maintenance FORD EXPEDITION 2000 1.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: EXPEDITION, Model: FORD EXPEDITION 2000 1.GPages: 256, PDF Size: 2.08 MB

Page 1 of 256

Before driving

Introduction 2

Instrumentation 6

Controls and features 19

Seating and safety restraints 92

Starting and driving

Starting 129

Driving 134

Roadside emergencies 159

Servicing

Maintenance and care 181

Capacities and specifications 226

Customer assistance 235

Reporting safety defects 247

Index 248

All rights reserved. Reproduction by any means, electronic or mechanical including

photocopying, recording or by any information storage and retrieval system or translation

in whole or part is not permitted without written authorization from Ford Motor Company.

Ford may change the contents without notice and without incurring obligation.

Copyright 1999 Ford Motor Company

Contents

1

Page 10 of 256

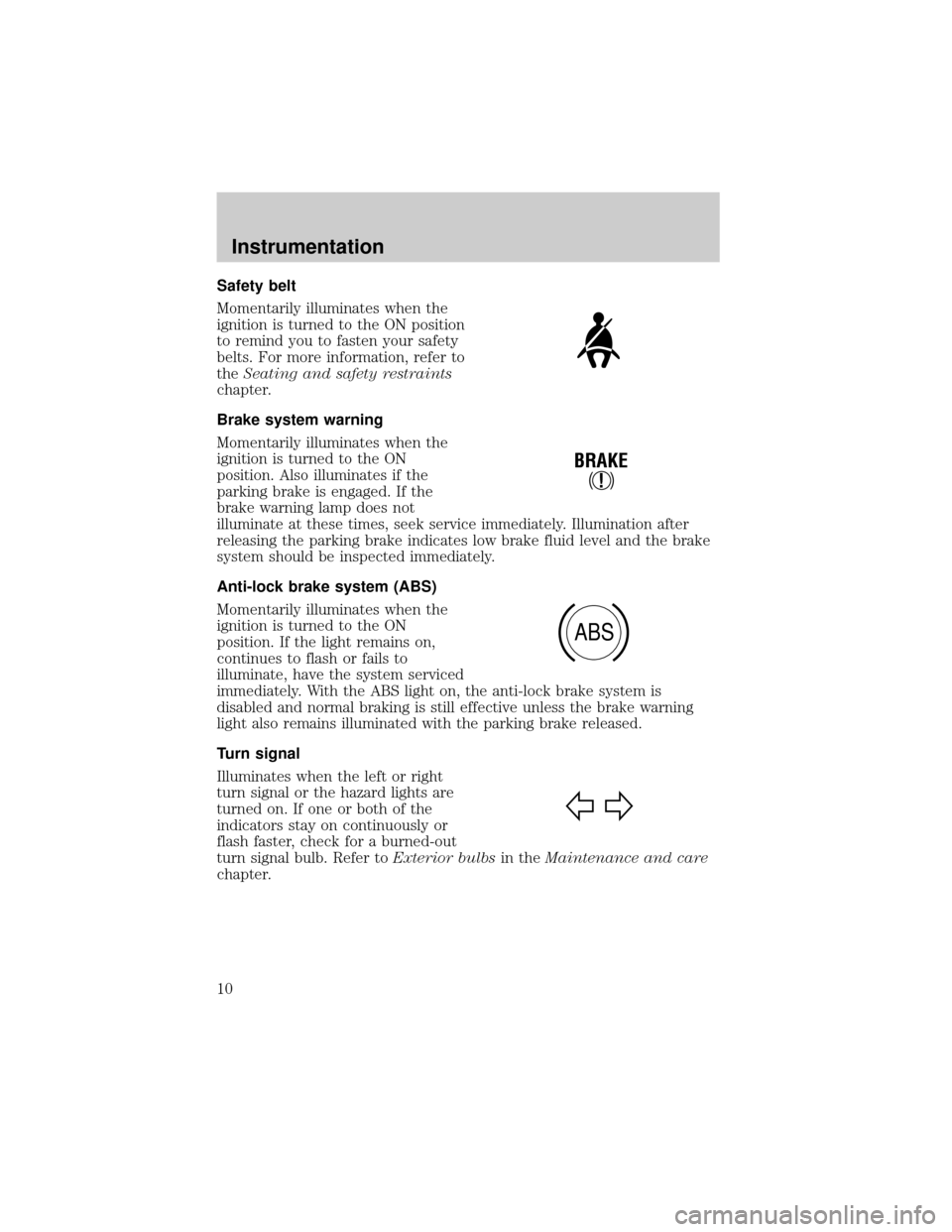

Safety belt

Momentarily illuminates when the

ignition is turned to the ON position

to remind you to fasten your safety

belts. For more information, refer to

theSeating and safety restraints

chapter.

Brake system warning

Momentarily illuminates when the

ignition is turned to the ON

position. Also illuminates if the

parking brake is engaged. If the

brake warning lamp does not

illuminate at these times, seek service immediately. Illumination after

releasing the parking brake indicates low brake fluid level and the brake

system should be inspected immediately.

Anti-lock brake system (ABS)

Momentarily illuminates when the

ignition is turned to the ON

position. If the light remains on,

continues to flash or fails to

illuminate, have the system serviced

immediately. With the ABS light on, the anti-lock brake system is

disabled and normal braking is still effective unless the brake warning

light also remains illuminated with the parking brake released.

Turn signal

Illuminates when the left or right

turn signal or the hazard lights are

turned on. If one or both of the

indicators stay on continuously or

flash faster, check for a burned-out

turn signal bulb. Refer toExterior bulbsin theMaintenance and care

chapter.

!

