clock FORD EXPEDITION 2004 2.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2004, Model line: EXPEDITION, Model: FORD EXPEDITION 2004 2.GPages: 344, PDF Size: 11.56 MB

Page 97 of 344

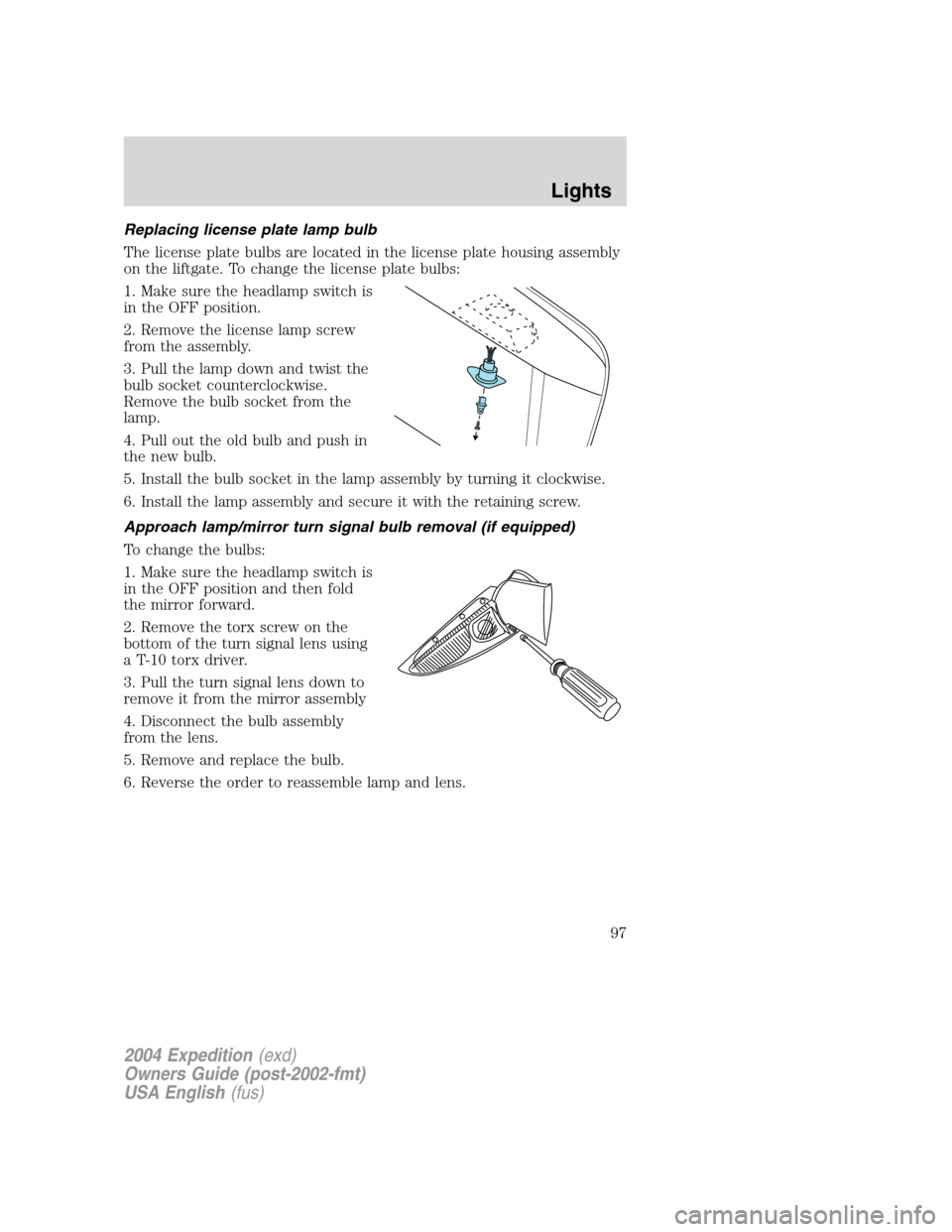

Replacing license plate lamp bulb

The license plate bulbs are located in the license plate housing assembly

on the liftgate. To change the license plate bulbs:

1. Make sure the headlamp switch is

in the OFF position.

2. Remove the license lamp screw

from the assembly.

3. Pull the lamp down and twist the

bulb socket counterclockwise.

Remove the bulb socket from the

lamp.

4. Pull out the old bulb and push in

the new bulb.

5. Install the bulb socket in the lamp assembly by turning it clockwise.

6. Install the lamp assembly and secure it with the retaining screw.

Approach lamp/mirror turn signal bulb removal (if equipped)

To change the bulbs:

1. Make sure the headlamp switch is

in the OFF position and then fold

the mirror forward.

