ABS FORD E150 1999 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1999, Model line: E150, Model: FORD E150 1999Pages: 208, PDF Size: 1.93 MB

Page 8 of 208

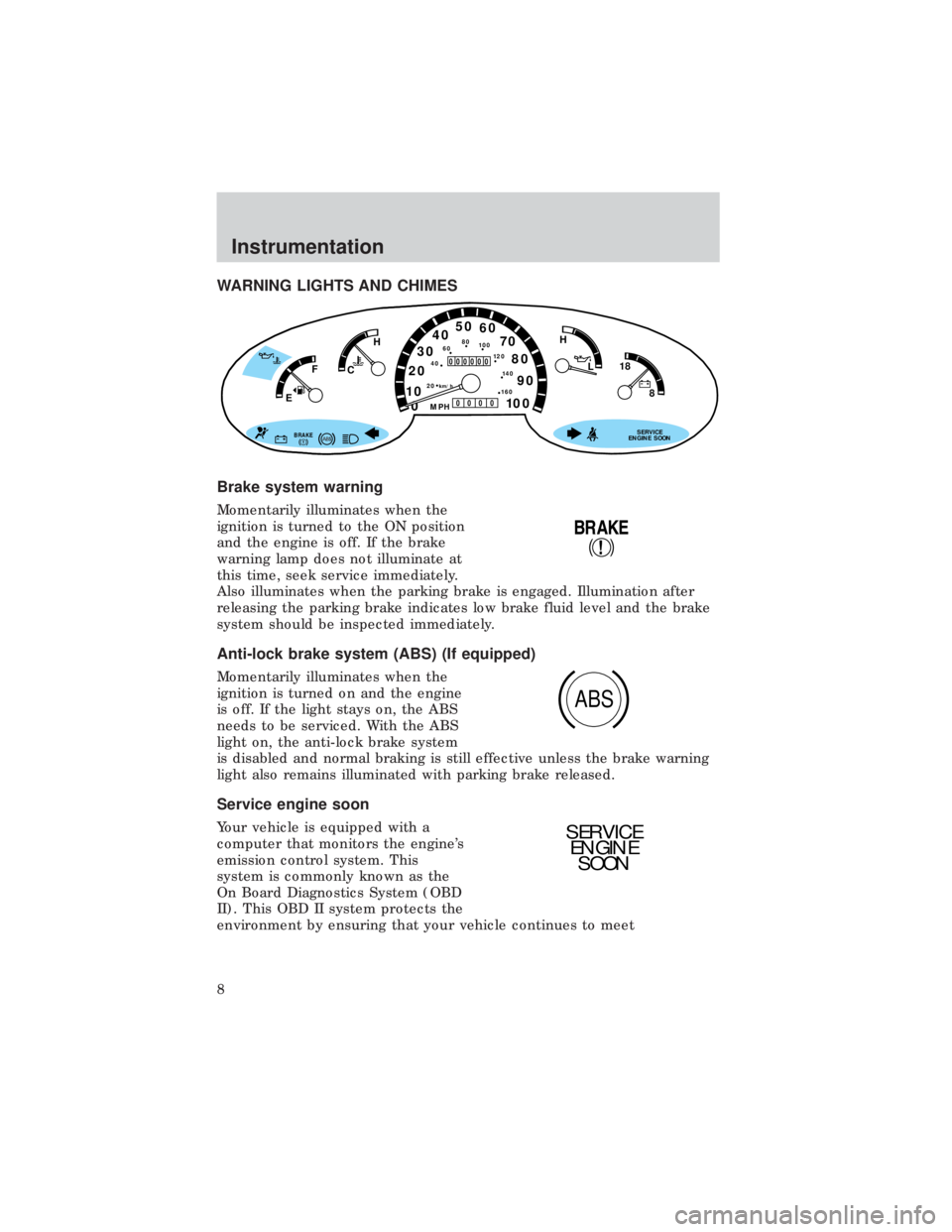

WARNING LIGHTS AND CHIMES

Brake system warning

Momentarily illuminates when the

ignition is turned to the ON position

and the engine is off. If the brake

warning lamp does not illuminate at

this time, seek service immediately.

Also illuminates when the parking brake is engaged. Illumination after

releasing the parking brake indicates low brake fluid level and the brake

system should be inspected immediately.

Anti-lock brake system (ABS) (If equipped)

Momentarily illuminates when the

ignition is turned on and the engine

is off. If the light stays on, the ABS

needs to be serviced. With the ABS

light on, the anti-lock brake system

is disabled and normal braking is still effective unless the brake warning

light also remains illuminated with parking brake released.

