lock FORD EXPEDITION 2000 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: EXPEDITION, Model: FORD EXPEDITION 2000 1.GPages: 256, PDF Size: 2.08 MB

Page 174 of 256

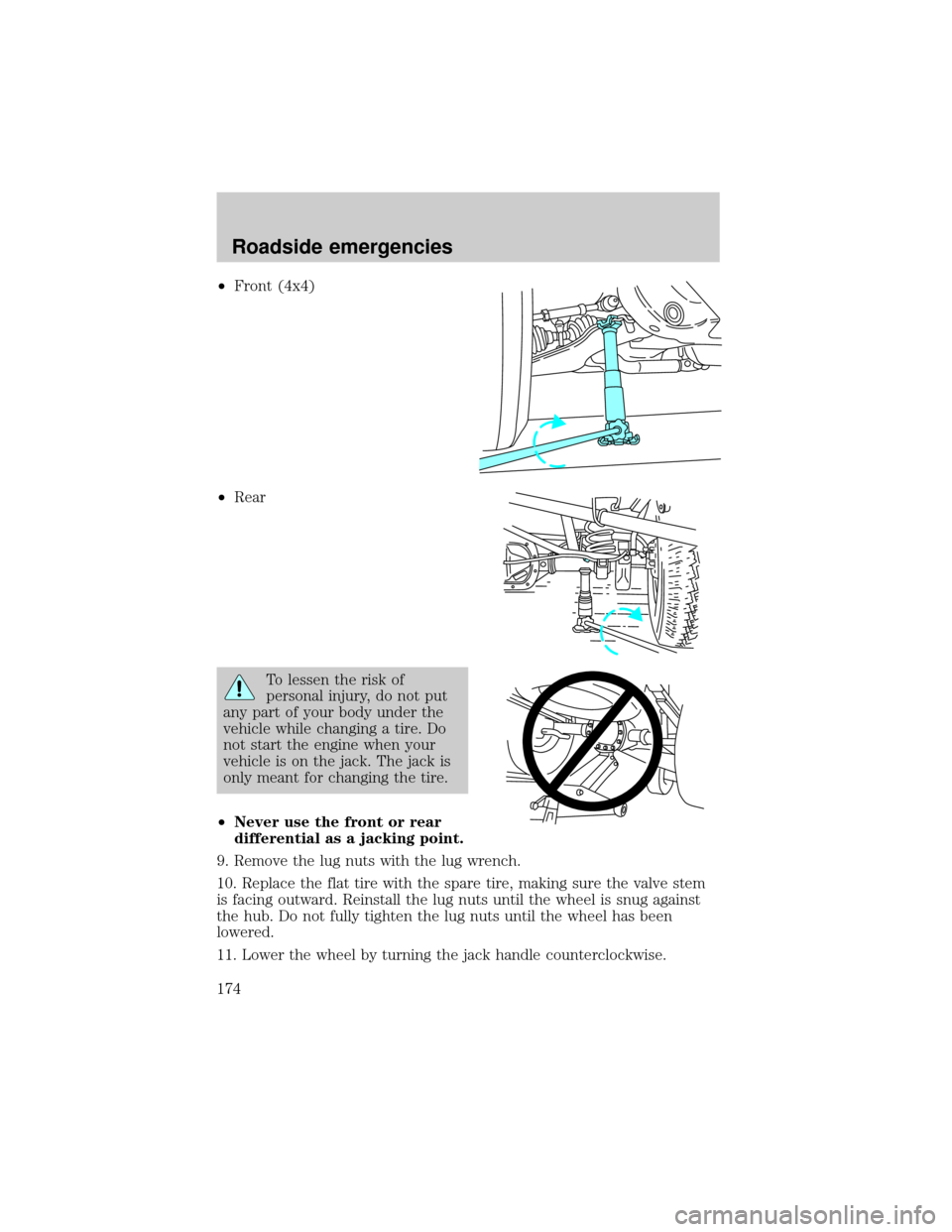

²Front (4x4)

²Rear

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

²Never use the front or rear

differential as a jacking point.

