fuel FORD E150 1999 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1999, Model line: E150, Model: FORD E150 1999Pages: 208, PDF Size: 1.93 MB

Page 123 of 208

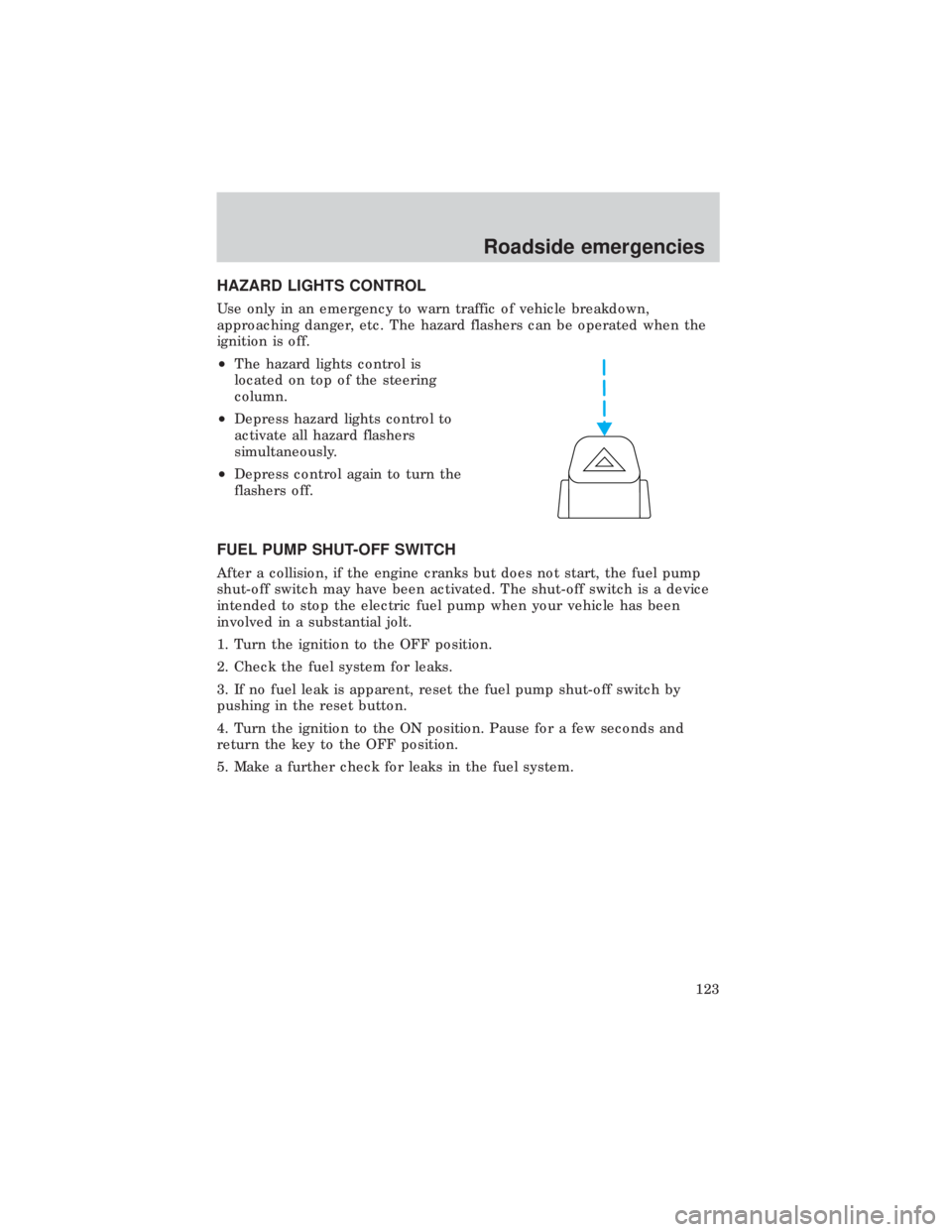

HAZARD LIGHTS CONTROL

Use only in an emergency to warn traffic of vehicle breakdown,

approaching danger, etc. The hazard flashers can be operated when the

ignition is off.

²The hazard lights control is

located on top of the steering

column.

²Depress hazard lights control to

activate all hazard flashers

simultaneously.

²Depress control again to turn the

flashers off.

FUEL PUMP SHUT-OFF SWITCH

After a collision, if the engine cranks but does not start, the fuel pump

shut-off switch may have been activated. The shut-off switch is a device

intended to stop the electric fuel pump when your vehicle has been

involved in a substantial jolt.

1. Turn the ignition to the OFF position.

2. Check the fuel system for leaks.

3. If no fuel leak is apparent, reset the fuel pump shut-off switch by

pushing in the reset button.

4. Turn the ignition to the ON position. Pause for a few seconds and

return the key to the OFF position.