Service engine soon

Your vehicle is equipped with a

computer that monitors the engine's

emission control system. This

system is commonly known as the

On Board Diagnostics System (OBD

II). This OBD II system protects the

environment by ensuring that your vehicle continues to meet

0 1020304050

60

70

80

90

10 0

20 km/h

406080

10 0

12 0

14 0

H

L

16 0

MPH

000000

0000

BRAKE

18

8

SERVICE

ENGINE SOON

FH

C

E

!

BRAKE

ABS

SERVICE

ENGINE

SOON

Instrumentation

8

Page 103 of 208

BRAKES

Your service brakes are self-adjusting. Refer to the ªService Guideº for

scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Four-wheel anti-lock brake system (ABS) (if equipped)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. If the vehicle has continuous vibration or shudder

in the steering wheel while braking, the vehicle should be inspected by a

qualified service technician.

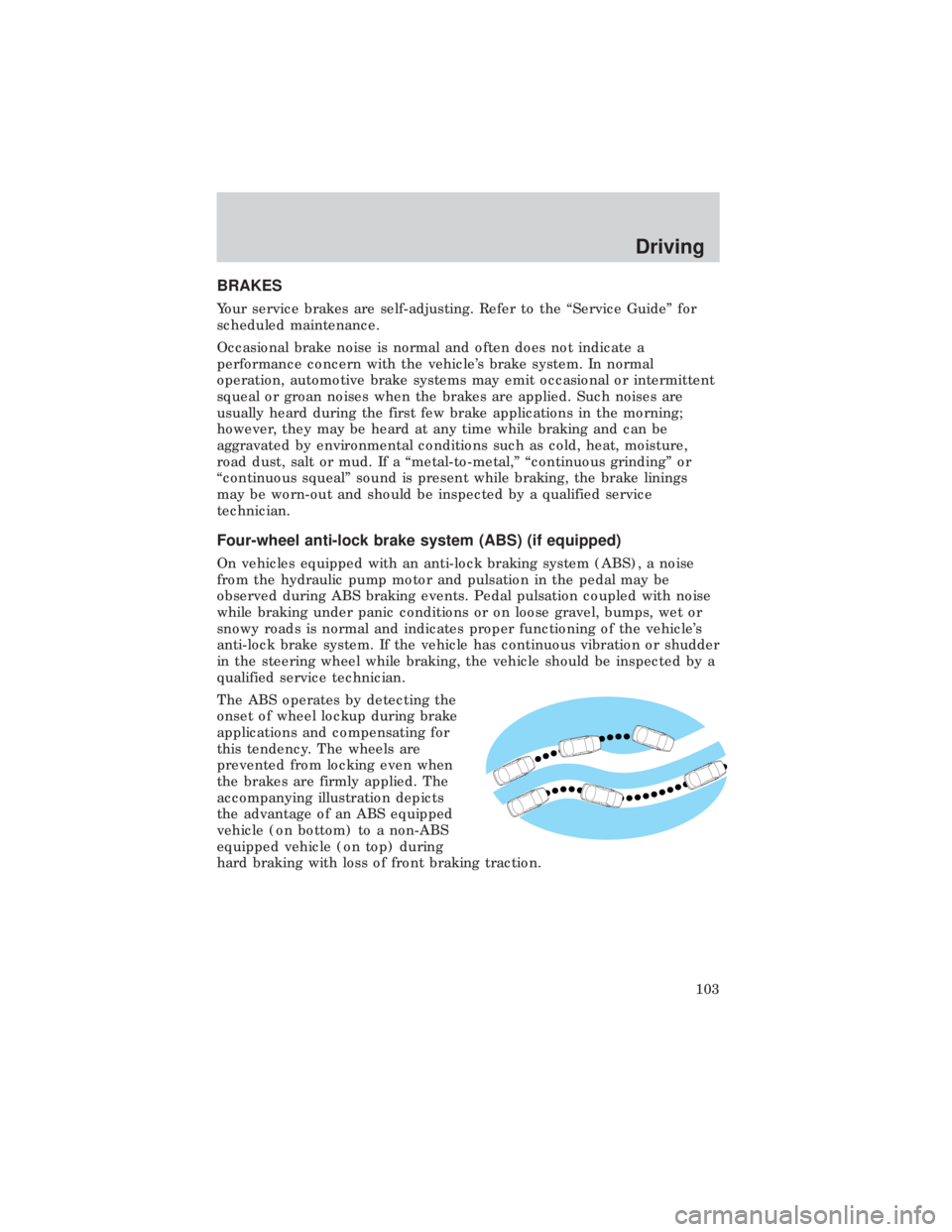

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensating for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during

hard braking with loss of front braking traction.

Driving

103

Page 104 of 208

ABS warning lamp

TheABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned on and the engine is off. If the light does not

illuminate momentarily at start up, remains on or continues to flash, the

ABS needs to be serviced.