9. Remove the lug nuts with the lug wrench.

10. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward. Reinstall the lug nuts until the wheel is snug against

the hub. Do not fully tighten the lug nuts until the wheel has been

lowered.

11. Lower the wheel by turning the jack handle counterclockwise.

Roadside emergencies

174

Page 175 of 256

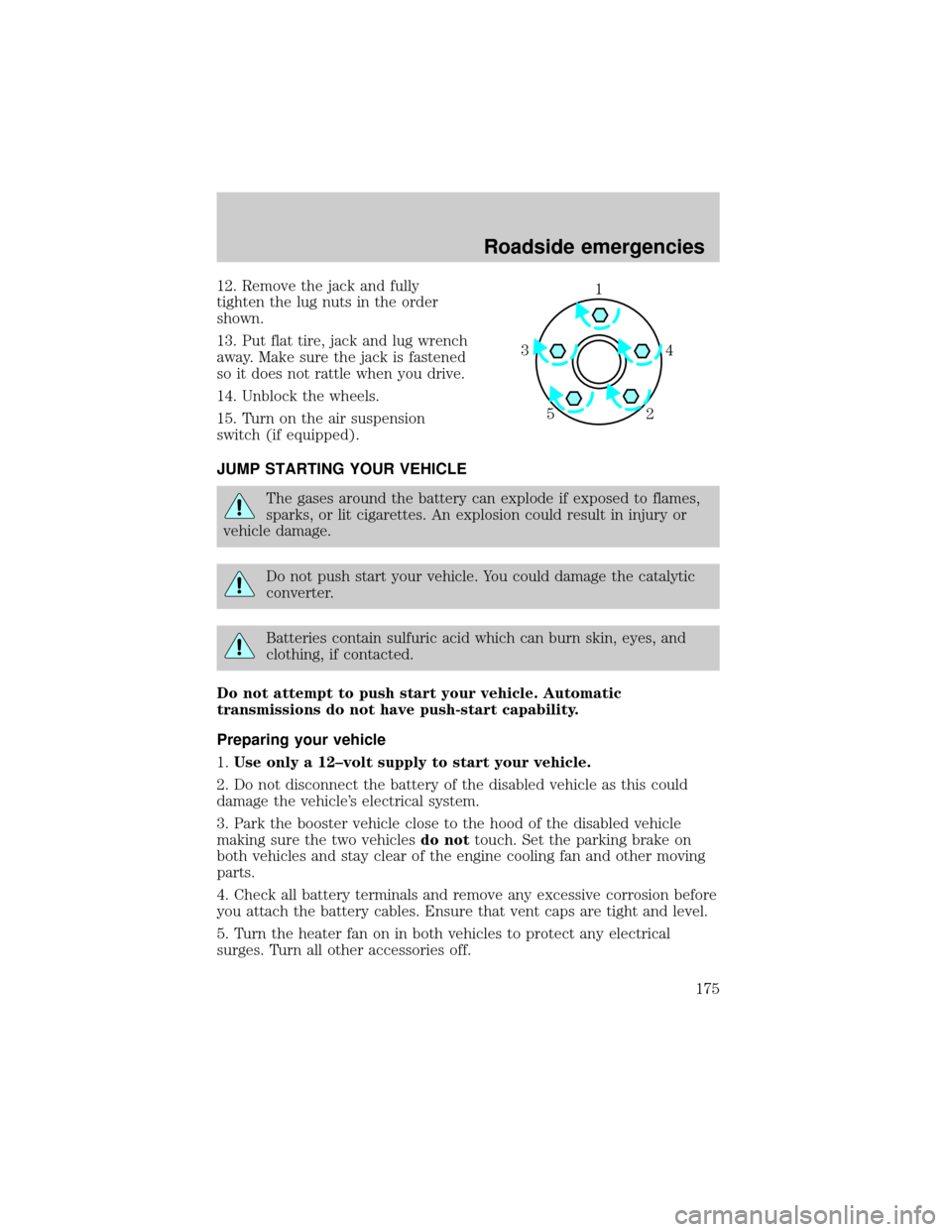

12. Remove the jack and fully

tighten the lug nuts in the order

shown.

