flat tire FORD E150 2010 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2010, Model line: E150, Model: FORD E150 2010Pages: 327, PDF Size: 2.43 MB

Page 156 of 327

In either case, the pressure sensor is covered by the tire and is

not visible unless the tire is removed. Care must be taken when

changing the tire to avoid damaging the sensor.It is recommended

that you always have your tires serviced by an authorized dealer.

The tire pressure should be checked periodically (at least monthly) using

an accurate tire gauge, refer toInflating your tiresin this chapter.

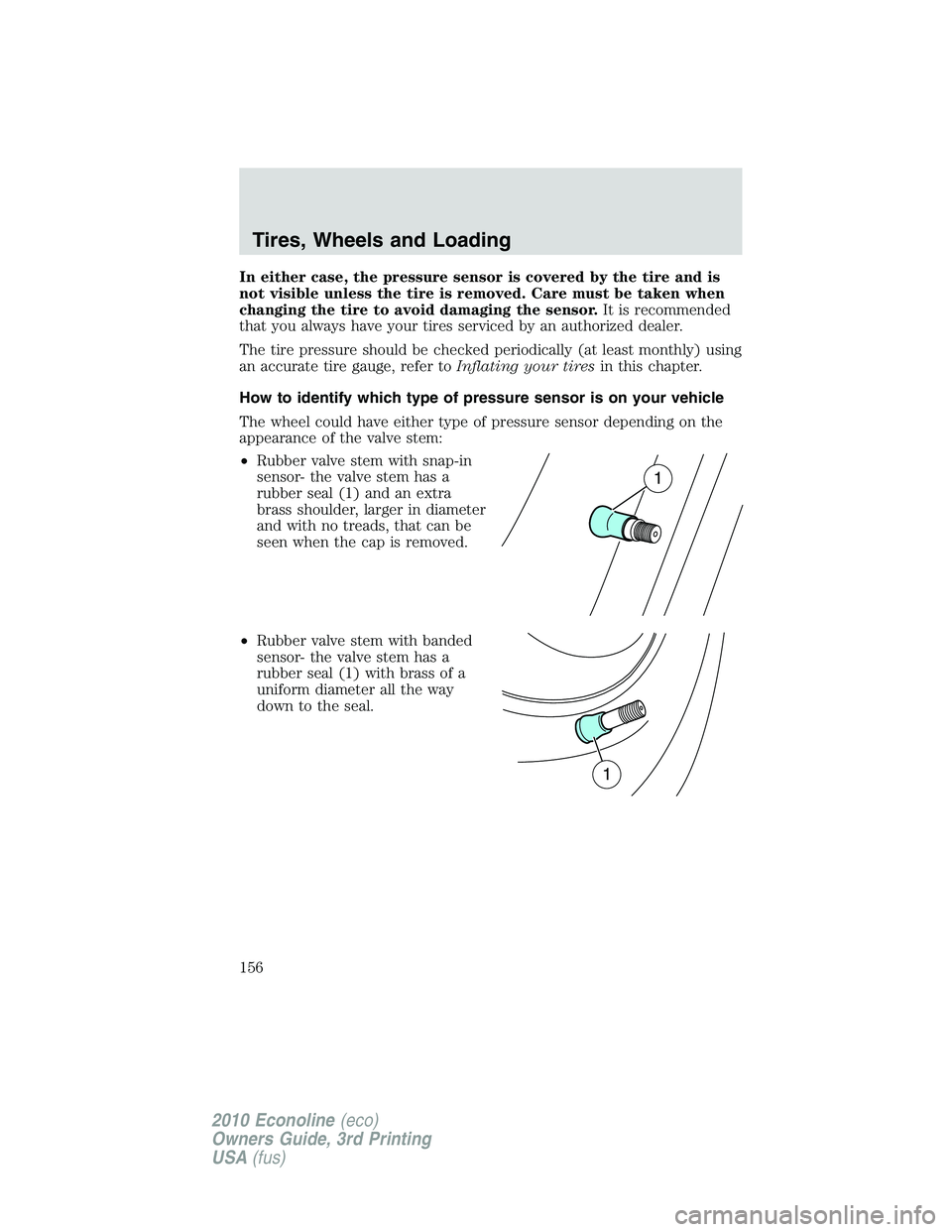

How to identify which type of pressure sensor is on your vehicle

The wheel could have either type of pressure sensor depending on the

appearance of the valve stem:

•Rubber valve stem with snap-in

sensor- the valve stem has a

rubber seal (1) and an extra

brass shoulder, larger in diameter

and with no treads, that can be

seen when the cap is removed.

•Rubber valve stem with banded

sensor- the valve stem has a

rubber seal (1) with brass of a

uniform diameter all the way

down to the seal.

1

1

Tires, Wheels and Loading

156

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 157 of 327

•Metal valve stem with banded

sensor- the valve stem is

completely metal.

Understanding your tire pressure monitoring system (TPMS)

The tire pressure monitoring system measures pressure in your four road

tires and sends the tire pressure readings to your vehicle. The low tire

pressure warning lamp will turn on if the tire pressure is significantly

low. Once the light is illuminated, your tires are under inflated and need

to be inflated to the manufacturer’s recommended tire pressure. Even if

the light turns on and a short time later turns off, your tire pressure still

needs to be checked. Visit www.checkmytires.org for additional

information.

When your temporary spare tire is installed

When one of your road tires needs to be replaced with the temporary

spare, the TPMS system will continue to identify an issue to remind you

that the damaged road wheel/tire needs to be repaired and put back on

your vehicle.

To restore the full functionality of the tire pressure monitoring system,

have the damaged road wheel/tire repaired and remounted on your

vehicle. For additional information, refer toChanging tires with TPMS

in this section.