BRAKE

ABS

Instrumentation

10

Page 15 of 256

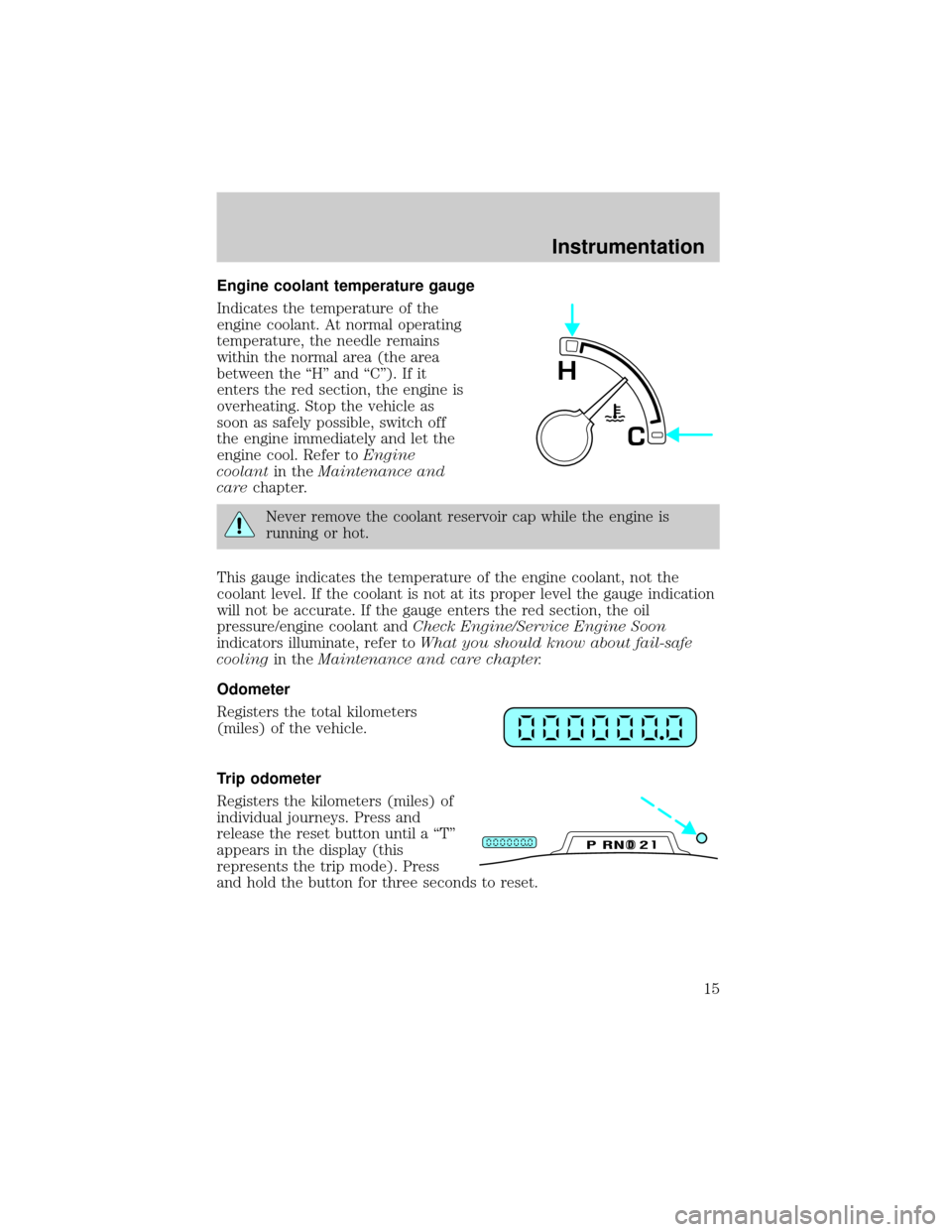

Engine coolant temperature gauge

Indicates the temperature of the

engine coolant. At normal operating

temperature, the needle remains

within the normal area (the area

between the ªHº and ªCº). If it

enters the red section, the engine is

overheating. Stop the vehicle as

soon as safely possible, switch off

the engine immediately and let the

engine cool. Refer toEngine

coolantin theMaintenance and

carechapter.

Never remove the coolant reservoir cap while the engine is

running or hot.

This gauge indicates the temperature of the engine coolant, not the

coolant level. If the coolant is not at its proper level the gauge indication

will not be accurate. If the gauge enters the red section, the oil

pressure/engine coolant andCheck Engine/Service Engine Soon

indicators illuminate, refer toWhat you should know about fail-safe

coolingin theMaintenance and care chapter.

Odometer

Registers the total kilometers

(miles) of the vehicle.

Trip odometer

Registers the kilometers (miles) of

individual journeys. Press and

release the reset button until a ªTº

appears in the display (this

represents the trip mode). Press

and hold the button for three seconds to reset.