13. Put flat tire, jack and lug wrench

away. Make sure the jack is fastened

so it does not rattle when you drive.

14. Unblock the wheels.

15. Turn on the air suspension

switch (if equipped).

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Do not push start your vehicle. You could damage the catalytic

converter.

Batteries contain sulfuric acid which can burn skin, eyes, and

clothing, if contacted.

Do not attempt to push start your vehicle. Automatic

transmissions do not have push-start capability.

Preparing your vehicle

1.Use only a 12±volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle's electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

1

4 3

2 5

Roadside emergencies

175

Page 181 of 256

SERVICE RECOMMENDATIONS

To help you service your vehicle:

²We highlight do-it-yourself items in the engine compartment for easy

location.

²We provide a Scheduled Maintenance Guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

necessary parts and service. Check your ªWarranty Guideº to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

²Do not work on a hot engine.

²When the engine is running, make sure that loose clothing, jewelry or

long hair does not get caught up in moving parts.

²Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

²Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must ªrelearnº its idle

conditions before your vehicle will drive properly, as explained inBattery

in this chapter.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Maintenance and care

181

Page 185 of 256

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

until three clicks can be heard.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Engine oil and filter recommendations

Look for this certification

trademark.

Use SAE 5W-30 motor oil certified for gasoline engines by the American

Petroleum Institute (API).

Motor oil displaying the API certification trademark will meet all

requirements for your vehicle's engine.

Ford oil specification is WSS-M2C153-G.

Do not use supplemental engine oil additives, oil treatments or engine

treatments. They are unnecessary and could, under certain conditions,

lead to engine damage which is not covered by your warranty.

Change your engine oil and filter according to the appropriate schedule

listed in the Scheduled Maintenance Guide.

Maintenance and care

185

Page 190 of 256

Do not put engine coolant in the windshield washer fluid

reservoir. If engine coolant is sprayed onto the windshield, it

could make it difficult to see through the windshield.

When the engine is cool, add a50/50 mixtureof engine coolant and

distilled water to the engine coolant reservoir, until the coolant is at the

ªcold fill levelº or within the ªcold fill rangeº as listed in the engine

coolant reservoir (depending upon application).

²NEVER increase the coolant concentration above 60%.

²NEVER decrease the coolant concentration below 40%.

²Engine coolant concentrations above 60% or below 40% will

decrease the freeze protection characteristics of the engine

coolant and may cause engine damage.

Plain water may be added in an emergency, but youmustreplace it with

a 50/50 mixture of engine coolant and distilled water as soon as possible.

Check the coolant level in the reservoir before you drive your vehicle the

next few times (with the engine cool). If necessary, add a50/50

mixtureof engine coolant and distilled water to the engine coolant

reservoir until the coolant level is at the ªcold fill levelº or within the

ªcold fill rangeº as listed on the reservoir (depending upon application).

Have your dealer check the engine cooling system for leaks if you have

to add more than 1.0 liter (1.0 quart) of engine coolant per month.

To avoid scalding hot steam or coolant from being released from

the engine cooling system, never remove the pressure relief cap

from the engine coolant reservoir while the engine is running or hot.

Failure to follow this warning may result in damage to the engine's

cooling system and possible severe personal injury.

If you must remove the pressure relief cap from the engine coolant

reservoir, follow these steps to avoid personal injury:

1. Before you remove the cap, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly

turn cap counterclockwise until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

Maintenance and care

190

Page 199 of 256

7. Drive the vehicle to complete the relearning process.

²The vehicle may need to be driven 16 km (10 miles) or more to

relearn the idle and fuel trim strategy.

