clock FORD E250 2010 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2010, Model line: E250, Model: FORD E250 2010Pages: 327, PDF Size: 2.43 MB

Page 61 of 327

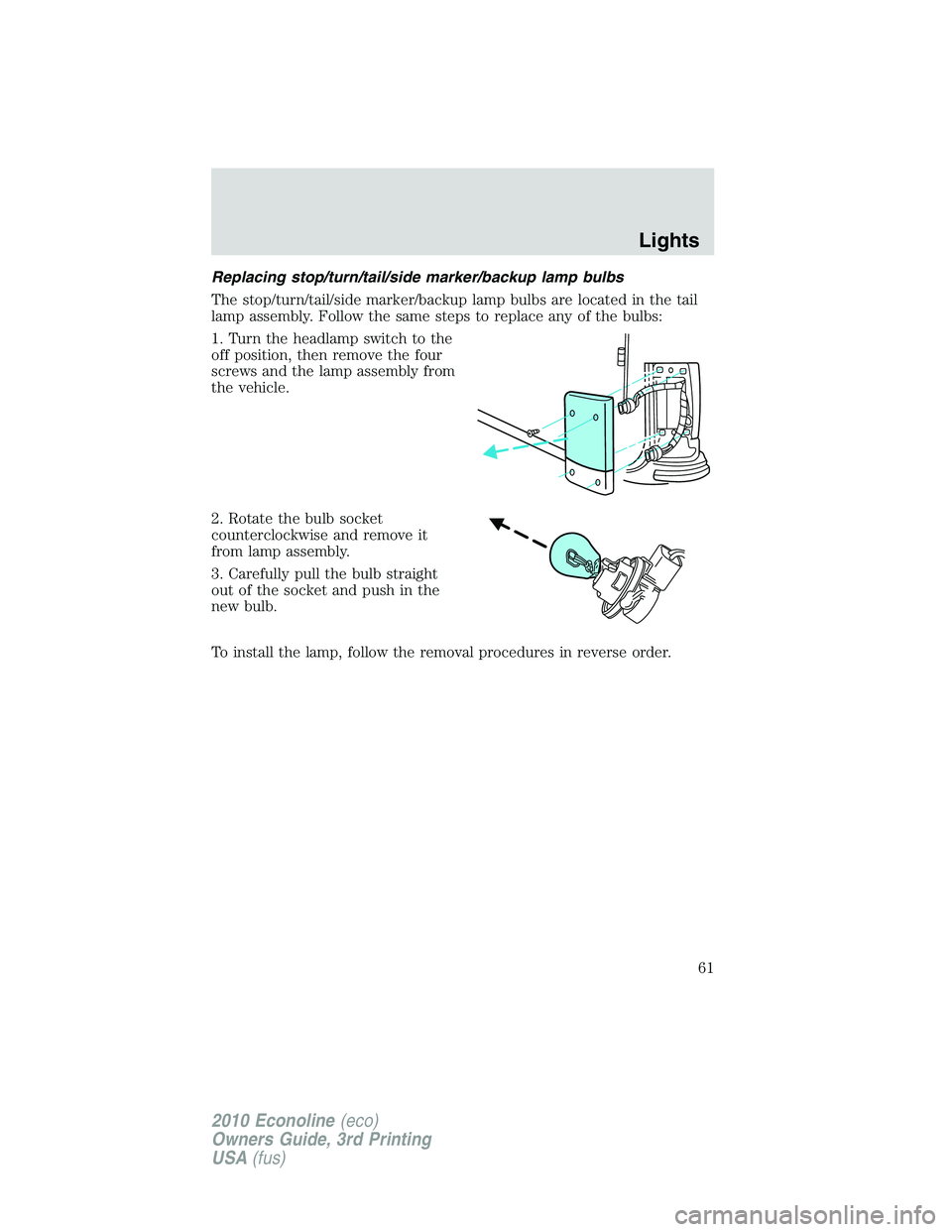

Replacing stop/turn/tail/side marker/backup lamp bulbs

The stop/turn/tail/side marker/backup lamp bulbs are located in the tail

lamp assembly. Follow the same steps to replace any of the bulbs:

1. Turn the headlamp switch to the

off position, then remove the four

screws and the lamp assembly from

the vehicle.

2. Rotate the bulb socket

counterclockwise and remove it

from lamp assembly.

3. Carefully pull the bulb straight

out of the socket and push in the

new bulb.

To install the lamp, follow the removal procedures in reverse order.

Lights

61

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 66 of 327

Note:If equipped with a reverse camera system, a video image will

display in the mirror or the Navigation system display (if equipped)

when the vehicle is put in R (Reverse). As you shift into any other gear

from R (Reverse), the image will remain for a few seconds and then turn

off. Refer toRearview camera systemin theDrivingchapter.