C

H

DPRND2

Instrumentation

15

Page 16 of 256

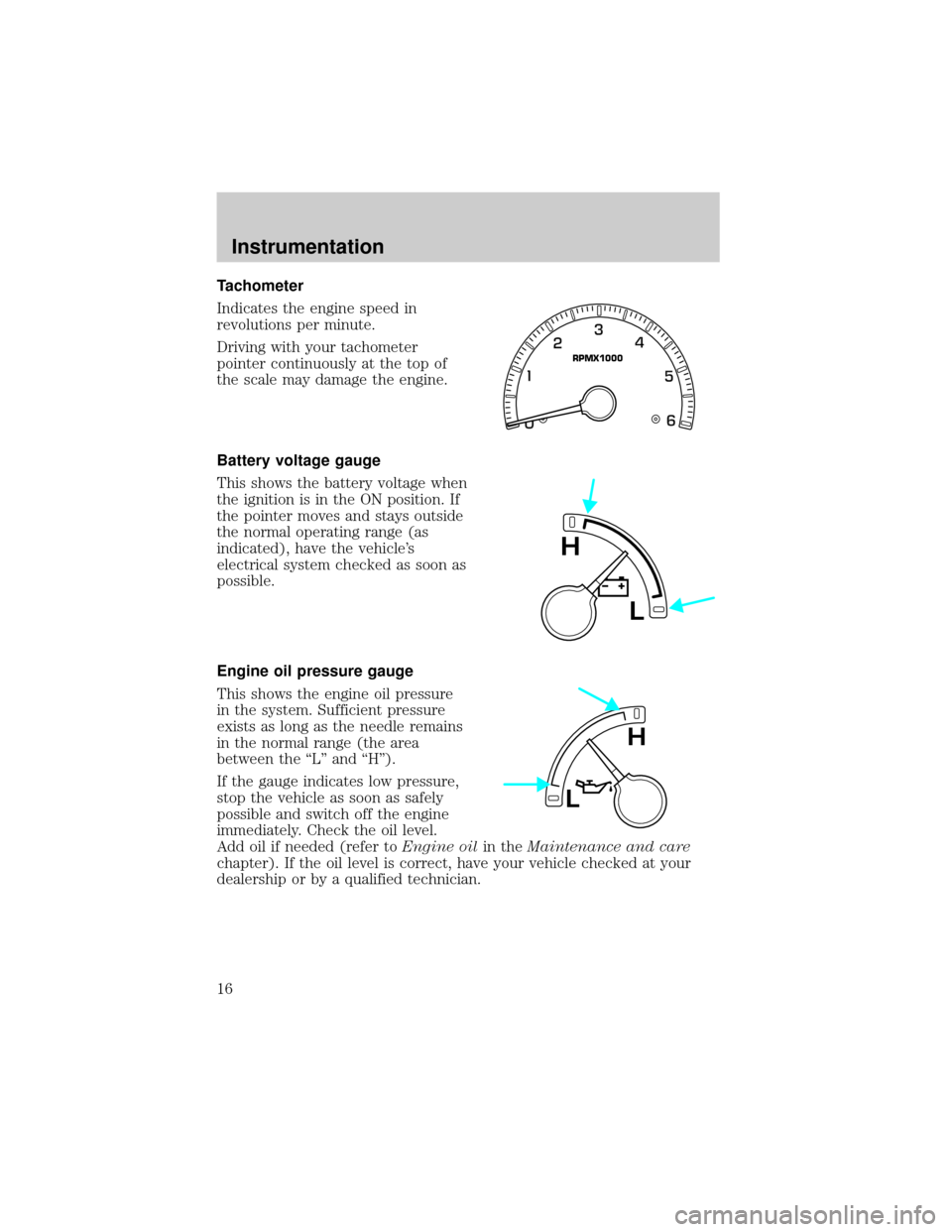

Tachometer

Indicates the engine speed in

revolutions per minute.

Driving with your tachometer

pointer continuously at the top of

the scale may damage the engine.

Battery voltage gauge

This shows the battery voltage when

the ignition is in the ON position. If

the pointer moves and stays outside

the normal operating range (as

indicated), have the vehicle's

electrical system checked as soon as

possible.

Engine oil pressure gauge

This shows the engine oil pressure

in the system. Sufficient pressure

exists as long as the needle remains

in the normal range (the area

between the ªLº and ªHº).

If the gauge indicates low pressure,

stop the vehicle as soon as safely

possible and switch off the engine

immediately. Check the oil level.

Add oil if needed (refer toEngine oilin theMaintenance and care

chapter). If the oil level is correct, have your vehicle checked at your

dealership or by a qualified technician.

RPMX1000

L

H

L

H

Instrumentation

16

Page 113 of 256

6. Within seven seconds of the safety belt warning light turning off,

buckle then unbuckle the safety belt.

²This will disable Belt Minder if it is currently enabled, or enable Belt

Minder if it is currently disabled.

7. Confirmation of disabling Belt Minder is provided by flashing the

safety belt warning light four times per second for three seconds.

8. Confirmation of enabling Belt Minder is provided by flashing the safety

belt warning light four times per second for three seconds, followed by

three seconds with the safety belt warning light off, then followed by

flashing the safety belt warning light four times per second for three

seconds again.

9. After receiving confirmation, the deactivation/activation procedure is

complete.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, wears or cuts, replacing if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), shoulder belt guide on seatback (if

equipped), child safety seat tether bracket assemblies (if equipped), and

attaching hardware, should be inspected after a collision. Ford

recommends that all safety belt assemblies used in vehicles involved in a

collision be replaced. However, if the collision was minor and a qualified

technician finds that the belts do not show damage and continue to

operate properly, they do not need to be replaced. Safety belt assemblies

not in use during a collision should also be inspected and replaced if

either damage or improper operation is noted.