2. Remove the torx screw on the

bottom of the turn signal lens using

a T-10 torx driver.

3. Pull the turn signal lens down to

remove it from the mirror assembly

4. Disconnect the bulb assembly

from the lens.

5. Remove and replace the bulb.

6. Reverse the order to reassemble lamp and lens.

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Lights

97

Page 205 of 344

If a load is added to, or removed from the vehicle, the load leveling

feature of the air suspension system will adjust the suspension to keep

the vehicle at a constant level.

When exiting the vehicle, the air suspension will automatically lower the

vehicle to its lowest height to provide easier exit. You may hear a buzz or

click from the air suspension system when the ignition is turned off. The

air suspension system will stay active for 40 minutes after the ignition is

turned off to accommodate any load changes. (The air compressor may

run when the vehicle is off; this is normal.)

The air suspension shut-off switch is

located behind two access panels on

the left rear quarter trim panel, near

the liftgate. To remove the first

panel, turn the control

counterclockwise and remove the

panel.

On vehicles equipped with

air suspension, turn the air

suspension and the ignition switch

off prior to jacking, hoisting or

towing your vehicle.

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Driving

205

Page 253 of 344

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

The use of tire sealants may damage your tires. The use of tire

sealants may also damage your tire pressure monitoring system

(if equipped).

Your vehicle may be equipped with a conventional spare tire that is

different in one or more of the following: type, brand, size, speed rating

and tread design. If this is the case, this dissimilar spare tire is still rated

for your vehicle loads (GAWR and GVWR). Your vehicle is equipped with

a spare wheel that does not match the road wheels and is not equipped

with a Tire Pressure Monitor System (TPMS) sensor.

Spare tire information

Note:If your vehicle is equipped with the tire pressure monitoring

system (TPMS), the system indicator light will illuminate when the spare

is in use. To restore the full functionality of the monitoring system, all

road wheels equipped with tire pressure monitoring sensors must be

mounted on the vehicle

If your vehicle is equipped with TPMS, have a flat tire serviced by a

dealer or qualified technician in order to prevent damage to the TPMS

sensor. Replace the spare tire with a road tire as soon as possible.