5. Make a further check for leaks in the fuel system.

Roadside emergencies

123

Page 124 of 208

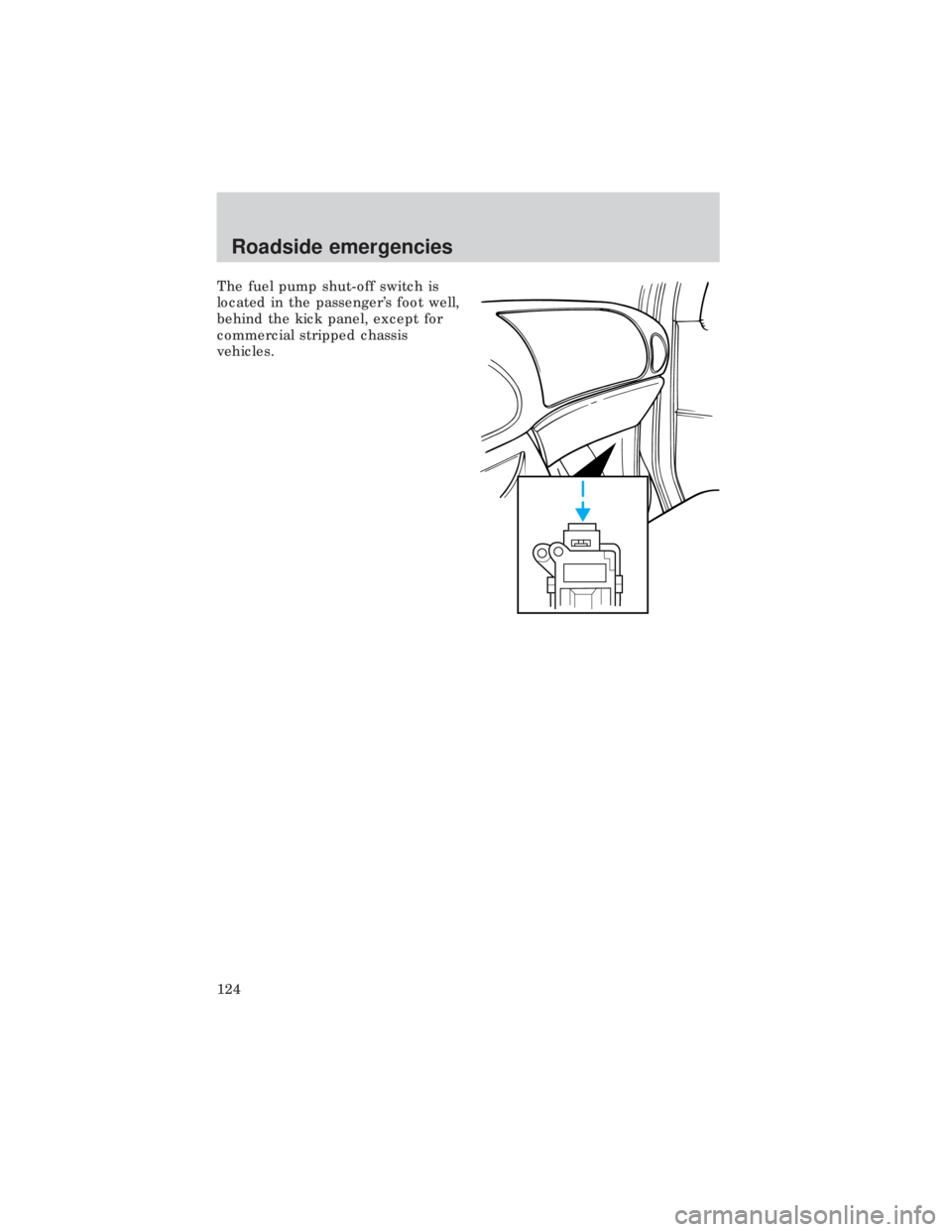

The fuel pump shut-off switch is

located in the passenger's foot well,

behind the kick panel, except for

commercial stripped chassis

vehicles.