Tires, Wheels and Loading

157

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 158 of 327

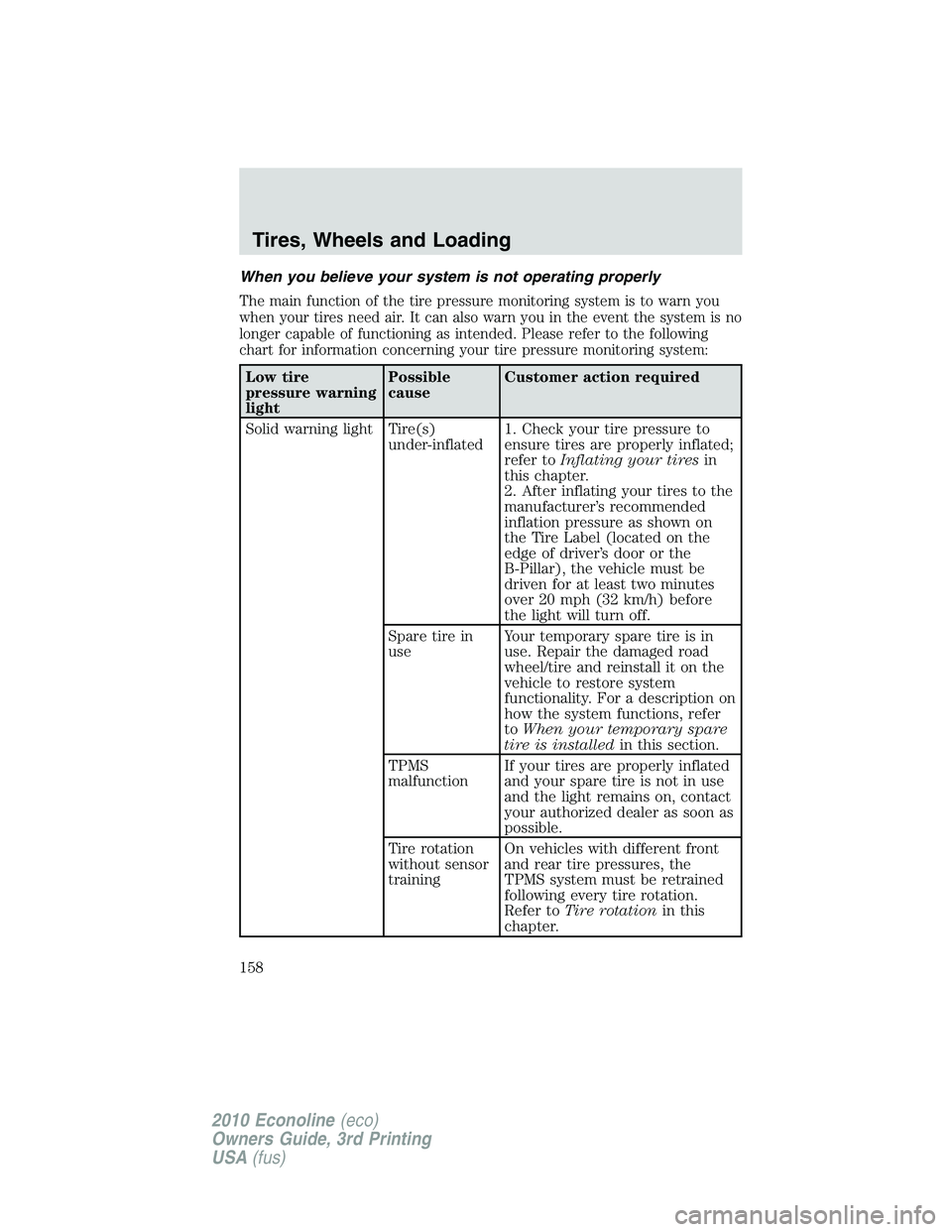

When you believe your system is not operating properly

The main function of the tire pressure monitoring system is to warn you

when your tires need air. It can also warn you in the event the system is no

longer capable of functioning as intended. Please refer to the following

chart for information concerning your tire pressure monitoring system:

Low tire

pressure warning

lightPossible

causeCustomer action required

Solid warning light Tire(s)

under-inflated1. Check your tire pressure to

ensure tires are properly inflated;

refer toInflating your tiresin

this chapter.

2. After inflating your tires to the

manufacturer’s recommended

inflation pressure as shown on

the Tire Label (located on the

edge of driver’s door or the

B-Pillar), the vehicle must be

driven for at least two minutes

over 20 mph (32 km/h) before

the light will turn off.

Spare tire in

useYour temporary spare tire is in

use. Repair the damaged road

wheel/tire and reinstall it on the

vehicle to restore system

functionality. For a description on

how the system functions, refer

toWhen your temporary spare

tire is installedin this section.

TPMS

malfunctionIf your tires are properly inflated

and your spare tire is not in use

and the light remains on, contact

your authorized dealer as soon as

possible.

Tire rotation

without sensor

trainingOn vehicles with different front

and rear tire pressures, the

TPMS system must be retrained

following every tire rotation.

Refer toTire rotationin this

chapter.

Tires, Wheels and Loading

158

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 159 of 327

Low tire

pressure warning

lightPossible

causeCustomer action required

Flashing warning

lightSpare tire in

useYour temporary spare tire is in

use. Repair the damaged road

wheel and re-mount it on the

vehicle to restore system

functionality. For a description of

how the system functions under

these conditions, refer toWhen

your temporary spare tire is

installedin this section.

TPMS

malfunctionIf your tires are properly inflated

and your spare tire is not in use

and the TPMS warning light still

flashes, contact your authorized

dealer as soon as possible.

When inflating your tires

When putting air into your tires (such as at a gas station or in your

garage), the tire pressure monitoring system may not respond

immediately to the air added to your tires.