EXTERIOR MIRRORS

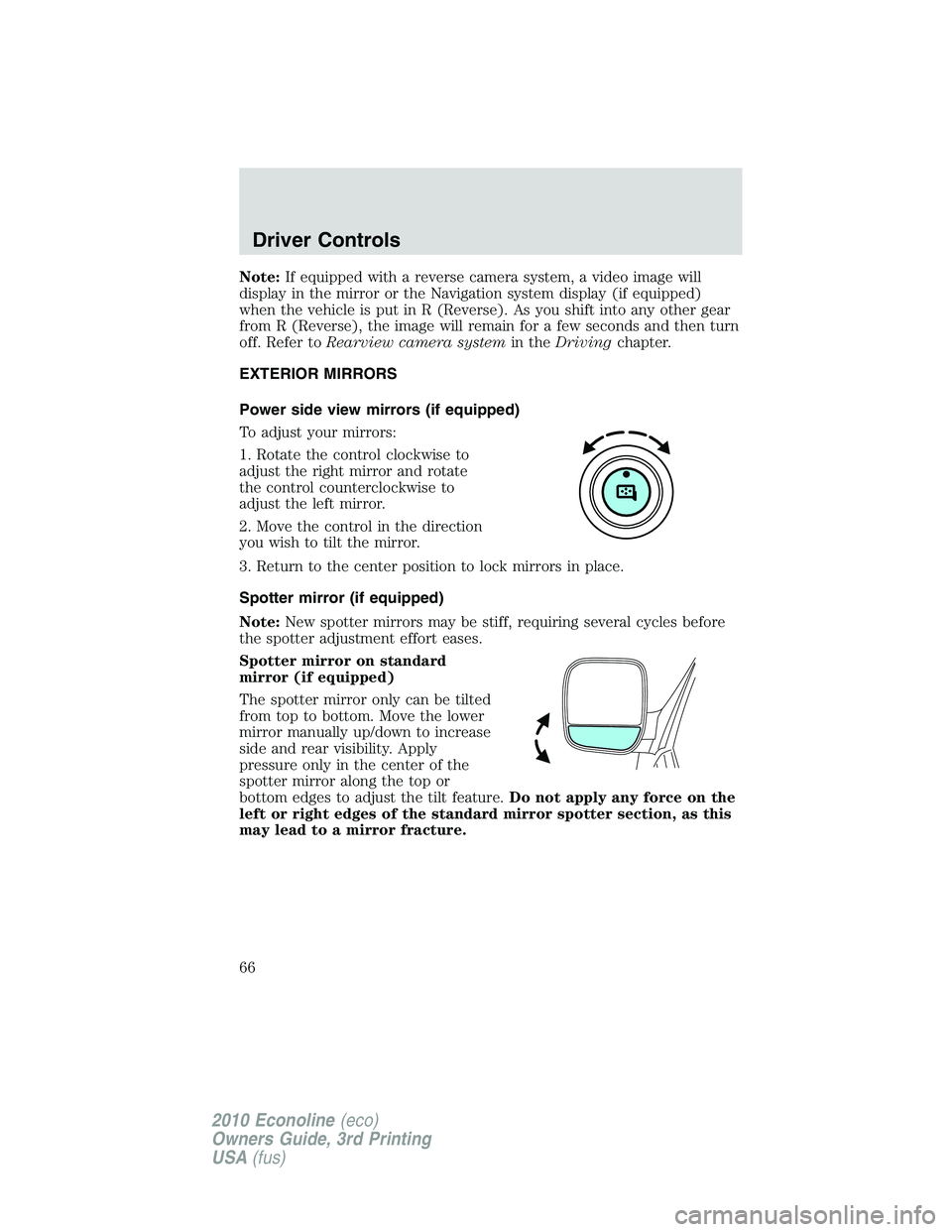

Power side view mirrors (if equipped)

To adjust your mirrors:

1. Rotate the control clockwise to

adjust the right mirror and rotate

the control counterclockwise to

adjust the left mirror.

2. Move the control in the direction

you wish to tilt the mirror.

3. Return to the center position to lock mirrors in place.

Spotter mirror (if equipped)

Note:New spotter mirrors may be stiff, requiring several cycles before

the spotter adjustment effort eases.

Spotter mirror on standard

mirror (if equipped)

The spotter mirror only can be tilted

from top to bottom. Move the lower

mirror manually up/down to increase

side and rear visibility. Apply

pressure only in the center of the

spotter mirror along the top or

bottom edges to adjust the tilt feature.Do not apply any force on the

left or right edges of the standard mirror spotter section, as this

may lead to a mirror fracture.

