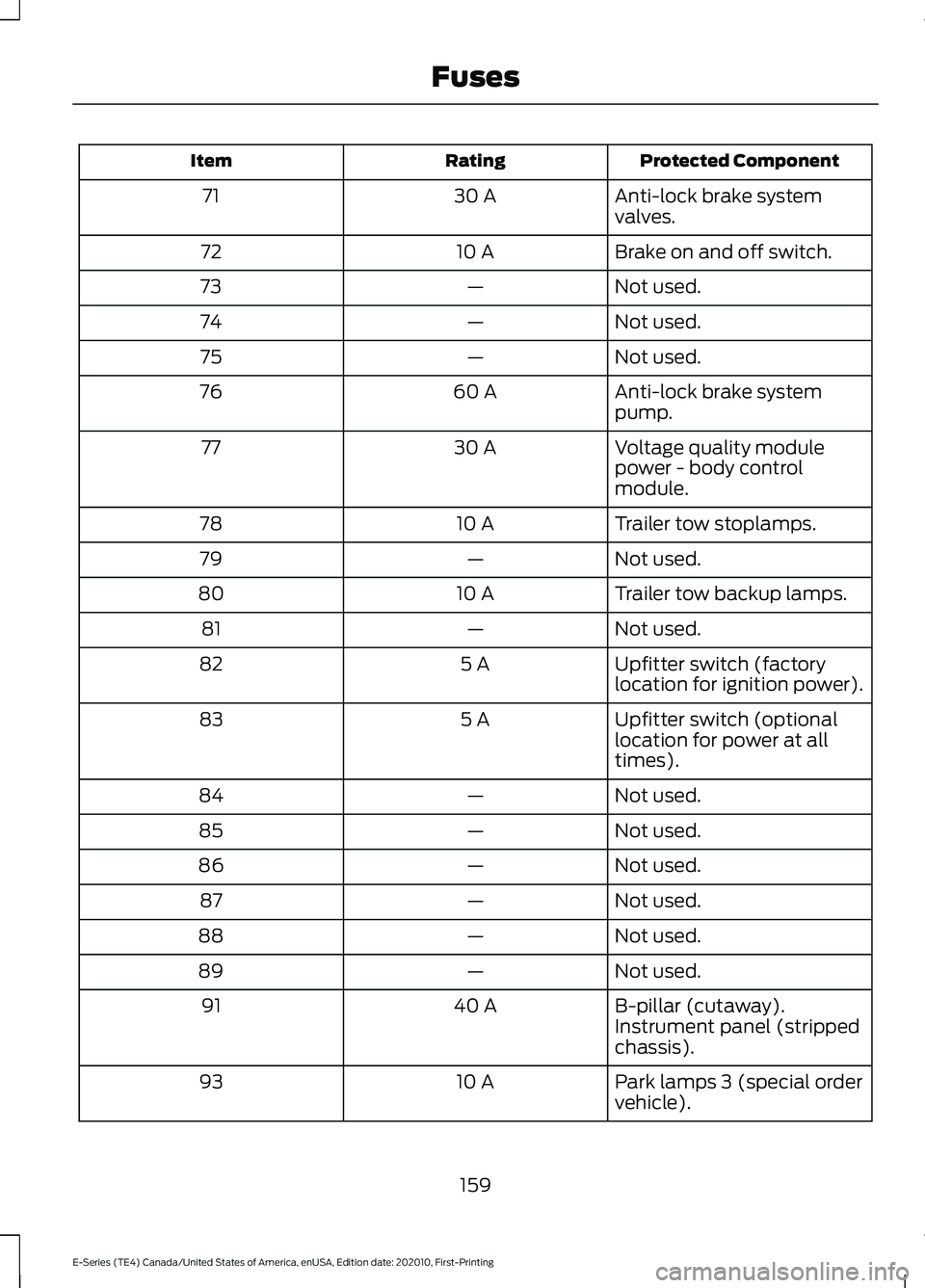

Protected Component

Rating

Item

Anti-lock brake system

valves.

30 A

71

Brake on and off switch.

10 A

72

Not used.

