FORD EXPLORER 1997 2.G Severe Duty Supplement Manual

Manufacturer: FORD, Model Year: 1997, Model line: EXPLORER, Model: FORD EXPLORER 1997 2.GPages: 28, PDF Size: 0.36 MB

Page 11 of 28

Oil change interval

The engine oil should be changed

every three months or 5,000 km

(3,000 miles), whichever occurs

first.

If the engine oil is not changed as

recommended, inaccurate oil

readings and engine damage may

occur.

Oil filter change

Use only an approved engine oil

filter such as the Motorcraft Long

Life type or an equivalent filter

meeting Ford specification

ES-E4EE-6714AA. Install a new oil

filter at each oil change.

Fuel filter

To prolong the life of the fuel

pump and ensure dependable fuel

system performance, the fuel filter

should be changed every 96,000

km (60,000 miles). This operation

is not required, but is

recommended for California

certified vehicles.

Maintenance recommendations

11

Page 12 of 28

COOLING SYSTEM

MAINTENANCE

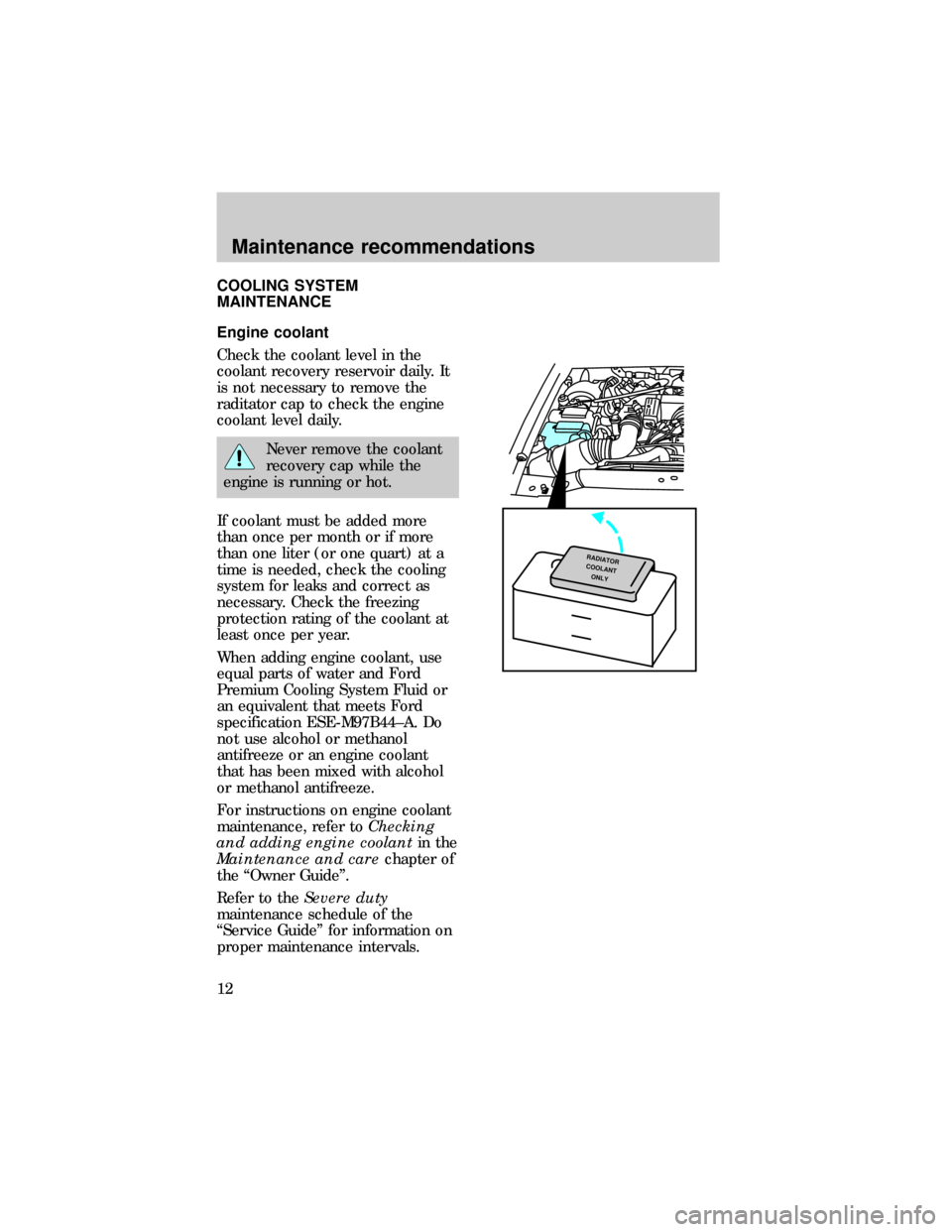

Engine coolant

Check the coolant level in the

coolant recovery reservoir daily. It

is not necessary to remove the

raditator cap to check the engine

coolant level daily.

Never remove the coolant

recovery cap while the

engine is running or hot.

If coolant must be added more

than once per month or if more

than one liter (or one quart) at a

time is needed, check the cooling

system for leaks and correct as

necessary. Check the freezing

protection rating of the coolant at

least once per year.

When adding engine coolant, use

equal parts of water and Ford

Premium Cooling System Fluid or

an equivalent that meets Ford

specification ESE-M97B44±A. Do

not use alcohol or methanol

antifreeze or an engine coolant

that has been mixed with alcohol

or methanol antifreeze.

For instructions on engine coolant

maintenance, refer toChecking

and adding engine coolantin the

Maintenance and carechapter of

the ªOwner Guideº.

Refer to theSevere duty

maintenance schedule of the

ªService Guideº for information on

proper maintenance intervals.