With the ABS light on, the anti-lock

brake system is disabled and normal

braking is still effective unless the

brake warning light also remains

illuminated with parking brake

released. (If your brake warning lamp illuminates, have your vehicle

serviced immediately).

Using ABS

²In an emergency or when maximum efficiency from the ABS is

required, apply continuous full force on the brake. The ABS will be

activated immediately, thus allowing you to retain full steering control

of your vehicle and, providing there is sufficient space, will enable you

to avoid obstacles and bring the vehicle to a controlled stop.

²The Anti-Lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

Rear anti-lock brake system (RABS) (if equipped)

Rear Anti-lock Brake System (RABS) is designed to help you maintain

directional stability in emergency stopping situations. With RABS, the

rear brakes are kept from locking during panic stops; however, the front

wheels can lock because they are not controlled by RABS.

A clicking noise and slight pedal pulsation during RABS braking events

indicates the RABS is functioning. Pedal pulsation coupled with clicking

noise while braking under panic conditions on loose gravel, wet or snowy

roads is normal and indicates proper functioning of the vehicle's RABS. If

the vehicle has continuous vibration or shudder in the steering wheel

while braking, the vehicle should be inspected by a qualified service

technician.

The RABS operates by detecting the onset of rear wheel lockup during

brake applications and compensating for this tendency.

!

BRAKE

Driving

104

Page 105 of 208

RABS warning lamp

TheABSwarning lamp in the instrument cluster illuminates if a RABS

fault is detected. Have your vehicle serviced as soon as possible.

Normal braking is still effective

unless the BRAKE warning lamp is

also illuminated.

Using RABS

²In an emergency, applying full pressure may cause the front wheels to

lock.If the front brakes lock, the vehicle cannot be steered.Yo u

should apply the brakes with steadily increasing force, as if

ªsqueezingº the brakes. If you feel the front wheels begin to lock,

momentarily release the pedal and repeat the ªsqueezeº technique.

²We recommend that you familiarize yourself with how the RABS

performs. However, avoid unnecessary risks.