—

73

Not used.

—

74

Not used.

—

75

Anti-lock brake system

pump.

60 A

76

Voltage quality module

power - body control

module.

30 A

77

Trailer tow stoplamps.

10 A

78

Not used.

—

79

Trailer tow backup lamps.

10 A

80

Not used.

—

81

Upfitter switch (factory

location for ignition power).

5 A

82

Upfitter switch (optional

location for power at all

times).

5 A

83

Not used.

—

84

Not used.

—

85

Not used.

—

86

Not used.

—

87

Not used.

—

88

Not used.

—

89

B-pillar (cutaway).

40 A

91

Instrument panel (stripped

chassis).

Park lamps 3 (special order

vehicle).

10 A

93

159

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Fuses

Page 165 of 300

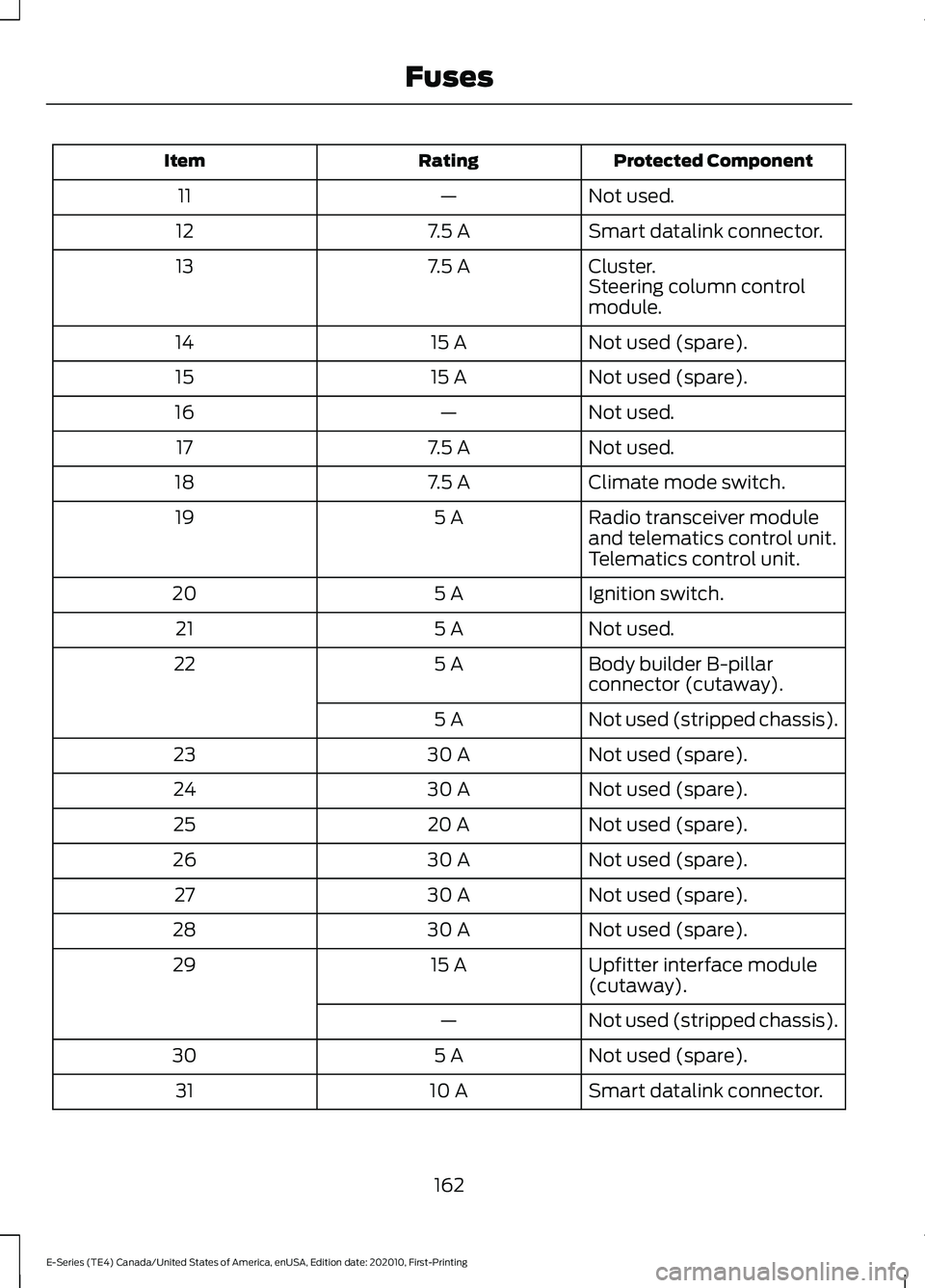

Protected Component

Rating

Item

Not used.

—

11

Smart datalink connector.

7.5 A

12

Cluster.

7.5 A

13

Steering column control

module.

Not used (spare).

15 A

14

Not used (spare).

15 A

15

Not used.

—

16

Not used.

7.5 A

17

Climate mode switch.

7.5 A

18

Radio transceiver module

and telematics control unit.

5 A

19

Telematics control unit.

Ignition switch.

5 A

20

Not used.

5 A

21

Body builder B-pillar

connector (cutaway).

5 A

22

Not used (stripped chassis).

5 A

Not used (spare).

30 A

23

Not used (spare).

30 A

24

Not used (spare).

20 A

25

Not used (spare).

30 A

26

Not used (spare).

30 A

27

Not used (spare).

30 A

28

Upfitter interface module

(cutaway).

15 A

29

Not used (stripped chassis).

—

Not used (spare).

5 A

30

Smart datalink connector.