Driver Controls

66

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 87 of 327

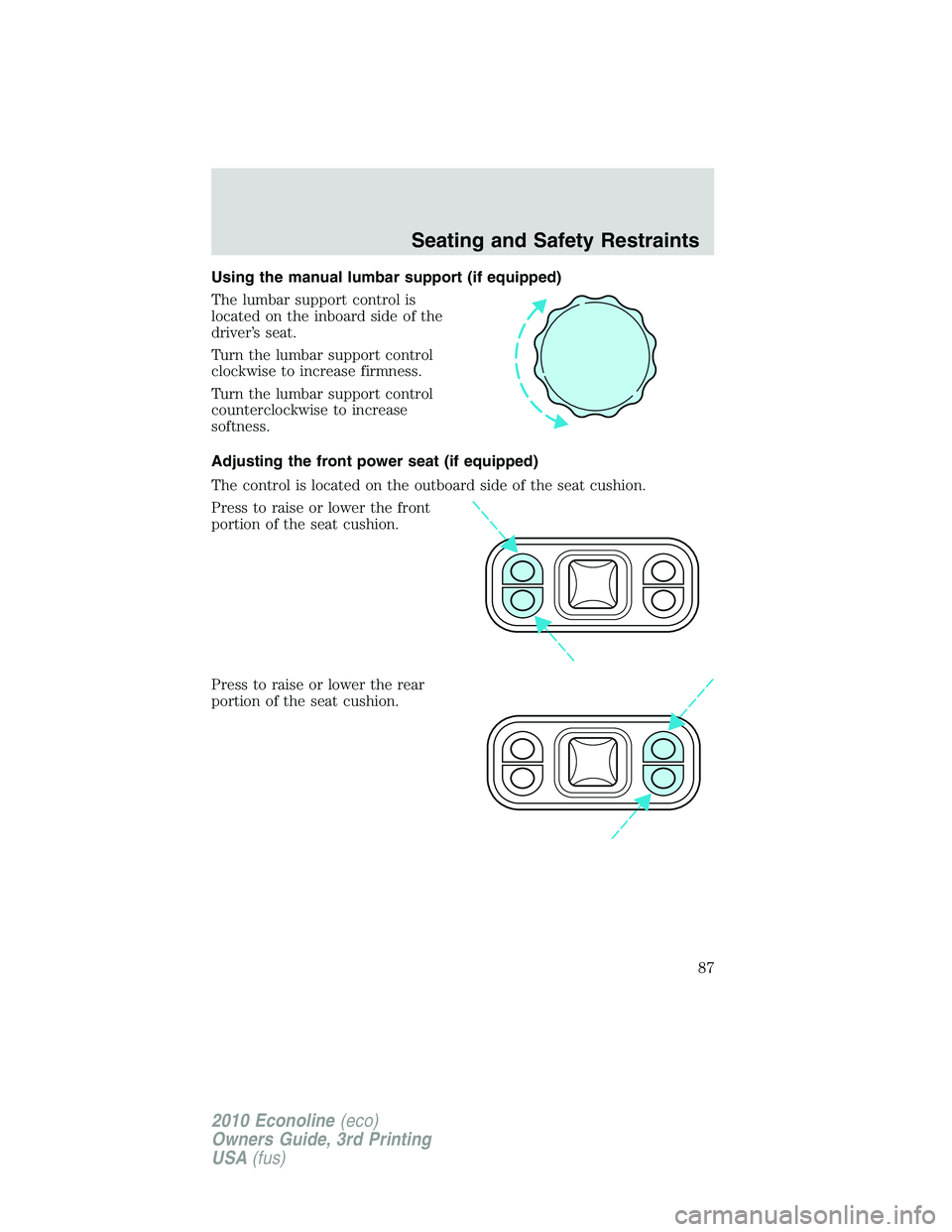

Using the manual lumbar support (if equipped)

The lumbar support control is

located on the inboard side of the

driver’s seat.

Turn the lumbar support control

clockwise to increase firmness.

Turn the lumbar support control

counterclockwise to increase

softness.

Adjusting the front power seat (if equipped)

The control is located on the outboard side of the seat cushion.

Press to raise or lower the front

portion of the seat cushion.

Press to raise or lower the rear

portion of the seat cushion.

Seating and Safety Restraints

87

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 162 of 327

5. Train the TPMS sensors in the tires using the following TPMS reset

sequence starting with theleft front tirein the following clockwise

order:

•Left front (Driver’s side front tire)

•Right front (Passenger’s side front tire)

•Right rear (Passenger’s side rear tire)

•Left rear (Driver’s side rear tire)

6. Remove the valve cap from the valve stem on the left front tire.

Decrease the air pressure until the horn sounds.

Note:The single horn chirp confirms that the sensor identification code

has been learned by the module for this position. If a double horn is

heard, the reset procedure was unsuccessful, and must be repeated.

7. Remove the valve cap from the valve stem on the right front tire.

Decrease the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire.

Decrease the air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire.

Decrease the air pressure until the horn sounds.

Training is complete after the horn sounds for the last tire trained

(driver’s side rear tire), the TPMS tell tale stops flashing, and the

message center (if equipped) displays:

TRAINING COMPLETE.