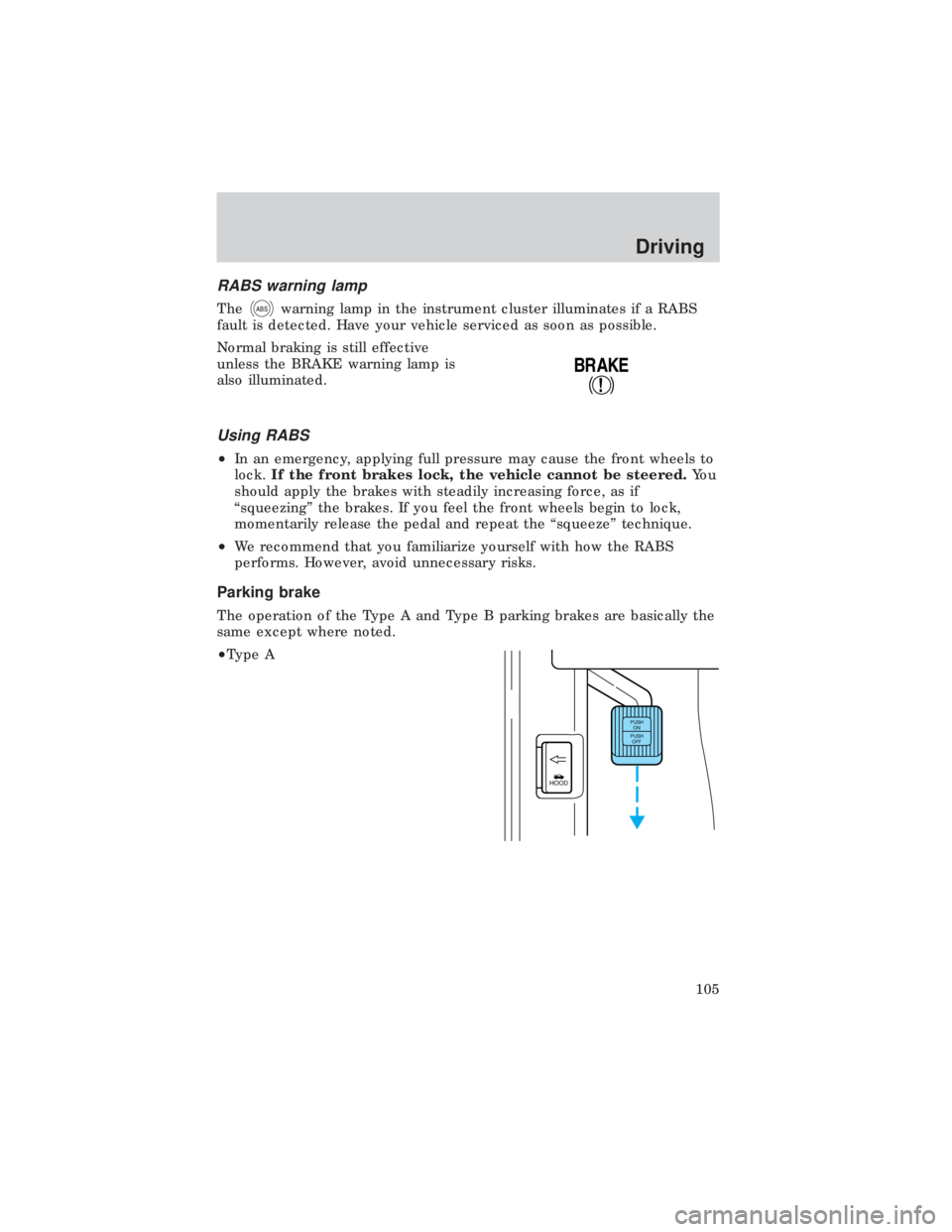

Parking brake

The operation of the Type A and Type B parking brakes are basically the

same except where noted.

²Type A

!

BRAKE

HOOD

PUSH

ON

PUSH

OFF

Driving

105

Page 127 of 208

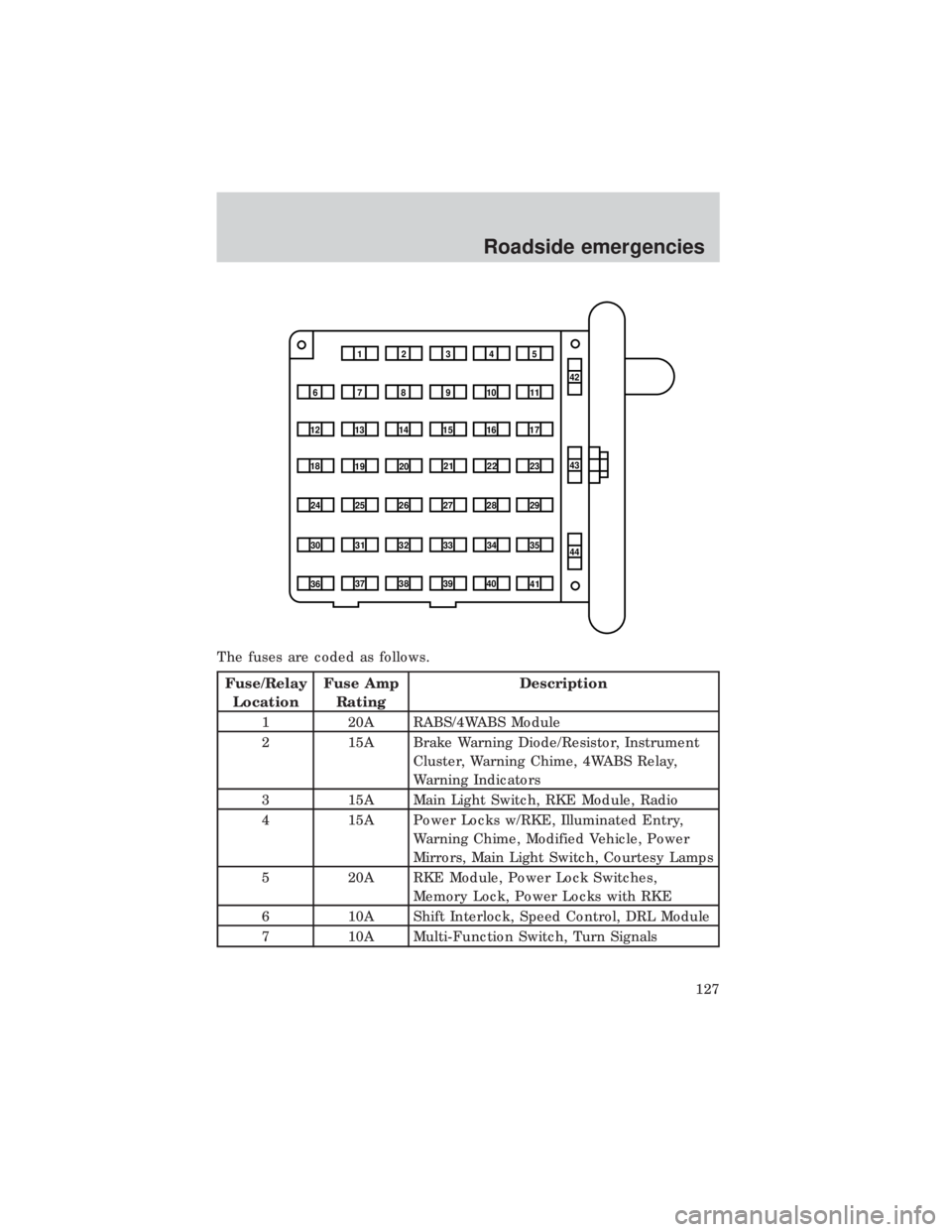

The fuses are coded as follows.