10 A

31

162

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Fuses

Page 170 of 300

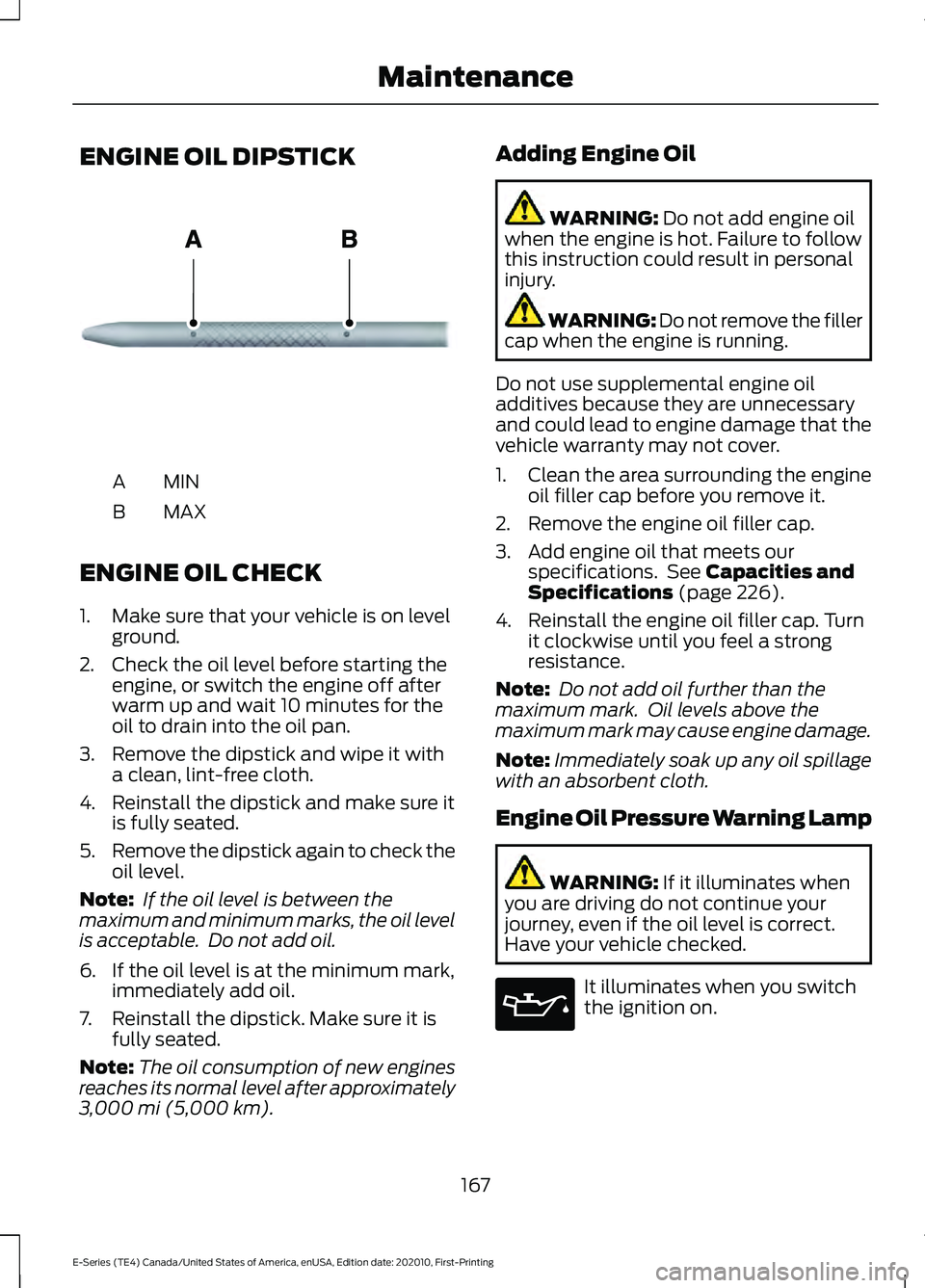

ENGINE OIL DIPSTICK

MINA

MAX

B

ENGINE OIL CHECK

1. Make sure that your vehicle is on level ground.

2. Check the oil level before starting the engine, or switch the engine off after

warm up and wait 10 minutes for the

oil to drain into the oil pan.

3. Remove the dipstick and wipe it with a clean, lint-free cloth.

4. Reinstall the dipstick and make sure it is fully seated.

5. Remove the dipstick again to check the

oil level.

Note: If the oil level is between the

maximum and minimum marks, the oil level

is acceptable. Do not add oil.

6. If the oil level is at the minimum mark, immediately add oil.

7. Reinstall the dipstick. Make sure it is fully seated.

Note: The oil consumption of new engines

reaches its normal level after approximately

3,000 mi (5,000 km). Adding Engine Oil WARNING:

Do not add engine oil

when the engine is hot. Failure to follow

this instruction could result in personal

injury. WARNING: Do not remove the filler

cap when the engine is running.

Do not use supplemental engine oil

additives because they are unnecessary

and could lead to engine damage that the

vehicle warranty may not cover.

1. Clean the area surrounding the engine oil filler cap before you remove it.

2. Remove the engine oil filler cap.

3. Add engine oil that meets our specifications. See

Capacities and

Specifications (page 226).