²If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

AIR FILTER MAINTENANCE

Refer to the Scheduled Maintenance Guide for the appropriate intervals

for changing the air filter element.

When changing the air filter element, use only the Motorcraft air filter

element listed. Refer toMotorcraft Part Numbersin theCapacities and

specificationschapter.

Do not start your engine with the air cleaner removed and do

not remove it while the engine is running.

LEAD

RETURN

RECYCLE

Maintenance and care

199

Page 201 of 256

WINDSHIELD WIPER BLADES

Check the wiper blades at least twice a year or when they seem less

effective. Substances such as tree sap and some hot wax treatments used

by commercial car washes reduce the effectiveness of wiper blades.

Checking the wiper blades

If the wiper blades do not wipe properly, clean both the windshield and

wiper blades using undiluted windshield wiper solution or a mild

detergent. Rinse thoroughly with clean water. To avoid damaging the

blades, do not use fuel, kerosene, paint thinner or other solvents.

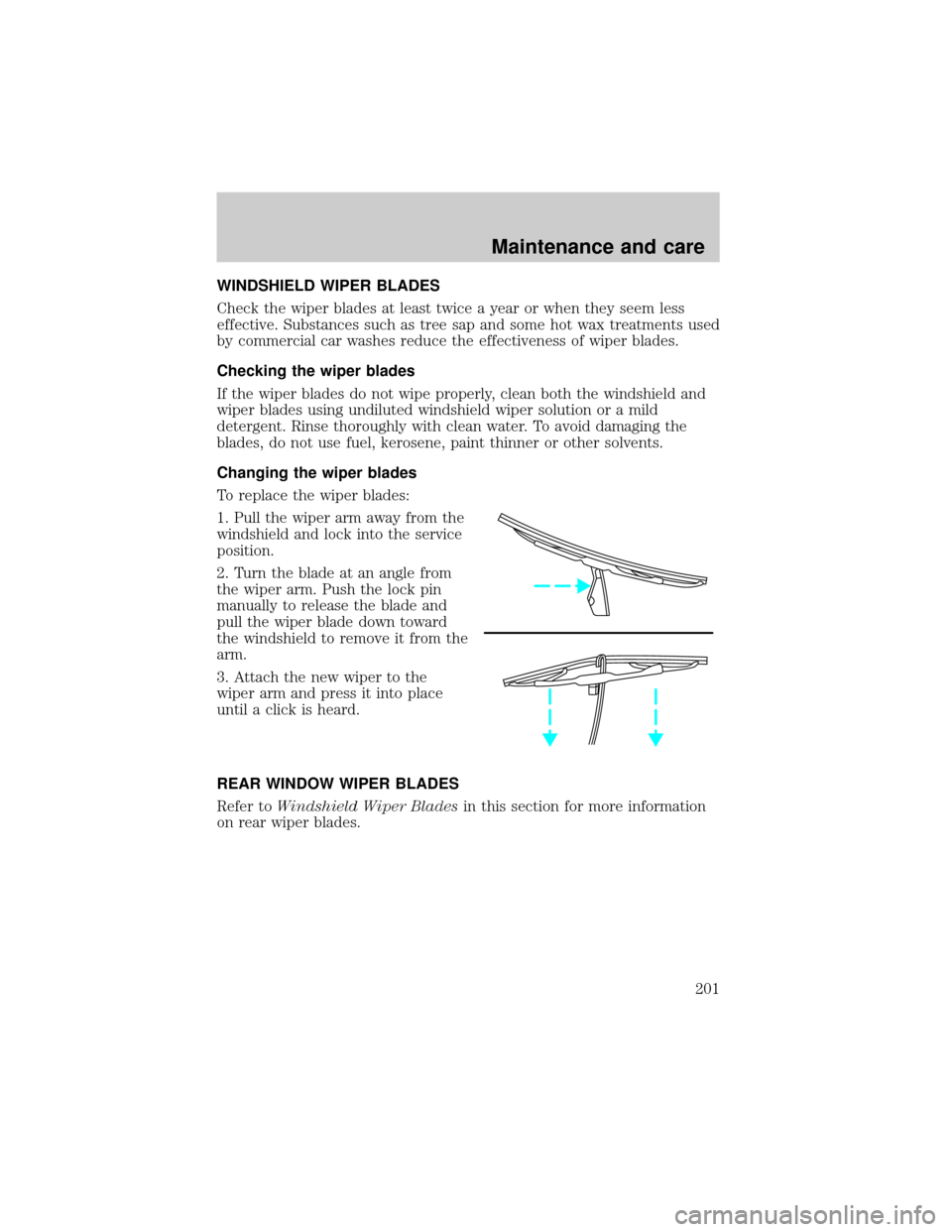

Changing the wiper blades

To replace the wiper blades:

1. Pull the wiper arm away from the

windshield and lock into the service

position.

2. Turn the blade at an angle from

the wiper arm. Push the lock pin

manually to release the blade and

pull the wiper blade down toward

the windshield to remove it from the

arm.

3. Attach the new wiper to the

wiper arm and press it into place

until a click is heard.

REAR WINDOW WIPER BLADES

Refer toWindshield Wiper Bladesin this section for more information

on rear wiper blades.

Maintenance and care

201

Page 209 of 256

Cleaner air

Ford approves the use of reformulated ªcleaner-burningº gasolines to

improve air quality. These gasolines may contain oxygenates up to 10%

ethanol or 15% MTBE.

Running out of fuel

Avoid running out of fuel because this situation may have an adverse

affect on powertrain components.

If you have run out of fuel:

²You may need to cycle the ignition from OFF to ON several times after

refueling, to allow the fuel system to pump the fuel from the tank to

the engine.

²Your ªService Engine Soonº indicator may come on. For more

information on the ªService Engine Soonº indicator, refer to the

Instrumentationchapter.

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a 1/8 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8 of a turn until it

stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it stops.