Fuse/Relay

LocationFuse Amp

RatingDescription

1 20A RABS/4WABS Module

2 15A Brake Warning Diode/Resistor, Instrument

Cluster, Warning Chime, 4WABS Relay,

Warning Indicators

3 15A Main Light Switch, RKE Module, Radio

4 15A Power Locks w/RKE, Illuminated Entry,

Warning Chime, Modified Vehicle, Power

Mirrors, Main Light Switch, Courtesy Lamps

5 20A RKE Module, Power Lock Switches,

Memory Lock, Power Locks with RKE

6 10A Shift Interlock, Speed Control, DRL Module

7 10A Multi-Function Switch, Turn Signals

1234

5

7

689101142

43

44 13 12 14

15 16 17

19 18

2021 22 23

25 24

26 27 28 29

31 30 32 33 3435

37

3638 3940

41

Roadside emergencies

127

Page 128 of 208

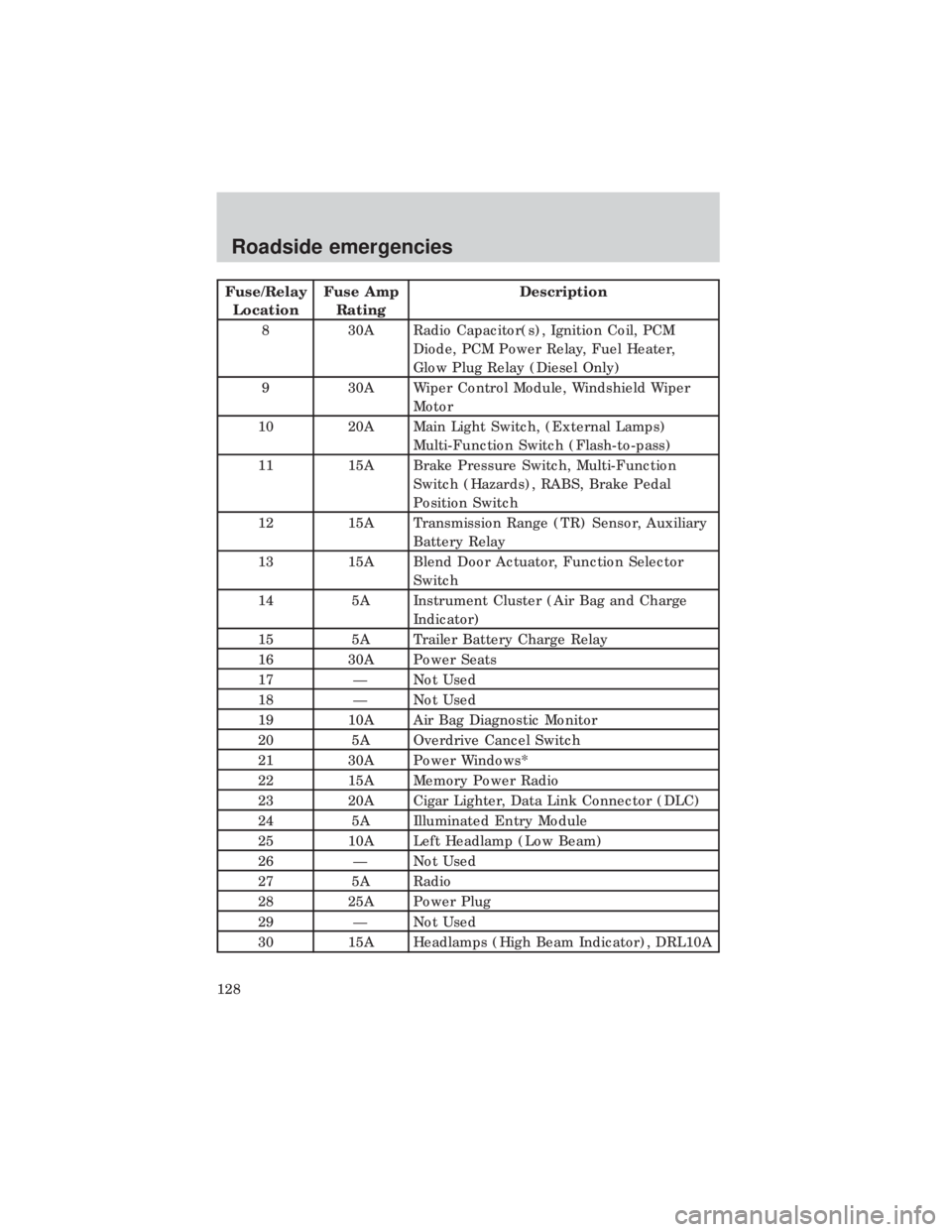

Fuse/Relay

LocationFuse Amp

RatingDescription

8 30A Radio Capacitor(s), Ignition Coil, PCM

Diode, PCM Power Relay, Fuel Heater,

Glow Plug Relay (Diesel Only)

