FORD EXPLORER 2016 5.G Owners Manual

Manufacturer: FORD, Model Year: 2016, Model line: EXPLORER, Model: FORD EXPLORER 2016 5.GPages: 541, PDF Size: 6.51 MB

Page 331 of 541

How Temperature Affects Your Tire

Pressure

The tire pressure monitoring system

monitors tire pressure in each pneumatic

tire. While driving in a normal manner, a

typical passenger tire inflation pressure

may increase about 2 to 4 psi (14 to 28

kPa) from a cold start situation. If the

vehicle is stationary overnight with the

outside temperature significantly lower

than the daytime temperature, the tire

pressure may decrease about 3 psi (21

kPa) for a drop of 30°F (17°C) in ambient

temperature. This lower pressure value

may be detected by the tire pressure

monitoring system as being significantly

lower than the recommended inflation

pressure and activate the system warning

light for low tire pressure. If the low tire

pressure warning light is on, visually check

each tire to verify that no tire is flat. If one

or more tires are flat, repair as necessary.

Check the air pressure in the road tires. If

any tire is under-inflated, carefully drive

the vehicle to the nearest location where

air can be added to the tires. Inflate all the

tires to the recommended inflation

pressure.

CHANGING A ROAD WHEEL

WARNINGS

The use of tire sealant may damage

your tire pressure monitoring system

and should only be used in roadside

emergencies. If you must use a sealant, the

Ford Tire Mobility Kit sealant should be

used. The tire pressure monitoring system

sensor and valve stem on the wheel must

be replaced by an authorized dealer after

use of the sealant. See Tire Pressure Monitoring

System (page 325). If the tire

pressure monitor sensor becomes

damaged, it will no longer function. Note:

The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not

apply the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe

place on the side of the road.

Have a flat serviced by an authorized

dealer in order to prevent damage to the

tire pressure monitoring system sensors.

See

Tire Pressure Monitoring System

(page 325). Replace the spare tire with a

road tire as soon as possible. During

repairing or replacing of the flat tire, have

the authorized dealer inspect the tire

pressure monitoring system sensor for

damage.

Dissimilar Spare Wheel and Tire

Assembly Information WARNING

Failure to follow these guidelines

could result in an increased risk of

loss of vehicle control, injury or death.

If you have a dissimilar spare wheel and

tire, then it is intended for temporary use

only. This means that if you need to use it,

you should replace it as soon as possible

with a road wheel and tire assembly that

is the same size and type as the road tires

and wheels that were originally provided

by Ford. If the dissimilar spare tire or wheel

is damaged, it should be replaced rather

than repaired.

A dissimilar spare wheel and tire assembly

is defined as a spare wheel and tire

assembly that is different in brand, size or

appearance from the road tires and wheels

and can be one of three types:

328

Explorer (TUB), enUSA, First Printing Wheels and Tires

Page 332 of 541

1.

T-type mini-spare: This spare tire

begins with the letter T for tire size and

may have Temporary Use Only molded in

the sidewall.

2. Full-size dissimilar spare with label

on wheel:

This spare tire has a label on

the wheel that states: THIS WHEEL AND

TIRE ASSEMBLY FOR TEMPORARY USE

ONLY.

When driving with one of the dissimilar

spare tires listed above, do not:

• Exceed

50 mph (80 km/h).

• Load the vehicle beyond maximum

vehicle load rating listed on the Safety

Compliance Label.

• Tow a trailer.

• Use snow chains on the end of the

vehicle with the dissimilar spare tire.

• Use more than one dissimilar spare tire

at a time.

• Use commercial car washing

equipment.

• Try to repair the dissimilar spare tire.

Use of one of the dissimilar spare tires

listed above at any one wheel location can

lead to impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability.

3. Full-size dissimilar spare without

label on wheel

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time. •

Use commercial car washing

equipment.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability.

When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

• Towing a trailer.

• Driving vehicles equipped with a

camper body.

• Driving vehicles with a load on the

cargo rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly

and seek service as soon as possible.

Tire Change Procedure WARNINGS

When one of the front wheels is off

the ground, the transmission alone

will not prevent your vehicle from

moving or slipping off the jack, even if the

transmission is in park (P) or neutral (N). To help prevent your vehicle from

moving when you change a tire, be

sure to place the transmission in park

(P) or neutral (N), set the parking brake,

and block (in both directions) the wheel

that is diagonally opposite (other side and

end of your vehicle) to the tire being

changed.

329

Explorer (TUB), enUSA, First Printing Wheels and Tires

Page 333 of 541

WARNINGS

Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured. Do not attempt to change a tire on

the side of the vehicle close to

moving traffic. Pull far enough off the

road to avoid the danger of being hit when

operating the jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one

provided as original equipment with your

vehicle, make sure the jack capacity is

adequate for the vehicle weight, including

any vehicle cargo or modifications. To reduce the risk of possible serious

injury or death, do not remove the full

size spare tire from the factory

secured location. This location is necessary

to achieve police-rated 75 mph rear impact

crash-test performance. Removal

increases the risk of fuel leak in high-speed

rear impacts. Note:

Passengers should not remain in your

vehicle when the vehicle is being jacked.

Note: Jack at the specified locations to

avoid damage to the vehicle.

1. Park on a level surface, set the parking

brake and activate the hazard flashers.

