ignition FORD EXPEDITION EL 2016 Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: EXPEDITION EL, Model: FORD EXPEDITION EL 2016Pages: 421, PDF Size: 7.39 MB

Page 240 of 421

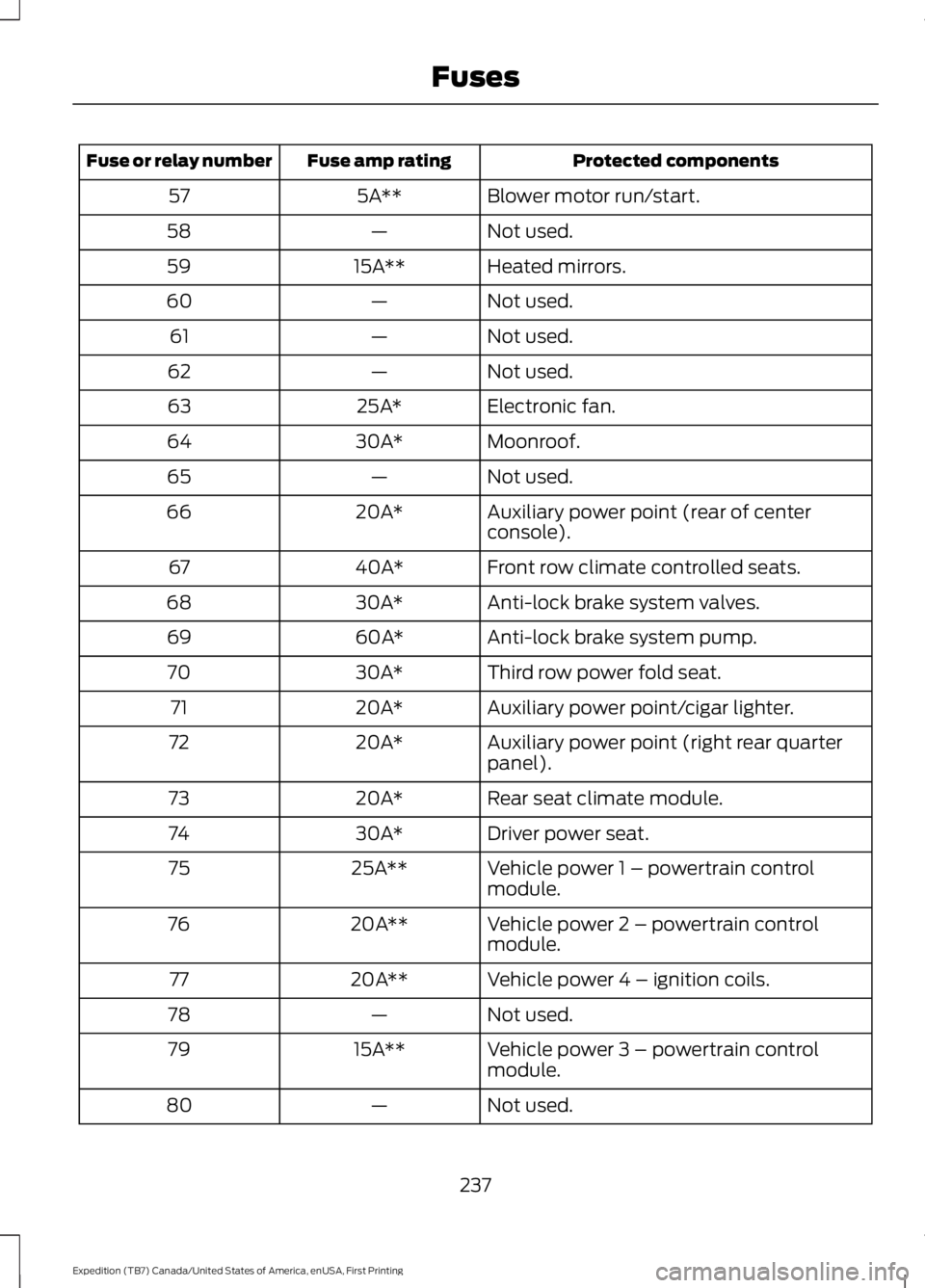

Protected componentsFuse amp ratingFuse or relay number

Blower motor run/start.5A**57

Not used.—58

Heated mirrors.15A**59

Not used.—60

Not used.—61

Not used.—62

Electronic fan.25A*63

Moonroof.30A*64

Not used.—65

Auxiliary power point (rear of centerconsole).20A*66

Front row climate controlled seats.40A*67

Anti-lock brake system valves.30A*68

Anti-lock brake system pump.60A*69

Third row power fold seat.30A*70

Auxiliary power point/cigar lighter.20A*71

Auxiliary power point (right rear quarterpanel).20A*72

Rear seat climate module.20A*73

Driver power seat.30A*74

Vehicle power 1 – powertrain controlmodule.25A**75

Vehicle power 2 – powertrain controlmodule.20A**76

Vehicle power 4 – ignition coils.20A**77

Not used.—78

Vehicle power 3 – powertrain controlmodule.15A**79

Not used.—80

237

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Fuses

Page 244 of 421

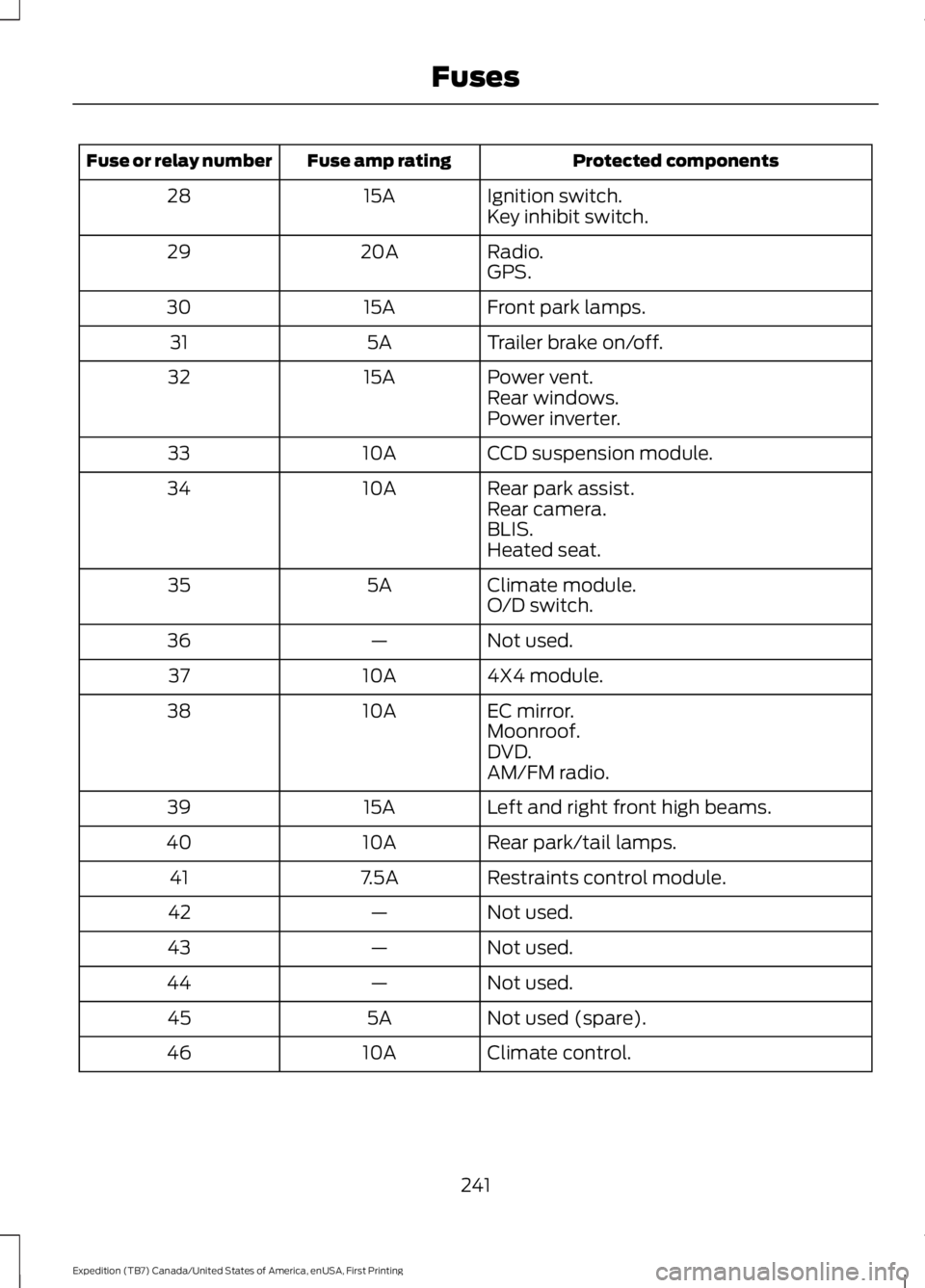

Protected componentsFuse amp ratingFuse or relay number

Ignition switch.15A28Key inhibit switch.

Radio.20A29GPS.

Front park lamps.15A30

Trailer brake on/off.5A31

Power vent.15A32Rear windows.Power inverter.

CCD suspension module.10A33

Rear park assist.10A34Rear camera.BLIS.Heated seat.

Climate module.5A35O/D switch.

Not used.—36

4X4 module.10A37

EC mirror.10A38Moonroof.DVD.AM/FM radio.

Left and right front high beams.15A39

Rear park/tail lamps.10A40

Restraints control module.7.5A41

Not used.—42

Not used.—43

Not used.—44

Not used (spare).5A45

Climate control.10A46

241

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Fuses

Page 257 of 421

Note:For flexible fuel vehicles, if you areoperating on E85, you may experience poorstarts or an inability to start the engine anddriveability problems until the fuel trim andethanol content have been relearned.

Make sure that you dispose of old batteriesin an environmentally friendly way. Seekadvice from your local authority aboutrecycling old batteries.

If storing your vehicle for more than 30days without recharging the battery, werecommend that you disconnect thebattery cables to maintain battery chargefor quick starting.

