wiring FORD EXPEDITION 2000 1.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: EXPEDITION, Model: FORD EXPEDITION 2000 1.GPages: 256, PDF Size: 2.08 MB

Page 117 of 256

The air bags inflate and deflate

rapidly upon activation. After air bag

deployment, it is normal to notice a

smoke-like, powdery residue or

smell the burnt propellant. This may

consist of cornstarch, talcum

powder (to lubricate the bag) or

sodium compounds (e.g., baking

soda) that result from the

combustion process that inflates the

air bag. Small amounts of sodium

hydroxide may be present which

may irritate the skin and eyes, but

none of the residue is toxic.

While the system is designed to help

reduce serious injuries, contact with

a deploying air bag may also cause abrasions, swelling or temporary

hearing loss. Because air bags must inflate rapidly and with considerable

force, there is the risk of death or serious injuries such as fractures,

facial and eye injuries or internal injuries, particularly to occupants who

are not properly restrained or are otherwise out of position at the time

of air bag deployment. Thus, it is extremely important that occupants be

properly restrained as far away from the air bag module as possible while

maintaining vehicle control.

Several air bag system components get hot after inflation. Do not

touch them after inflation.

If the air bag is deployed,the air bag will not function again

and must be replaced immediately.If the air bag is not

replaced, the unrepaired area will increase the risk of injury in a

collision.

The SRS consists of:

²driver and passenger air bag modules (which include the inflators and

air bags),

²one or more impact and safing sensors and diagnostic monitor (RCM),

²a readiness light and tone,

²and the electrical wiring which connects the components.

Seating and safety restraints

117

Page 118 of 256

The RCM (restraints control module) monitors its own internal circuits

and the supplemental air bag electrical system warning (including the

impact sensors, the system wiring, the air bag system readiness light, the

air bag back up power and the air bag ignitors).

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after ignition is turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a

collision.

Disposal of air bags and air bag equipped vehicles

(including pretensioners)

For disposal of air bags or air bag equipped vehicles, see your local

dealership or qualified technician. Air bags MUST BE disposed of by

qualified personnel.

SIDE AIR BAG SYSTEM (IF EQUIPPED)

Do not place objects or mount equipment on or near the air bag

cover on the side of the seatbacks of the front seats or in front

seat areas that may come into contact with a deploying air bag. Failure

to follow these instructions may increase the risk of personal injury in

the event of a collision.

Seating and safety restraints

118

Page 152 of 256

2. Weigh your vehicle as you customarily operate the vehicle without

cargo. To obtain correct weights, try taking your vehicle to a shipping

company or an inspection station for trucks.

3. Subtract your loaded vehicle weight from the maximum GCWR on the

following charts. This is the maximum trailer weight your vehicle can tow

and must fall below the maximum shown under maximum trailer weight

on the chart.

TRAILER TOWING

Trailer towing with your vehicle may

require the use of a trailer tow

option package.

Trailer towing puts additional loads

on your vehicle's engine,

transmission, axle, brakes, tires, and

suspension. For your safety and to

maximize vehicle performance, be

sure to use the proper equipment

while towing.

Follow these guidelines to ensure safe towing procedure:

²Stay within your vehicle's load limits. If exceeded, cargo should be

removed from the trailer and/or the vehicle until all weights are within

specified limits.

²Thoroughly prepare your vehicle for towing. Refer toPreparing to

towin this chapter.

²Use extra caution when driving while trailer towing. Refer toDriving

while you towin this chapter.

²Service your vehicle more frequently if you tow a trailer. Refer to the

severe duty schedule in the ªService Guideº.

²Do not tow a trailer until your vehicle has been driven at least 800 km

(500 miles).

²Refer to the instructions included with towing accessories for the

proper installation and adjustment specifications.