4. Reinstall the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Immediately soak up any oil spillage

with an absorbent cloth.

Engine Oil Pressure Warning Lamp WARNING:

If it illuminates when

you are driving do not continue your

journey, even if the oil level is correct.

Have your vehicle checked. It illuminates when you switch

the ignition on.

167

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing MaintenanceE161560

Page 183 of 300

5. Locate the vertical adjuster on each

headlamp. Using a Phillips #2

screwdriver, turn the adjuster either

clockwise or counterclockwise in order

to adjust the vertical aim of the

headlamp.

6. Repeat steps 3 through 5 to adjust the

other headlamp.

7. Close the hood and switch off the lamps.

WASHER FLUID CHECK WARNING: If you operate your

vehicle in temperatures below 40°F

(5°C), use washer fluid with antifreeze

protection. Failure to use washer fluid

with antifreeze protection in cold

weather could result in impaired

windshield vision and increase the risk

of injury or accident.

Add fluid to fill the reservoir if the level is

low. Only use a washer fluid that meets

Ford specifications. See

Capacities and

Specifications (page 229). State or local regulations on volatile

organic compounds may restrict the use

of methanol, a common windshield washer

antifreeze additive. Washer fluids

containing non-methanol antifreeze

agents should be used only if they provide

cold weather protection without damaging

the vehicle

’s paint finish, wiper blades or

washer system.