10. Turn the ignition off. If two short horn beeps are heard, the reset

procedure was unsuccessful and must be repeated.

If after repeating the procedure and two short beeps are heard when the

ignition is turned to off, seek assistance from your authorized dealer.

11. Set all four tires to the recommended air pressure as indicated on

the Safety Compliance Certification Label or Tire Label located on the

B-Pillar or the edge of the driver’s door. SeeVehicle loading - with and

without a trailerin this chapter for more information.

Tires, Wheels and Loading

162

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 165 of 327

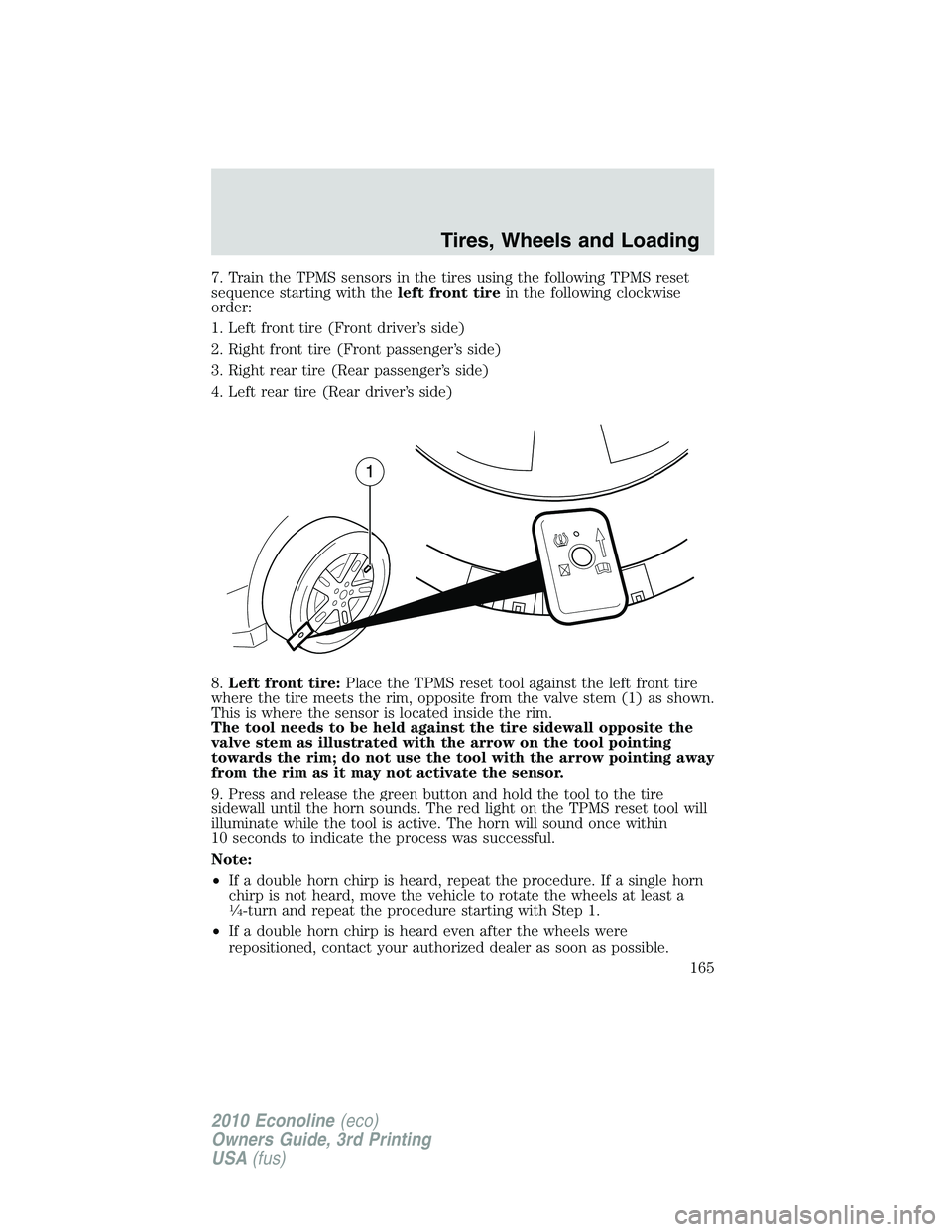

7. Train the TPMS sensors in the tires using the following TPMS reset

sequence starting with theleft front tirein the following clockwise

order:

1. Left front tire (Front driver’s side)

2. Right front tire (Front passenger’s side)

3. Right rear tire (Rear passenger’s side)

4. Left rear tire (Rear driver’s side)

8.Left front tire:Place the TPMS reset tool against the left front tire

where the tire meets the rim, opposite from the valve stem (1) as shown.

This is where the sensor is located inside the rim.

The tool needs to be held against the tire sidewall opposite the

valve stem as illustrated with the arrow on the tool pointing

towards the rim; do not use the tool with the arrow pointing away

from the rim as it may not activate the sensor.

