clock FORD EXPLORER SPORT TRAC 2001 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2001, Model line: EXPLORER SPORT TRAC, Model: FORD EXPLORER SPORT TRAC 2001Pages: 264, PDF Size: 2.19 MB

Page 172 of 264

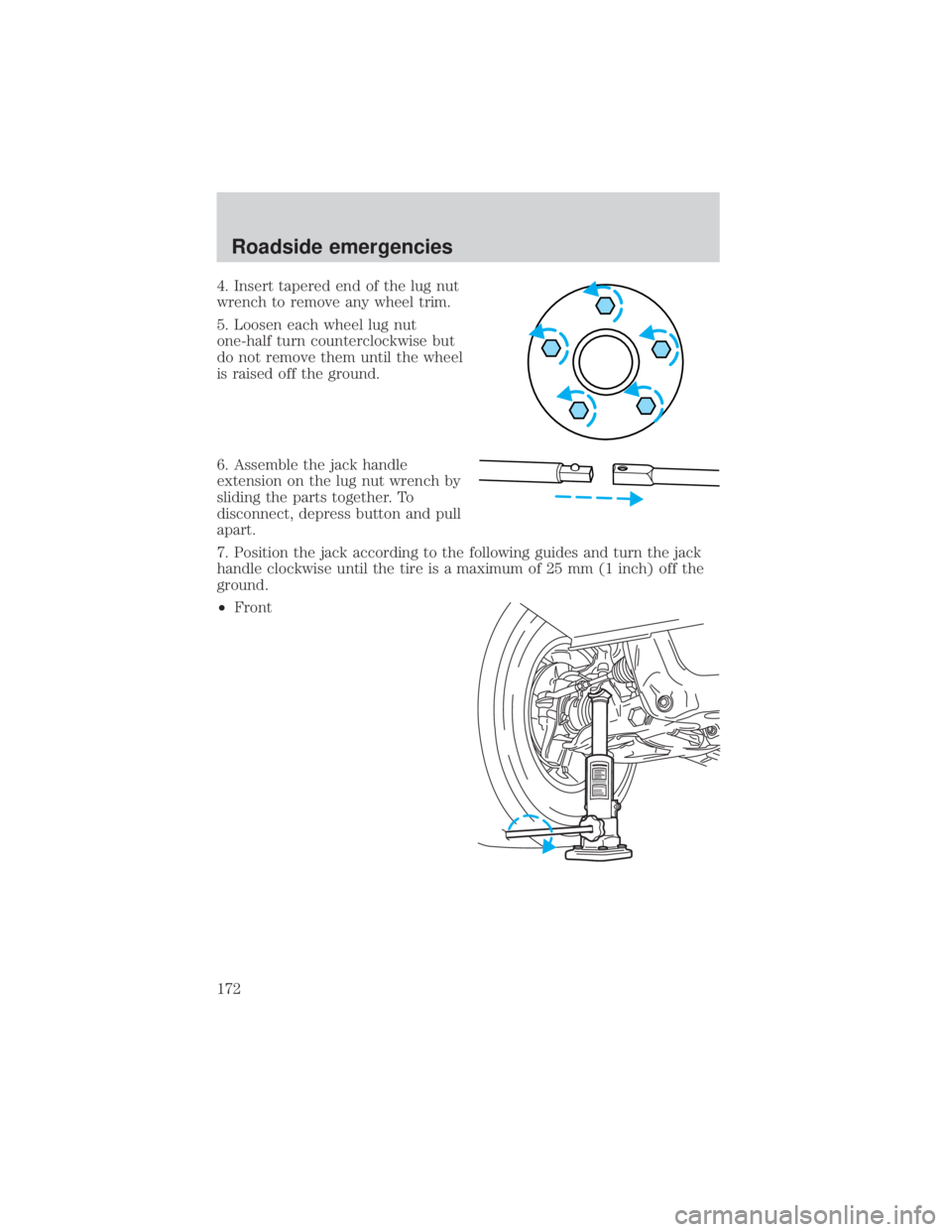

4. Insert tapered end of the lug nut

wrench to remove any wheel trim.

5. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

6. Assemble the jack handle

extension on the lug nut wrench by

sliding the parts together. To

disconnect, depress button and pull

apart.