2. Place the transmission in park (P) and

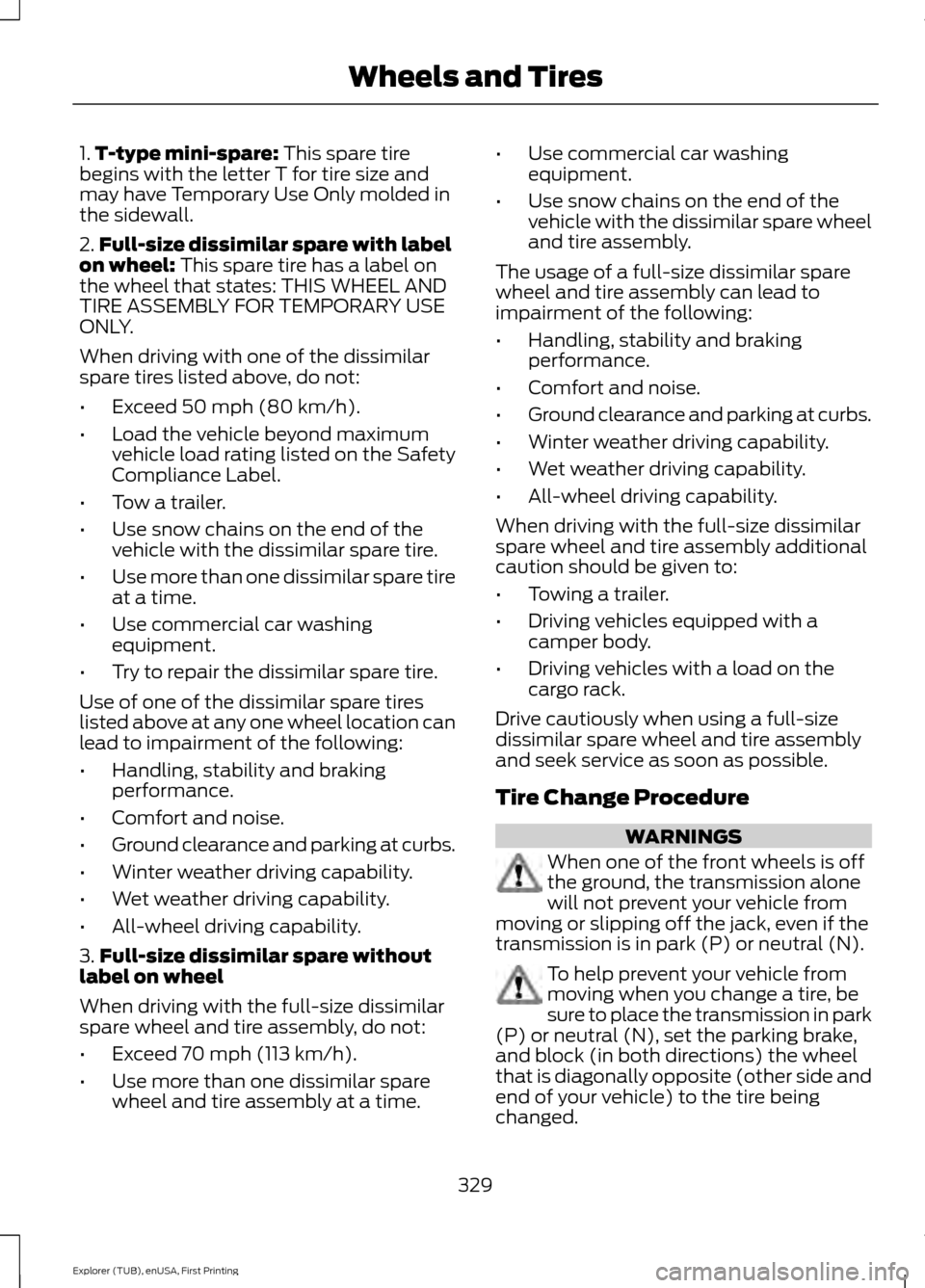

turn the engine off. 3. Block the diagonally opposite wheel.