9 30A Wiper Control Module, Windshield Wiper

Motor

10 20A Main Light Switch, (External Lamps)

Multi-Function Switch (Flash-to-pass)

11 15A Brake Pressure Switch, Multi-Function

Switch (Hazards), RABS, Brake Pedal

Position Switch

12 15A Transmission Range (TR) Sensor, Auxiliary

Battery Relay

13 15A Blend Door Actuator, Function Selector

Switch

14 5A Instrument Cluster (Air Bag and Charge

Indicator)

15 5A Trailer Battery Charge Relay

16 30A Power Seats

17 Ð Not Used

18 Ð Not Used

19 10A Air Bag Diagnostic Monitor

20 5A Overdrive Cancel Switch

21 30A Power Windows*

22 15A Memory Power Radio

23 20A Cigar Lighter, Data Link Connector (DLC)

24 5A Illuminated Entry Module

25 10A Left Headlamp (Low Beam)

26 Ð Not Used

27 5A Radio

28 25A Power Plug

29 Ð Not Used

30 15A Headlamps (High Beam Indicator), DRL10A

Roadside emergencies

128

Page 131 of 208

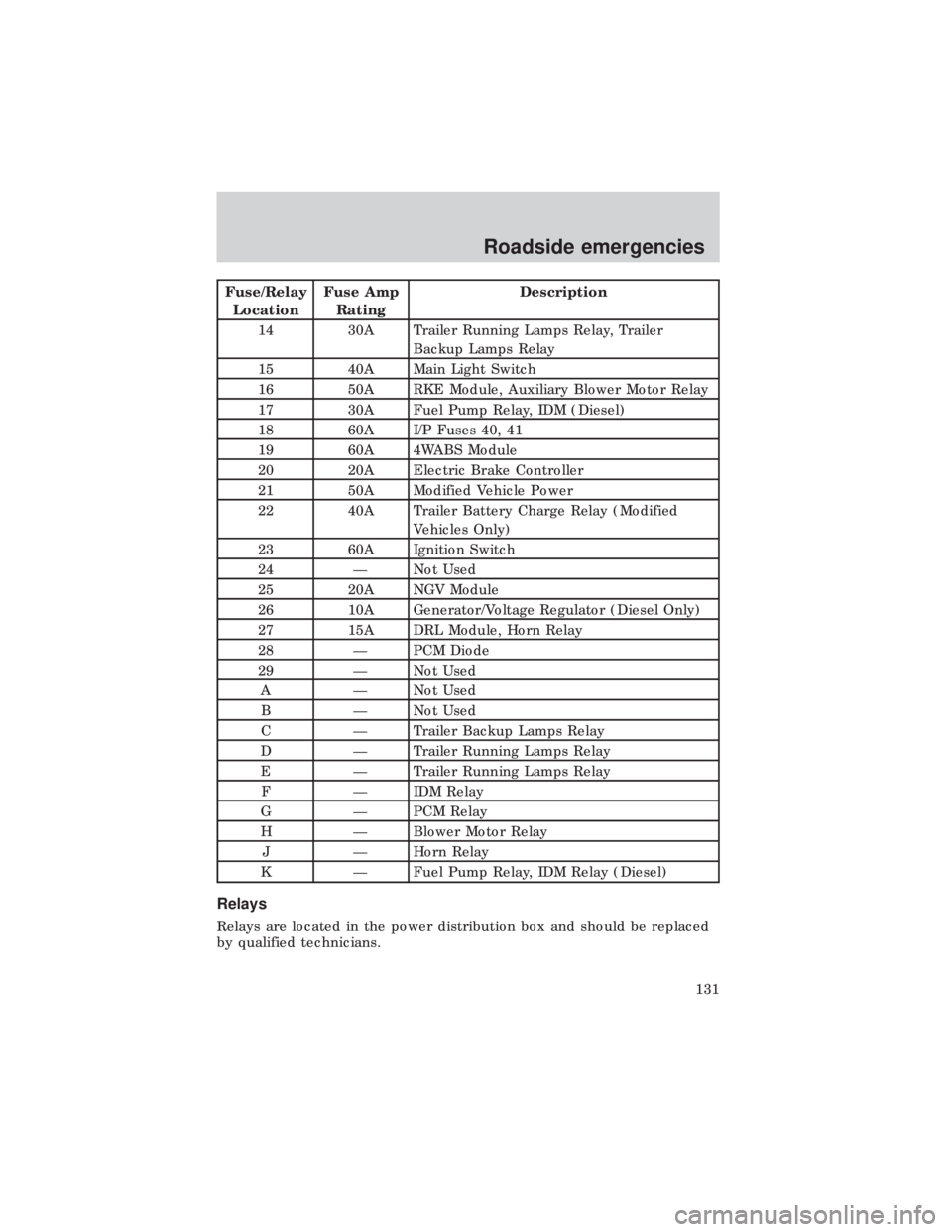

Fuse/Relay

LocationFuse Amp

RatingDescription

14 30A Trailer Running Lamps Relay, Trailer

Backup Lamps Relay

15 40A Main Light Switch

16 50A RKE Module, Auxiliary Blower Motor Relay

17 30A Fuel Pump Relay, IDM (Diesel)