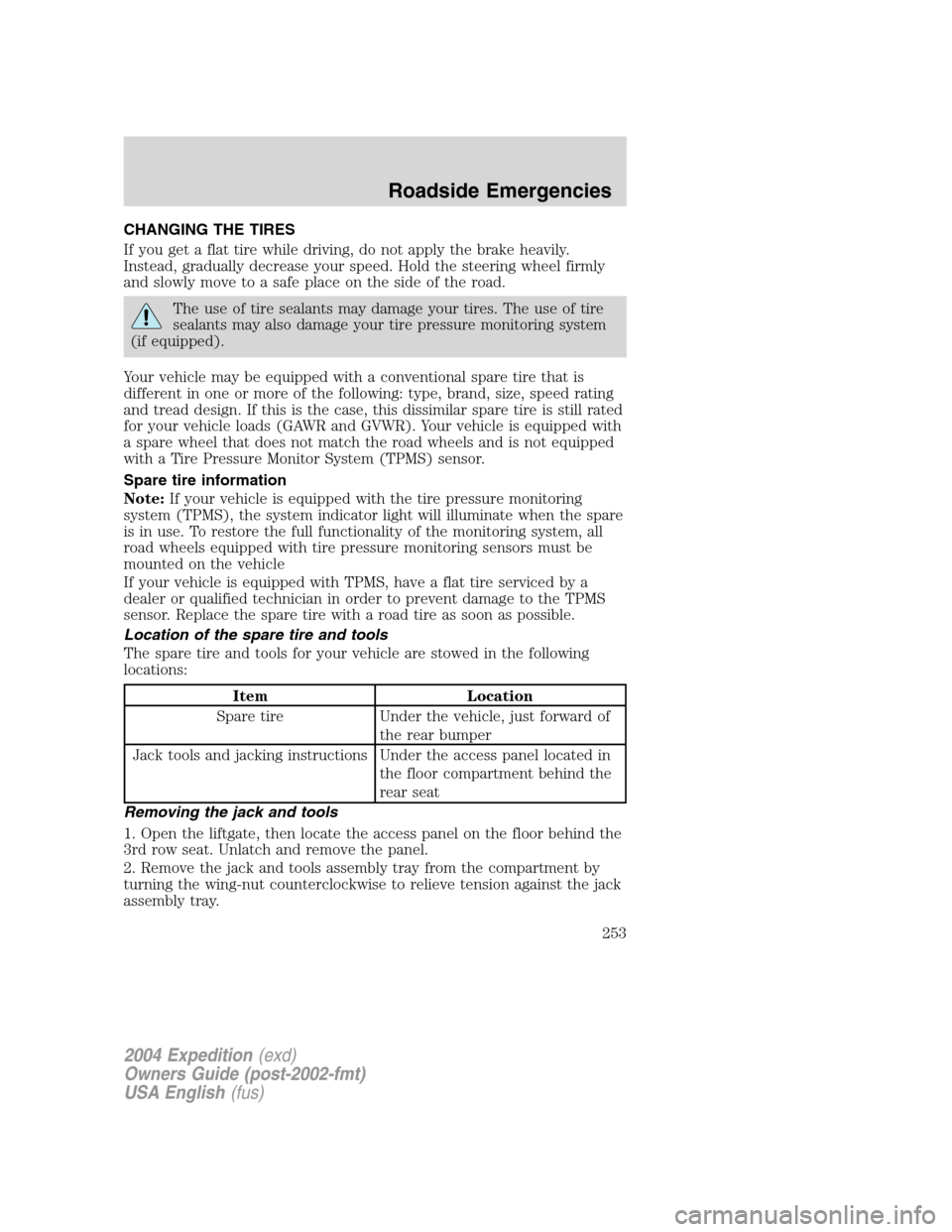

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Item Location

Spare tire Under the vehicle, just forward of

the rear bumper

Jack tools and jacking instructions Under the access panel located in

the floor compartment behind the

rear seat

Removing the jack and tools

1. Open the liftgate, then locate the access panel on the floor behind the

3rd row seat. Unlatch and remove the panel.

2. Remove the jack and tools assembly tray from the compartment by

turning the wing-nut counterclockwise to relieve tension against the jack

assembly tray.

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

253

Page 254 of 344

3. Unsnap the wheel lug nut wrench, jack extension and handle from the

plastic tray. Remove the jack and instruction sheet from the tray

assembly.

Removing the spare tire

1. Fold the rear seat down. Refer to

Rear seatsin theSeating and

safety restraintschapter.

2. Remove the jack handle and

winch extension from the tray and

assemble them.

3. Open the spare tire winch access

plug in the bottom of the

compartment located behind the 3rd

row seat, very close to the jack and

tools tray.

4. Insert the winch extension tool

assembly through the access hole in

the floor and engage the winch.

5. To remove the spare tire, turn the handle counterclockwise until the

tire is lowered to the ground and the cable is slightly slack.