FUEL FILTER

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

is not needed.

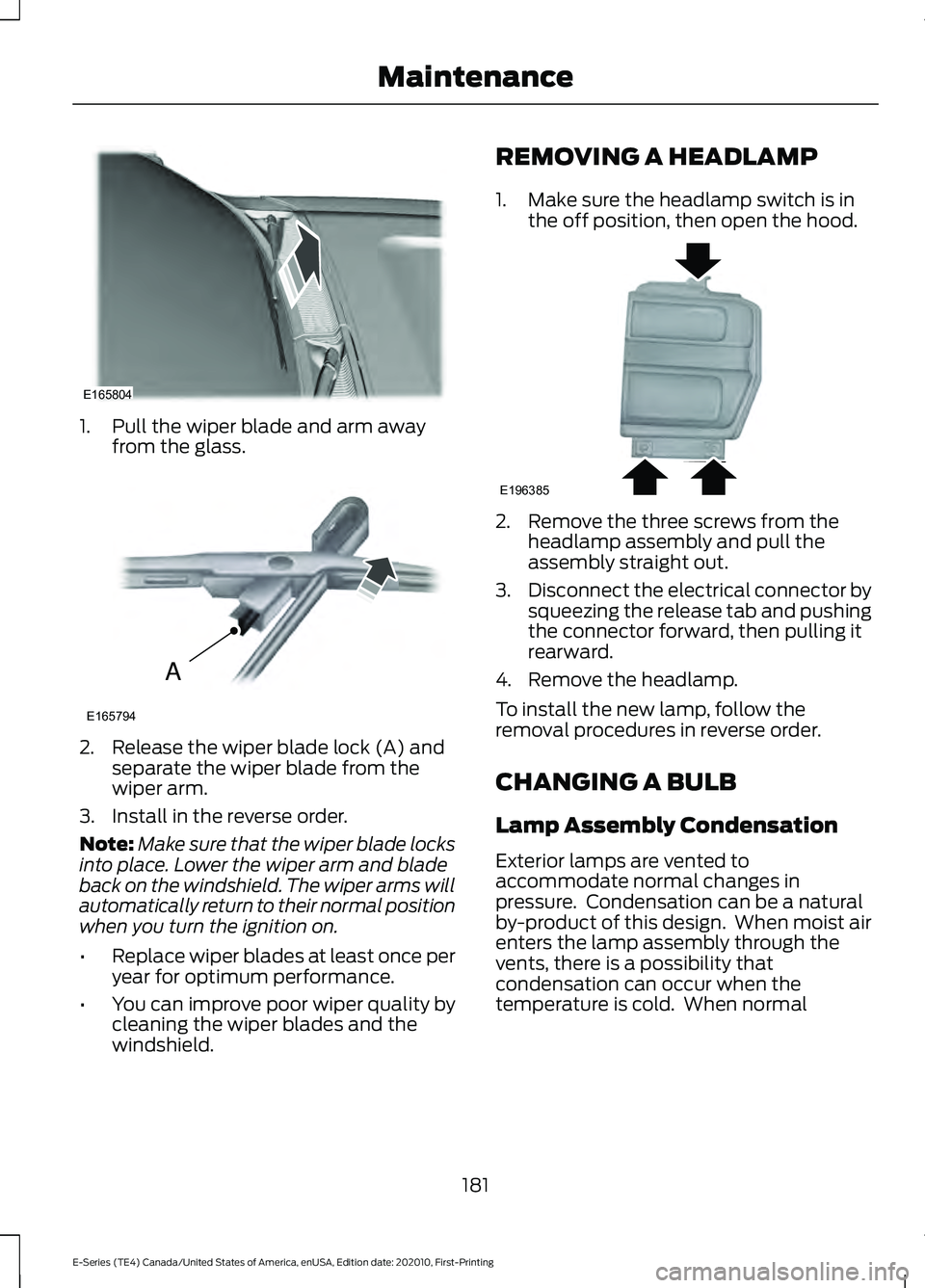

CHECKING THE WIPER

BLADES Run the tip of your fingers over the edge of

the blade to check for roughness.