9. Press and release the green button and hold the tool to the tire

sidewall until the horn sounds. The red light on the TPMS reset tool will

illuminate while the tool is active. The horn will sound once within

10 seconds to indicate the process was successful.

Note:

•If a double horn chirp is heard, repeat the procedure. If a single horn

chirp is not heard, move the vehicle to rotate the wheels at least a

1�4-turn and repeat the procedure starting with Step 1.

•If a double horn chirp is heard even after the wheels were

repositioned, contact your authorized dealer as soon as possible.

Tires, Wheels and Loading

165

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 240 of 327

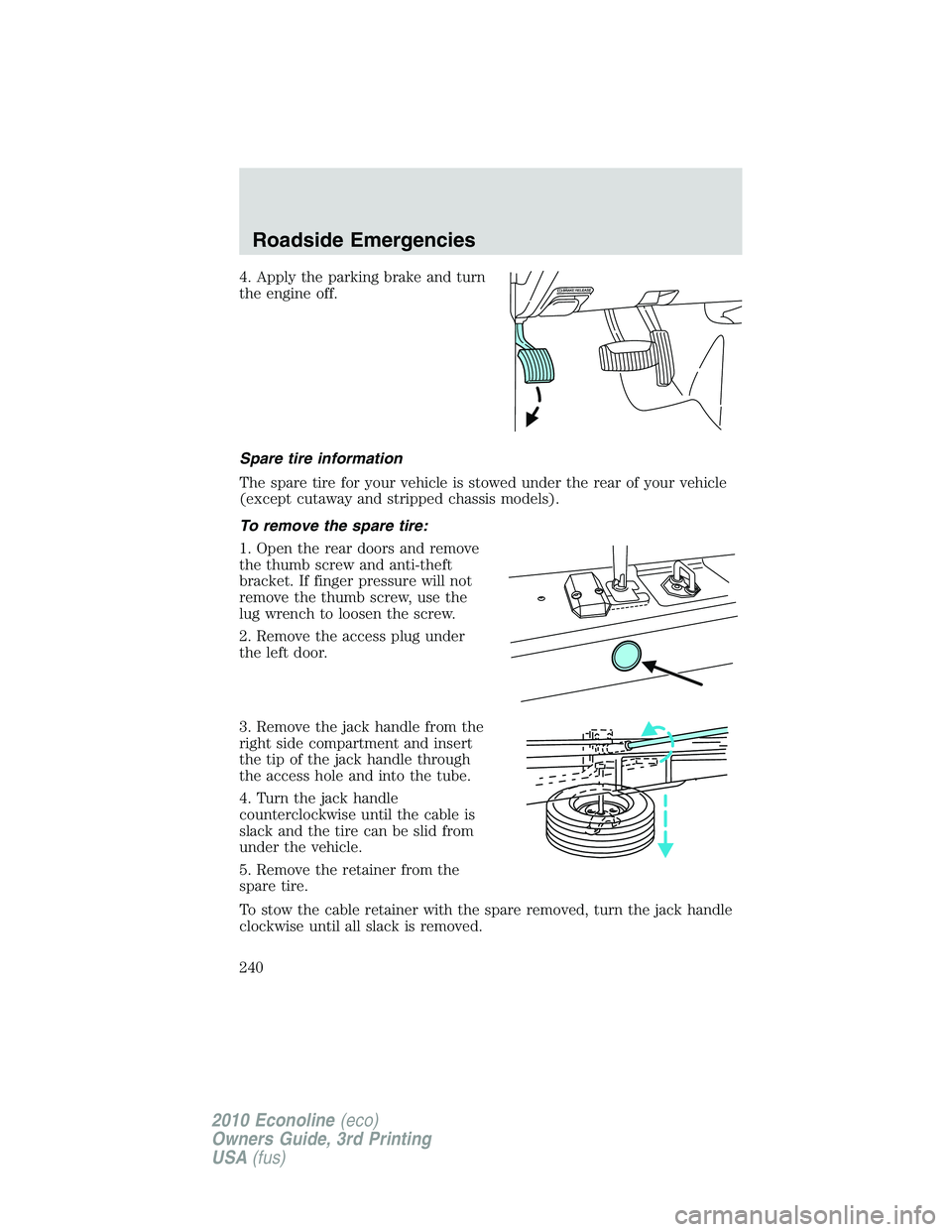

4. Apply the parking brake and turn

the engine off.

Spare tire information

The spare tire for your vehicle is stowed under the rear of your vehicle

(except cutaway and stripped chassis models).

To remove the spare tire:

1. Open the rear doors and remove

the thumb screw and anti-theft

bracket. If finger pressure will not

remove the thumb screw, use the

lug wrench to loosen the screw.

2. Remove the access plug under

the left door.

3. Remove the jack handle from the

right side compartment and insert

the tip of the jack handle through

the access hole and into the tube.