Roadside emergencies

124

Page 125 of 208

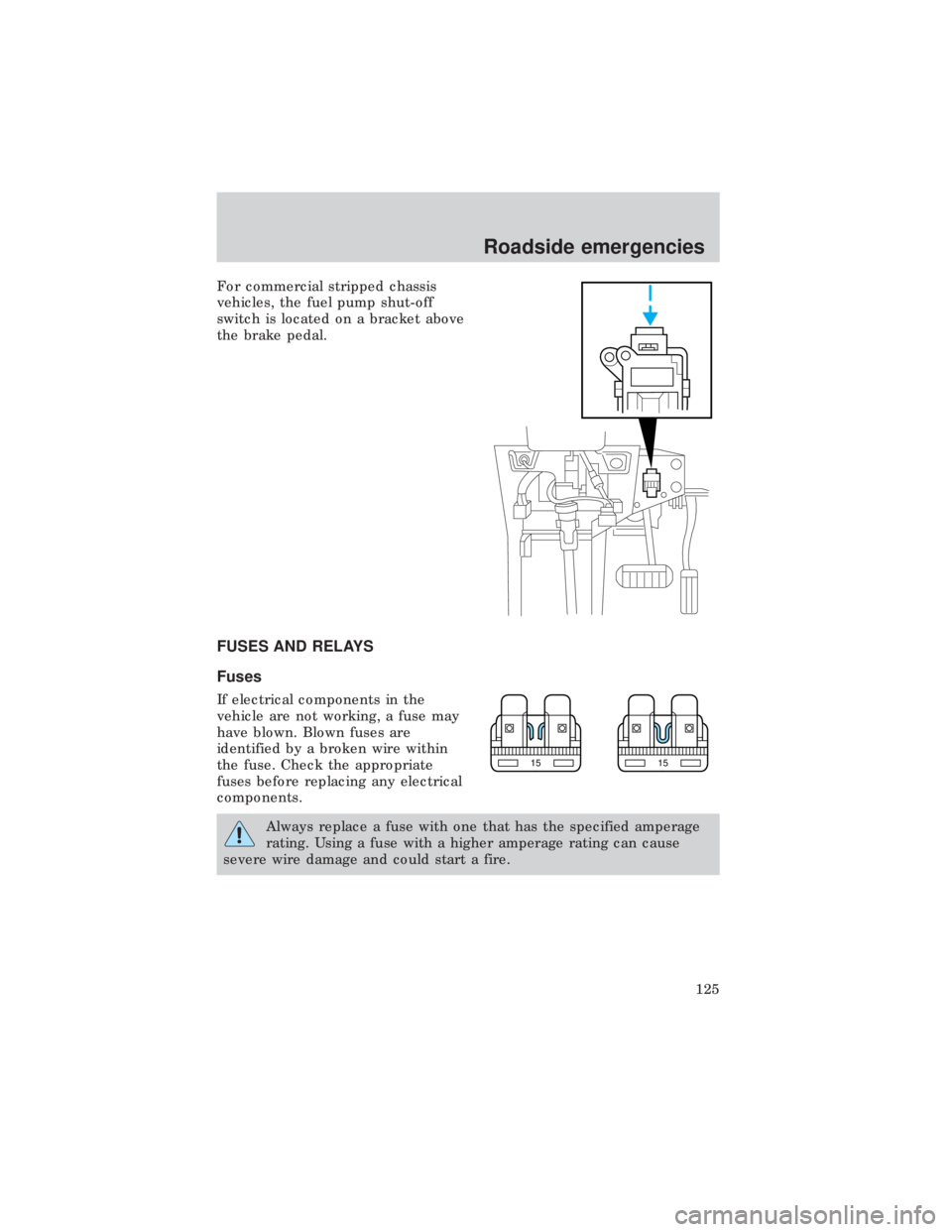

For commercial stripped chassis

vehicles, the fuel pump shut-off

switch is located on a bracket above

the brake pedal.

FUSES AND RELAYS

Fuses

If electrical components in the

vehicle are not working, a fuse may

have blown. Blown fuses are

identified by a broken wire within

the fuse. Check the appropriate

fuses before replacing any electrical

components.

Always replace a fuse with one that has the specified amperage

rating. Using a fuse with a higher amperage rating can cause

severe wire damage and could start a fire.