18 60A I/P Fuses 40, 41

19 60A 4WABS Module

20 20A Electric Brake Controller

21 50A Modified Vehicle Power

22 40A Trailer Battery Charge Relay (Modified

Vehicles Only)

23 60A Ignition Switch

24 Ð Not Used

25 20A NGV Module

26 10A Generator/Voltage Regulator (Diesel Only)

27 15A DRL Module, Horn Relay

28 Ð PCM Diode

29 Ð Not Used

A Ð Not Used

B Ð Not Used

C Ð Trailer Backup Lamps Relay

D Ð Trailer Running Lamps Relay

E Ð Trailer Running Lamps Relay

F Ð IDM Relay

G Ð PCM Relay

H Ð Blower Motor Relay

J Ð Horn Relay

K Ð Fuel Pump Relay, IDM Relay (Diesel)

Relays

Relays are located in the power distribution box and should be replaced

by qualified technicians.

Roadside emergencies

131

Page 171 of 208

²Avoid inhaling fuel vapors. Inhaling too much fuel vapor of any kind

can lead to eye and respiratory tract irritation. In severe cases,

excessive or prolonged breathing of fuel vapor can cause serious

illness and permanent injury.

²Avoid getting fuel liquid in your eyes. If fuel is splashed in the eyes,

remove contact lenses (if worn), flush with water for 15 minutes and

seek medical attention. Failure to seek proper medical attention could

lead to permanent injury.

²Fuels can also be harmful if absorbed through the skin. If fuel is

splashed on the skin and/or clothing, promptly remove contaminated

clothing and wash skin thoroughly with soap and water. Repeated or

prolonged skin contact with fuel liquid or vapor causes skin irritation.

²Be particularly careful if you are taking ªAntabuseº or other forms of

disulfiram for the treatment of alcoholism. Breathing gasoline vapors,

or skin contact could cause an adverse reaction. In sensitive

individuals, serious personal injury or sickness may result. If fuel is

splashed on the skin, promptly wash skin thoroughly with soap and

water. Consult a physician immediately if you experience an adverse

reaction.

Choosing the right fuel

Use only UNLEADED FUEL. The use of leaded fuel is prohibited by law

and could damage your vehicle.

Do not use gasolines containing methanol. It can damage critical fuel

systems components.

Vehicles certified to meet California emission standards (indicated on the

underhood Vehicle Emissions Control Information label) are designed to

operate on California cleaner-burning, low-sulfur gasolines. If you have a

California-certified vehicle and California cleanerÐburning gasoline is not

available when you refuel, your engine should perform adequately.

However, the performance of the emission control devices and systems

may be adversely affected. In New York and Massachusetts, which have

adopted California's emission standards without requiring the sale of

California cleaner-burning gasoline, repairs to correct the effects of using

non-California fuel may not be covered by the emissions warranty.

Your vehicle was not designed to use fuel or fuel additives with metallic

compounds, including manganese-based compounds containing (MMT).

Repairs to correct the effects of using a fuel for which your vehicle was

not designed may not be covered by your warranty.

Maintenance and care

171

Page 173 of 208

²Your ªService Engine Soonº light may come on. For more information

on the ªService Engine Soonº light, refer to theInstrumentation

chapter.

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a one-eighth turn

on/off feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8 of a turn until it

stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it stops.

If the ªService Engine Soon/Check Engine ª indicator comes on and stays

on when you start the engine, the fuel filler cap may not be properly

installed. Turn off the engine, remove the fuel filler cap and reinstall it

being careful to align the cap properly.

If you must replace the fuel filler cap, replace it with a genuine

Ford or Motorcraft part. The customer warranty may be void for

any damage to the fuel tank or fuel system if a genuine Ford or

Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If the fuel filler cap is

venting vapor or if you hear a hissing sound, wait until it stops

before completely removing the fuel filler cap. Otherwise, fuel may

spray out and injure you or others.

If you do not use the proper fuel filler cap, the pressure in the

fuel tank can damage the fuel system or cause it to work

improperly in a collision.