6. Slide the retainer through the center of the spare tire wheel.

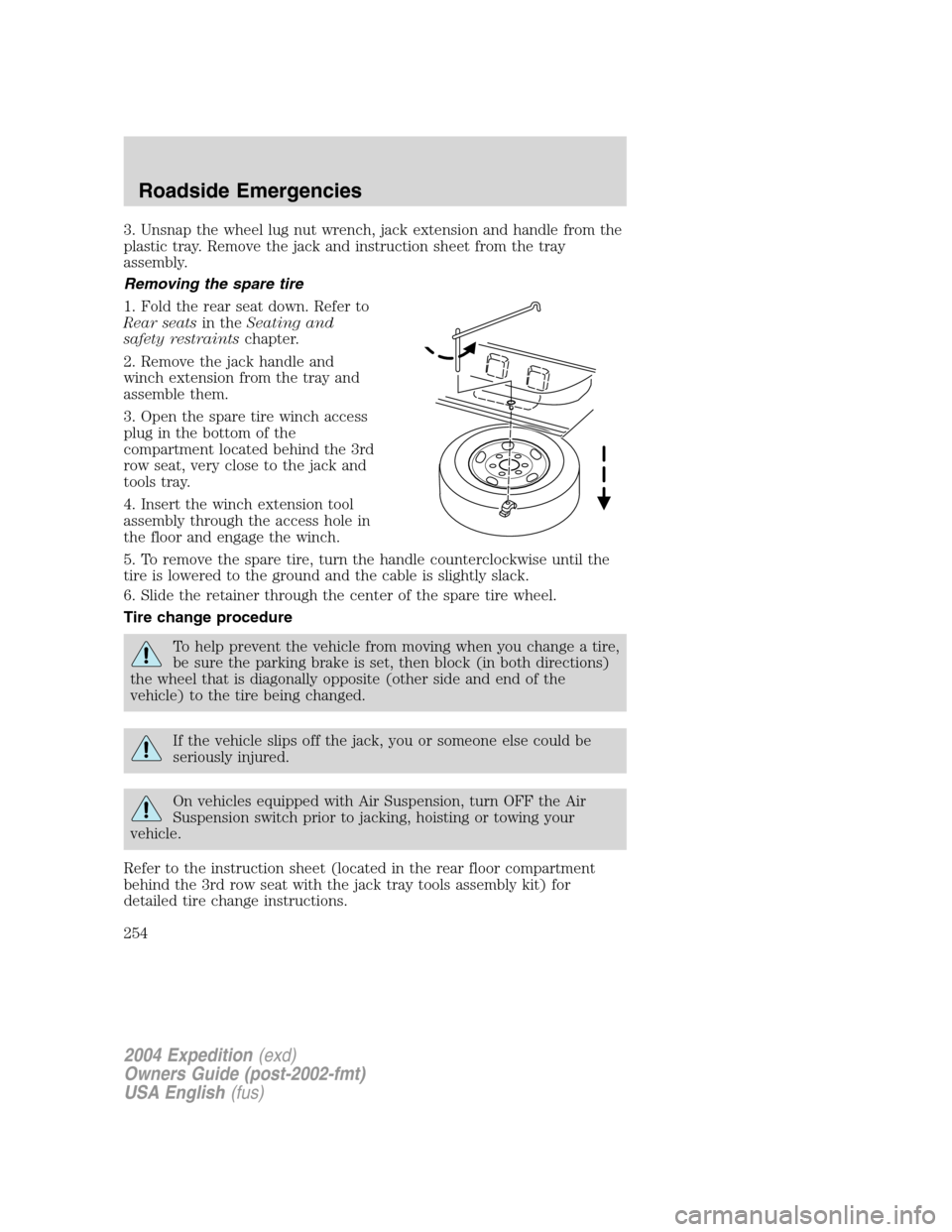

Tire change procedure

To help prevent the vehicle from moving when you change a tire,

be sure the parking brake is set, then block (in both directions)

the wheel that is diagonally opposite (other side and end of the

vehicle) to the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

On vehicles equipped with Air Suspension, turn OFF the Air

Suspension switch prior to jacking, hoisting or towing your

vehicle.

Refer to the instruction sheet (located in the rear floor compartment

behind the 3rd row seat with the jack tray tools assembly kit) for

detailed tire change instructions.