Failure to inspect and if necessary replace the safety belt

assembly under the above conditions could result in severe

personal injuries in the event of a collision.

Refer toCleaning and maintaining the safety beltsin the

Maintenance and caresection.

Seating and safety restraints

113

Page 118 of 256

The RCM (restraints control module) monitors its own internal circuits

and the supplemental air bag electrical system warning (including the

impact sensors, the system wiring, the air bag system readiness light, the

air bag back up power and the air bag ignitors).

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after ignition is turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a

collision.

Disposal of air bags and air bag equipped vehicles

(including pretensioners)

For disposal of air bags or air bag equipped vehicles, see your local

dealership or qualified technician. Air bags MUST BE disposed of by

qualified personnel.

SIDE AIR BAG SYSTEM (IF EQUIPPED)

Do not place objects or mount equipment on or near the air bag

cover on the side of the seatbacks of the front seats or in front

seat areas that may come into contact with a deploying air bag. Failure

to follow these instructions may increase the risk of personal injury in

the event of a collision.

Seating and safety restraints

118

Page 120 of 256

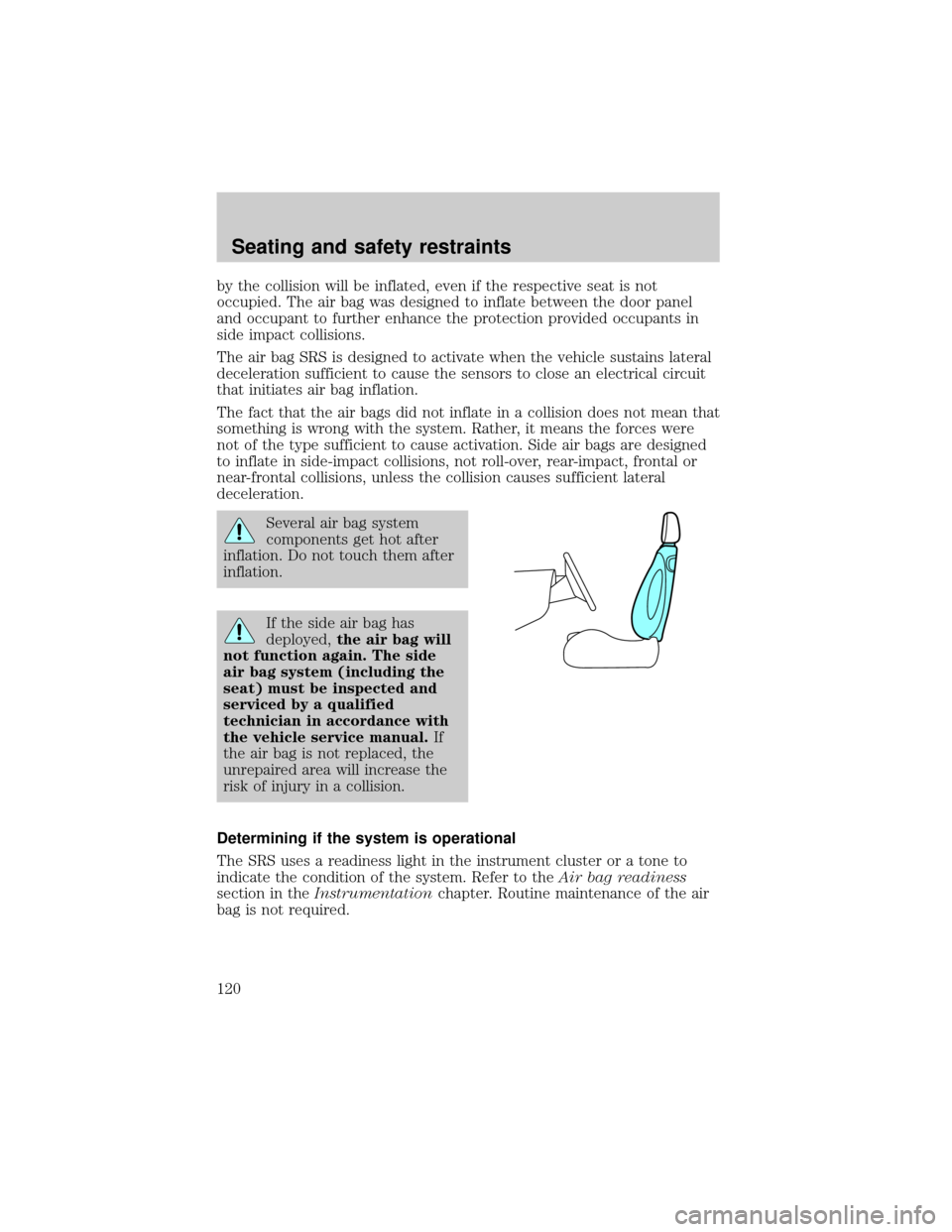

by the collision will be inflated, even if the respective seat is not

occupied. The air bag was designed to inflate between the door panel

and occupant to further enhance the protection provided occupants in

side impact collisions.

The air bag SRS is designed to activate when the vehicle sustains lateral

deceleration sufficient to cause the sensors to close an electrical circuit

that initiates air bag inflation.

The fact that the air bags did not inflate in a collision does not mean that

something is wrong with the system. Rather, it means the forces were

not of the type sufficient to cause activation. Side air bags are designed

to inflate in side-impact collisions, not roll-over, rear-impact, frontal or

near-frontal collisions, unless the collision causes sufficient lateral

deceleration.

Several air bag system

components get hot after

inflation. Do not touch them after

inflation.

If the side air bag has

deployed,the air bag will

not function again. The side

air bag system (including the

seat) must be inspected and

serviced by a qualified

technician in accordance with

the vehicle service manual.If

the air bag is not replaced, the

unrepaired area will increase the

risk of injury in a collision.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

