trailer FORD EXPEDITION 1998 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1998, Model line: EXPEDITION, Model: FORD EXPEDITION 1998 1.GPages: 216, PDF Size: 1.51 MB

Page 124 of 216

upshifting for optimum fuel

economy and transmission

cooling.

²Anticipate stops and brake

gradually.

Servicing after towing

If you tow a trailer for long

distances, your vehicle will require

more frequent service intervals.

Refer to the Severe Duty Schedule

in your ªService Guideº for more

information.

Towing behind another vehicle

Do not tow your vehicle behind

another vehicle, such as an RV.

Your vehicle cannot be flat towed

with all wheels on the ground.

Trailer towing tips

²Practice turning, stopping and

backing up in an area before

starting on a trip to get the feel

of the vehicle trailer

combination. When turning,

make wider turns so the trailer

wheels will clear curbs and

other obstacles.

²Allow more distance for

stopping with a trailer attached.

²The trailer tongue weight should

be 10±15% of the loaded trailer

weight.

²After you have traveled 80 km

(50 miles), thoroughly check

your hitch, electrical

connections and trailer wheel

lug nuts.

Driving

124

Page 125 of 216

²When stopped in traffic for long

periods of time in hot weather,

place the gearshift in P (Park)

and increase idle speed. This

aids engine cooling and air

conditioner efficiency.

²Vehicles with trailers should not

be parked on a grade. If you

must park on a grade, place

wheel chocks under the trailer's

wheels.

Launching or retrieving a boat

When backing down a ramp during

boat launching or retrieval,

²Do not allow the static water

level to rise above the bottom

edge of the rear bumper and

²Do not allow waves to break

higher than 15 cm (six inches)

above the bottom edge of the

rear bumper.

Exceeding these limits may allow

water to enter critical vehicle

components, adversely affecting

driveability, emissions and

reliability.

If the rear axle is submerged in

water, the rear axle lubricant

should be checked and changed, if

necessary. The rear axle is filled

with a synthetic lubricant and does

not normally require a lubricant

change for the life of the vehicle.

Rear axle lubricant quantities

should not need to be checked

unless a leak is suspected.

Driving

125

Page 132 of 216

Fuse/Relay

LocationFuse Amp

RatingDescription

16 20A Instrument Cluster (W/O DRL),

Daytime Running Lamps (DRL)

Module, Hi-Beam Headlamps

(Power supplied through

Multi-Function Switch)

17 10A Heated Backlight Switch, Left

Power/Heated Signal Mirror, Right

Power/Heated Signal Mirror

18 5A Main Light Switch, Generic

Electronic Module (GEM),

Instrument Illumination (Power

supplied through Main Light

Switch)

19 10A Instrument Cluster, Air Bag

Diagnostic Monitor

20 5A 4 Wheel Air Suspension (4WAS),

Generic Electronic Module (GEM)

21 15A Digital Transmission Range (DTR)

Sensor, Junction Box Fuse/Relay

Panel (Fuse 20)