Battery Management System (If

Equipped)

The battery management system monitorsbattery conditions and takes actions toextend battery life. If excessive batterydrain is detected, the system temporarilydisables some electrical systems toprotect the battery.

Systems included are:

•Heated rear window.

•Heated seats.

•Climate control.

•Heated steering wheel.

•Audio unit.

•Navigation system.

A message may appear in the informationdisplays to alert you that batteryprotection actions are active. Thesemessages are only for notification that anaction is taking place, and not intended toindicate an electrical problem or that thebattery requires replacement.

After battery replacement, or in somecases after charging the battery with anexternal charger, the battery managementsystem requires eight hours of vehicle sleeptime to relearn the battery state of charge.During this time your vehicle must remainfully locked with the ignition switched off.

Note:Prior to relearning the battery stateof charge, the battery management systemmay temporarily disable some electricalsystems.

Electrical Accessory Installation

To make sure the battery managementsystem works correctly, do not connect anelectrical device ground connectiondirectly to the battery negative post. Thiscan cause inaccurate measurements ofthe battery condition and potentialincorrect system operation.

Note:If you add electrical accessories orcomponents to the vehicle, it may adverselyaffect battery performance and durability.This may also affect the performance ofother electrical systems in the vehicle.

CHECKING THE WIPER

BLADES

Run the tip of your fingers over the edge ofthe blade to check for roughness.

Clean the wiper blades with washer fluidor water applied with a soft sponge orcloth.