RADIATOR

COOLANT

ONLY

Maintenance recommendations

12

Page 13 of 28

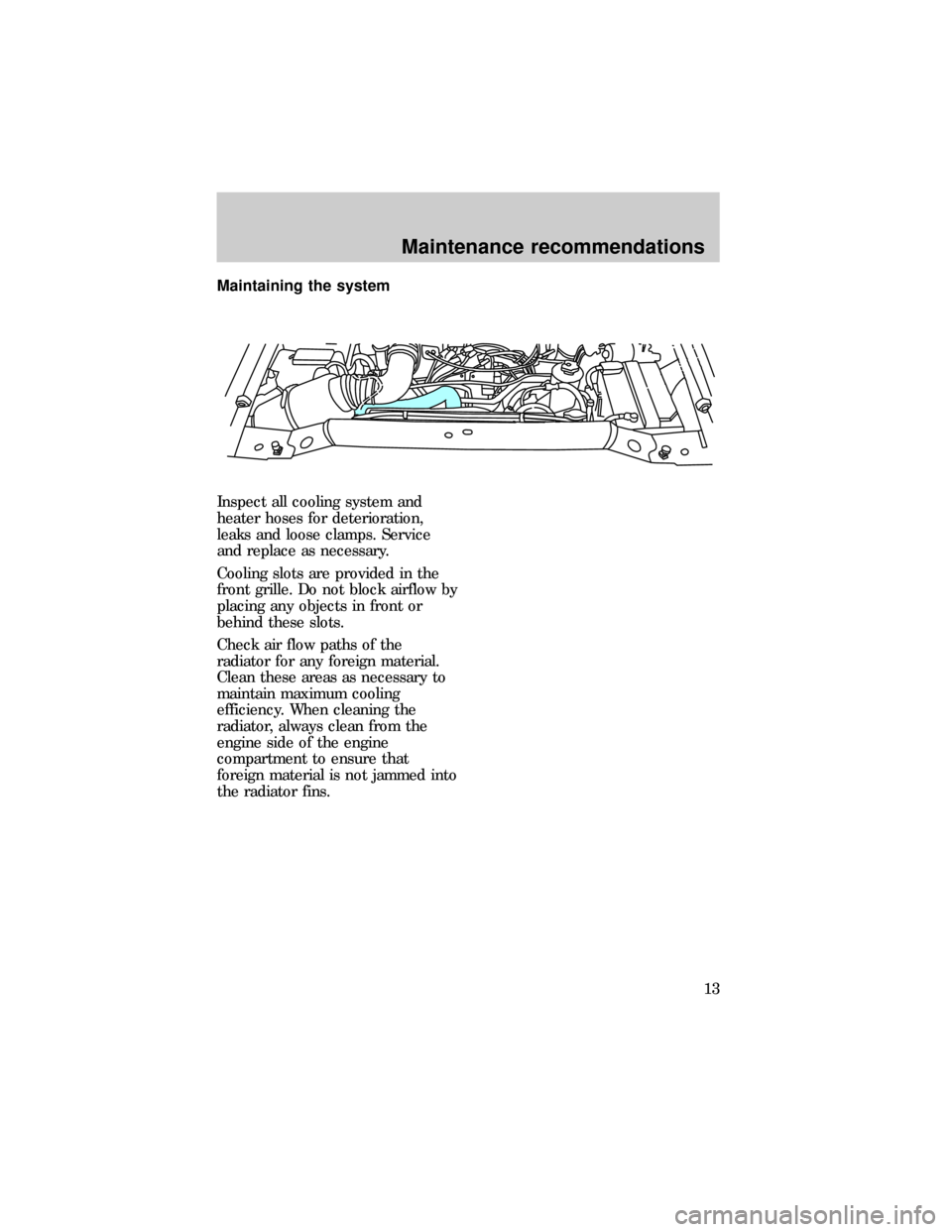

Maintaining the system

Inspect all cooling system and

heater hoses for deterioration,

leaks and loose clamps. Service

and replace as necessary.

Cooling slots are provided in the

front grille. Do not block airflow by

placing any objects in front or

behind these slots.

Check air flow paths of the

radiator for any foreign material.

Clean these areas as necessary to

maintain maximum cooling

efficiency. When cleaning the

radiator, always clean from the

engine side of the engine

compartment to ensure that

foreign material is not jammed into

the radiator fins.