22 10A Air Bag Diagnostic Monitor

23 10A Trailer Tow Battery Charge Relay,

4X4 Center Axle Disconnect

solenoid, 4X2 Center Axle

Disconnect Solenoid, Function

Selector Switch, Rear Integrated

Control Panel, Recirculation

Vacuum Solenoid, Auxiliary A/C

Mode Acturator, Auxiliary A/C

Control Module

24 10A Function Selector Switch

25 5A 4 Wheel Anti-Lock Brake System

(4WABS) Module, 4WABS Relay

Roadside emergencies

132

Page 134 of 216

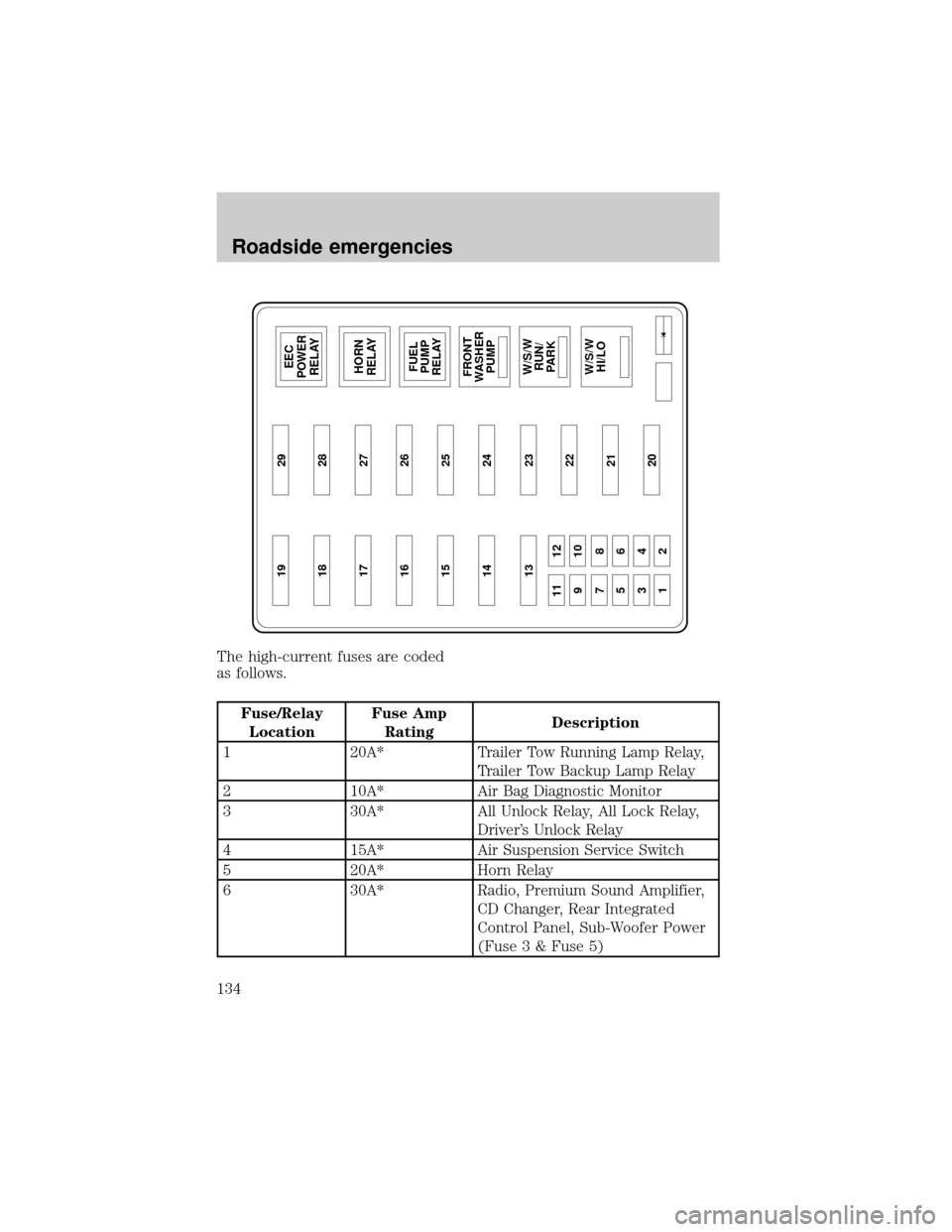

The high-current fuses are coded

as follows.

Fuse/Relay

LocationFuse Amp

RatingDescription

1 20A* Trailer Tow Running Lamp Relay,

Trailer Tow Backup Lamp Relay

2 10A* Air Bag Diagnostic Monitor

3 30A* All Unlock Relay, All Lock Relay,

Driver's Unlock Relay

4 15A* Air Suspension Service Switch

5 20A* Horn Relay

6 30A* Radio, Premium Sound Amplifier,

CD Changer, Rear Integrated

Control Panel, Sub-Woofer Power

(Fuse 3 & Fuse 5)