If your vehicle is equipped with the optional heavy duty trailer tow

wiring, it is pre-wired for trailer towing. An electrical connector is

provided under the instrument panel for installing a customer-supplied

electric brake controller. Another electrical connector is provided at the

hitch. This connector provides power to the trailer for taillamps, stop

Driving

152

Page 158 of 256

Disconnect the wiring to the trailer before backing the trailer into the

water. Reconnect the wiring to the trailer after the trailer is removed

from the water.

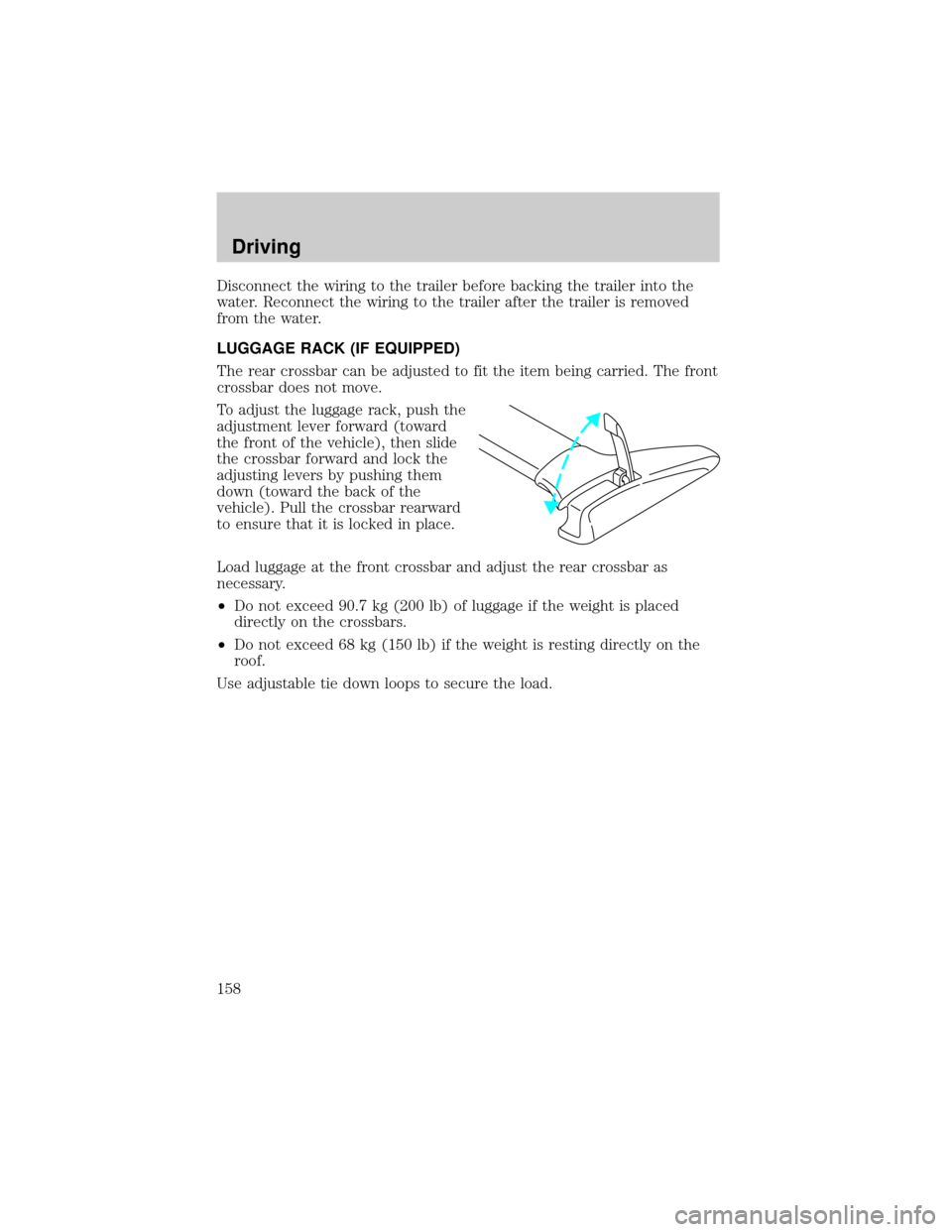

LUGGAGE RACK (IF EQUIPPED)

The rear crossbar can be adjusted to fit the item being carried. The front

crossbar does not move.