4. Turn the jack handle

counterclockwise until the cable is

slack and the tire can be slid from

under the vehicle.

5. Remove the retainer from the

spare tire.

To stow the cable retainer with the spare removed, turn the jack handle

clockwise until all slack is removed.

Roadside Emergencies

240

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 242 of 327

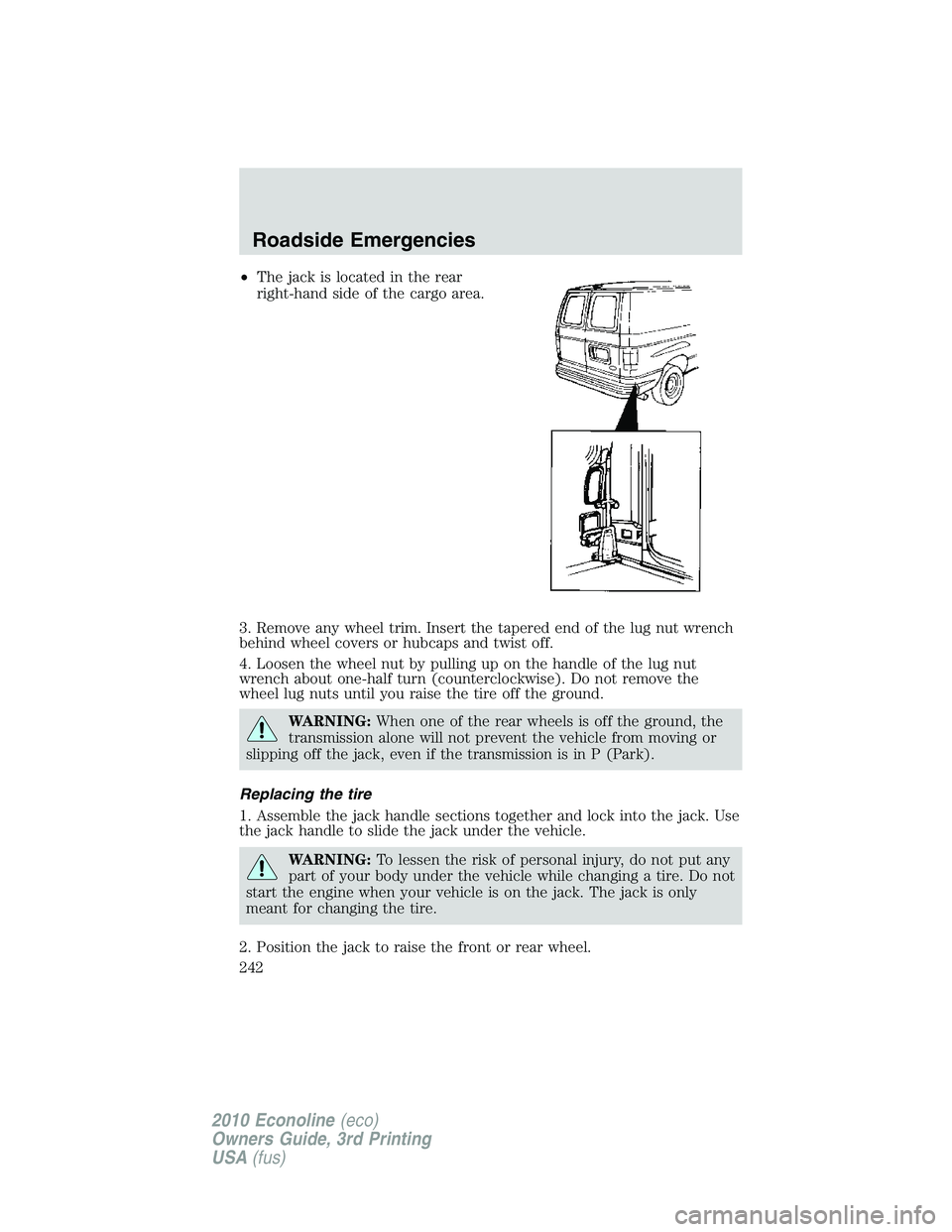

•The jack is located in the rear

right-hand side of the cargo area.

3. Remove any wheel trim. Insert the tapered end of the lug nut wrench

behind wheel covers or hubcaps and twist off.

4. Loosen the wheel nut by pulling up on the handle of the lug nut

wrench about one-half turn (counterclockwise). Do not remove the

wheel lug nuts until you raise the tire off the ground.

WARNING:When one of the rear wheels is off the ground, the

transmission alone will not prevent the vehicle from moving or

slipping off the jack, even if the transmission is in P (Park).

Replacing the tire

1. Assemble the jack handle sections together and lock into the jack. Use

the jack handle to slide the jack under the vehicle.

WARNING:To lessen the risk of personal injury, do not put any

part of your body under the vehicle while changing a tire. Do not

start the engine when your vehicle is on the jack. The jack is only

meant for changing the tire.