19 29

18 28EEC

POWER

RELAY

FUEL

PUMP

RELAY

FRONT

WASHER

PUMP HORN

RELAY 17 27

16 26

15 25

14 24

13

11 12

910

78

56

34

1223

22

21

20

W/S/W

RUN/

PARKW/S/W

HI/LO

Roadside emergencies

134

Page 135 of 216

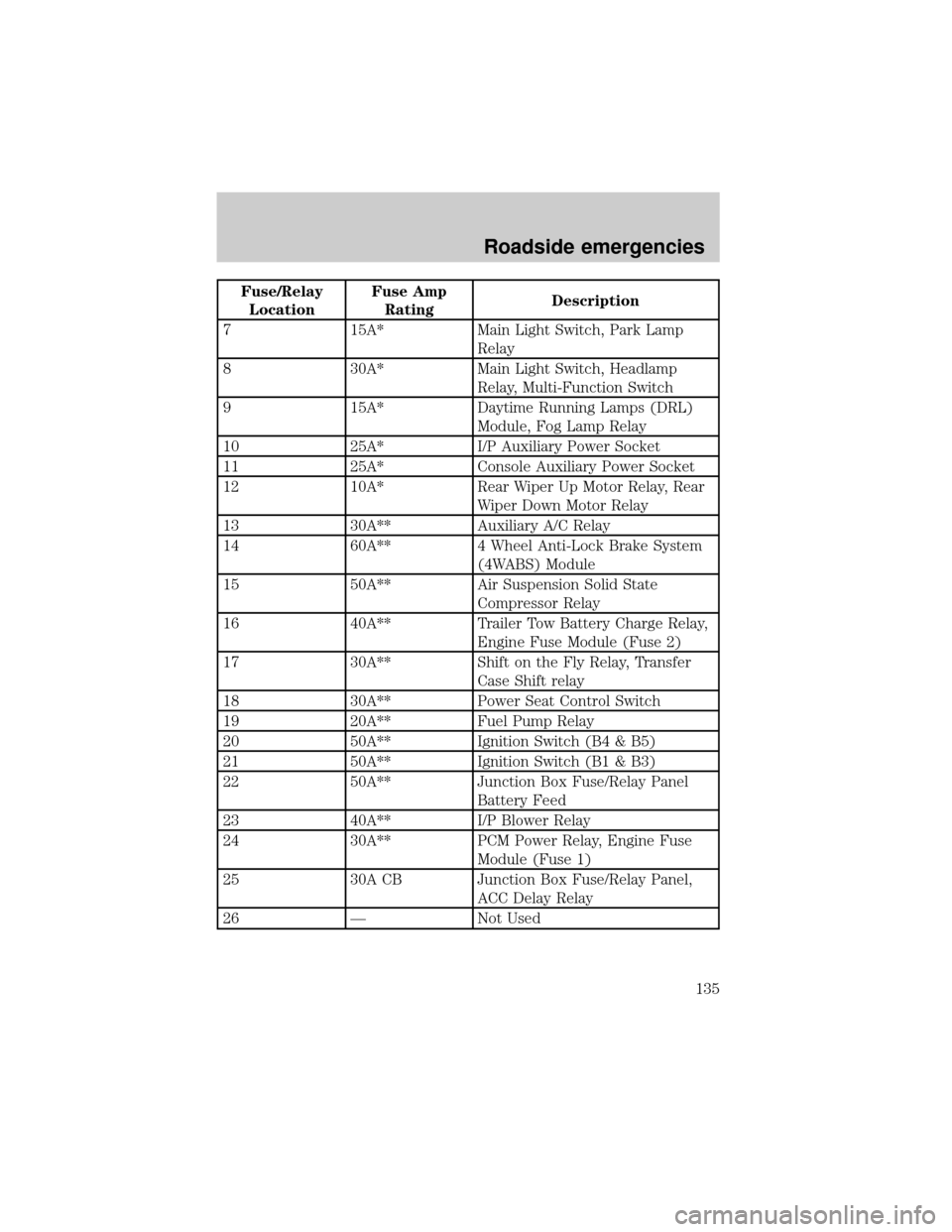

Fuse/Relay

LocationFuse Amp

RatingDescription

7 15A* Main Light Switch, Park Lamp

Relay

8 30A* Main Light Switch, Headlamp

Relay, Multi-Function Switch

9 15A* Daytime Running Lamps (DRL)

Module, Fog Lamp Relay

10 25A* I/P Auxiliary Power Socket

11 25A* Console Auxiliary Power Socket

12 10A* Rear Wiper Up Motor Relay, Rear

Wiper Down Motor Relay

13 30A** Auxiliary A/C Relay

14 60A** 4 Wheel Anti-Lock Brake System

(4WABS) Module

15 50A** Air Suspension Solid State

Compressor Relay

16 40A** Trailer Tow Battery Charge Relay,

Engine Fuse Module (Fuse 2)

17 30A** Shift on the Fly Relay, Transfer

Case Shift relay

18 30A** Power Seat Control Switch

19 20A** Fuel Pump Relay

20 50A** Ignition Switch (B4 & B5)

21 50A** Ignition Switch (B1 & B3)

22 50A** Junction Box Fuse/Relay Panel

Battery Feed

23 40A** I/P Blower Relay

24 30A** PCM Power Relay, Engine Fuse

Module (Fuse 1)

25 30A CB Junction Box Fuse/Relay Panel,

ACC Delay Relay

26 Ð Not Used

Roadside emergencies

135

Page 136 of 216

Fuse/Relay

LocationFuse Amp

RatingDescription

27 40A** Junction Box Fuse/Relay Panel,

Heated Grid Relay

28 30A** Trailer Electronic Brake

Controller

29 30A** Flip Window Relay, Hybrid

Cooling Fan Relay

* Mini Fuses ** Maxi Fuses

Relays

Relays are located in the power

distribution box and should be

replaced by qualified technicians.