Maintenance recommendations

13

Page 14 of 28

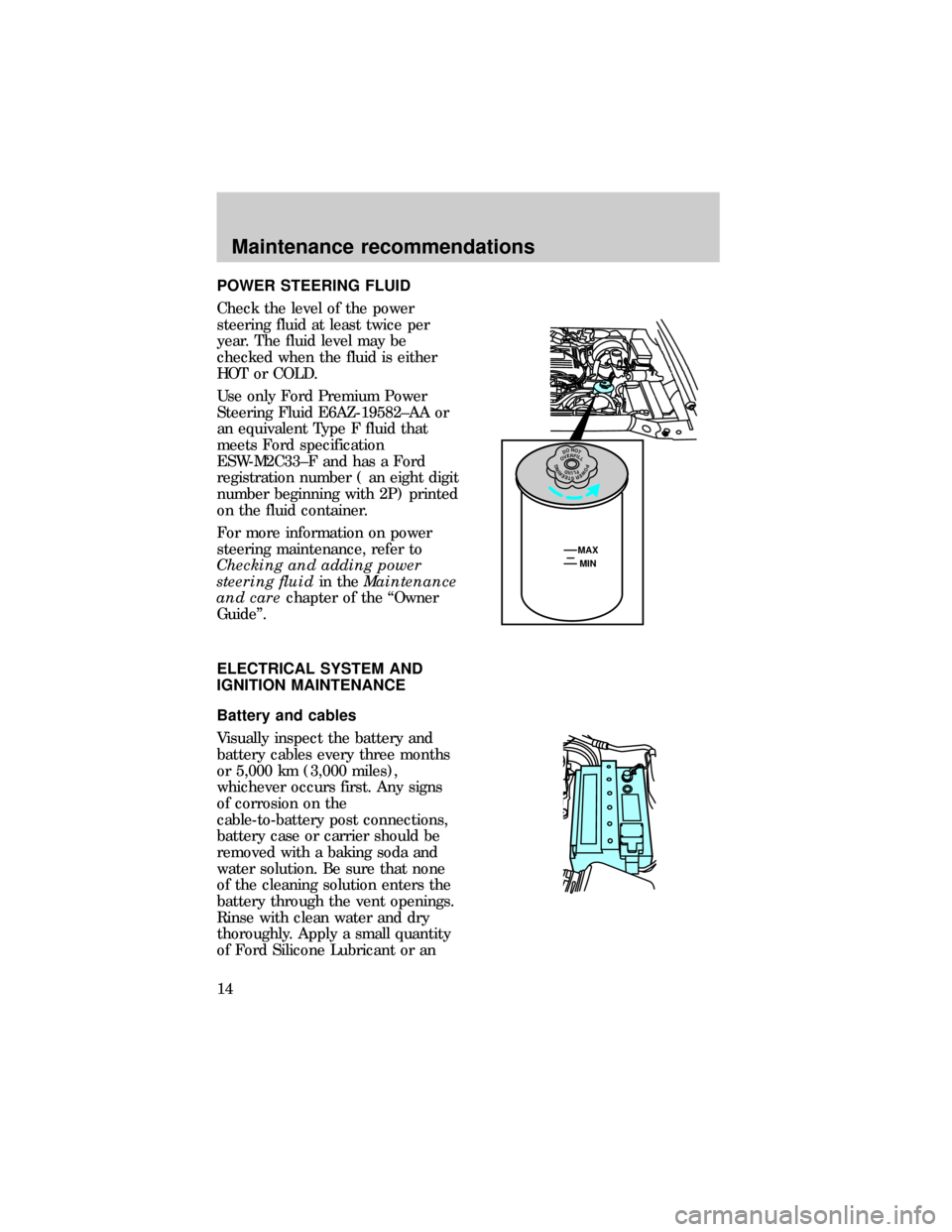

POWER STEERING FLUID

Check the level of the power

steering fluid at least twice per

year. The fluid level may be

checked when the fluid is either

HOT or COLD.

Use only Ford Premium Power

Steering Fluid E6AZ-19582±AA or

an equivalent Type F fluid that

meets Ford specification

ESW-M2C33±F and has a Ford

registration number ( an eight digit

number beginning with 2P) printed

on the fluid container.

For more information on power

steering maintenance, refer to

Checking and adding power

steering fluidin theMaintenance

and carechapter of the ªOwner

Guideº.

ELECTRICAL SYSTEM AND

IGNITION MAINTENANCE

Battery and cables

Visually inspect the battery and

battery cables every three months

or 5,000 km (3,000 miles),

whichever occurs first. Any signs

of corrosion on the

cable-to-battery post connections,

battery case or carrier should be

removed with a baking soda and

water solution. Be sure that none

of the cleaning solution enters the

battery through the vent openings.

Rinse with clean water and dry

thoroughly. Apply a small quantity

of Ford Silicone Lubricant or an

MAX

MIN

DONOTOVERFILLPOWERSTEERINGFLUID

Maintenance recommendations

14

Page 15 of 28

equivalent that meets Ford

specification ESR-M13P4±A to the

terminal surfaces to help prevent

corrosion from forming.

Check the tightness of the cables

to the battery post by hand. It may

be necessary to tighten the clamp

with a suitable wrench.

Ignition system

Visually inspect the plug wires and

ignition coil pack. Any oily dirt

should be removed and the area

cleaned with a damp cloth. Ensure

that all high voltage wires are

firmly attached to the coil pack

and that the other ends are firmly

seated over each spark plug.

Other electrical systems

Wiring, lighting and aftermarket

electrical equipment should be

checked monthly for proper

routing, deterioration or chafing on

other components.

UNDER VEHICLE

MAINTENANCE

Catalytic converters

During normal engine operation,

the catalytic converter surface

temperature can reach up to 816ÉC

(1500ÉF). To avoid injury, ensure

that the converter has cooled

before attempting maintenance.