Clean the wiper blades with washer fluid

or water applied with a soft sponge or

cloth.

CHANGING THE WIPER

BLADES

You can manually move the wiper arms

when the ignition is off. This allows for ease

of blade replacement and cleaning under

the blades.

180

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing MaintenanceE163806 E142463

Page 184 of 300

1. Pull the wiper blade and arm away

from the glass. 2. Release the wiper blade lock (A) and

separate the wiper blade from the

wiper arm.

3. Install in the reverse order.

Note: Make sure that the wiper blade locks

into place. Lower the wiper arm and blade

back on the windshield. The wiper arms will

automatically return to their normal position

when you turn the ignition on.

• Replace wiper blades at least once per

year for optimum performance.

• You can improve poor wiper quality by

cleaning the wiper blades and the

windshield. REMOVING A HEADLAMP

1. Make sure the headlamp switch is in

the off position, then open the hood. 2. Remove the three screws from the

headlamp assembly and pull the

assembly straight out.

3. Disconnect the electrical connector by

squeezing the release tab and pushing

the connector forward, then pulling it

rearward.

4. Remove the headlamp.

To install the new lamp, follow the

removal procedures in reverse order.

CHANGING A BULB

Lamp Assembly Condensation

Exterior lamps are vented to

accommodate normal changes in

pressure. Condensation can be a natural

by-product of this design. When moist air

enters the lamp assembly through the

vents, there is a possibility that

condensation can occur when the

temperature is cold. When normal

181

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing MaintenanceE165804 A

E165794 E196385

Page 190 of 300

•

Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage.

• Never wash or rinse any ignition coil,

spark plug wire or spark plug well, or

the area in and around these locations.

• Cover the battery, power distribution

box, and air filter assembly to prevent

water damage when cleaning the

engine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmental

fallout can result in windshield and wiper

blade contamination. Dirty windshield and

wipers will result in poor windshield wiper

operation. Keep the windshield and wiper

blades clean to maintain windshield wiper

performance.

To clean the windshield and wiper blades:

• Clean the windshield with a

non-abrasive glass cleaner. When

cleaning the interior of the windshield,

avoid getting any glass cleaner on the

instrument panel or door panels. Wipe

any glass cleaner off these surfaces

immediately.

• For windshields contaminated with

tree sap, chemicals, wax or bugs, clean

the entire windshield using steel wool

(no greater than 0000 grade) in a

circular motion and rinse with water.

• Clean the wiper blades with isopropyl

rubbing alcohol or windshield washer

concentrate.

Note: Do not use razor blades or other

sharp objects to clean or remove decals

from the inside of the heated rear window.

The vehicle warranty does not cover

damage caused to the heated rear window

grid lines. CLEANING THE INTERIOR WARNING: Do not use cleaning

solvents, bleach or dye on the vehicle's

seatbelts, as these actions may weaken

the belt webbing. WARNING:

On vehicles equipped

with seat-mounted airbags, do not use

chemical solvents or strong detergents.

Such products could contaminate the

side airbag system and affect

performance of the side airbag in a crash.

For fabric, carpets, cloth seats and seats

equipped with side airbags:

• Remove dust and loose dirt with a

vacuum cleaner.

• Remove light stains and soil with

Motorcraft Professional Strength

Carpet & Upholstery Cleaner.

• If grease or tar is present on the

material, spot-clean the area first with

Motorcraft Spot and Stain Remover. In

Canada, use Motorcraft Multi-Purpose

Cleaner.

• If a ring forms on the fabric after spot

cleaning, clean the entire area

immediately (but do not oversaturate)

or the ring will set.

• Do not use household cleaning

products or glass cleaners, which can

stain and discolor the fabric and affect

the flame retardant abilities of the seat

materials.

Mirrors

Do not clean the housing or glass of any

mirror with harsh abrasives, fuel or other

petroleum or ammonia-based cleaning

products.