1515

Roadside emergencies

125

Page 128 of 208

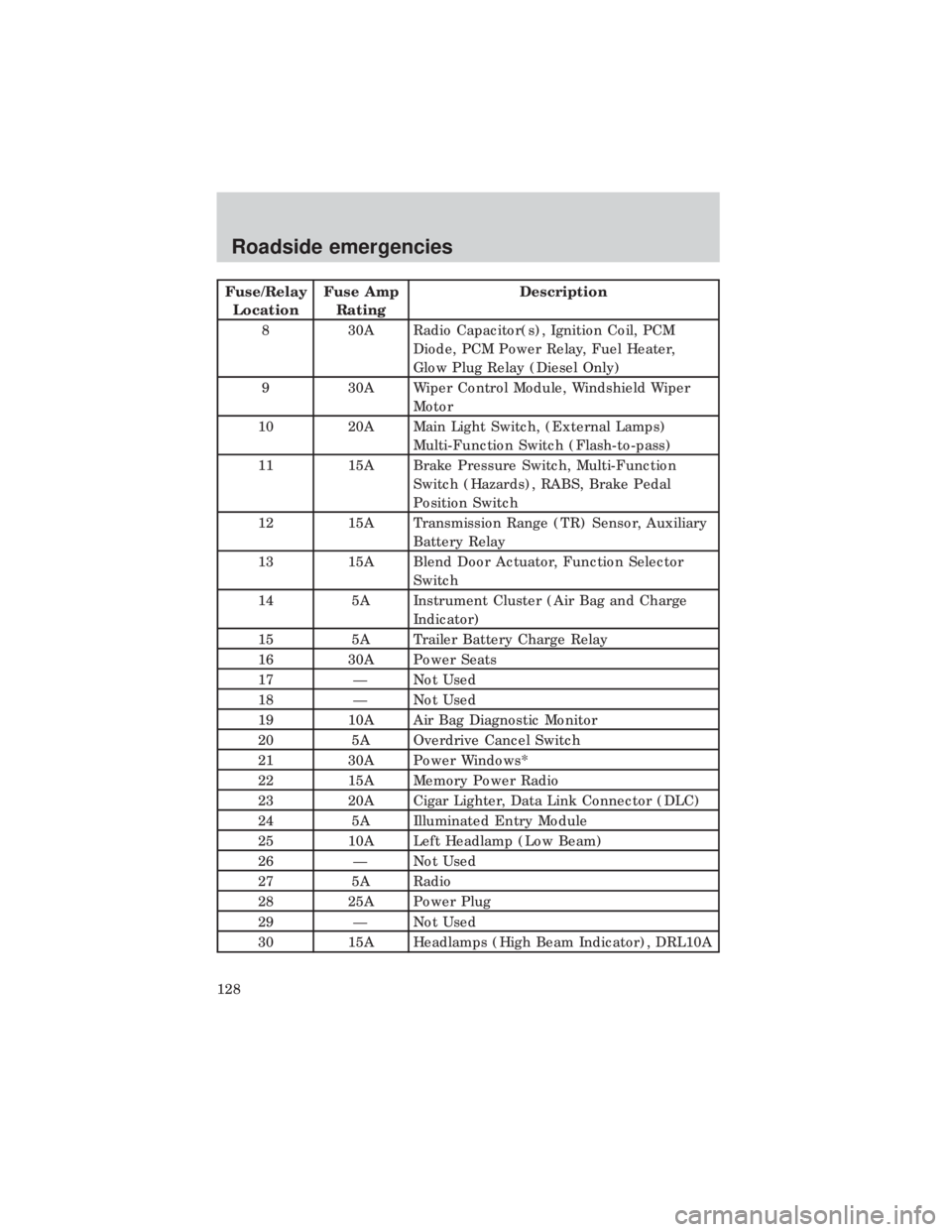

Fuse/Relay

LocationFuse Amp

RatingDescription

8 30A Radio Capacitor(s), Ignition Coil, PCM

Diode, PCM Power Relay, Fuel Heater,

Glow Plug Relay (Diesel Only)

9 30A Wiper Control Module, Windshield Wiper

Motor

10 20A Main Light Switch, (External Lamps)

Multi-Function Switch (Flash-to-pass)

11 15A Brake Pressure Switch, Multi-Function

Switch (Hazards), RABS, Brake Pedal

Position Switch

12 15A Transmission Range (TR) Sensor, Auxiliary

Battery Relay

13 15A Blend Door Actuator, Function Selector

Switch

14 5A Instrument Cluster (Air Bag and Charge

Indicator)

15 5A Trailer Battery Charge Relay

16 30A Power Seats

17 Ð Not Used

18 Ð Not Used

19 10A Air Bag Diagnostic Monitor

20 5A Overdrive Cancel Switch

21 30A Power Windows*

22 15A Memory Power Radio

23 20A Cigar Lighter, Data Link Connector (DLC)

24 5A Illuminated Entry Module

25 10A Left Headlamp (Low Beam)