Seating and safety restraints

120

Page 134 of 256

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

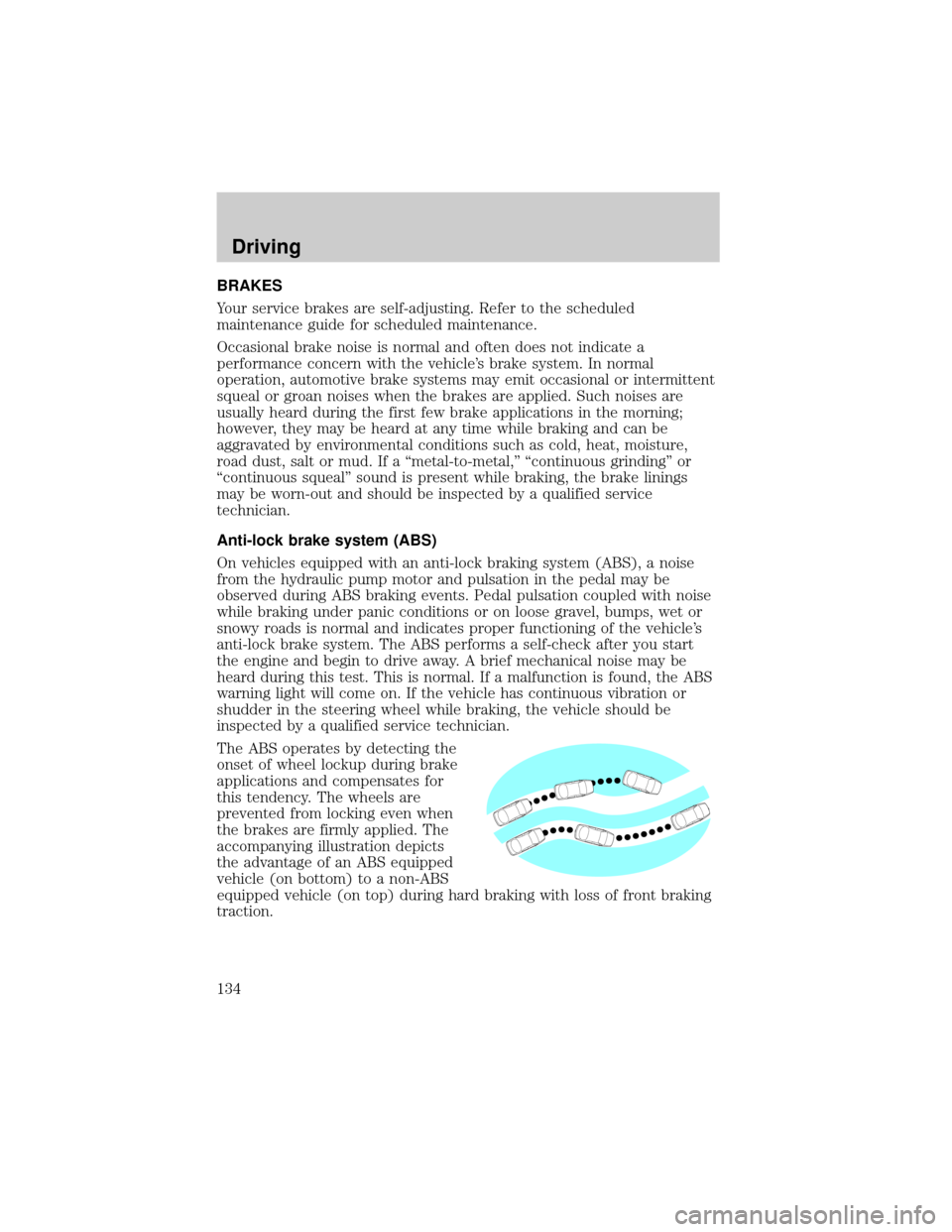

Anti-lock brake system (ABS)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

134

Page 156 of 256

1 814 kg (4 000 lb.) trailer weight and 181 kg (400 lb.) tongue weight

capability.

Use a frame-mounted weight distributing hitch for trailers over 1814 kg

(4 000 lb).

Driving while you tow

When towing a trailer:

²Ensure that you turn off your speed control. The speed control may

shut off automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²Use a lower gear when towing up or down steep hills. This will

eliminate excessive downshifting and upshifting for optimum fuel

economy and transmission cooling.

²Anticipate stops and brake gradually.

Exceeding the GCWR rating may cause internal transmission

damage and void your warranty coverage.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your Scheduled Maintenance guide

for more information.

Recreational towing (all wheels on the ground)

An example of recreational towing would be towing your vehicle behind

a Motorhome. Follow these guidelines if you have the need for

recreational towing your vehicle with all four wheels on the ground.

These guidelines are designed to ensure that your transmission is not

damaged.

2WD vehicles (with automatic transmissions)

²Place the transmission in N (Neutral)

²Maximum speed is 56 km (35 mph)

²Maximum distance is 80 km (50 miles)

If a distance of 80 km (50 miles) or a speed of 56 km (35 mph) must be

exceeded, the drive shaft will have to be removed until the vehicle is

being towed.

Ford recommends the driveshaft be removed/installed only by a qualified

technician. See your local dealer for driveshaft removal/installation.