To adjust the luggage rack, push the

adjustment lever forward (toward

the front of the vehicle), then slide

the crossbar forward and lock the

adjusting levers by pushing them

down (toward the back of the

vehicle). Pull the crossbar rearward

to ensure that it is locked in place.

Load luggage at the front crossbar and adjust the rear crossbar as

necessary.

²Do not exceed 90.7 kg (200 lb) of luggage if the weight is placed

directly on the crossbars.

²Do not exceed 68 kg (150 lb) if the weight is resting directly on the

roof.

Use adjustable tie down loops to secure the load.

Driving

158

Page 205 of 256

Do not replace your tires with ªhigh performanceº tires or larger

size tires.

Failure to follow these precautions may adversely affect the

handling of the vehicle and make it easier for the driver to lose

control and roll over.

Tires that are larger or smaller than your vehicle's original tires may also

affect the accuracy of your speedometer.

SNOW TIRES AND CHAINS

Snow tires must be the same size and grade as the tires you

currently have on your vehicle.

The tires on your vehicle have all weather treads to provide traction in

rain and snow. However, in some climates, you may need to use snow

tires and chains.

Follow these guidelines when using snow tires and chains:

²Use only cable type chains offered by Ford as an accessory or

equivalent. SAE class ªSº or other conventional link type chains may

contact and cause damage to the vehicle's wheel house and/or body.

²Install chains securely, verifying that the chains do not touch any

wiring, brake lines or fuel lines.

²Drive cautiously. If you hear the chains rub or bang against your

vehicle, stop and re-tighten the chains. If this does not work, remove

the chains to prevent damage to your vehicle.

²If possible, avoid fully loading your vehicle.

²Remove the tire chains when they are no longer needed. Do not use

tire chains on dry roads.

²The suspension insulation and bumpers will help prevent vehicle

damage. Do not remove these components from your vehicle when

using snow tires and chains.

²Do not exceed 48 km/h (30 mph) with tire chains on your vehicle.