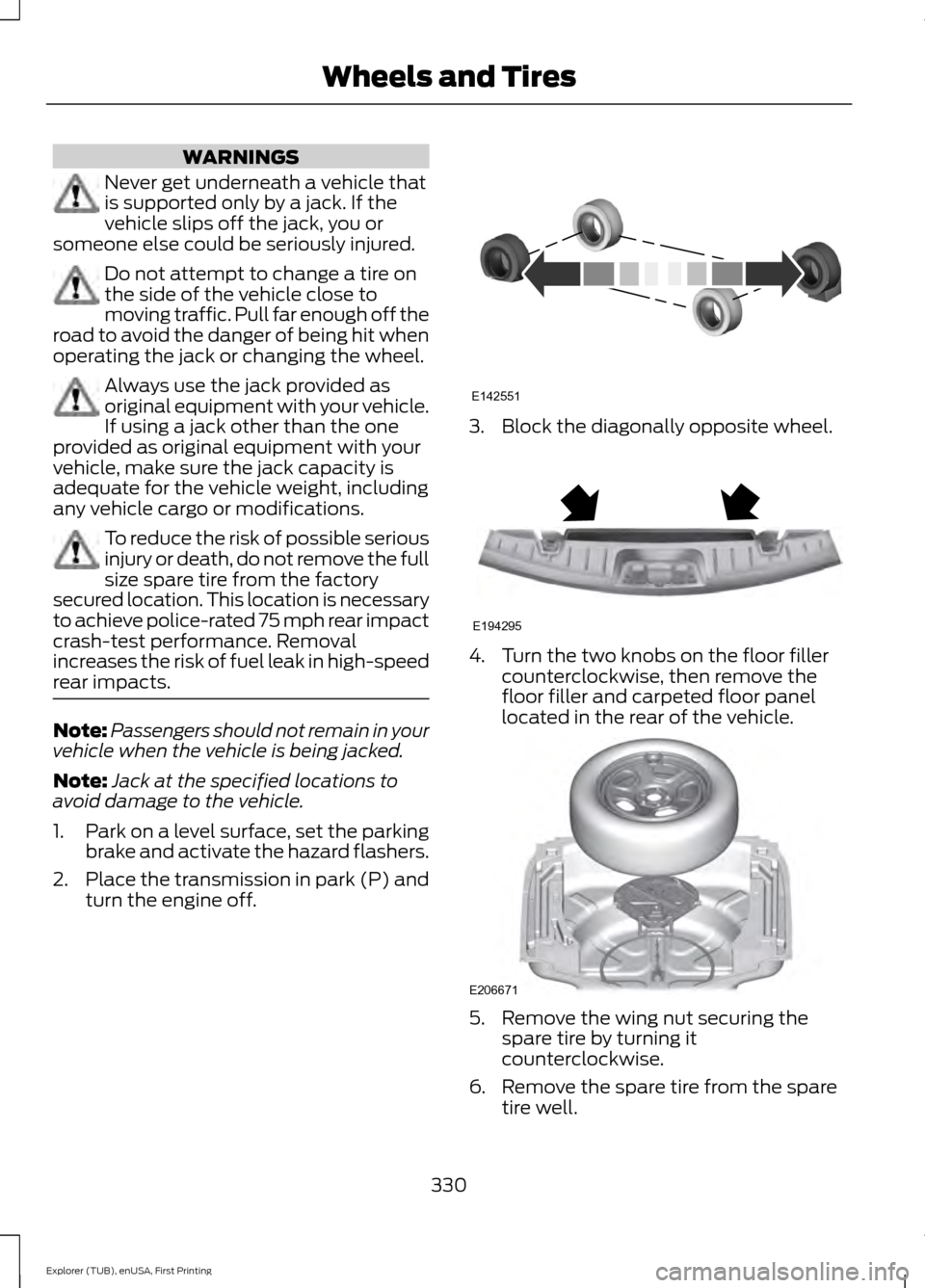

4. Turn the two knobs on the floor filler

counterclockwise, then remove the

floor filler and carpeted floor panel

located in the rear of the vehicle. 5. Remove the wing nut securing the

spare tire by turning it

counterclockwise.

6. Remove the spare tire from the spare tire well.

330

Explorer (TUB), enUSA, First Printing Wheels and TiresE142551 E194295 E206671

Page 334 of 541

7.

Remove the wing nut bolt that secures

the jack kit by turning it

counterclockwise.

8. Remove the jack kit, which includes the

jack, lug wrench, L-shaped bolt and

tow recovery hook.

9. Turn the lead screw (where the lug wrench attaches) of the jack by hand

to release the lug wrench from the jack.

Press the button on the wrench to

extend the handle. Fold down the

wrench socket.

10. Loosen each wheel lug nut one-half turn counterclockwise, but do not

remove them until the wheel is raised

off the ground. 11.

The vehicle jacking points are shown

here, and are depicted on the warning

label on the jack.

12. Small arrow-shaped marks on the sills show the location of the jacking

points. 13. Raise the wheel by turning the jack

handle clockwise.

14. Remove the lug nuts with the lug wrench.

15. Replace the flat tire with the spare tire, marking sure the valve stem is

facing outward. Reinstall the lug nuts

until the wheel is snug against the

hub. Do not fully tighten the lug nuts

until the wheel has been lowered.

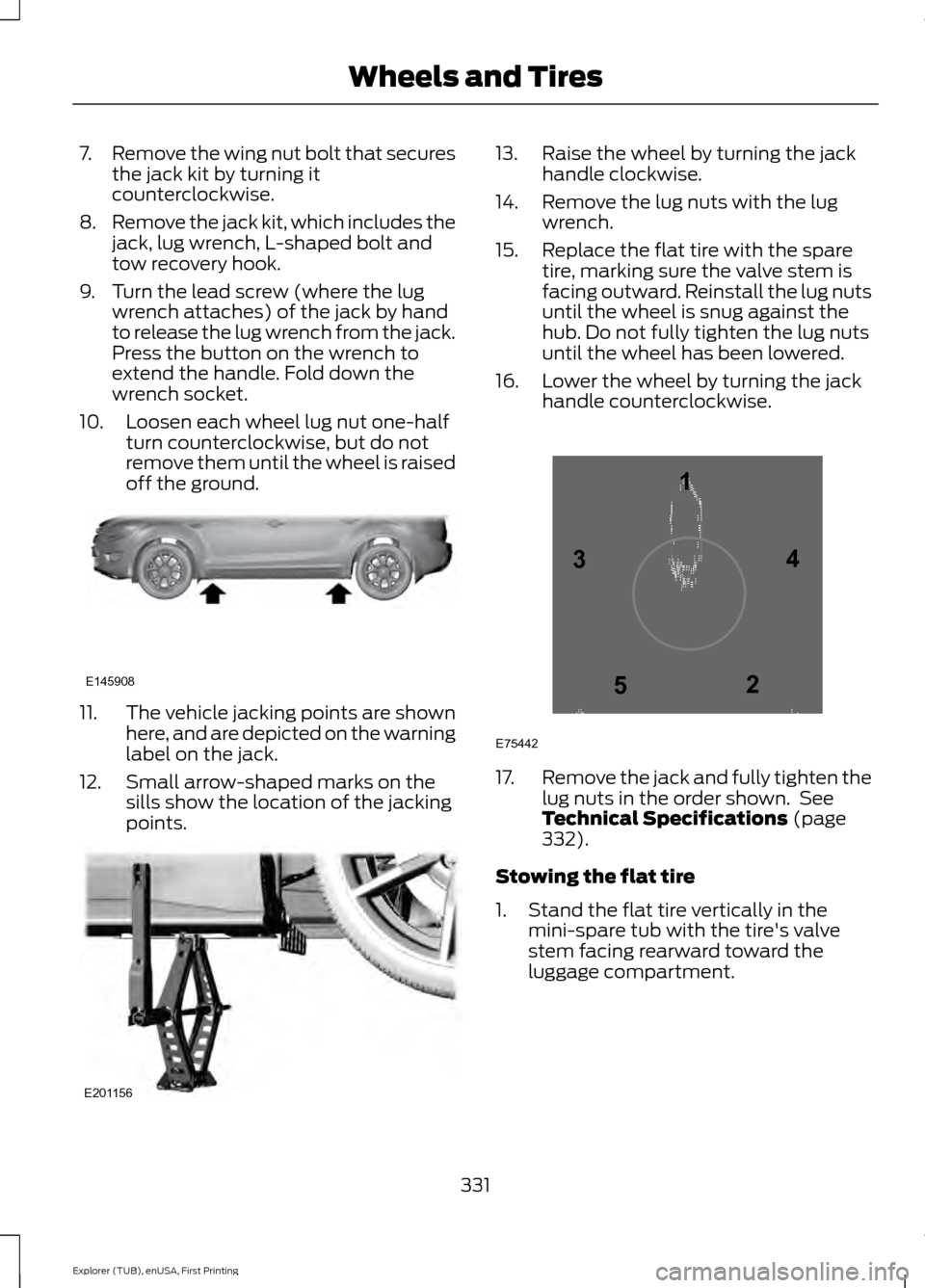

16. Lower the wheel by turning the jack handle counterclockwise. 17.

Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page

332).