Primary battery fuses

(megafuses)

Roadside emergencies

136

Page 138 of 216

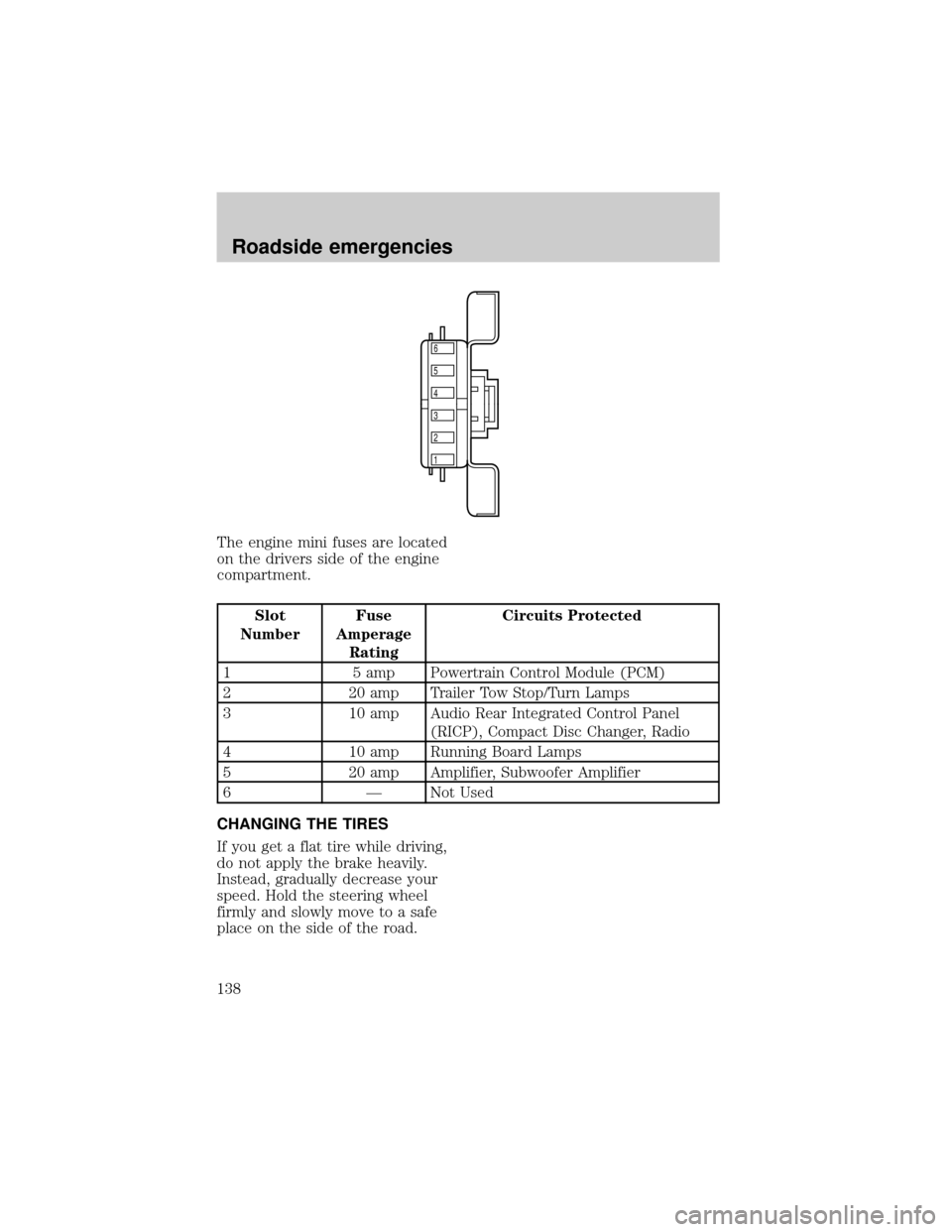

The engine mini fuses are located

on the drivers side of the engine

compartment.