254

Expedition (TB7) Canada/United States of America, enUSA, First Printing

MaintenanceE142463

Page 259 of 421

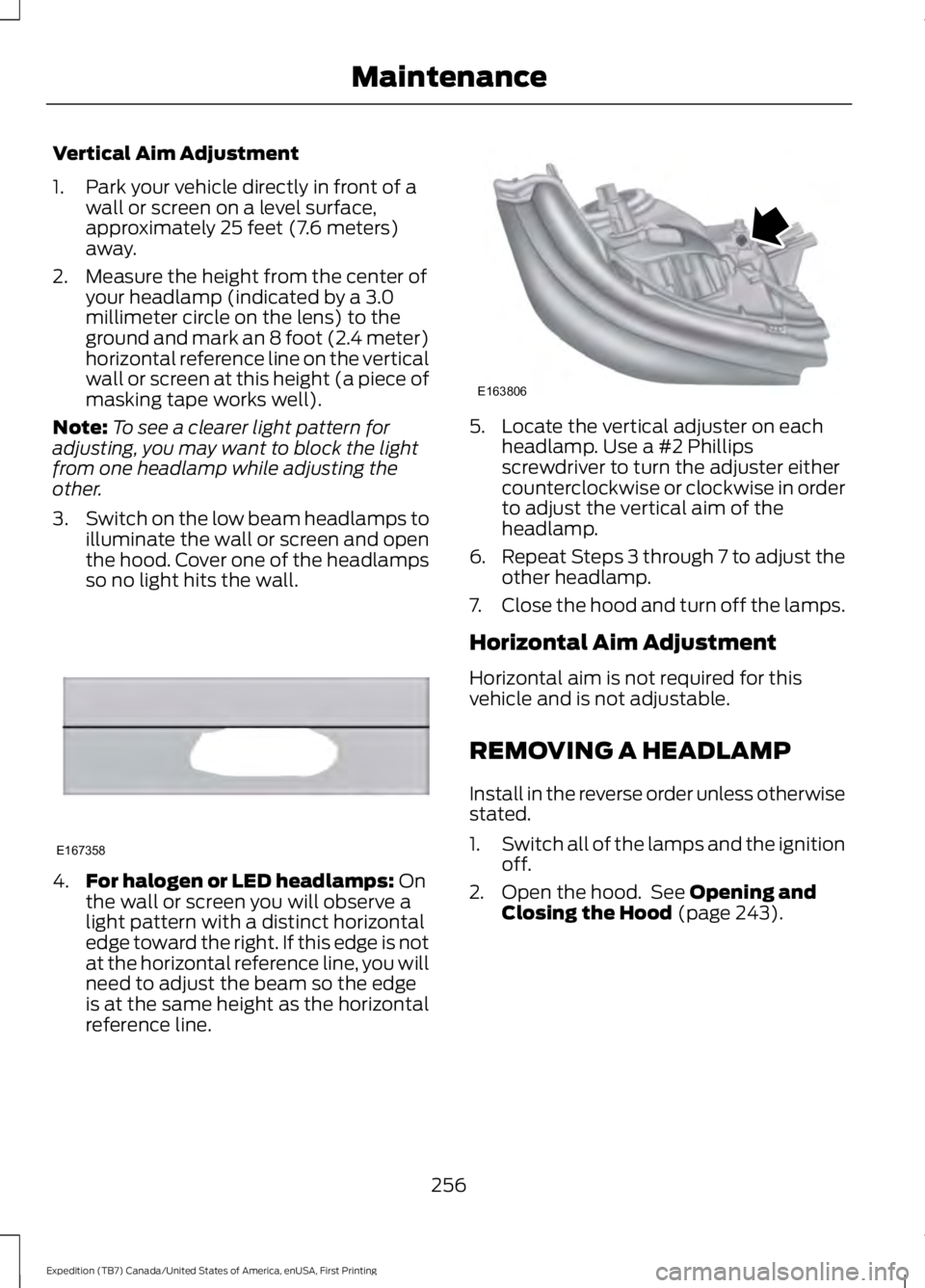

Vertical Aim Adjustment

1. Park your vehicle directly in front of awall or screen on a level surface,approximately 25 feet (7.6 meters)away.

2. Measure the height from the center ofyour headlamp (indicated by a 3.0millimeter circle on the lens) to theground and mark an 8 foot (2.4 meter)horizontal reference line on the verticalwall or screen at this height (a piece ofmasking tape works well).

Note:To see a clearer light pattern foradjusting, you may want to block the lightfrom one headlamp while adjusting theother.

3.Switch on the low beam headlamps toilluminate the wall or screen and openthe hood. Cover one of the headlampsso no light hits the wall.

4.For halogen or LED headlamps: Onthe wall or screen you will observe alight pattern with a distinct horizontaledge toward the right. If this edge is notat the horizontal reference line, you willneed to adjust the beam so the edgeis at the same height as the horizontalreference line.

5. Locate the vertical adjuster on eachheadlamp. Use a #2 Phillipsscrewdriver to turn the adjuster eithercounterclockwise or clockwise in orderto adjust the vertical aim of theheadlamp.

6.Repeat Steps 3 through 7 to adjust theother headlamp.

7.Close the hood and turn off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for thisvehicle and is not adjustable.

REMOVING A HEADLAMP

Install in the reverse order unless otherwisestated.

1.Switch all of the lamps and the ignitionoff.