Stowing the flat tire

1. Stand the flat tire vertically in the mini-spare tub with the tire's valve

stem facing rearward toward the

luggage compartment.

331

Explorer (TUB), enUSA, First Printing Wheels and TiresE145908 E201156 12

3

4

5

E75442

Page 335 of 541

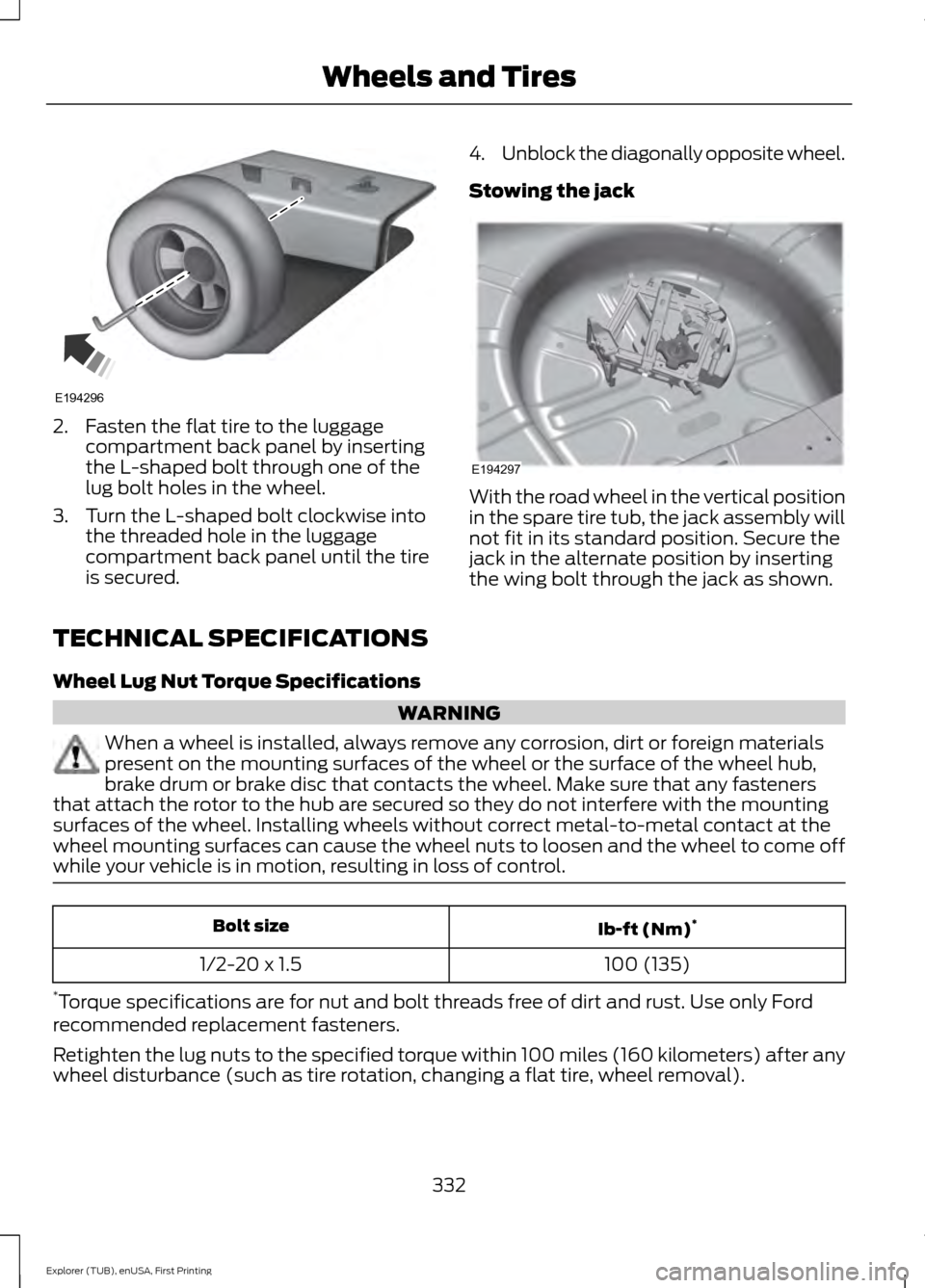

2. Fasten the flat tire to the luggage

compartment back panel by inserting

the L-shaped bolt through one of the

lug bolt holes in the wheel.

3. Turn the L-shaped bolt clockwise into the threaded hole in the luggage

compartment back panel until the tire

is secured. 4.

Unblock the diagonally opposite wheel.

Stowing the jack With the road wheel in the vertical position

in the spare tire tub, the jack assembly will

not fit in its standard position. Secure the

jack in the alternate position by inserting

the wing bolt through the jack as shown.

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign materials

present on the mounting surfaces of the wheel or the surface of the wheel hub,

brake drum or brake disc that contacts the wheel. Make sure that any fasteners

that attach the rotor to the hub are secured so they do not interfere with the mounting

surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off

while your vehicle is in motion, resulting in loss of control. Ib-ft (Nm)

*

Bolt size

100 (135)

1/2-20 x 1.5

* Torque specifications are for nut and bolt threads free of dirt and rust. Use only Ford

recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kilometers) after any

wheel disturbance (such as tire rotation, changing a flat tire, wheel removal).