It may take up to two minutes of driving over 20 mph (32 km/h) for the

light to turn off after you have filled your tires to the recommended

inflation pressure.

How temperature affects your tire pressure

The tire pressure monitoring system (TPMS) monitors tire pressure in

each pneumatic tire. While driving in a normal manner, a typical

passenger tire inflation pressure may increase approximately 2 to 4 psi

(14 to 28 kPa) from a cold start situation. If the vehicle is stationary

over night with the outside temperature significantly lower than the

daytime temperature, the tire pressure may decrease approximately 3 psi

(21 kPa) for a drop of 30°F (17°C) in ambient temperature. This lower

pressure value may be detected by the TPMS as being significantly lower

than the recommended inflation pressure and activate the TPMS warning

for low tire pressure. If the low tire pressure warning light is on, visually

check each tire to verify that no tire is flat. If one or more tires are flat,

repair as necessary. Check air pressure in the road tires. If any tire is

under-inflated, carefully drive the vehicle to the nearest location where

air can be added to the tires. Inflate all the tires to the recommended

inflation pressure.

Tires, Wheels and Loading

159

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 206 of 327

STEERING

To help prevent damage to the power steering system:

•Never hold the steering wheel at its furthest turning points (until it

stops) for more than a few seconds when the engine is running.

•Do not operate the vehicle with a low power steering pump fluid level

(If the fluid level is below the FULL COLD range on the dipstick).

•Some noise is normal during operation. If the noise is excessive, check

for low power steering pump fluid level before seeking service by your

authorized dealer.

•Heavy or uneven steering efforts may be caused by low power steering

pump fluid level. Check for low power steering pump fluid level before

seeking service by your authorized dealer.

•Do not fill the power steering pump reservoir above the FULL COLD

range on the dipstick, as this may result in leaks from the reservoir.

If the power steering system breaks down (or if the engine is turned

off), you can steer the vehicle manually, but it takes more effort.

If the steering wanders or pulls, check for:

•an improperly inflated tire.

•uneven tire wear.

•loose or worn suspension components.

•loose or worn steering components.

•improper steering alignment.

A high crown in the road or high crosswinds may also make the steering

seem to wander/pull.

TRACTION-LOK AXLE (IF EQUIPPED)

This axle provides added traction on slippery surfaces, particularly when

one wheel is on a poor traction surface. Under normal conditions, the

traction-lok axle functions like a standard rear axle. The axle may exhibit

a slight noise or vibration in tight turns with low vehicle speed. This is

normal behavior and indicates the axle is working.

Driving

206

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 225 of 327

ROADSIDE ASSISTANCE

Getting roadside assistance

To fully assist you should you have a vehicle concern, Ford Motor

Company offers a complimentary roadside assistance program. This

program is separate from the New Vehicle Limited Warranty. The service

is available:

•24–hours, seven days a week

•for the coverage period listed on the Roadside Assistance Card

included in your Owner Guide portfolio.

Roadside assistance will cover:

•a flat tire change with a good spare, if provided with the vehicle

(except vehicles that have been supplied with a tire inflation kit)

•battery jump start

•lock-out assistance (key replacement cost is the customer’s

responsibility)

•fuel delivery – Independent Service Contractors, if not prohibited by

state, local or municipal law shall deliver up to 2.0 gallons (7.5L) of

gasoline or 5.0 gallons (18.9L) of diesel fuel to a disabled vehicle. Fuel

delivery service is limited to two no-charge occurrences within a

12-month period.

•winch out – available within 100 feet (30.5 meters) of a paved or

county maintained road, no recoveries.

•towing – Ford/Mercury/Lincoln eligible vehicle towed to an authorized

dealer within 35 miles (56 km) of the disablement location or to the

nearest authorized dealer. If a member requests to be towed to an

authorized dealer more than 35 miles (56 km) from the disablement

location, the member shall be responsible for any mileage costs in

excess of 35 miles (56 km).