If the ªService Engine Soon/Check Engineº indicator comes on and stays

on when you start the engine, the fuel filler cap may not be properly

installed. Turn off the engine, remove the fuel filler cap, align the cap

properly and reinstall it.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

Maintenance and care

209

Page 216 of 256

Replacing headlamp bulbs

1. Make sure that the headlamp control is in the OFF position.

2. Open the hood.

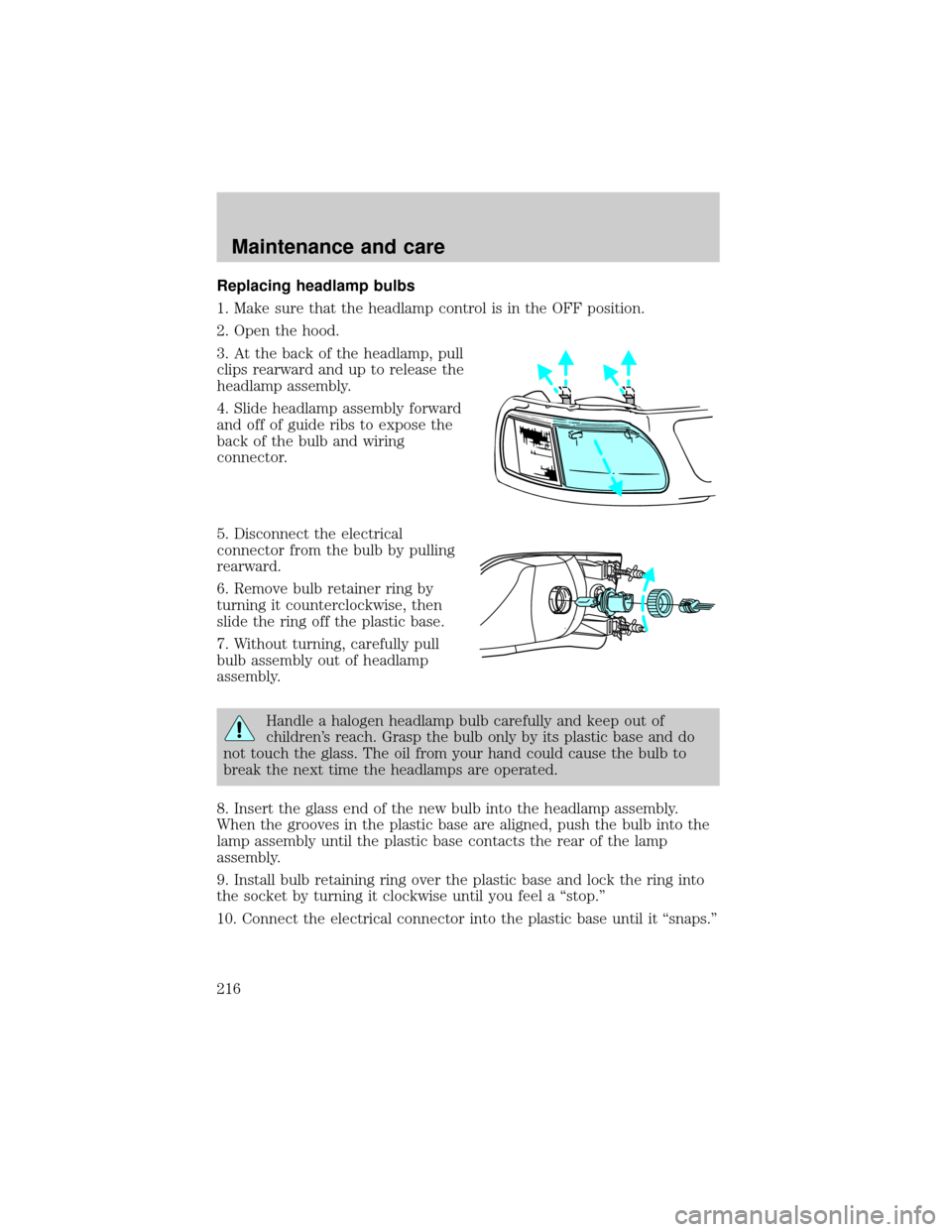

3. At the back of the headlamp, pull

clips rearward and up to release the

headlamp assembly.

4. Slide headlamp assembly forward

and off of guide ribs to expose the

back of the bulb and wiring

connector.

5. Disconnect the electrical

connector from the bulb by pulling

rearward.

6. Remove bulb retainer ring by

turning it counterclockwise, then

slide the ring off the plastic base.

7. Without turning, carefully pull

bulb assembly out of headlamp

assembly.

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

8. Insert the glass end of the new bulb into the headlamp assembly.

When the grooves in the plastic base are aligned, push the bulb into the

lamp assembly until the plastic base contacts the rear of the lamp

assembly.