2. Open the hood. See Opening andClosing the Hood (page 243).

256

Expedition (TB7) Canada/United States of America, enUSA, First Printing

MaintenanceE167358 E163806

Page 260 of 421

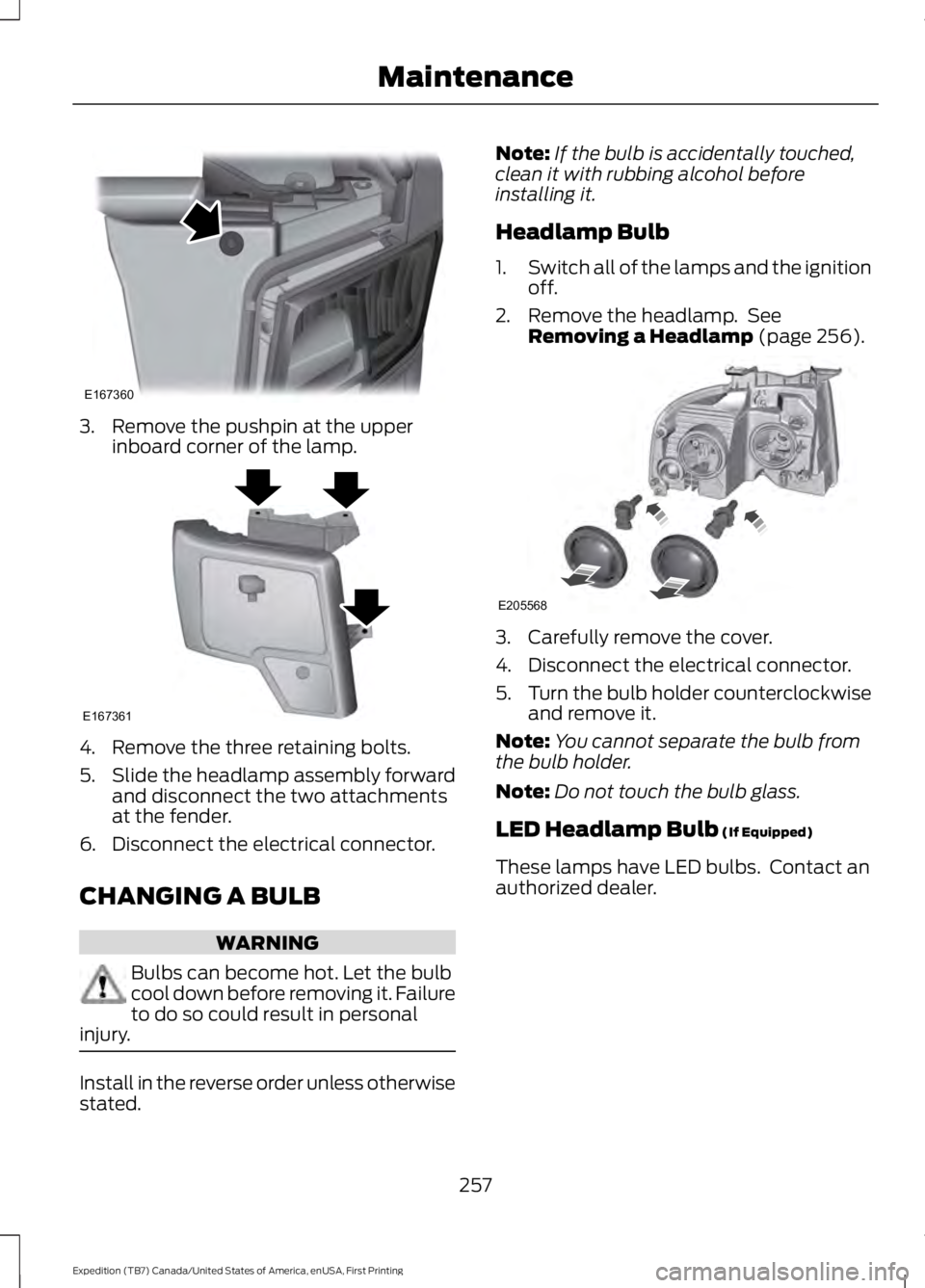

3. Remove the pushpin at the upperinboard corner of the lamp.

4. Remove the three retaining bolts.

5.Slide the headlamp assembly forwardand disconnect the two attachmentsat the fender.

6. Disconnect the electrical connector.

CHANGING A BULB

WARNING

Bulbs can become hot. Let the bulbcool down before removing it. Failureto do so could result in personalinjury.

Install in the reverse order unless otherwisestated.

Note:If the bulb is accidentally touched,clean it with rubbing alcohol beforeinstalling it.

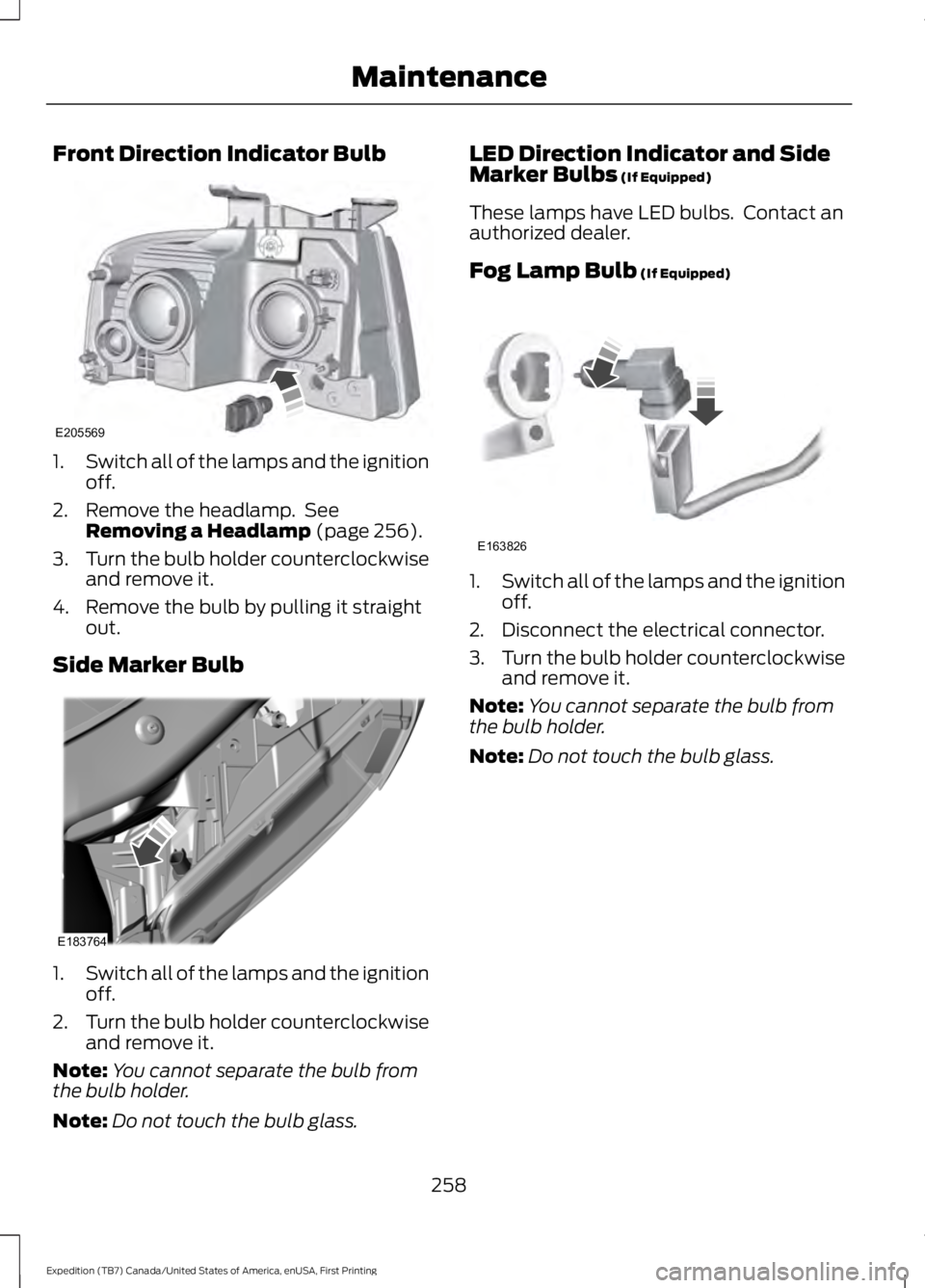

Headlamp Bulb

1.Switch all of the lamps and the ignitionoff.