26 Ð Not Used

27 5A Radio

28 25A Power Plug

29 Ð Not Used

30 15A Headlamps (High Beam Indicator), DRL10A

Roadside emergencies

128

Page 131 of 208

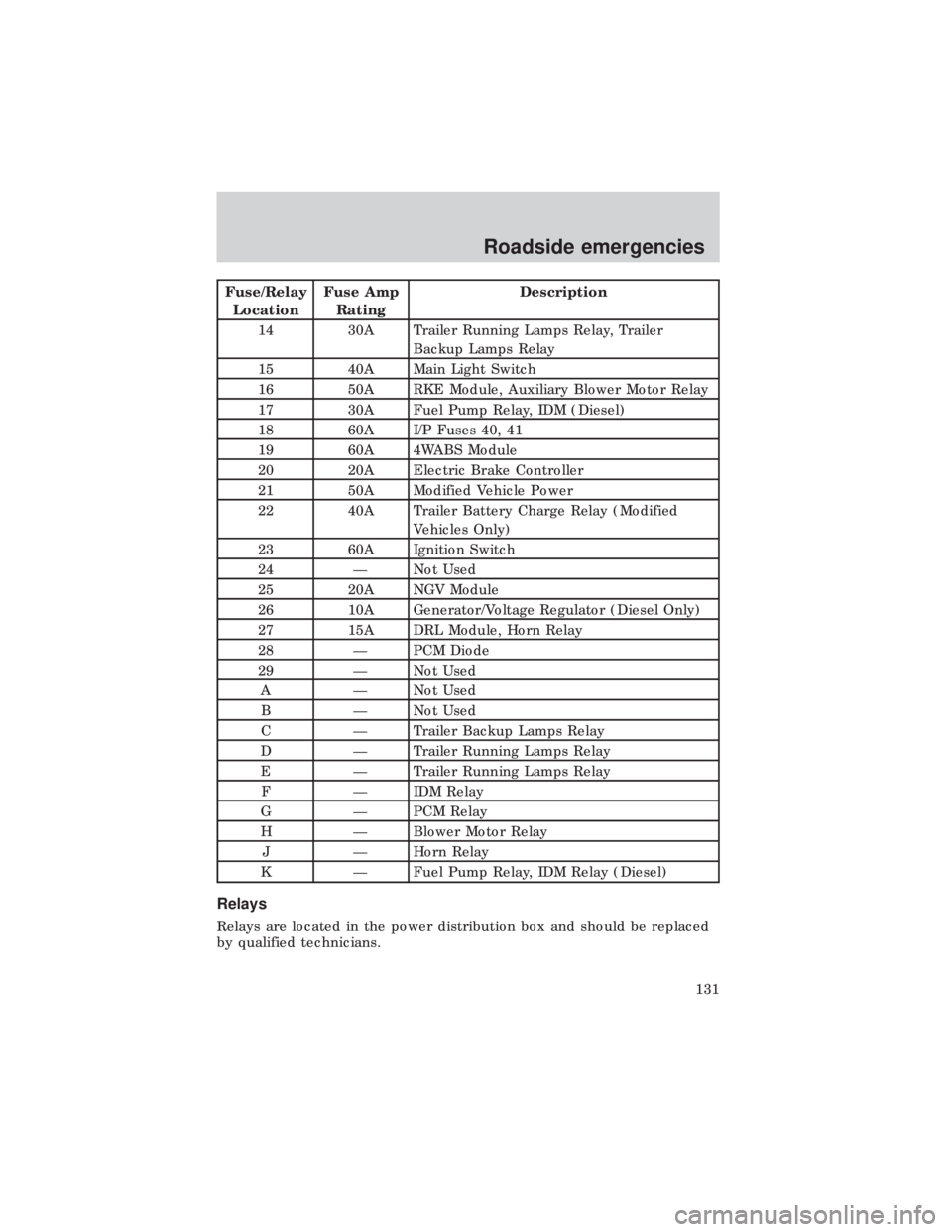

Fuse/Relay

LocationFuse Amp

RatingDescription

14 30A Trailer Running Lamps Relay, Trailer

Backup Lamps Relay

15 40A Main Light Switch

16 50A RKE Module, Auxiliary Blower Motor Relay

17 30A Fuel Pump Relay, IDM (Diesel)

18 60A I/P Fuses 40, 41

19 60A 4WABS Module

20 20A Electric Brake Controller

21 50A Modified Vehicle Power

22 40A Trailer Battery Charge Relay (Modified

Vehicles Only)

23 60A Ignition Switch

24 Ð Not Used

25 20A NGV Module

26 10A Generator/Voltage Regulator (Diesel Only)

27 15A DRL Module, Horn Relay

28 Ð PCM Diode

29 Ð Not Used

A Ð Not Used

B Ð Not Used

C Ð Trailer Backup Lamps Relay

D Ð Trailer Running Lamps Relay

E Ð Trailer Running Lamps Relay

F Ð IDM Relay

G Ð PCM Relay

H Ð Blower Motor Relay

J Ð Horn Relay

K Ð Fuel Pump Relay, IDM Relay (Diesel)

Relays

Relays are located in the power distribution box and should be replaced

by qualified technicians.