332

Explorer (TUB), enUSA, First Printing Wheels and TiresE194296 E194297

Page 336 of 541

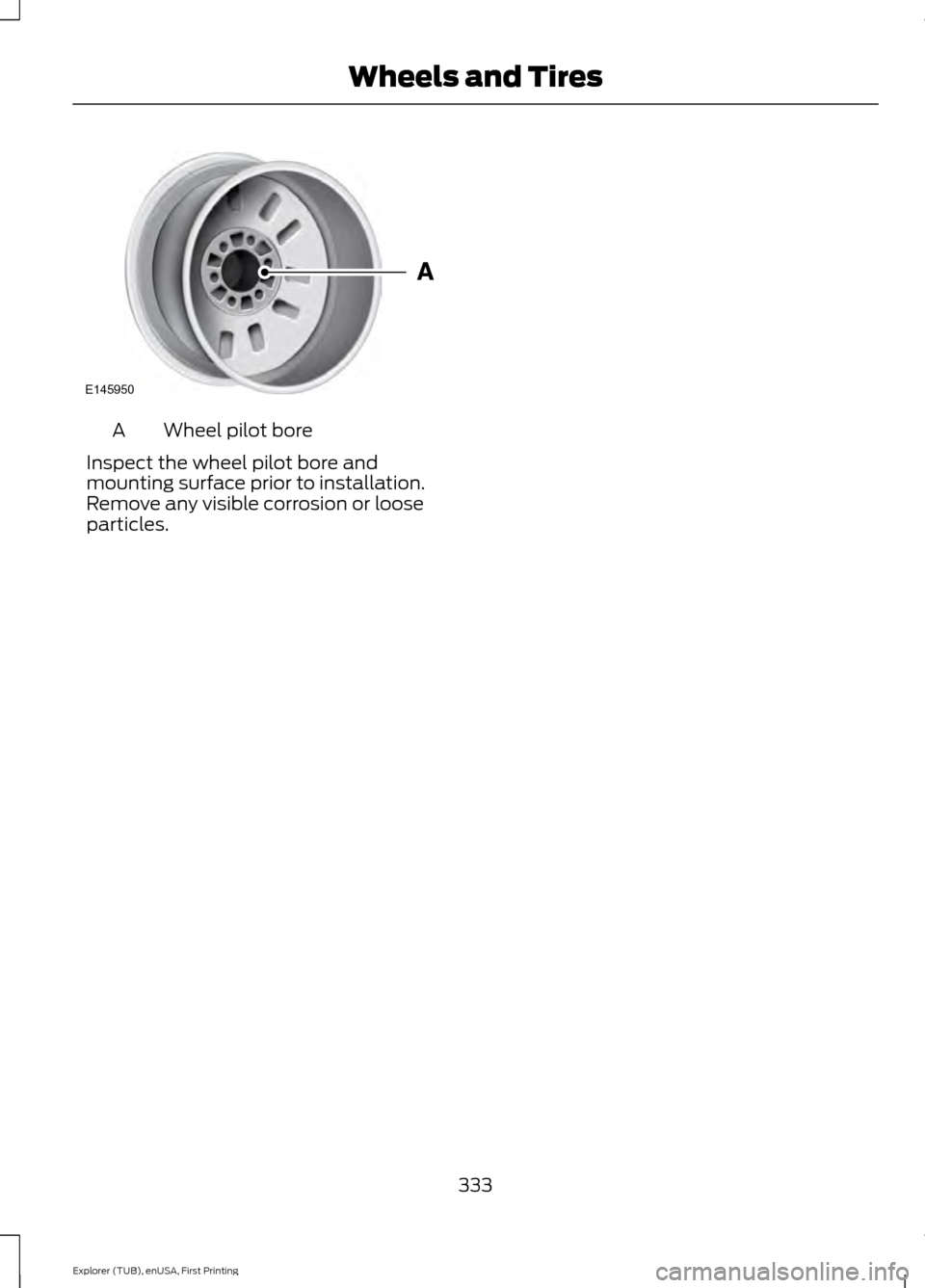

Wheel pilot bore

A

Inspect the wheel pilot bore and

mounting surface prior to installation.

Remove any visible corrosion or loose

particles.

333

Explorer (TUB), enUSA, First Printing Wheels and TiresE145950

Page 337 of 541

ENGINE SPECIFICATIONS - 2.3L ECOBOOST™

2.3L EcoBoost

Engine

138

Cubic inches

Minimum 87 octane

Required fuel

1-3-4-2

Firing order

Coil on plug

Ignition system

0.027 - 0.031 in (0.70 - 0.80 mm)