2. Position the jack to raise the front or rear wheel.

Roadside Emergencies

242

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 244 of 327

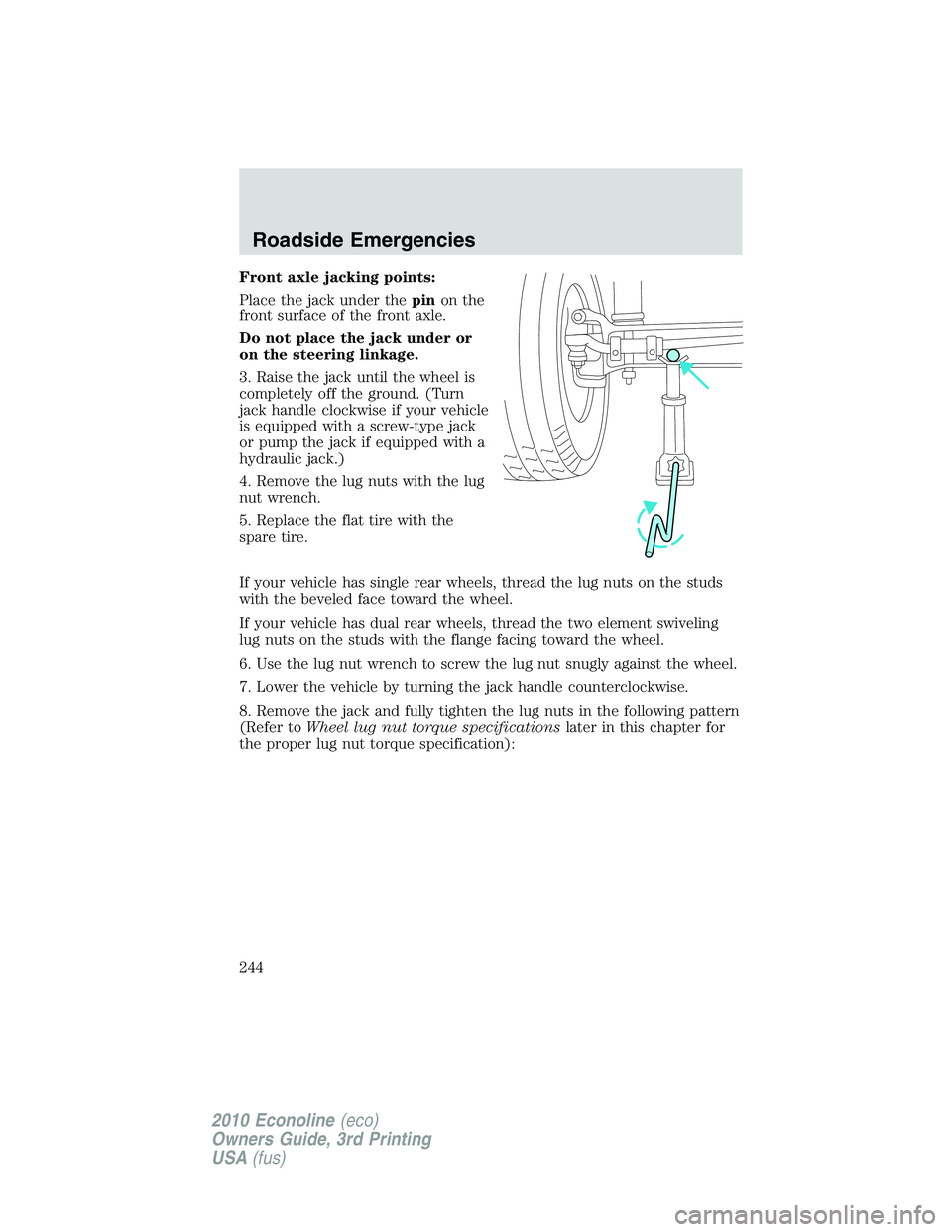

Front axle jacking points:

Place the jack under thepinon the

front surface of the front axle.

Do not place the jack under or

on the steering linkage.

3. Raise the jack until the wheel is

completely off the ground. (Turn

jack handle clockwise if your vehicle

is equipped with a screw-type jack

or pump the jack if equipped with a

hydraulic jack.)

4. Remove the lug nuts with the lug

nut wrench.

5. Replace the flat tire with the

spare tire.

If your vehicle has single rear wheels, thread the lug nuts on the studs

with the beveled face toward the wheel.

If your vehicle has dual rear wheels, thread the two element swiveling

lug nuts on the studs with the flange facing toward the wheel.