Roadside emergencies

131

Page 141 of 208

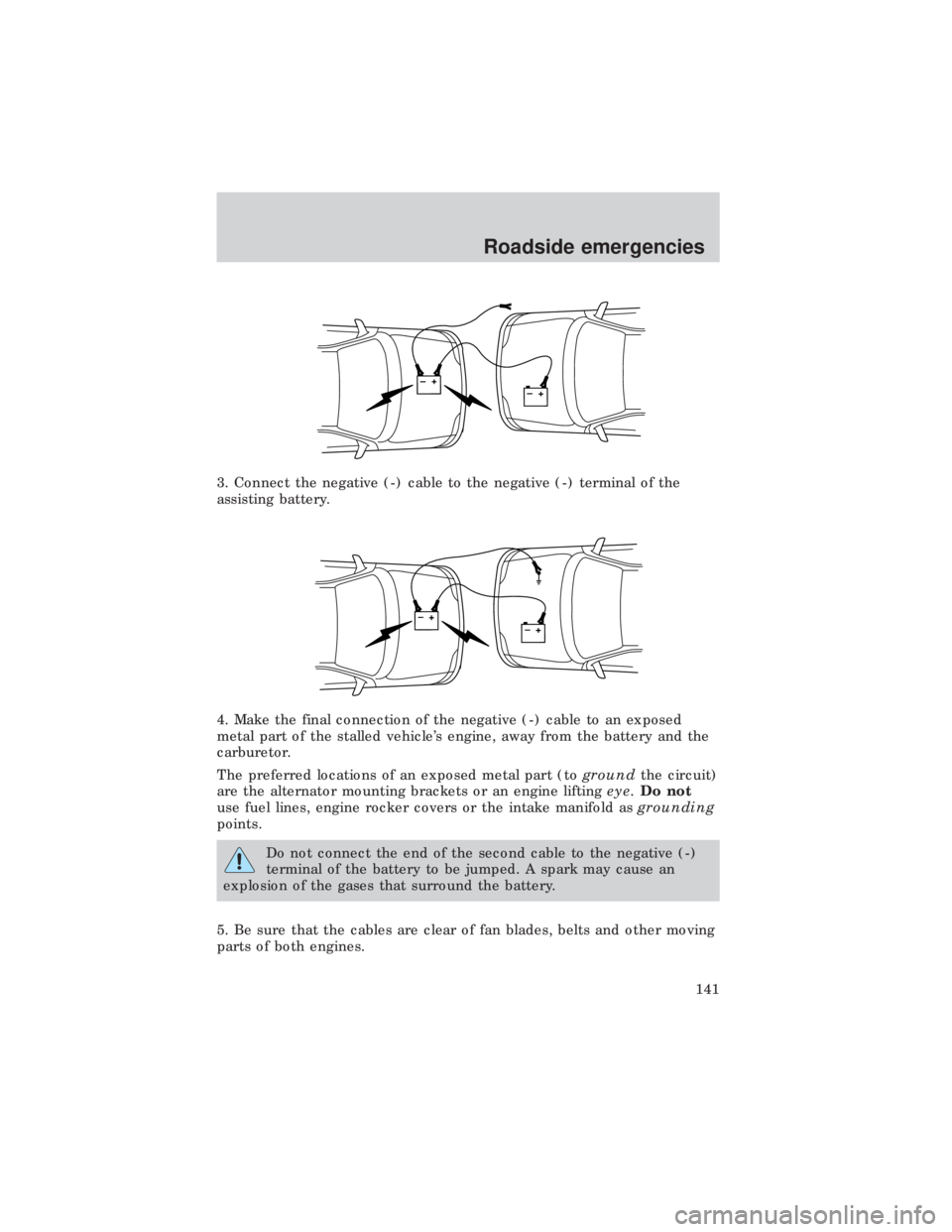

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle's engine, away from the battery and the

carburetor.

The preferred locations of an exposed metal part (togroundthe circuit)

are the alternator mounting brackets or an engine liftingeye.Do not

use fuel lines, engine rocker covers or the intake manifold asgrounding

points.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Be sure that the cables are clear of fan blades, belts and other moving

parts of both engines.

+–+–

+–+–

Roadside emergencies

141

Page 145 of 208

SERVICE RECOMMENDATIONS

To help you service your vehicle:

²We highlight do-it-yourself items in the engine compartment for easy

location.

²We provide a ªService Guideº which makes tracking routine service

easy.

If your vehicle requires professional service, your dealership can provide

necessary parts and service. Check your ªWarranty Guideº to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

²Do not work on a hot engine.

²When the engine is running, make sure that loose clothing, jewelry or

long hair does not get caught up in moving parts.

²Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

²Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must ªrelearnº its idle

conditions before your vehicle will drive properly, as explained inBattery

in this chapter.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Maintenance and care

145

Page 151 of 208

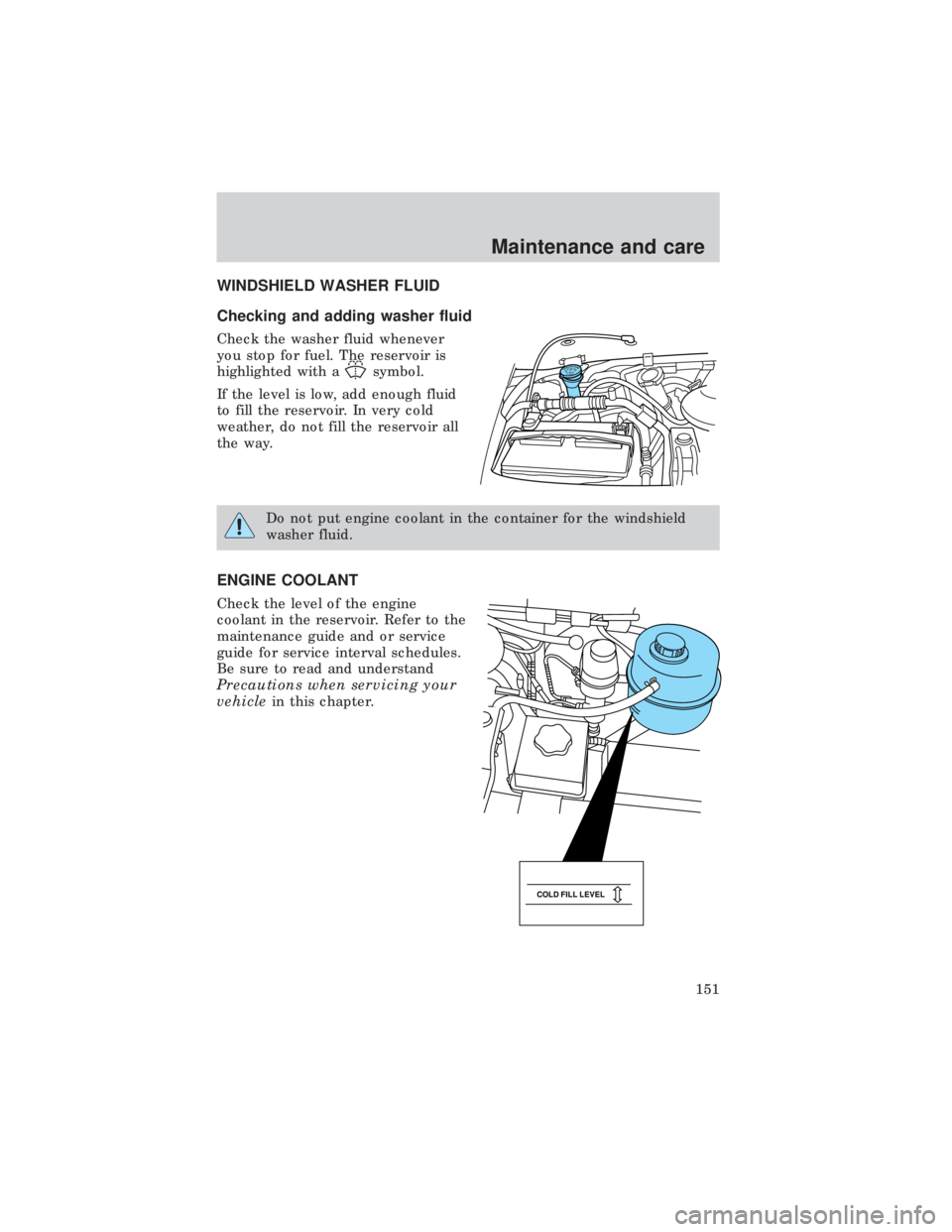

WINDSHIELD WASHER FLUID

Checking and adding washer fluid

Check the washer fluid whenever

you stop for fuel. The reservoir is

highlighted with a

symbol.

If the level is low, add enough fluid

to fill the reservoir. In very cold

weather, do not fill the reservoir all

the way.

Do not put engine coolant in the container for the windshield

washer fluid.

ENGINE COOLANT

Check the level of the engine

coolant in the reservoir. Refer to the

maintenance guide and or service

guide for service interval schedules.

Be sure to read and understand

Precautions when servicing your

vehiclein this chapter.

COLD FILL LEVEL

Maintenance and care

151

Page 160 of 208

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

When lifting a plastic-cased battery, excessive pressure on the

end walls could cause acid to flow through the vent caps,

resulting in personal injury and/or damage to the vehicle or battery.

Lift the battery with a battery carrier or with your hands on opposite

corners.

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

Because your vehicle's engine is electronically controlled by a computer,

some control conditions are maintained by power from the battery. When

the battery is disconnected or a new battery is installed, the engine must

relearn its idle and fuel trim strategy for optimum driveability and

performance. To begin this process:

1. Set your parking brake.

2. Put the gearshift in P (Park), turn off all accessories and start the

engine.

3. Let the engine idle for at least one minute.

4. The relearning process will automatically complete as you drive the

vehicle.

²The vehicle may need to be driven 16 km (10 miles) or more to

relearn the idle and fuel trim strategy.