Spark plug gap

9.5:1

Compression ratio

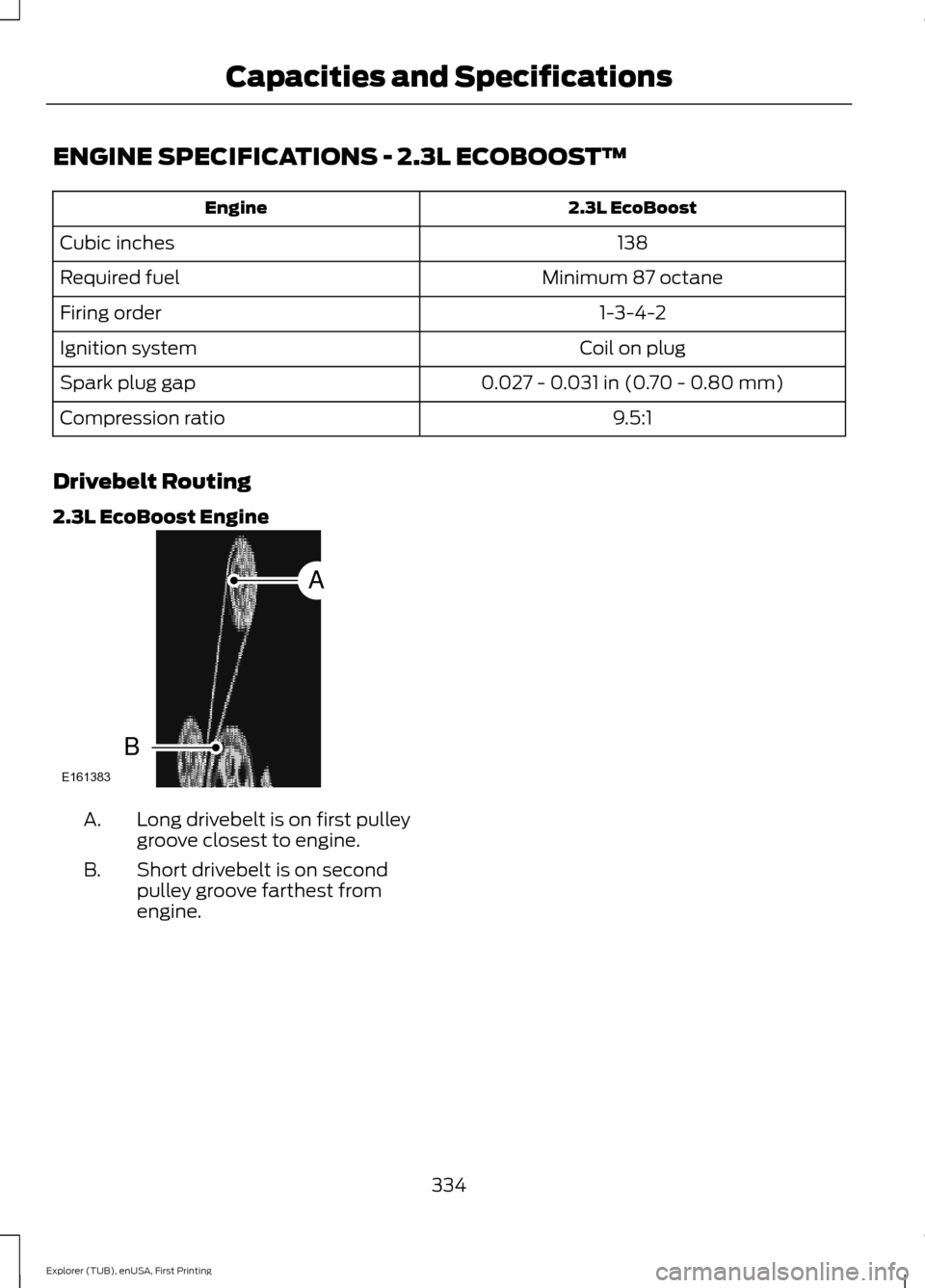

Drivebelt Routing

2.3L EcoBoost Engine Long drivebelt is on first pulley

groove closest to engine.

A.

Short drivebelt is on second

pulley groove farthest from

engine.

B.

334

Explorer (TUB), enUSA, First Printing Capacities and SpecificationsE161383

A

B

Page 338 of 541

ENGINE SPECIFICATIONS - 3.5L DURATEC

3.5L V6

Engine

214

Cubic inches

Minimum 87 octane

Required fuel

1-4-2-5-3-6

Firing order

Coil on plug

Ignition system

0.049 - 0.053 in (1.25 mm - 1.35 mm)