6. Use the lug nut wrench to screw the lug nut snugly against the wheel.

7. Lower the vehicle by turning the jack handle counterclockwise.

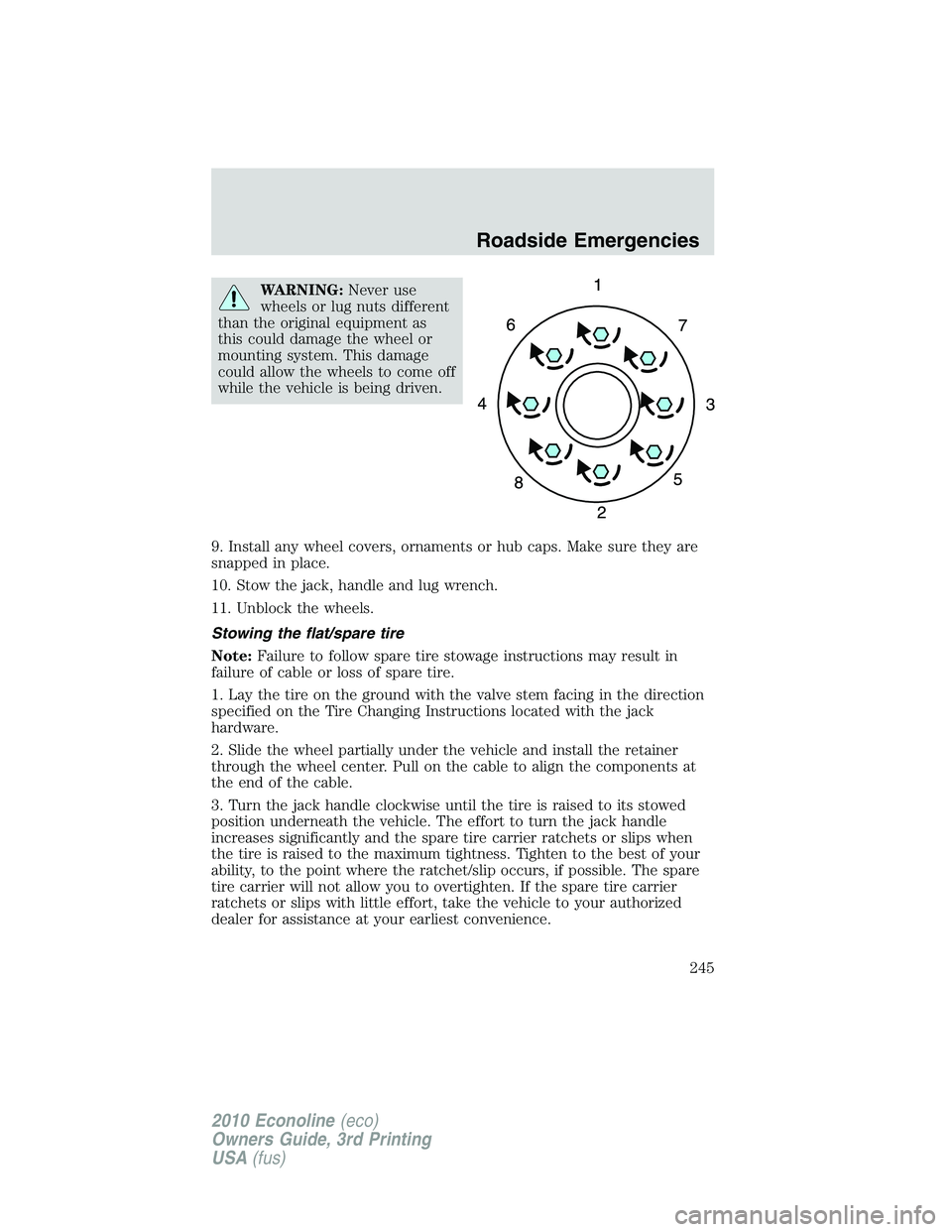

8. Remove the jack and fully tighten the lug nuts in the following pattern

(Refer toWheel lug nut torque specificationslater in this chapter for

the proper lug nut torque specification):

Roadside Emergencies

244

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 245 of 327

WARNING:Never use

wheels or lug nuts different

than the original equipment as

this could damage the wheel or

mounting system. This damage

could allow the wheels to come off

while the vehicle is being driven.

9. Install any wheel covers, ornaments or hub caps. Make sure they are

snapped in place.

10. Stow the jack, handle and lug wrench.

11. Unblock the wheels.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located with the jack

hardware.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your authorized

dealer for assistance at your earliest convenience.

Roadside Emergencies

245

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)

Page 275 of 327

•If the oil level is below the lower

hole or the MIN mark, add

enough oil to raise the level

within the lower and upper holes

or within the MIN-MAX range.

•Oil levels above the upper hole or the MAX mark may cause engine

damage. Some oil must be removed from the engine by an authorized

dealer.

7. Put the dipstick back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

normal operating range on the engine oil level dipstick.

4. Install the dipstick and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until three clicks are heard or until the cap is fully seated.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level dipstick and/or the engine oil filler cap removed.

Maintenance and Specifications

275

2010 Econoline(eco)

Owners Guide, 3rd Printing

USA(fus)