9. Install bulb retaining ring over the plastic base and lock the ring into

the socket by turning it clockwise until you feel a ªstop.º

10. Connect the electrical connector into the plastic base until it ªsnaps.º

Maintenance and care

216

Page 217 of 256

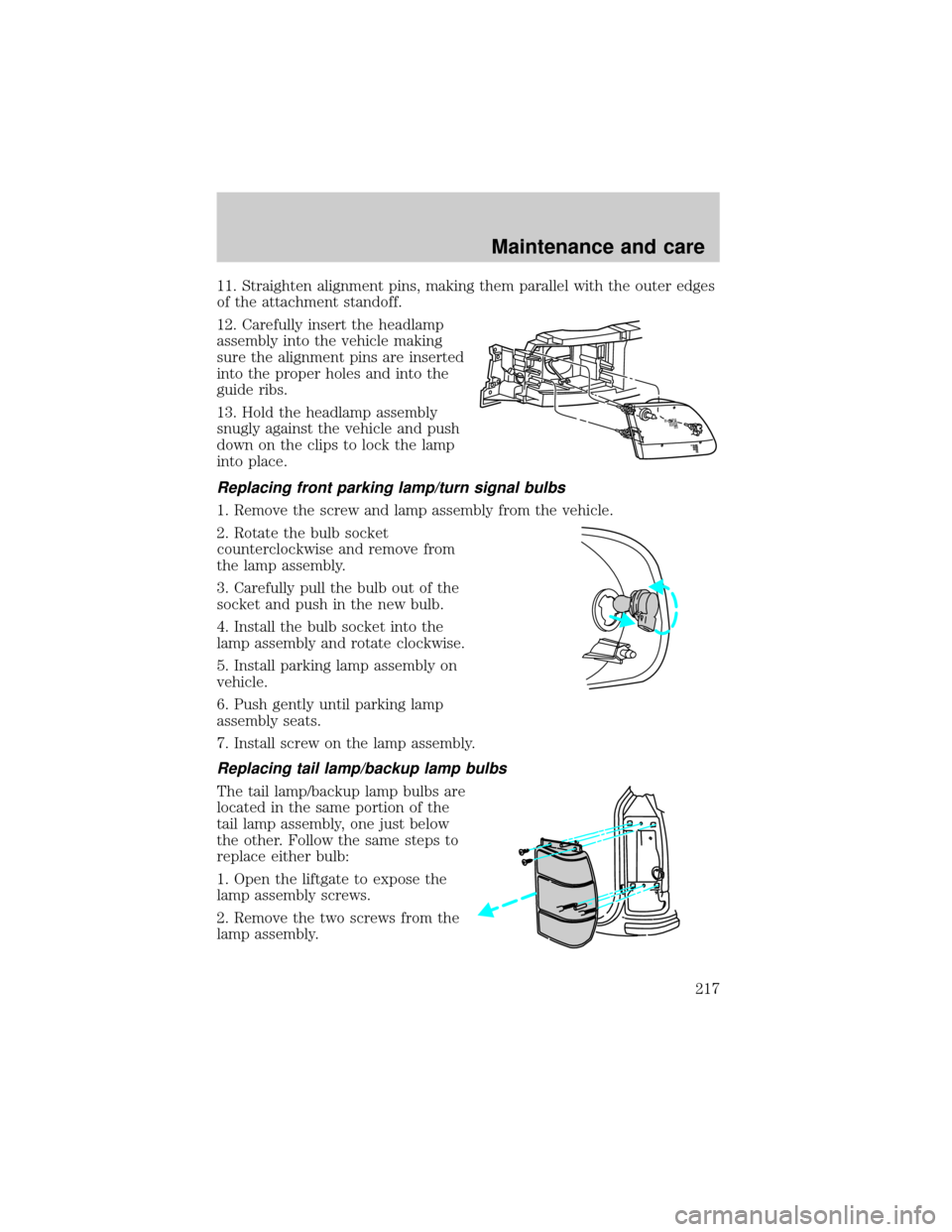

11. Straighten alignment pins, making them parallel with the outer edges

of the attachment standoff.

12. Carefully insert the headlamp

assembly into the vehicle making

sure the alignment pins are inserted

into the proper holes and into the

guide ribs.

13. Hold the headlamp assembly

snugly against the vehicle and push

down on the clips to lock the lamp

into place.

Replacing front parking lamp/turn signal bulbs

1. Remove the screw and lamp assembly from the vehicle.

2. Rotate the bulb socket

counterclockwise and remove from

the lamp assembly.

3. Carefully pull the bulb out of the

socket and push in the new bulb.

4. Install the bulb socket into the

lamp assembly and rotate clockwise.

5. Install parking lamp assembly on

vehicle.

6. Push gently until parking lamp

assembly seats.

7. Install screw on the lamp assembly.

Replacing tail lamp/backup lamp bulbs

The tail lamp/backup lamp bulbs are

located in the same portion of the

tail lamp assembly, one just below

the other. Follow the same steps to

replace either bulb:

1. Open the liftgate to expose the

lamp assembly screws.

2. Remove the two screws from the

lamp assembly.

Maintenance and care

217