Spark plug gap

10.8:1

Compression ratio

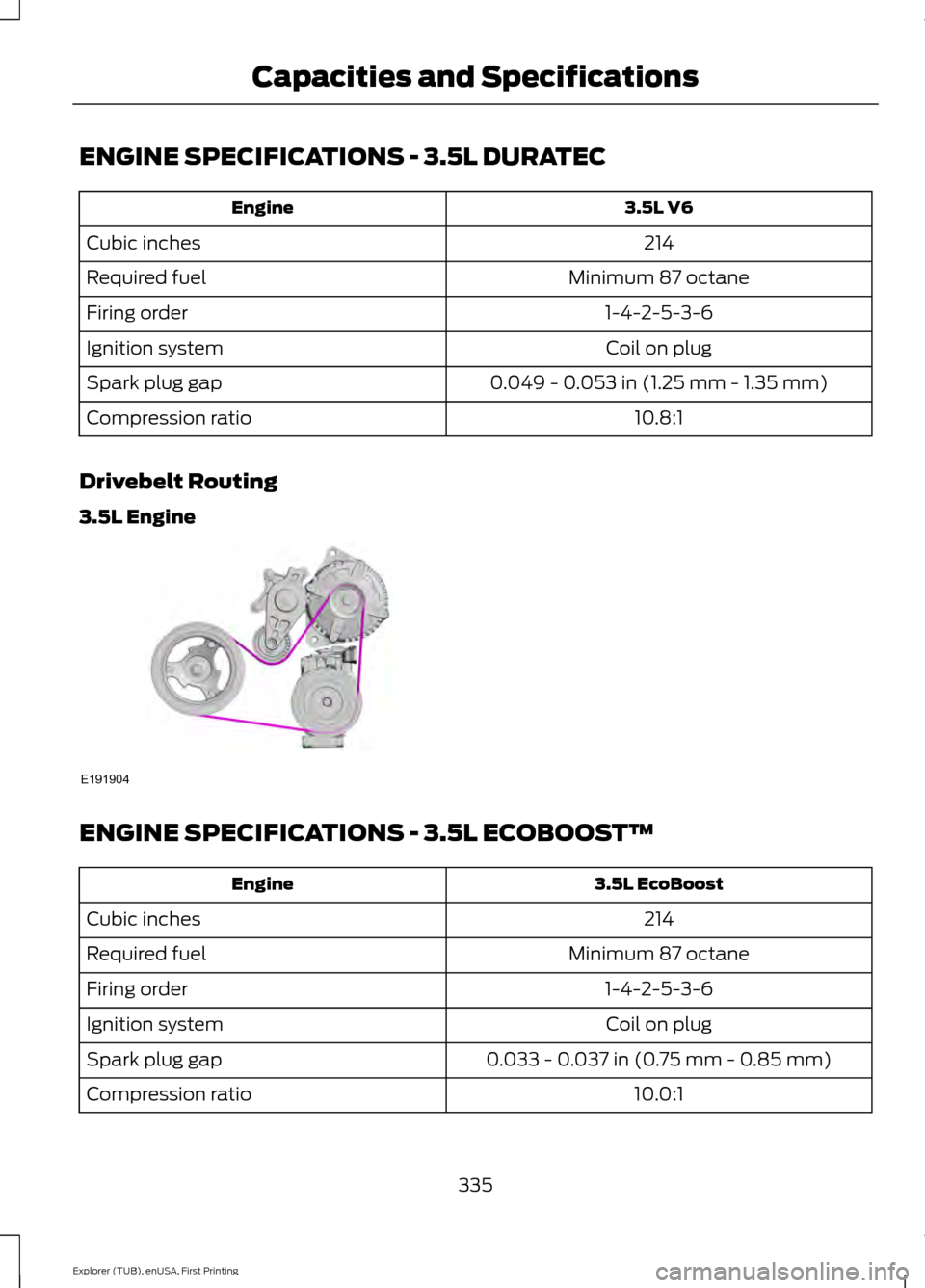

Drivebelt Routing

3.5L Engine ENGINE SPECIFICATIONS - 3.5L ECOBOOST™

3.5L EcoBoost

Engine

214

Cubic inches

Minimum 87 octane

Required fuel

1-4-2-5-3-6

Firing order

Coil on plug

Ignition system

0.033 - 0.037 in (0.75 mm - 0.85 mm)

Spark plug gap

10.0:1

Compression ratio

335

Explorer (TUB), enUSA, First Printing Capacities and SpecificationsE191904

Page 339 of 541

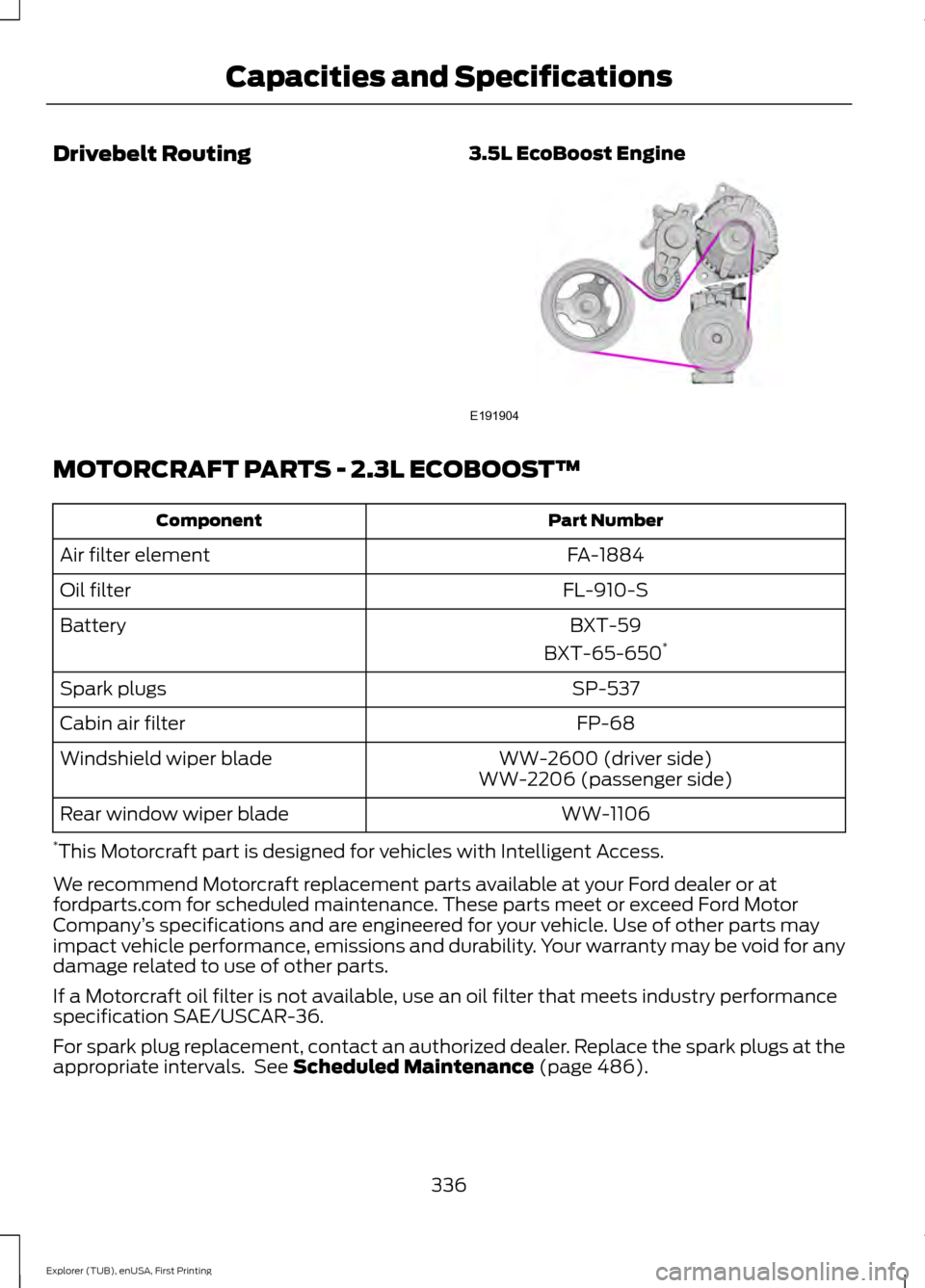

Drivebelt Routing

3.5L EcoBoost EngineMOTORCRAFT PARTS - 2.3L ECOBOOST™

Part Number

Component

FA-1884

Air filter element

FL-910-S

Oil filter

BXT-59

Battery

BXT-65-650*

SP-537

Spark plugs

FP-68

Cabin air filter

WW-2600 (driver side)

Windshield wiper blade

WW-2206 (passenger side)

WW-1106

Rear window wiper blade

* This Motorcraft part is designed for vehicles with Intelligent Access.