Slot

NumberFuse

Amperage

RatingCircuits Protected

1 5 amp Powertrain Control Module (PCM)

2 20 amp Trailer Tow Stop/Turn Lamps

3 10 amp Audio Rear Integrated Control Panel

(RICP), Compact Disc Changer, Radio

4 10 amp Running Board Lamps

5 20 amp Amplifier, Subwoofer Amplifier

6 Ð Not Used

CHANGING THE TIRES

If you get a flat tire while driving,

do not apply the brake heavily.

Instead, gradually decrease your

speed. Hold the steering wheel

firmly and slowly move to a safe

place on the side of the road.

6

5

4

3

2

1

Roadside emergencies

138

Page 156 of 216

Do not use supplemental engine oil

additives, oil treatments or engine

treatments. They are unnecessary

and could, under certain

conditions, lead to engine damage

which is not covered by your

warranty.

Changing the engine oil and

filter

Change your engine oil and filter

according to the following mileage

and time requirements, whichever

occurs first:

²Normal Schedule ± 8,000 km

(5,000 miles) or six months.

²Severe Duty Schedule - 5,000

km (3,000 miles) or three

months. Severe duty operation

would include extensive idling,

trailer towing, driving in severe

dust and police, taxi or delivery

service.

Ford production and aftermarket

(Motorcraft) oil filters are designed

for added engine protection and

long life. If a replacement oil filter

is used that does not meet Ford

material and design specifications,

startup engine noises or knock

may be experienced.

It is recommended you use the

appropriate Motorcraft oil filter (or

another brand meeting Ford

specifications) for your engine

application.

Maintenance and care

156

Page 166 of 216

![FORD EXPEDITION 1998 1.G User Guide The transmission fluid should be in

this range if at room temperature

(10ÉC-35ÉC [50ÉF-95ÉF]) (see

figure to the right).

If your vehicle has been operated

for an extended period at high

speeds, in FORD EXPEDITION 1998 1.G User Guide The transmission fluid should be in

this range if at room temperature

(10ÉC-35ÉC [50ÉF-95ÉF]) (see

figure to the right).

If your vehicle has been operated

for an extended period at high

speeds, in](/img/11/4906/w960_4906-165.png)

The transmission fluid should be in

this range if at room temperature

(10ÉC-35ÉC [50ÉF-95ÉF]) (see

figure to the right).

If your vehicle has been operated

for an extended period at high

speeds, in city traffic during hot

weather or pulling a trailer, the

vehicle should be turned off for

about 30 minutes to allow the fluid

to cool before checking.

1. Park the vehicle on a level

surface and engage the parking

brake.

2. With the parking brake engaged

and your foot on the brake pedal,

start the engine and move the

gearshift lever through all of the

gear ranges. Allow sufficient time

for each gear to engage.

3. Latch the gearshift lever in P

(Park) and leave the engine

running.

4. Remove the dipstick, wiping it

clean with a clean, dry lint free

rag.

5. Install the dipstick making sure

it is fully seated in the filler tube.

6. Remove the dipstick and inspect

the fluid level. The fluid level

should be in the crosshatched area

on the dipstick.DON'T ADD IF IN CROSSHATCHED AREA • CHECK WHEN HOT IDLING IN PARK