Trailers shall be covered up to $200 if the disabled eligible vehicle

requires service at the nearest authorized dealer. If the trailer is disabled,

but the towing vehicle is operational, the trailer does not qualify for any

roadside services.

Canadian customers refer to your Customer Information Guide

for information on:

•coverage period

•exact fuel amounts

Roadside Emergencies

225

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 237 of 327

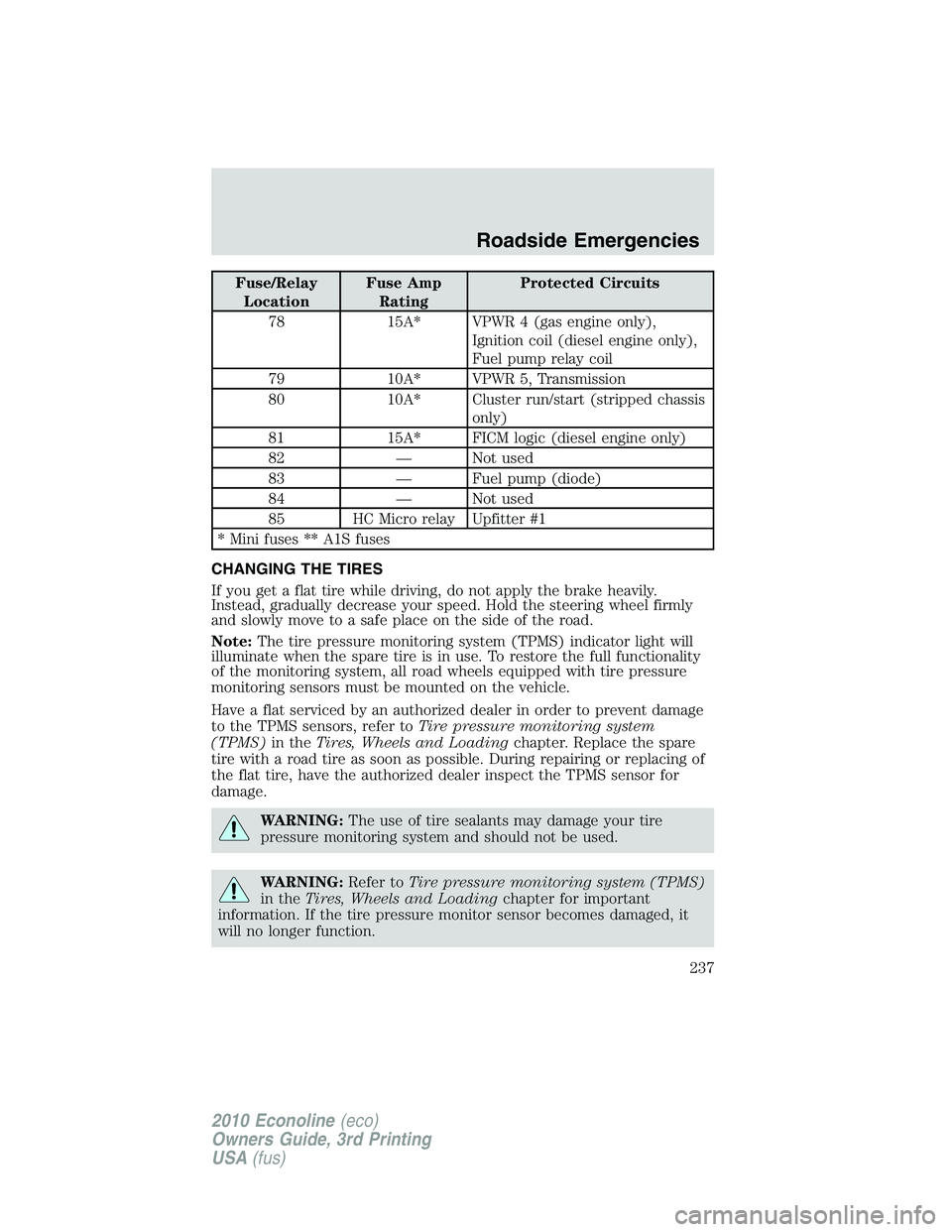

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

78 15A* VPWR 4 (gas engine only),

Ignition coil (diesel engine only),

Fuel pump relay coil

79 10A* VPWR 5, Transmission

80 10A* Cluster run/start (stripped chassis

only)