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

254

Page 255 of 344

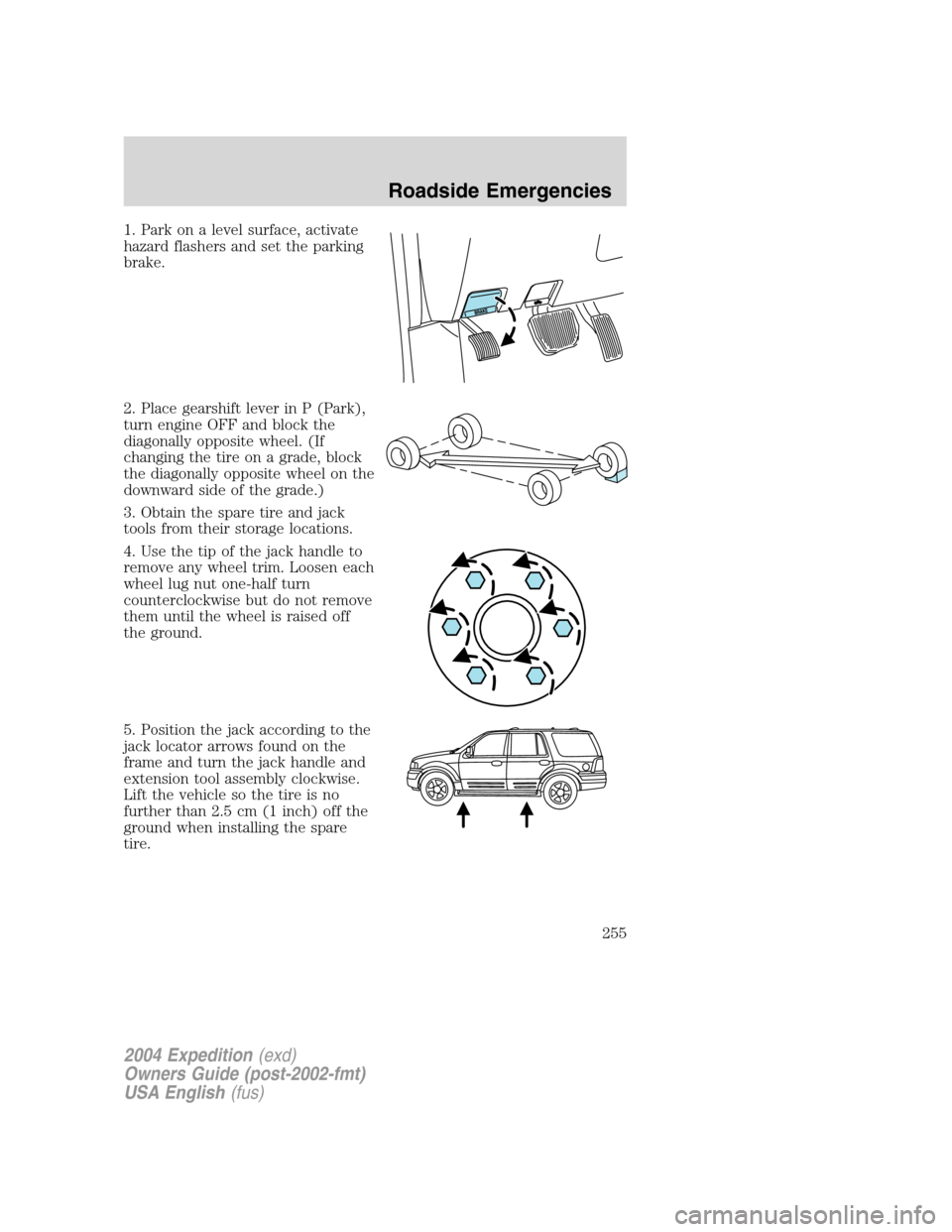

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

2. Place gearshift lever in P (Park),

turn engine OFF and block the

diagonally opposite wheel. (If

changing the tire on a grade, block

the diagonally opposite wheel on the

downward side of the grade.)

3. Obtain the spare tire and jack

tools from their storage locations.

4. Use the tip of the jack handle to

remove any wheel trim. Loosen each

wheel lug nut one-half turn

counterclockwise but do not remove

them until the wheel is raised off

the ground.

5. Position the jack according to the

jack locator arrows found on the

frame and turn the jack handle and

extension tool assembly clockwise.

Lift the vehicle so the tire is no

further than 2.5 cm (1 inch) off the

ground when installing the spare

tire.

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

255

Page 257 of 344

•Never use the front or rear differential as a jacking point.