Ford recommends that an under

vehicle inspection be performed at

Severe Dutyintervals listed in the

ªService Guideº. With the vehicle

Maintenance recommendations

15

Page 16 of 28

supported on a jack or jack stands,

inspect the converter and exhaust

system. Be sure that no foreign

materials are caught in the exhaust

system shielding. Any underbody

sealant or foreign material should

be removed and all possible

contaminants cleaned off of the

shell surfaces.

Visual inspections

Inspect the radiator, engine,

transmission and power steering

for fluid leaks and deterioration

every 24,000 km (15,000 miles) or

three months, whichever comes

first. Any leakage should be

corrected immediately. It is normal

for minor seepage to occur at

gasketed surfaces.

Check the routing of the

speedometer cable and cable

housing. Be sure that it flows

smoothly over its entire area

(routed away from the exhaust

system components) and is free of

kinks or crushed areas.

Maintenance recommendations

16

Page 17 of 28

Chassis lubrication intervals

Chassis lubrication should be

performed every 5,000 km (3,000

miles).

Wheel bearings

No wheel bearing adjustment is

required for either front or rear

wheels.

Maintenance recommendations

17

Page 18 of 28

SPECIAL SERVICE EQUIPMENT

The Explorer is not designed

nor intended to be used as a

pursuit vehicle or an

ambulance.

The following optional equipment

is designed to meet Ford

Corporate Product Standards;

however, the equipment does not

meet corporate guidelines relative

to police packages. therefore, the

optional equipment is intended for

use in limited law enforcement

services only. Use of DSO special

service options does not imply nor

allow use as a pursuit vehicle.

Components that are part of some

available options are listed below

and on the following pages, along

with a brief outline of their major

features.

ELECTRICAL

Heavy-duty alternator

Handling the high electrical loads

imposed on special service vehicles

by the broad range of necessary

equipment requires a high ampere

output alternator.

The 4.0 L SOHC or 5.0 L Explorer

engine, when equipped with a 130

ampere alternator, has the voltage

regulator integral with the

alternator. No external voltage

regulator is required.

Severe duty equipment

18

Page 19 of 28

Heavy-duty battery special

service

Special service vehicles are

equipped with a maintenance-free

battery which does not require the

addition of water or other regular

service.

Installing aftermarket equipment

When installing aftermarket

equipment, avoid using fasteners

that are too long for the

application or are in an area that

might damage other vehicle

components (i.e., wiring, brake

lines, fuel tank and lines,

powertrain components exhaust

system, suspension, etc.).

Do not make electrical connections

to vehicle electrical systems not

specifically designed for

aftermarket equipment installation.

Do not install and components into

the Powertrain control module

(PCM) harness. Connecting into

this system may affect engine and

transmission operation. As an

example, connection of

aftermarket electrical equipment

into the brake light circuit or any

other circuit which is connected to

the PCM, anti-lock brake

computer, air bag system,

transmission or any other vehicle

system may cause vehicle

malfunction.

Severe duty equipment

19

Page 20 of 28

Do not place objects or

mount equipment on or

near the air bag covers that may

come into contact with an

inflating air bag.

Mobile communication systems

Note: The Federal Communication

Commission (FCC) regulates the

use of mobile communication

systems such as two-way radios,

telephones and anti-theft alarms

that are equipped with radio

transmitters. If you install this

equipment in your vehicle, you

should comply with those rules.

Ford Motor Company vehicles are

in compliance with FCC

regulations (CFR 47 Part 15) and

SAE J551d for radiated

electromagnetic emissions.

Note: Mobile communication

systems may harm the operation of

your vehicle, particularly if they

are not properly designed for

automotive use or are not properly

installed. For example: when

operated, such systems may cause

the engine to stumble or stall and

may affect electronically controlled

transmission operation. In addition,

such systems may themselves be

damaged or their operation

affected by operating your vehicle.

(Citizen Band [CB] transceivers,

garage door openers, and other

transmitters whose power output if

5 watts or less will not ordinarily

affect your vehicle's operation.)

Severe duty equipment

20