2. Remove the headlamp. SeeRemoving a Headlamp (page 256).

3. Carefully remove the cover.

4. Disconnect the electrical connector.

5.Turn the bulb holder counterclockwiseand remove it.

Note:You cannot separate the bulb fromthe bulb holder.

Note:Do not touch the bulb glass.

LED Headlamp Bulb (If Equipped)

These lamps have LED bulbs. Contact anauthorized dealer.

257

Expedition (TB7) Canada/United States of America, enUSA, First Printing

MaintenanceE167360 E167361 E205568

Page 261 of 421

Front Direction Indicator Bulb

1.Switch all of the lamps and the ignitionoff.

2. Remove the headlamp. SeeRemoving a Headlamp (page 256).

3.Turn the bulb holder counterclockwiseand remove it.

4. Remove the bulb by pulling it straightout.

Side Marker Bulb

1.Switch all of the lamps and the ignitionoff.

2.Turn the bulb holder counterclockwiseand remove it.

Note:You cannot separate the bulb fromthe bulb holder.

Note:Do not touch the bulb glass.

LED Direction Indicator and SideMarker Bulbs (If Equipped)

These lamps have LED bulbs. Contact anauthorized dealer.

Fog Lamp Bulb (If Equipped)

1.Switch all of the lamps and the ignitionoff.

2. Disconnect the electrical connector.

3.Turn the bulb holder counterclockwiseand remove it.

Note:You cannot separate the bulb fromthe bulb holder.

Note:Do not touch the bulb glass.