Maintenance and care

173

Page 181 of 208

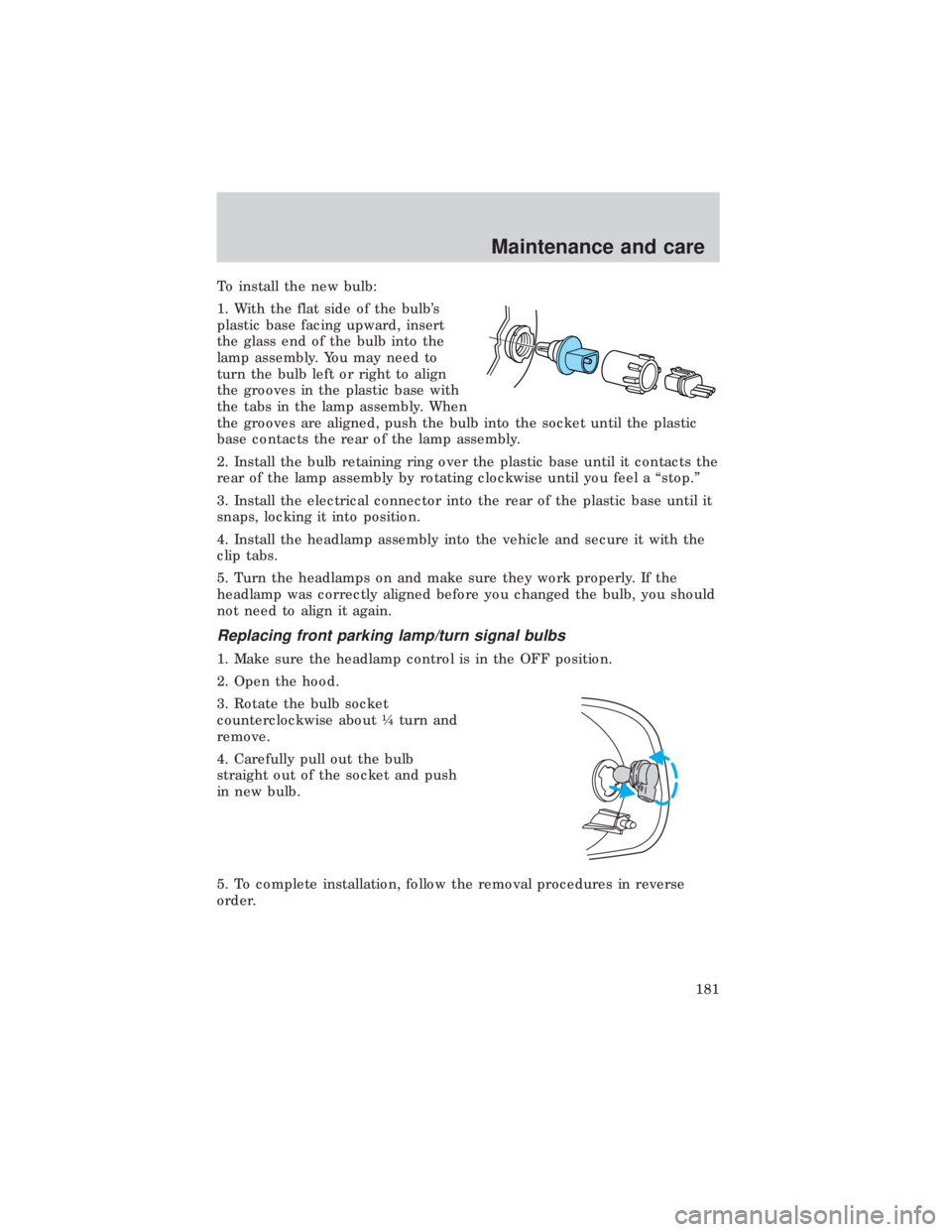

To install the new bulb:

1. With the flat side of the bulb's

plastic base facing upward, insert

the glass end of the bulb into the

lamp assembly. You may need to

turn the bulb left or right to align

the grooves in the plastic base with

the tabs in the lamp assembly. When

the grooves are aligned, push the bulb into the socket until the plastic

base contacts the rear of the lamp assembly.

2. Install the bulb retaining ring over the plastic base until it contacts the

rear of the lamp assembly by rotating clockwise until you feel a ªstop.º

3. Install the electrical connector into the rear of the plastic base until it

snaps, locking it into position.

4. Install the headlamp assembly into the vehicle and secure it with the

clip tabs.

5. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Replacing front parking lamp/turn signal bulbs

1. Make sure the headlamp control is in the OFF position.

2. Open the hood.

3. Rotate the bulb socket

counterclockwise about ò turn and

remove.

4. Carefully pull out the bulb

straight out of the socket and push

in new bulb.

5. To complete installation, follow the removal procedures in reverse

order.

Maintenance and care

181