²If you do not allow the engine to relearn its idle trim, the idle quality

of your vehicle may be adversely affected until the idle trim is

eventually relearned.

Maintenance and care

160

Page 165 of 208

WINDSHIELD WIPER BLADES

Check the wiper blades at least twice a year or when they seem less

effective. Substances such as tree sap and some hot wax treatments used

by commercial car washes reduce the effectiveness of wiper blades.

Checking the wiper blades

If the wiper blades do not wipe properly, clean both the windshield and

wiper blades using undiluted windshield wiper solution or a mild

detergent. Rinse thoroughly with clean water. To avoid damaging the

blades, do not use fuel, kerosene, paint thinner or other solvents.

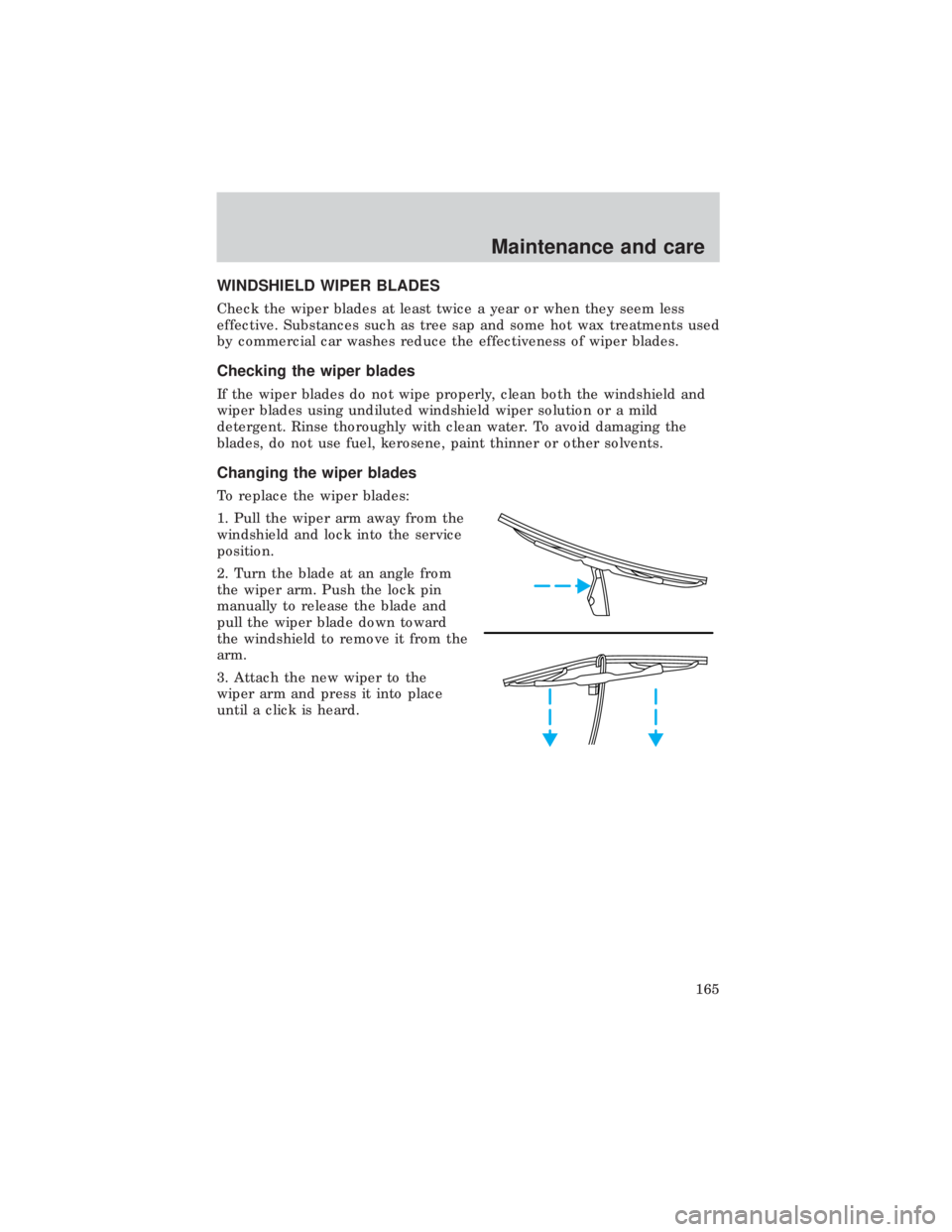

Changing the wiper blades

To replace the wiper blades:

1. Pull the wiper arm away from the

windshield and lock into the service

position.

2. Turn the blade at an angle from

the wiper arm. Push the lock pin

manually to release the blade and

pull the wiper blade down toward

the windshield to remove it from the

arm.

3. Attach the new wiper to the

wiper arm and press it into place

until a click is heard.

Maintenance and care

165