Driving

156

Page 166 of 256

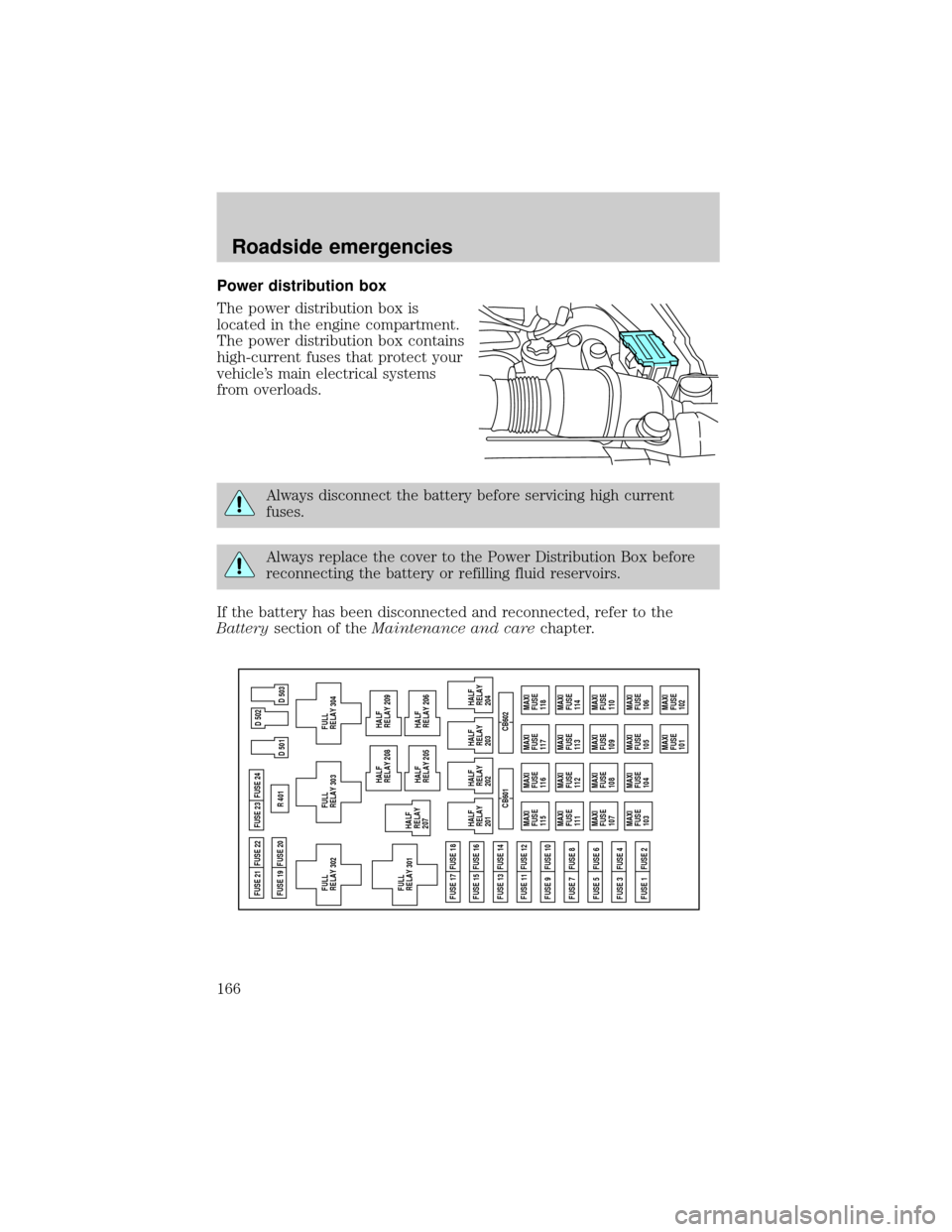

Power distribution box

The power distribution box is

located in the engine compartment.

The power distribution box contains

high-current fuses that protect your

vehicle's main electrical systems

from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and carechapter.

MAXI

FUSE

115MAXI

FUSE

116MAXI

FUSE

117

MAXI

FUSE

118

MAXI

FUSE

111MAXI

FUSE

112MAXI

FUSE

113

MAXI

FUSE

114

MAXI

FUSE

107MAXI

FUSE

108MAXI

FUSE

109

MAXI

FUSE

110

MAXI

FUSE

103MAXI

FUSE

104MAXI

FUSE

105

MAXI

FUSE

106

MAXI

FUSE

101MAXI

FUSE

102 CB601 CB602 FUSE 17 FUSE 18FUSE 21 FUSE 22

FUSE 19 FUSE 20FUSE 23

FULL

RELAY 302R 401

D 501 FUSE 24

FUSE 15 FUSE 16

FUSE 13 FUSE 14

FUSE 11 FUSE 12

FUSE 9 FUSE 10

FUSE 7 FUSE 8

FUSE 5 FUSE 6

FUSE 3 FUSE 4

FUSE 1 FUSE 2

D 503 D 502

FULL

RELAY 301HALF

RELAY

207

FULL

RELAY 303

FULL

RELAY 304

HALF

RELAY

201

HALF

RELAY

202HALF

RELAY 208

HALF

RELAY 209

HALF

RELAY 205

HALF

RELAY 206

HALF

RELAY

203

HALF

RELAY

204

Roadside emergencies

166