ADD COLD HOT DO NOT ADD

P R N D 2 1

Maintenance and care

166

Page 206 of 216

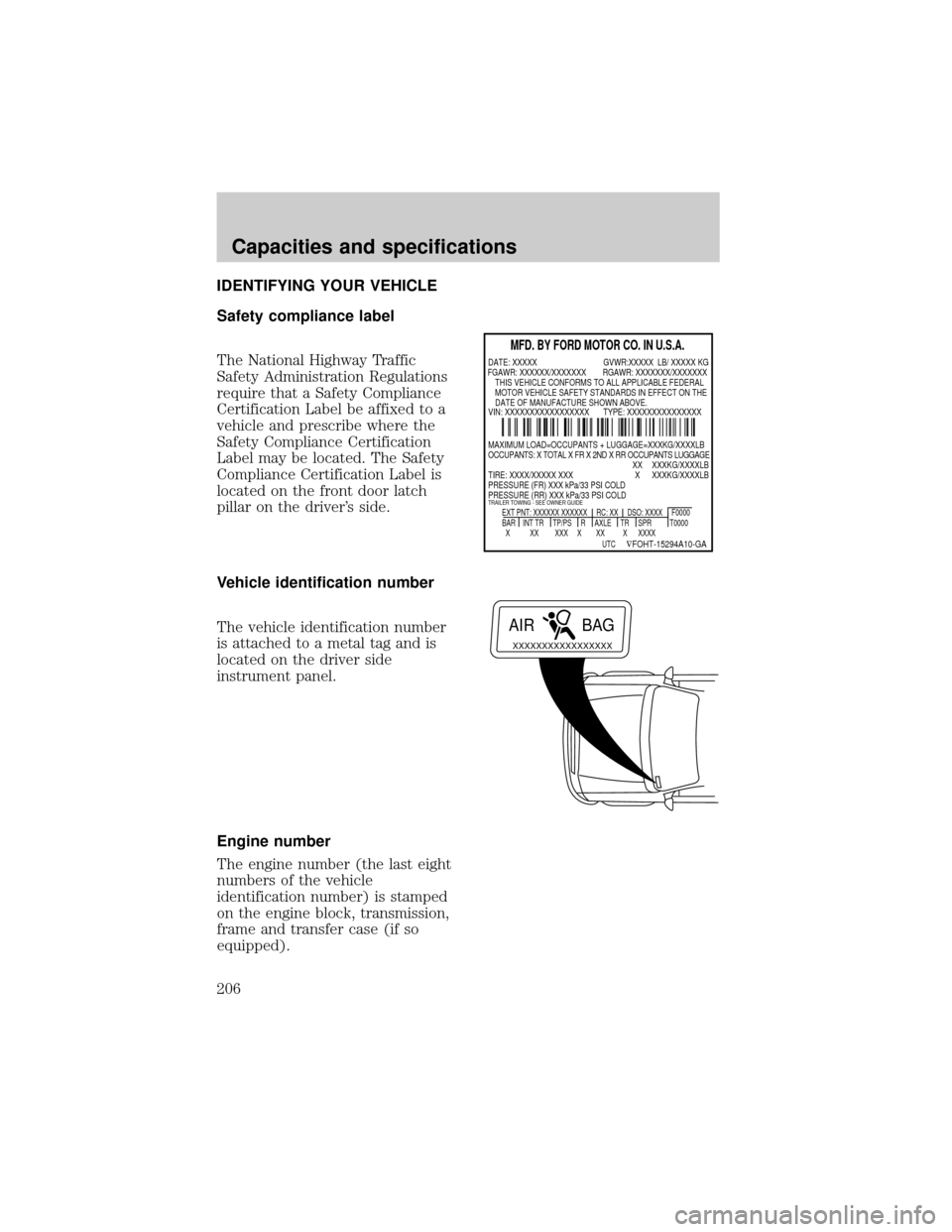

IDENTIFYING YOUR VEHICLE

Safety compliance label

The National Highway Traffic

Safety Administration Regulations

require that a Safety Compliance

Certification Label be affixed to a

vehicle and prescribe where the

Safety Compliance Certification

Label may be located. The Safety

Compliance Certification Label is

located on the front door latch

pillar on the driver's side.

Vehicle identification number

The vehicle identification number

is attached to a metal tag and is

located on the driver side

instrument panel.

Engine number

The engine number (the last eight

numbers of the vehicle

identification number) is stamped

on the engine block, transmission,

frame and transfer case (if so

equipped).

MFD. BY FORD MOTOR CO. IN U.S.A.

EXT PNT: XXXXXX XXXXXX RC: XX DSO: XXXX F0000

BAR INT TR TP/PS R AXLE TR SPR T0000

X XX XXX X XX X XXXX

UTC

ÑFOHT-15294A10-GA

MAXIMUM LOAD=OCCUPANTS + LUGGAGE=XXXKG/XXXXLB

OCCUPANTS: X TOTAL X FR X 2ND X RR OCCUPANTS LUGGAGE

XX XXXKG/XXXXLB

TIRE: XXXX/XXXXX XXX X XXXKG/XXXXLB

PRESSURE (FR) XXX kPa/33 PSI COLD

PRESSURE (RR) XXX kPa/33 PSI COLD

TRAILER TOWING - SEE OWNER GUIDE

DATE: XXXXX GVWR:XXXXX LB/ XXXXX KG

VIN: XXXXXXXXXXXXXXXXX TYPE: XXXXXXXXXXXXXXX FGAWR: XXXXXX/XXXXXXX RGAWR: XXXXXXX/XXXXXXX

THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL

MOTOR VEHICLE SAFETY STANDARDS IN EFFECT ON THE

DATE OF MANUFACTURE SHOWN ABOVE.

XXXXXXXXXXXXXXXXX

AIR BAG

Capacities and specifications

206