187

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Vehicle Care

Page 219 of 300

How Temperature Affects Your Tire

Pressure

The tire pressure monitoring system

monitors tire pressure in each pneumatic

tire. When driving in a normal manner, a

typical passenger tire inflation pressure

may increase about 2

–4 psi (14– 28 kPa)

from a cold start situation. If the vehicle is

stationary overnight with the outside

temperature significantly lower than the

daytime temperature, the tire pressure may

decrease about 3 psi (21 kPa) for a drop of

30°F (17°C) in ambient temperature. This

lower pressure value may be detected by

the tire pressure monitoring system as

being significantly lower than the

recommended inflation pressure and

activate the system warning light for low

tire pressure. If the low tire pressure

warning light is on, visually check each tire

to verify that no tire is flat. If one or more

tires are flat, repair as necessary. Check

the air pressure in the road tires. If any tire

is under-inflated, carefully drive the vehicle

to the nearest location where air can be

added to the tires. Inflate all the tires to

the recommended inflation pressure.

Tire Pressure Monitoring System Reset

Procedure WARNING:

To determine the

required pressure(s) for your vehicle, see

the Safety Compliance Certification

Label (on the door hinge pillar,

door-latch post or the door edge that

meets the door-latch post, next to the

driver seat) or the Tire Label on the

B-Pillar or the edge of the driver door.

Note: You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation. To provide the vehicle's load carrying

capability, some vehicles require different

recommended tire pressures in the front

tires as compared to the rear tires. The tire

pressure monitoring system on these

vehicles illuminate the low tire pressure

warning light at two different pressures:

one for the front tires and one for the rear

tires.

Since tires need to be rotated to provide

consistent performance and maximum tire

life, the tire pressure monitoring system

needs to know when the tires are rotated

to determine which set of tires are on the

front and which are on the rear. With this

information, the system can detect and

properly warn of low tire pressures.

System reset tips:

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least

3 ft

(1 m) away from another vehicle

undergoing the system reset procedure

at the same time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system can time-out and you have

to repeat the entire procedure on all

four wheels.

• A double horn sounds indicating the

need to repeat the procedure.

Performing the System Reset Procedure

- Single Rear Wheel

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

216

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Wheels and Tires

Page 220 of 300

3. Cycle the ignition to the on position

with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, have the system checked as

soon as possible.

5. Train the tire pressure monitoring system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front -

driver side front tire, Right front -

passenger side front tire, Right rear -

passenger side rear tire, Left rear -

driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn tone confirms that

the sensor identification code has been

learned by the module for this position. If

you hear a double horn, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds. 9. Remove the valve cap from the valve

stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver

side rear tire, the system indicator

stops flashing, and a message shows

in the information display.

10. Turn the ignition off. If you hear two short tones, the reset procedure was

unsuccessful and you must repeat it.

If you hear two short beeps when the

ignition is off after repeating the

procedure, have the system checked

as soon as possible

11. Set all four tires to the recommended

air pressure as indicated on the

Safety Compliance Certification

Label, affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver seating position or

Tire Label located on the B-Pillar or

the edge of the driver door.

CHANGING A ROAD WHEEL WARNING: To determine the

required pressure(s) for your vehicle, see

the Safety Compliance Certification

Label (on the door hinge pillar,

door-latch post or the door edge that

meets the door-latch post, next to the

driver seat) or the Tire Label on the

B-Pillar or the edge of the driver door.