6. Remove the lug nuts with the lug wrench.

7. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

8. Lower the wheel by turning the jack handle counterclockwise.

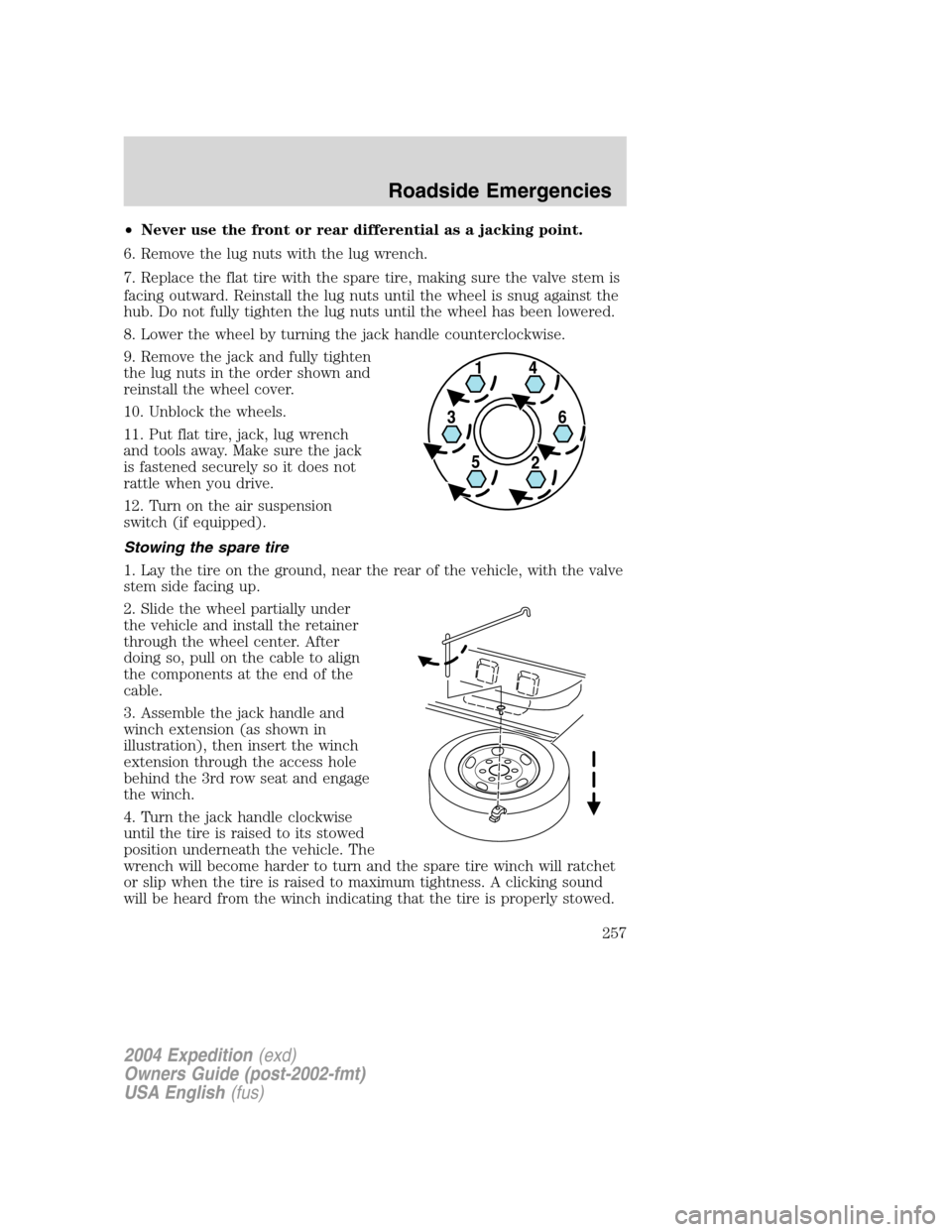

9. Remove the jack and fully tighten

the lug nuts in the order shown and

reinstall the wheel cover.

10. Unblock the wheels.

11. Put flat tire, jack, lug wrench

and tools away. Make sure the jack

is fastened securely so it does not

rattle when you drive.

12. Turn on the air suspension

switch (if equipped).

Stowing the spare tire

1. Lay the tire on the ground, near the rear of the vehicle, with the valve

stem side facing up.

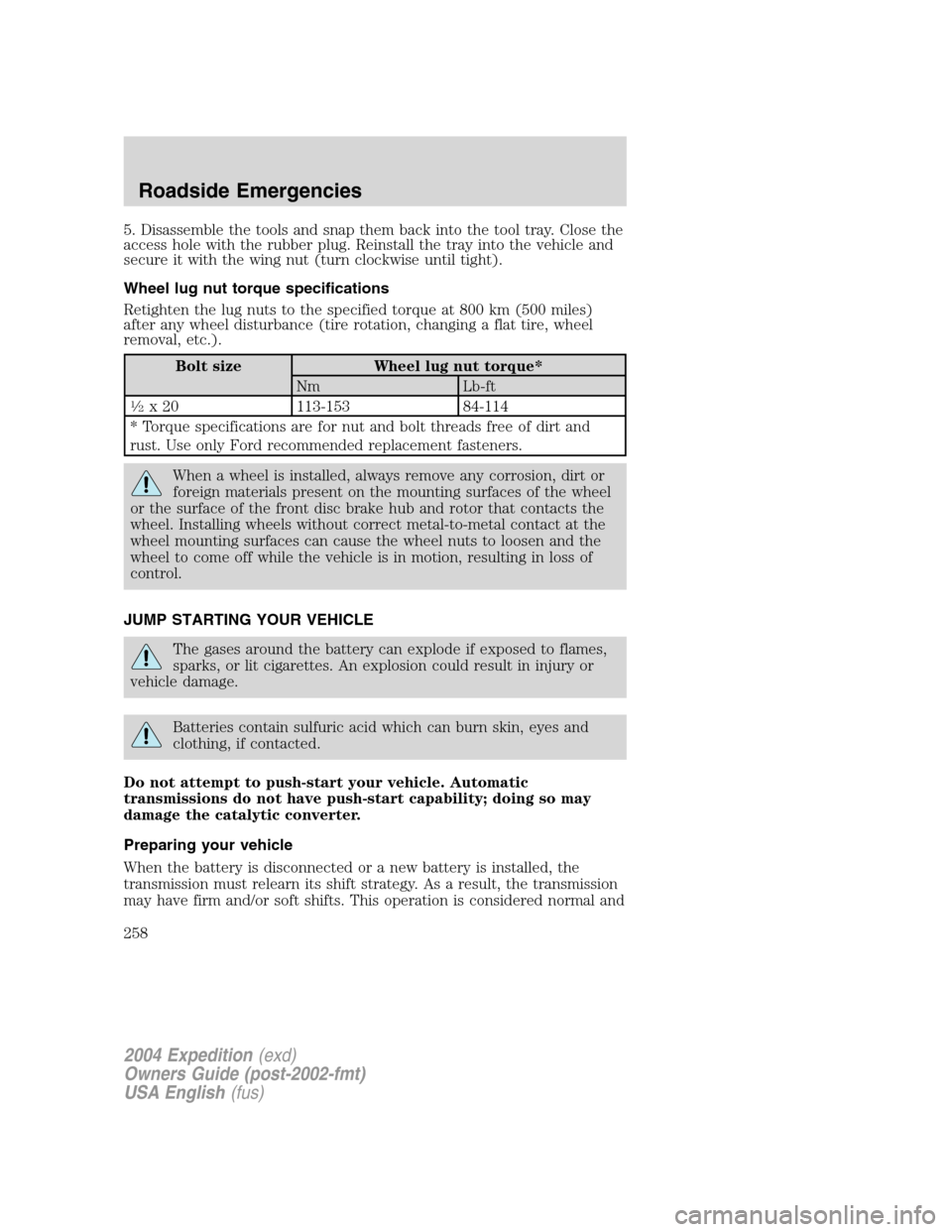

2. Slide the wheel partially under

the vehicle and install the retainer

through the wheel center. After

doing so, pull on the cable to align

the components at the end of the

cable.