258

Expedition (TB7) Canada/United States of America, enUSA, First Printing

MaintenanceE205569 E183764 E163826

Page 262 of 421

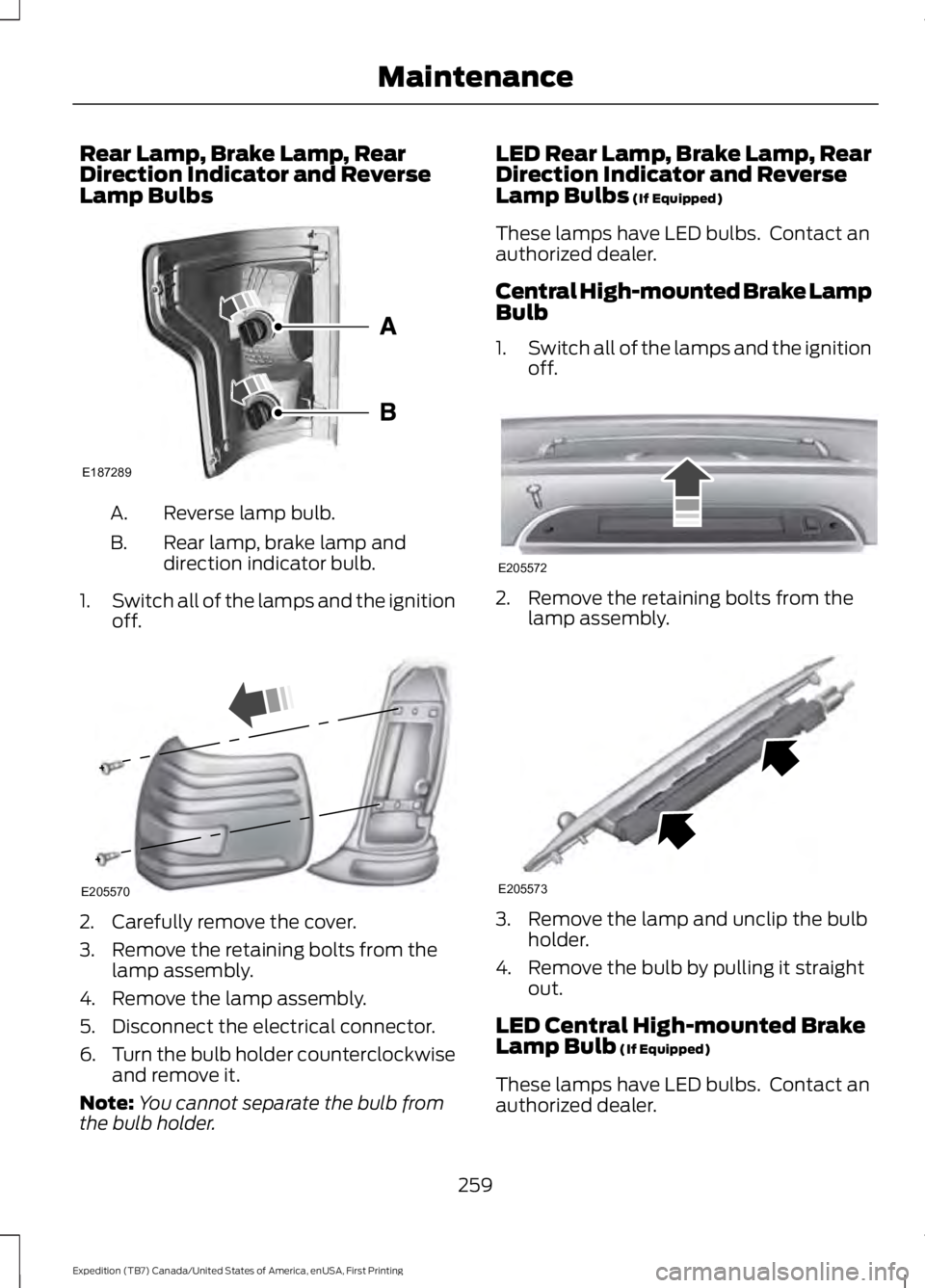

Rear Lamp, Brake Lamp, RearDirection Indicator and ReverseLamp Bulbs

Reverse lamp bulb.A.

Rear lamp, brake lamp anddirection indicator bulb.B.

1.Switch all of the lamps and the ignitionoff.

2. Carefully remove the cover.

3. Remove the retaining bolts from thelamp assembly.

4. Remove the lamp assembly.

5. Disconnect the electrical connector.

6.Turn the bulb holder counterclockwiseand remove it.

Note:You cannot separate the bulb fromthe bulb holder.

LED Rear Lamp, Brake Lamp, RearDirection Indicator and ReverseLamp Bulbs (If Equipped)

These lamps have LED bulbs. Contact anauthorized dealer.

Central High-mounted Brake LampBulb

1.Switch all of the lamps and the ignitionoff.

2. Remove the retaining bolts from thelamp assembly.

3. Remove the lamp and unclip the bulbholder.

4. Remove the bulb by pulling it straightout.

LED Central High-mounted BrakeLamp Bulb (If Equipped)

These lamps have LED bulbs. Contact anauthorized dealer.

259

Expedition (TB7) Canada/United States of America, enUSA, First Printing

MaintenanceE187289 E205570 E205572 E205573

Page 269 of 421

•Never wash or rinse any ignition coil,spark plug wire or spark plug well, orthe area in and around these locations.

•Cover the battery, power distributionbox, and air filter assembly to preventwater damage when cleaning theengine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmentalfallout can result in windshield and wiperblade contamination. Dirty windshield andwipers will result in poor windshield wiperoperation. Keep the windshield and wiperblades clean to maintain windshield wiperperformance.

To clean the windshield and wiper blades:

•Clean the windshield with anon-abrasive glass cleaner. Whencleaning the interior of the windshield,avoid getting any glass cleaner on theinstrument panel or door panels. Wipeany glass cleaner off these surfacesimmediately.

•For windshields contaminated withtree sap, chemicals, wax or bugs, cleanthe entire windshield using steel wool(no greater than 0000 grade) in acircular motion and rinse with water.

•Clean the wiper blades with isopropylrubbing alcohol or windshield washerconcentrate.

Note: Do not use razor blades or othersharp objects to clean or remove decalsfrom the inside of the heated rear window.The vehicle warranty does not coverdamage caused to the heated rear windowgrid lines.

CLEANING THE INTERIOR

WARNINGS

Do not use cleaning solvents, bleachor dye on the vehicle’s safety belts,as these actions may weaken thebelt webbing.

On vehicles equipped withseat-mounted airbags, do not usechemical solvents or strongdetergents. Such products couldcontaminate the side airbag system andaffect performance of the side airbag in acollision.

For fabric, carpets, cloth seats, safety beltsand seats equipped with side airbags:

•Remove dust and loose dirt with avacuum cleaner.

•Remove light stains and soil withMotorcraft Professional StrengthCarpet & Upholstery Cleaner.

•If grease or tar is present on thematerial, spot-clean the area first withMotorcraft Spot and Stain Remover. InCanada, use Motorcraft Multi-PurposeCleaner.

•If a ring forms on the fabric after spotcleaning, clean the entire areaimmediately (but do not oversaturate)or the ring will set.

•Do not use household cleaningproducts or glass cleaners, which canstain and discolor the fabric and affectthe flame retardant abilities of the seatmaterials.

266

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Vehicle Care

Page 298 of 421

•To reduce the chances of interferencefrom another vehicle, perform thesystem reset procedure at least threefeet (one meter) away from anotherFord Motor Company vehicleundergoing the system reset procedureat the same time.

•Do not wait more than two minutesbetween resetting each tire sensor orthe system will time-out and the entireprocedure will have to be repeated onall four wheels.

•A double horn will sound indicating theneed to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure beforeattempting.

1. Drive the vehicle above 20 mph (32km/h) for at least two minutes, thenpark in a safe location where you caneasily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3. Cycle the ignition to the on positionwith the engine off.

4. Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If the reset modehas been entered successfully, the hornwill sound once, the system indicatorwill flash and a message is shown inthe information display. If this does notoccur, please try again starting at Step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message is shown in theinformation display, seek service fromyour authorized dealer.

5. Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing clockwise order: Left front(driver's side front tire), Right front(passenger's side front tire), Right rear(passenger's side rear tire), Left rear(driver's side rear tire).

6. Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.Note: The single horn chirp confirmsthat the sensor identification code hasbeen learned by the module for thisposition. If a double horn is heard, thereset procedure was unsuccessful, andyou must repeat it.

7. Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8. Remove the valve cap from the valvestem on the right rear tire. Decrease theair pressure until the horn sounds.

9. Remove the valve cap from the valvestem on the left rear tire. Decrease theair pressure until the horn sounds.Training is complete after the hornsounds for the last tire trained (driver'sside rear tire), the system indicatorstops flashing, and a message is shownin the information display.

10.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

295

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 306 of 421

ENGINE SPECIFICATIONS

3.5L EcoboostEngine

214Cubic inches

1-4-2-5-3-6Firing order

Coil on plugIgnition system

10.0:1Compression ratio

0.030 in (0.75 mm) - 0.033 in (0.85 mm)Spark plug gap

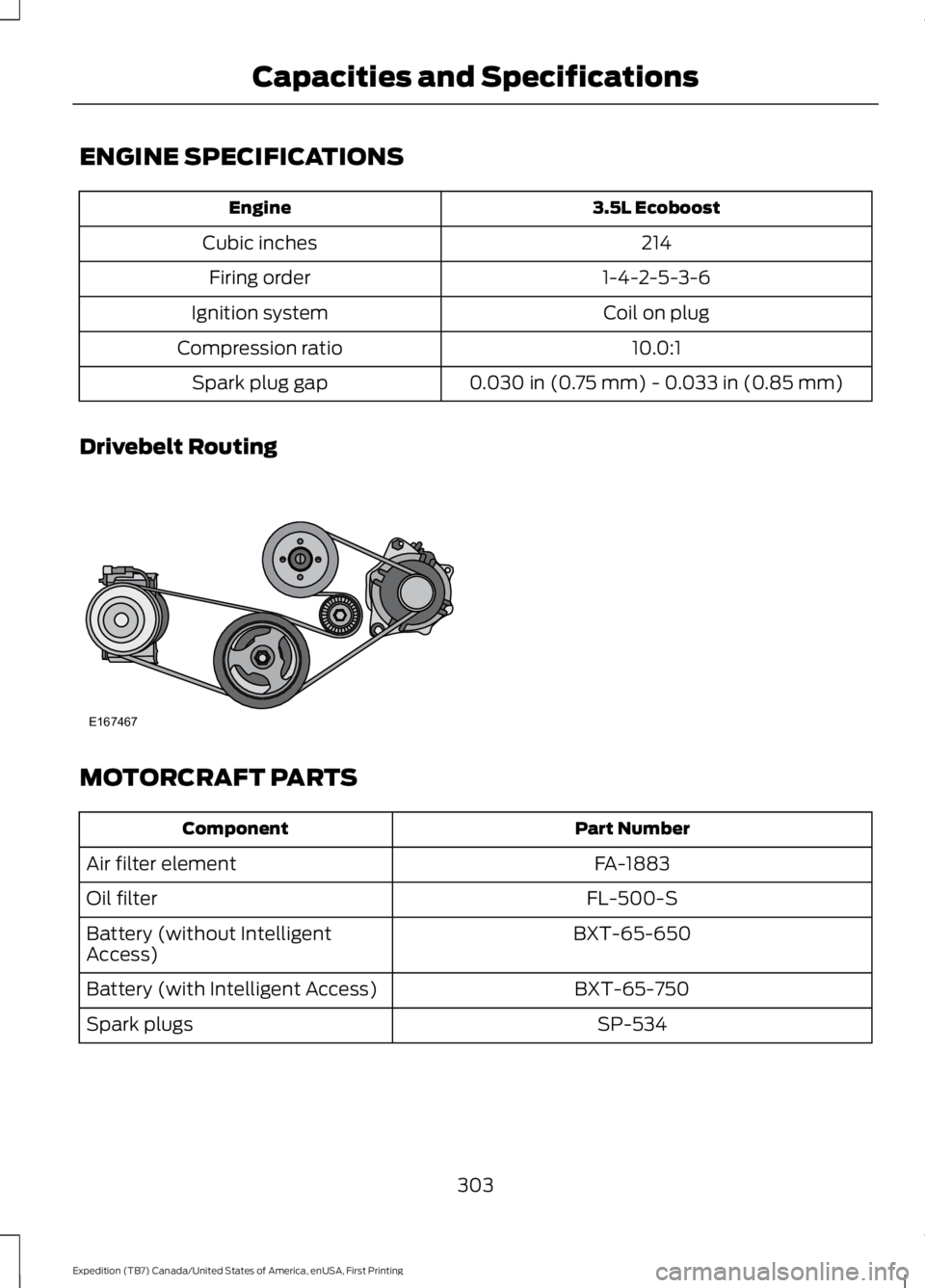

Drivebelt Routing

MOTORCRAFT PARTS

Part NumberComponent

FA-1883Air filter element

FL-500-SOil filter

BXT-65-650Battery (without IntelligentAccess)

BXT-65-750Battery (with Intelligent Access)

SP-534Spark plugs

303

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Capacities and SpecificationsE167467