Note: You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

217

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Wheels and Tires

Page 226 of 300

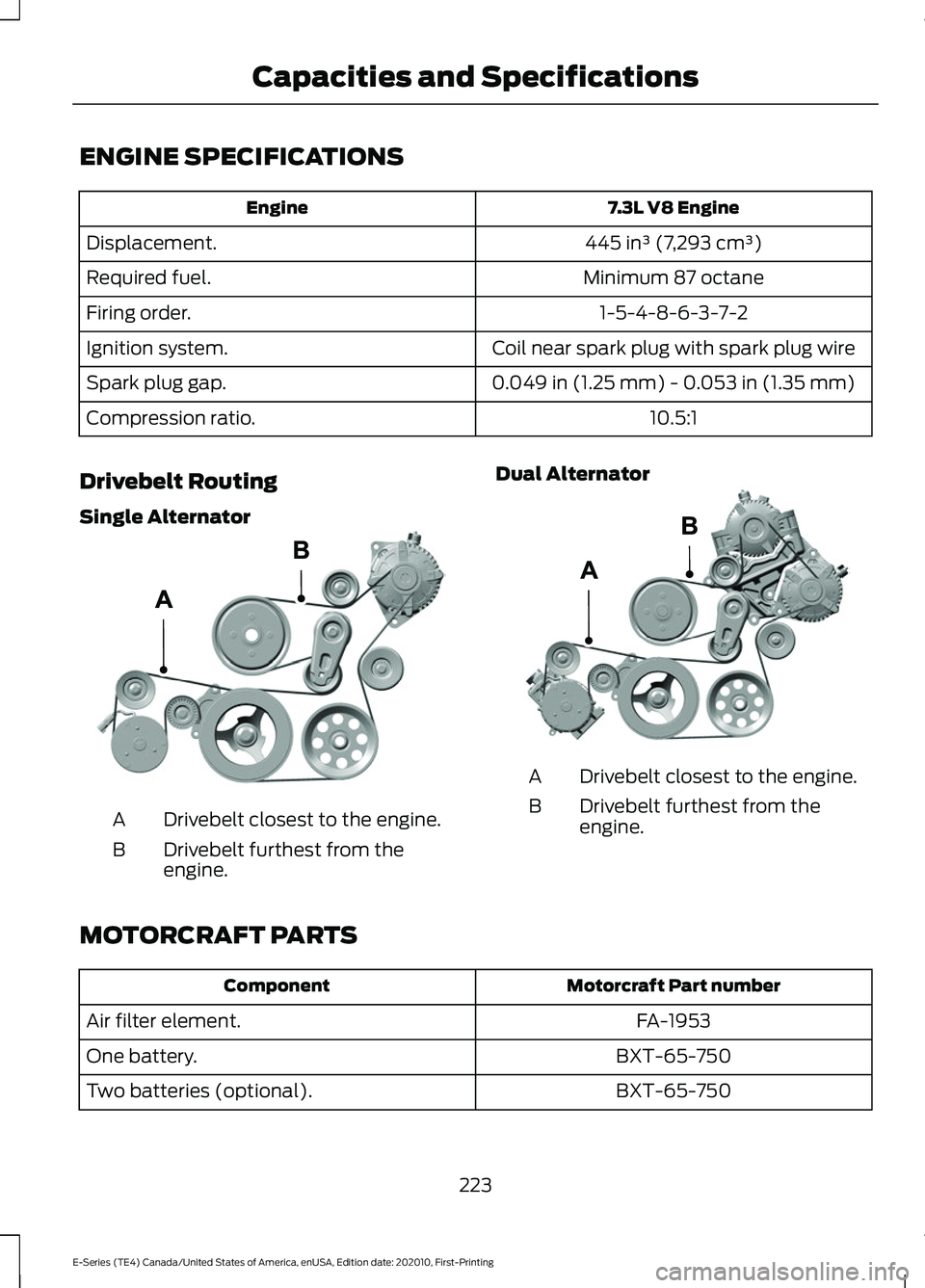

ENGINE SPECIFICATIONS

7.3L V8 Engine

Engine

445 in³ (7,293 cm³)

Displacement.

Minimum 87 octane

Required fuel.

1-5-4-8-6-3-7-2

Firing order.

Coil near spark plug with spark plug wire

Ignition system.

0.049 in (1.25 mm) - 0.053 in (1.35 mm)

Spark plug gap.

10.5:1

Compression ratio.

Drivebelt Routing

Single Alternator Drivebelt closest to the engine.

A

Drivebelt furthest from the

engine.

B Dual Alternator Drivebelt closest to the engine.

A

Drivebelt furthest from the

engine.

B

MOTORCRAFT PARTS Motorcraft Part number

Component

FA-1953

Air filter element.

BXT-65-750

One battery.

BXT-65-750

Two batteries (optional).

223

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Capacities and SpecificationsE305075 E298579