3. Assemble the jack handle and

winch extension (as shown in

illustration), then insert the winch

extension through the access hole

behind the 3rd row seat and engage

the winch.

4. Turn the jack handle clockwise

until the tire is raised to its stowed

position underneath the vehicle. The

wrench will become harder to turn and the spare tire winch will ratchet

or slip when the tire is raised to maximum tightness. A clicking sound

will be heard from the winch indicating that the tire is properly stowed.

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

257

Page 258 of 344

5. Disassemble the tools and snap them back into the tool tray. Close the

access hole with the rubber plug. Reinstall the tray into the vehicle and

secure it with the wing nut (turn clockwise until tight).

Wheel lug nut torque specifications

Retighten the lug nuts to the specified torque at 800 km (500 miles)

after any wheel disturbance (tire rotation, changing a flat tire, wheel

removal, etc.).

Bolt size Wheel lug nut torque*

Nm Lb-ft

1�2x 20 113-153 84-114

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

When a wheel is installed, always remove any corrosion, dirt or

foreign materials present on the mounting surfaces of the wheel

or the surface of the front disc brake hub and rotor that contacts the

wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the

wheel to come off while the vehicle is in motion, resulting in loss of

control.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; doing so may

damage the catalytic converter.

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

258

Page 287 of 344

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until the cap is fully seated.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