81 15A* FICM logic (diesel engine only)

82 — Not used

83 — Fuel pump (diode)

84 — Not used

85 HC Micro relay Upfitter #1

* Mini fuses ** A1S fuses

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Note:The tire pressure monitoring system (TPMS) indicator light will

illuminate when the spare tire is in use. To restore the full functionality

of the monitoring system, all road wheels equipped with tire pressure

monitoring sensors must be mounted on the vehicle.

Have a flat serviced by an authorized dealer in order to prevent damage

to the TPMS sensors, refer toTire pressure monitoring system

(TPMS)in theTires, Wheels and Loadingchapter. Replace the spare

tire with a road tire as soon as possible. During repairing or replacing of

the flat tire, have the authorized dealer inspect the TPMS sensor for

damage.

WARNING:The use of tire sealants may damage your tire

pressure monitoring system and should not be used.

WARNING:Refer toTire pressure monitoring system (TPMS)

in theTires, Wheels and Loadingchapter for important

information. If the tire pressure monitor sensor becomes damaged, it

will no longer function.

Roadside Emergencies

237

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 244 of 327

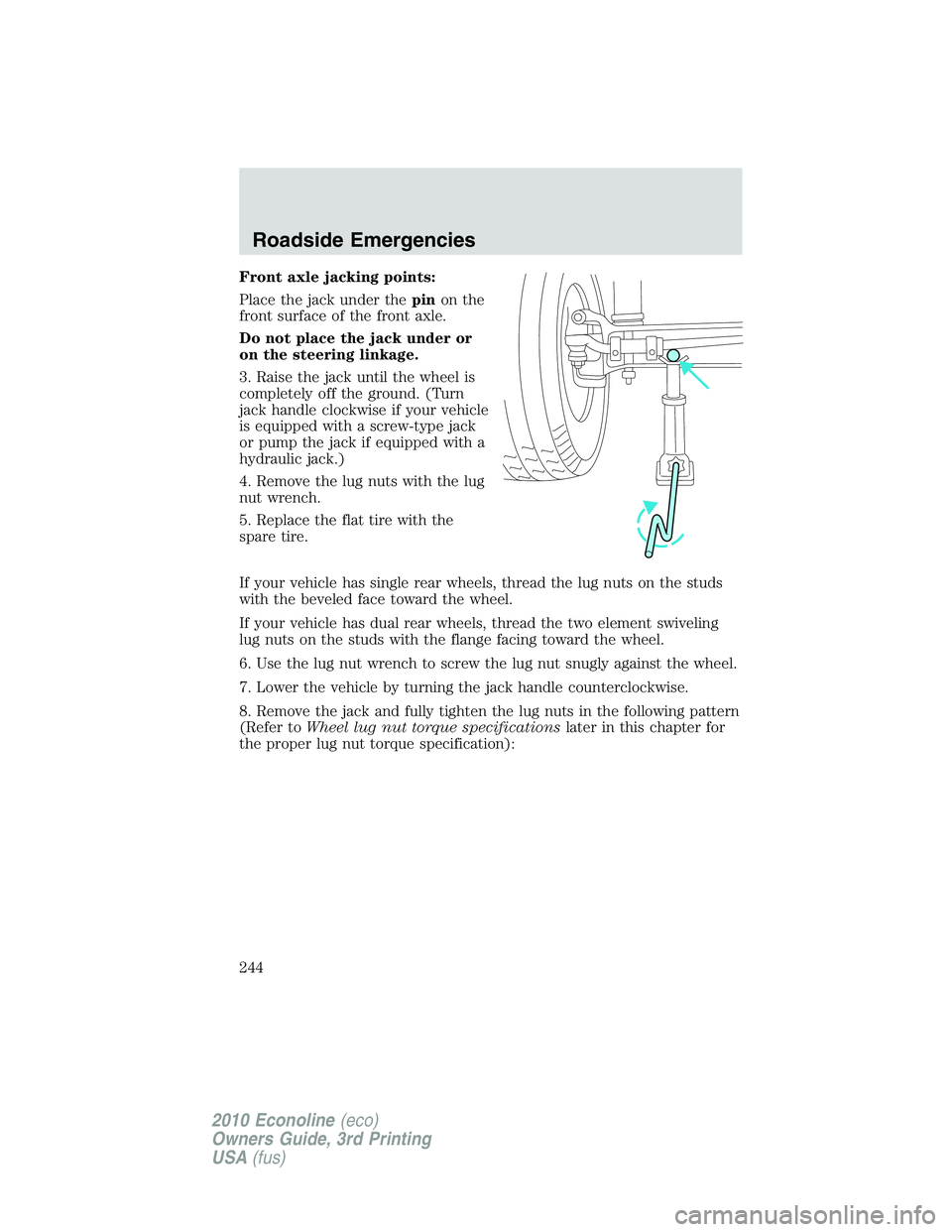

Front axle jacking points:

Place the jack under thepinon the

front surface of the front axle.

Do not place the jack under or

on the steering linkage.

3. Raise the jack until the wheel is

completely off the ground. (Turn

jack handle clockwise if your vehicle

is equipped with a screw-type jack

or pump the jack if equipped with a

hydraulic jack.)

4. Remove the lug nuts with the lug

nut wrench.

5. Replace the flat tire with the

spare tire.

If your vehicle has single rear wheels, thread the lug nuts on the studs

with the beveled face toward the wheel.

If your vehicle has dual rear wheels, thread the two element swiveling

lug nuts on the studs with the flange facing toward the wheel.