We recommend Motorcraft replacement parts available at your Ford dealer or at

fordparts.com for scheduled maintenance. These parts meet or exceed Ford Motor

Company ’s specifications and are engineered for your vehicle. Use of other parts may

impact vehicle performance, emissions and durability. Your warranty may be void for any

damage related to use of other parts.

If a Motorcraft oil filter is not available, use an oil filter that meets industry performance

specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the

appropriate intervals. See Scheduled Maintenance (page 486).

336

Explorer (TUB), enUSA, First Printing Capacities and SpecificationsE191904

Page 340 of 541

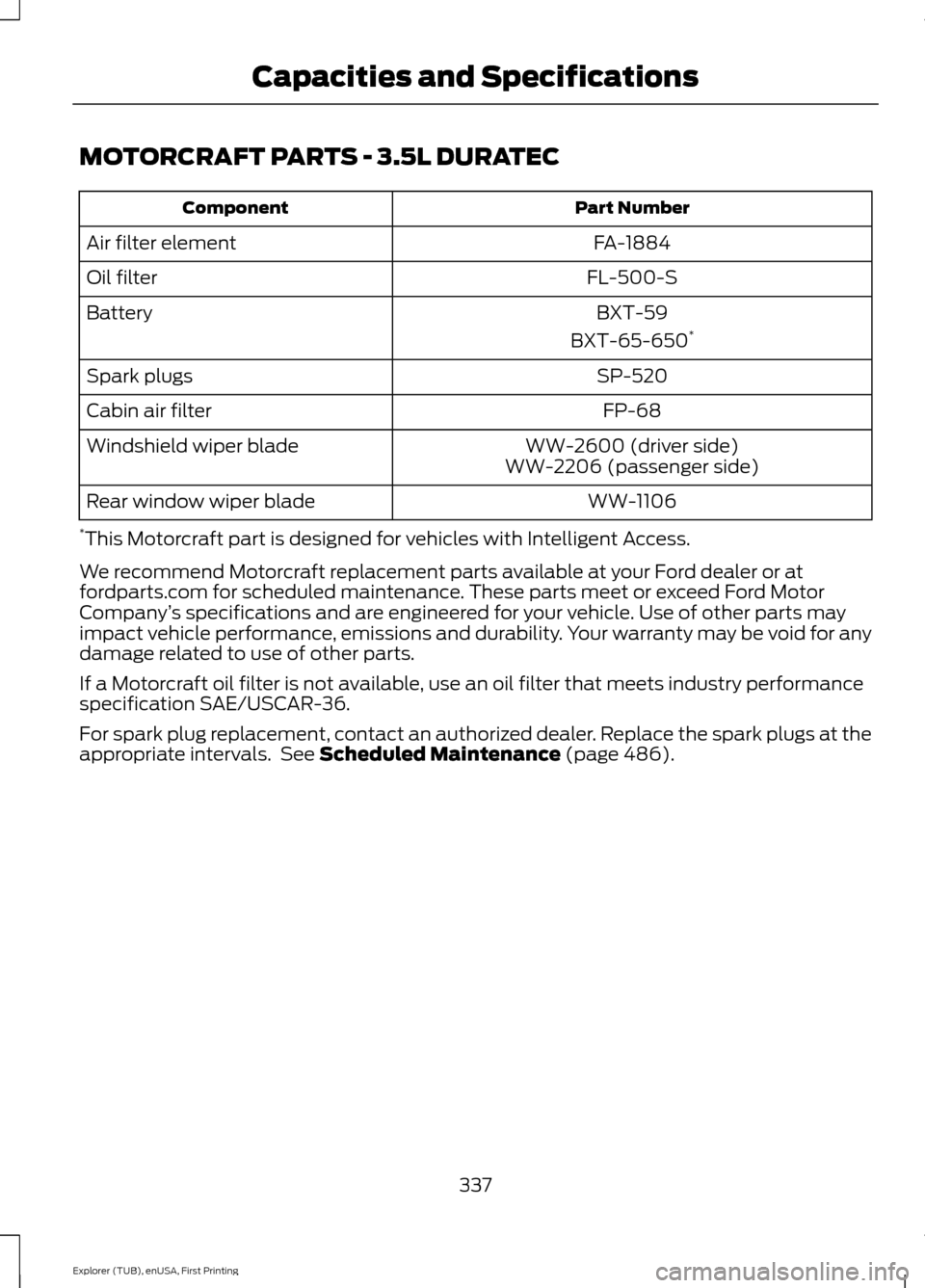

MOTORCRAFT PARTS - 3.5L DURATEC

Part Number

Component

FA-1884

Air filter element

FL-500-S

Oil filter

BXT-59

Battery

BXT-65-650*

SP-520

Spark plugs

FP-68

Cabin air filter

WW-2600 (driver side)

Windshield wiper blade

WW-2206 (passenger side)

WW-1106

Rear window wiper blade

* This Motorcraft part is designed for vehicles with Intelligent Access.

We recommend Motorcraft replacement parts available at your Ford dealer or at

fordparts.com for scheduled maintenance. These parts meet or exceed Ford Motor

Company ’s specifications and are engineered for your vehicle. Use of other parts may

impact vehicle performance, emissions and durability. Your warranty may be void for any

damage related to use of other parts.

If a Motorcraft oil filter is not available, use an oil filter that meets industry performance

specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the

appropriate intervals. See Scheduled Maintenance (page 486).

337

Explorer (TUB), enUSA, First Printing Capacities and Specifications