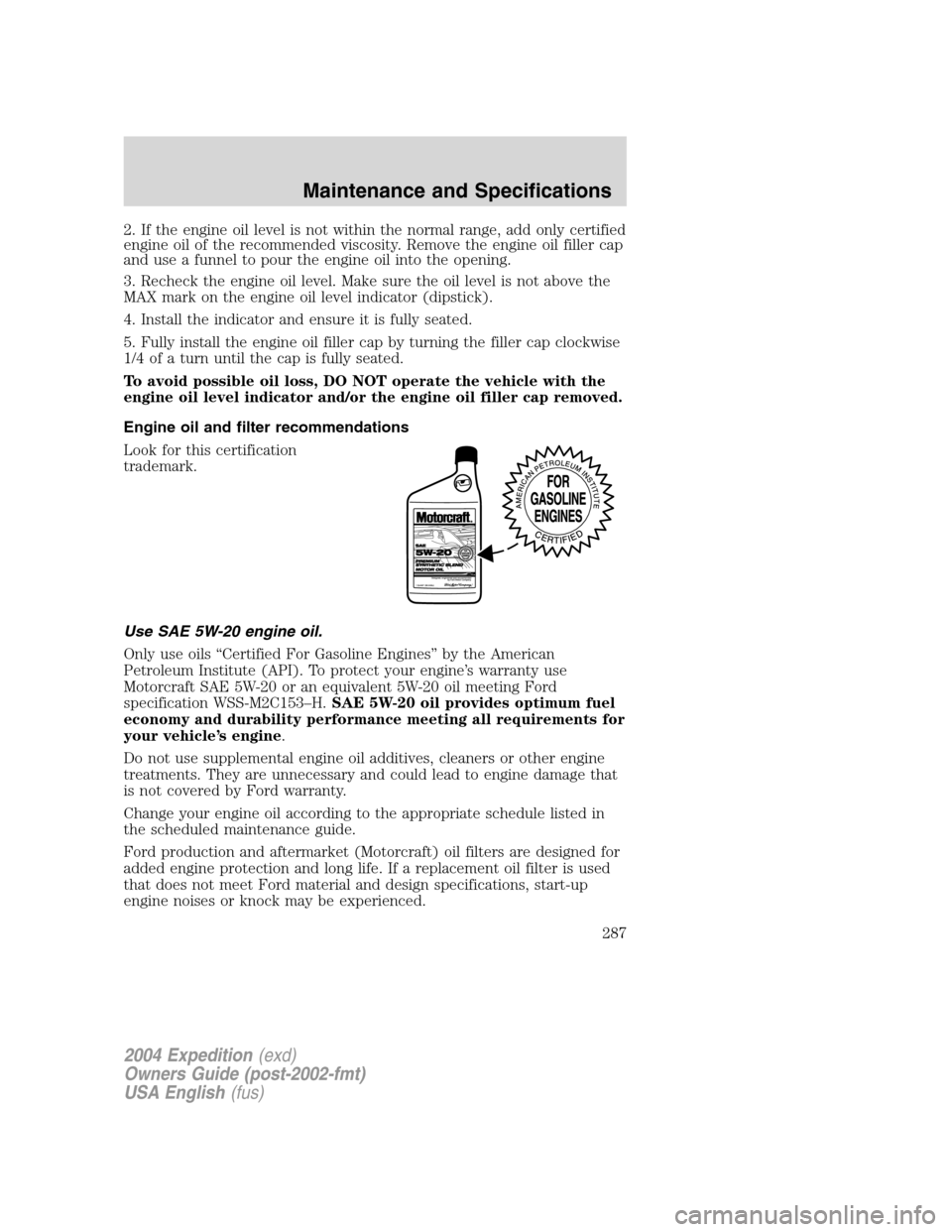

Engine oil and filter recommendations

Look for this certification

trademark.

Use SAE 5W-20 engine oil.

Only use oils“Certified For Gasoline Engines”by the American

Petroleum Institute (API). To protect your engine’s warranty use

Motorcraft SAE 5W-20 or an equivalent 5W-20 oil meeting Ford

specification WSS-M2C153–H.SAE 5W-20 oil provides optimum fuel

economy and durability performance meeting all requirements for

your vehicle’s engine.

Do not use supplemental engine oil additives, cleaners or other engine

treatments. They are unnecessary and could lead to engine damage that

is not covered by Ford warranty.

Change your engine oil according to the appropriate schedule listed in

the scheduled maintenance guide.

Ford production and aftermarket (Motorcraft) oil filters are designed for

added engine protection and long life. If a replacement oil filter is used

that does not meet Ford material and design specifications, start-up

engine noises or knock may be experienced.

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Maintenance and Specifications

287

Page 290 of 344

battery. When the battery is disconnected or a new battery is installed,

the engine must relearn its idle and fuel trim strategy for optimum

driveability and performance. To begin this process:

1. With the vehicle at a complete stop, set the parking brake.

2. Put the gearshift in P (Park), turn off all accessories and start the

engine.

3. Run the engine until it reaches normal operating temperature.

4. Allow the engine to idle for at least one minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

6. With your foot on the brake pedal and with the A/C on, put the

vehicle in D (Drive) and allow the engine to idle for at least one minute.

7. Drive the vehicle to complete the relearning process.

•The vehicle may need to be driven 16 km (10 miles) or more to

relearn the idle and fuel trim strategy.

•If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

•Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

mileage intervals listed in the scheduled maintenance guide. The coolant

concentration should be maintained at 50/50 coolant and distilled water,

which equates to a freeze point of -36°C (-34°F). Coolant concentration

LEAD

RETURN

RECYCLE

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Maintenance and Specifications

290

Page 293 of 344

•Do not use alcohol, methanol, brine or any engine coolants

mixed with alcohol or methanol antifreeze (coolant).Alcohol

and other liquids can cause engine damage from overheating or

freezing.

•Do not add extra inhibitors or additives to the coolant.These

can be harmful and compromise the corrosion protection of the engine

coolant.

For vehicles with overflow coolant systems with a non-pressurized cap

on the coolant recovery system, add coolant to the coolant recovery

reservoir when the engine is cool. Add the proper mixture of coolant and

water to the“cold full”level. For all other vehicles, which have a coolant

degas system with a pressurized cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator of a vehicle with an overflow

system, follow these steps to add engine coolant.

To reduce the risk of personal injury, make sure the engine is

cool before unscrewing the coolant pressure relief cap. The

cooling system is under pressure; steam and hot liquid can come out

forcefully when the cap is loosened slightly.

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (a translucent plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

5. Fill the coolant reservoir slowly with the proper coolant mixture (see

above), to within the“cold fill range”or the“cold full”level on the

reservoir. If you removed the radiator cap in an overflow system, fill the

radiator until the coolant is visible and radiator is almost full.

6. Replace the cap. Turn until tightly installed. (Cap must be tightly

installed to prevent coolant loss.)

After any coolant has been added, check the coolant concentration, refer

toChecking Engine Coolantsection. If the concentration is not 50/50

(protection to–34°F/–36°C), drain some coolant and adjust the

concentration. It may take several drains and additions to obtain a 50/50

coolant concentration.

Whenever coolant has been added, the coolant level in the coolant

reservoir should be checked the next few times you drive the vehicle. If

2004 Expedition(exd)

Owners Guide (post-2002-fmt)

USA English(fus)

Maintenance and Specifications

293