6. Use the lug nut wrench to screw the lug nut snugly against the wheel.

7. Lower the vehicle by turning the jack handle counterclockwise.

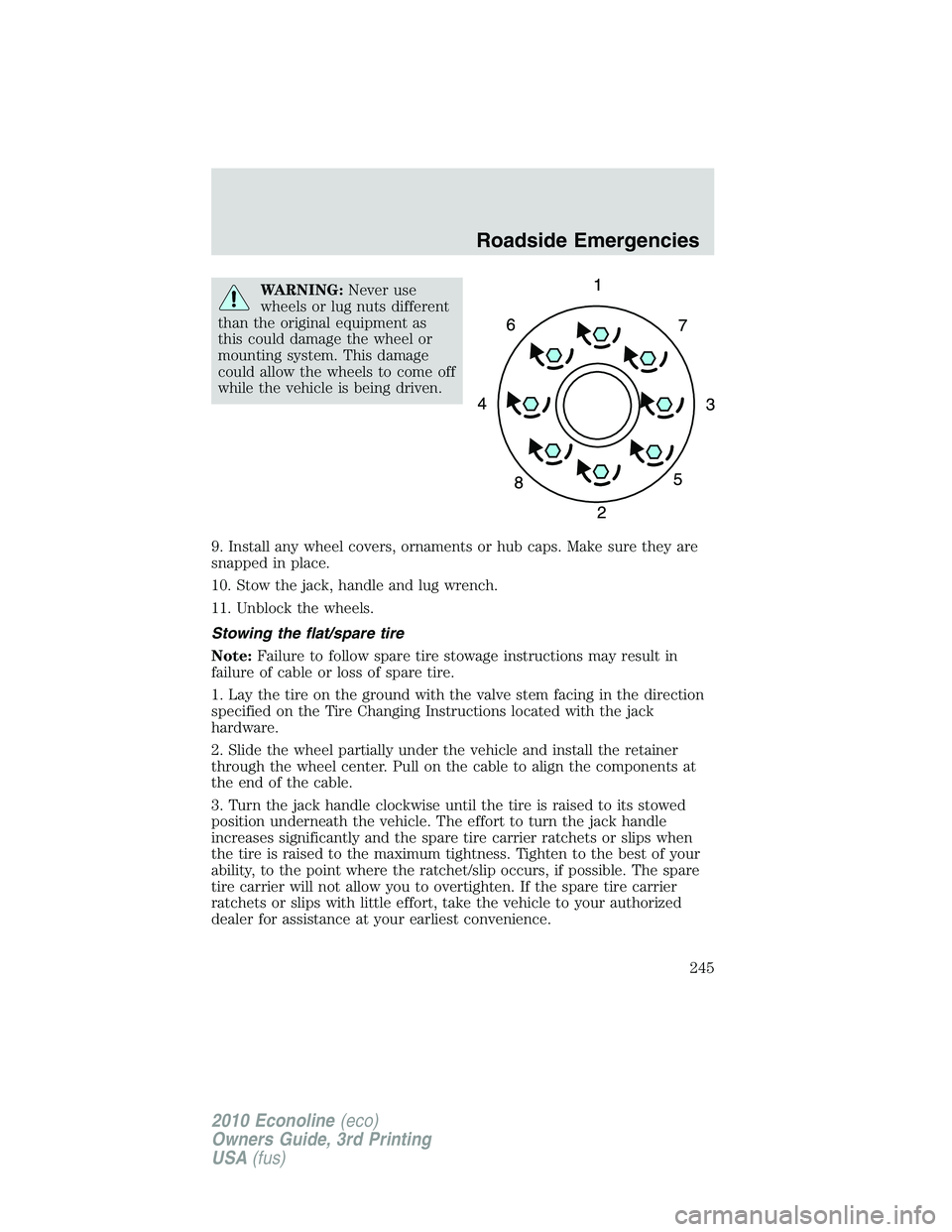

8. Remove the jack and fully tighten the lug nuts in the following pattern

(Refer toWheel lug nut torque specificationslater in this chapter for

the proper lug nut torque specification):

Roadside Emergencies

244

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 245 of 327

WARNING:Never use

wheels or lug nuts different

than the original equipment as

this could damage the wheel or

mounting system. This damage

could allow the wheels to come off

while the vehicle is being driven.

9. Install any wheel covers, ornaments or hub caps. Make sure they are

snapped in place.

10. Stow the jack, handle and lug wrench.

11. Unblock the wheels.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located with the jack

hardware.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your authorized

dealer for assistance at your earliest convenience.

Roadside Emergencies

245

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 246 of 327

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, as per yourscheduled maintenance

information),or at any time that the spare tire is disturbed through

service of other components.

6. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.

WHEEL LUG NUT TORQUE SPECIFICATIONS

On vehicles equipped with single rear wheels, retighten the lug nuts to

the specified torque at 100 miles (160 km) after any wheel disturbance

(tire rotation, changing a flat tire, wheel removal, etc.).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts

to the specified torque at 100 miles (160 km), and again at 500 miles

(800 km) of new vehicle operation and after any wheel disturbance (tire

rotation, changing a flat tire, wheel removal, etc.).

Bolt size and wheel

lug nut typeWheel lug nut torque*

ft-lb N•m

9/16 x 18 conical lug

nut150 200

9/16 x 18 two-piece

lug nut140 190

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

On all two-piece flat wheel nuts,

apply one drop of motor oil between

the flat washer and the nut. Do not

apply motor oil to the wheel nut

threads or the wheel stud threads.

Roadside Emergencies

246

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)