Maintenance and care

205

Page 216 of 256

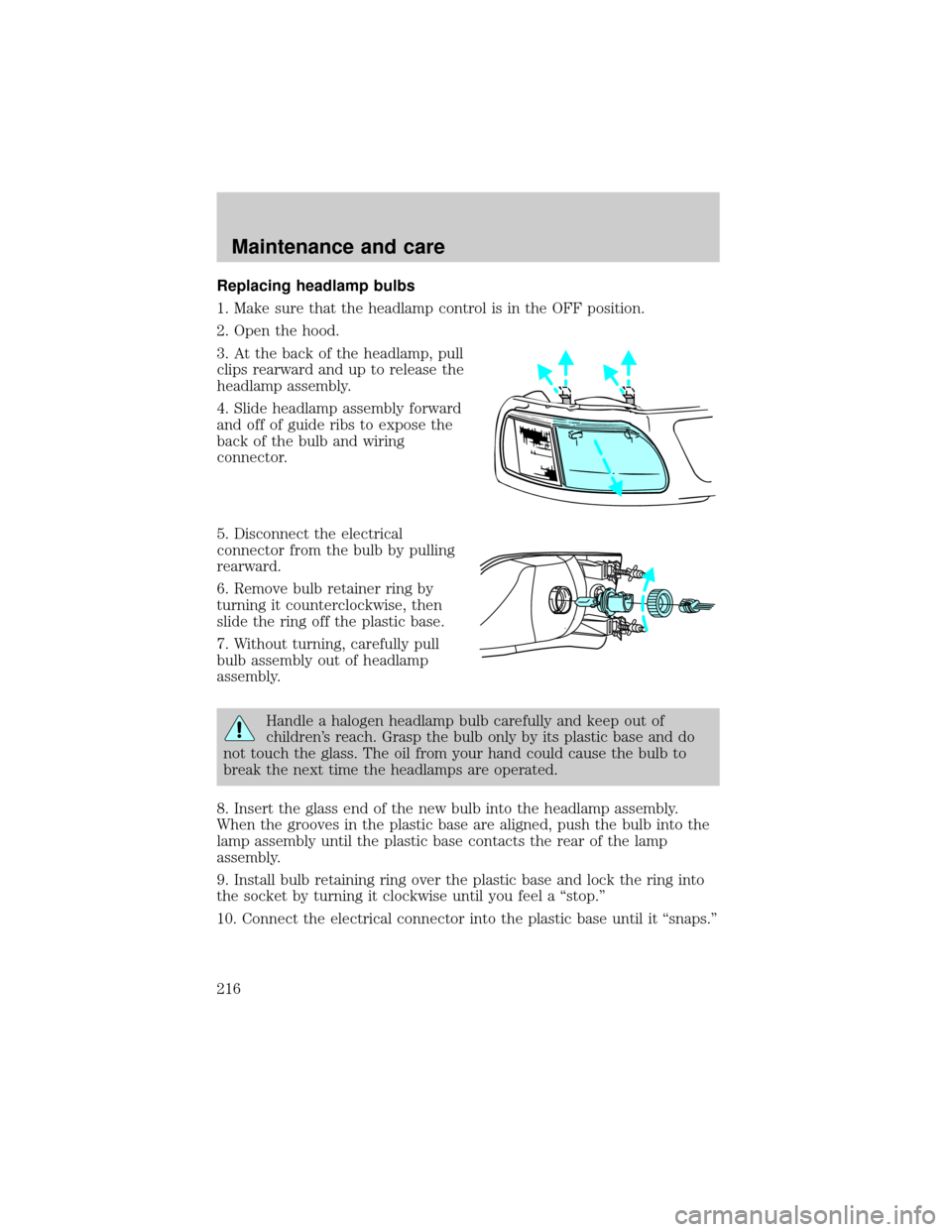

Replacing headlamp bulbs

1. Make sure that the headlamp control is in the OFF position.

2. Open the hood.

3. At the back of the headlamp, pull

clips rearward and up to release the

headlamp assembly.

4. Slide headlamp assembly forward

and off of guide ribs to expose the

back of the bulb and wiring

connector.

5. Disconnect the electrical

connector from the bulb by pulling

rearward.

6. Remove bulb retainer ring by

turning it counterclockwise, then

slide the ring off the plastic base.

7. Without turning, carefully pull

bulb assembly out of headlamp

assembly.

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

8. Insert the glass end of the new bulb into the headlamp assembly.

When the grooves in the plastic base are aligned, push the bulb into the

lamp assembly until the plastic base contacts the rear of the lamp

assembly.

9. Install bulb retaining ring over the plastic base and lock the ring into

the socket by turning it clockwise until you feel a ªstop.º

10. Connect the electrical connector into the plastic base until it ªsnaps.º

Maintenance and care

216

Page 244 of 256

Comfort and convenience

Cabin air filter

Cargo nets

Cargo organizers

Cargo trays

Dash trim (wood grain)

Engine block heaters

Tire step

Travel equipment

Auto headlamps with DRL

Bumper mount bike carrier

Daytime running lights (DRL)

Factory luggage rack adaptors

Fog lights

Framed luggage covers

Heavy-duty battery

Luggage/cargo basket

Removable luggage rack (Track rider bars)

Removable luggage rack adapters

Running boards (Molded and tubular)

Snow traction cables

Soft luggage cover

Towing mirrors (Removable and permanent)

Trailer hitch (Class III)

Trailer hitch bars and balls

Trailer hitch wiring adaptor

Protection and appearance equipment

Air bag anti-theft locks

Car/truck covers

Cargo liners, interior

Customer assistance

244