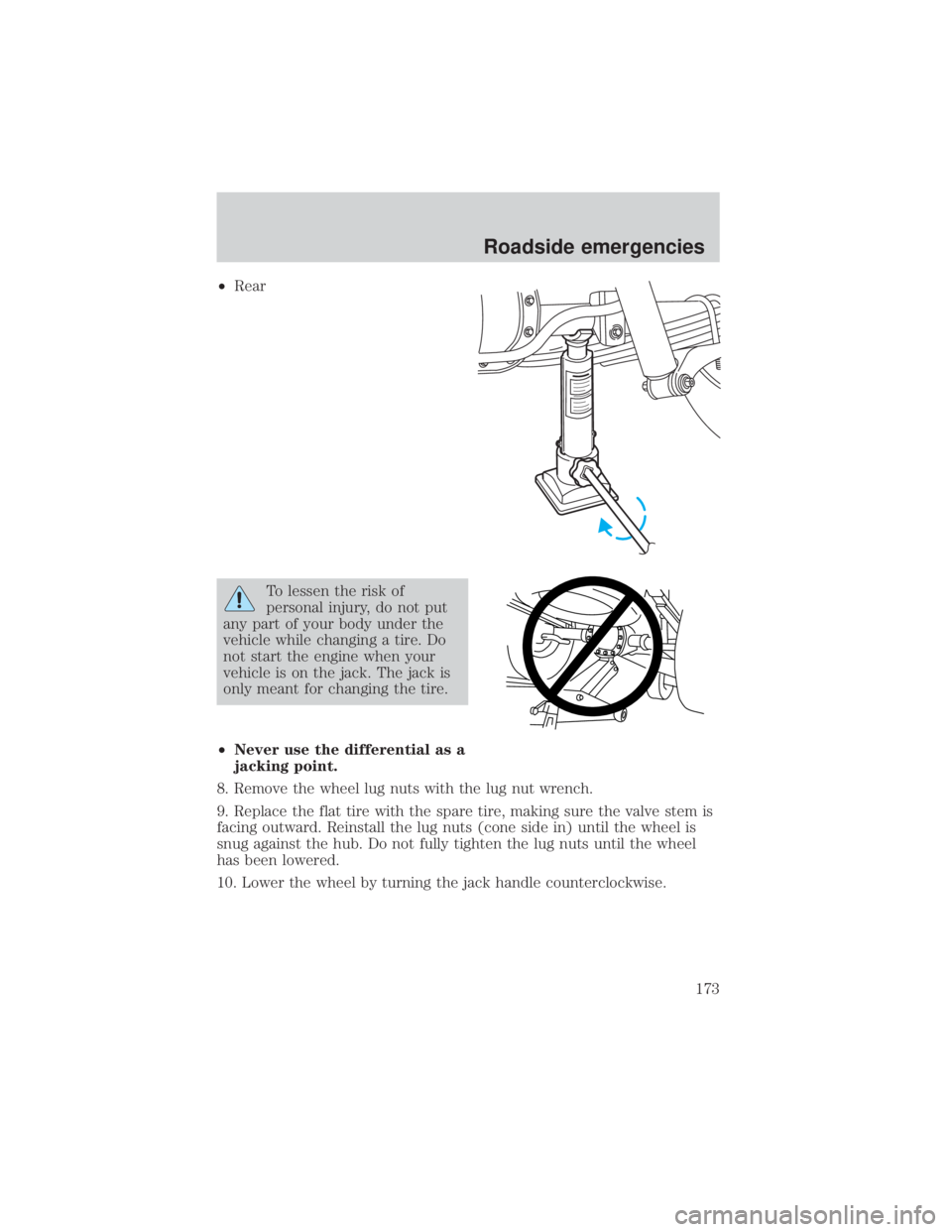

7. Position the jack according to the following guides and turn the jack

handle clockwise until the tire is a maximum of 25 mm (1 inch) off the

ground.

²Front

Roadside emergencies

172

Page 173 of 264

²Rear

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

²Never use the differential as a

jacking point.

8. Remove the wheel lug nuts with the lug nut wrench.

9. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts (cone side in) until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

10. Lower the wheel by turning the jack handle counterclockwise.

Roadside emergencies

173

Page 186 of 264

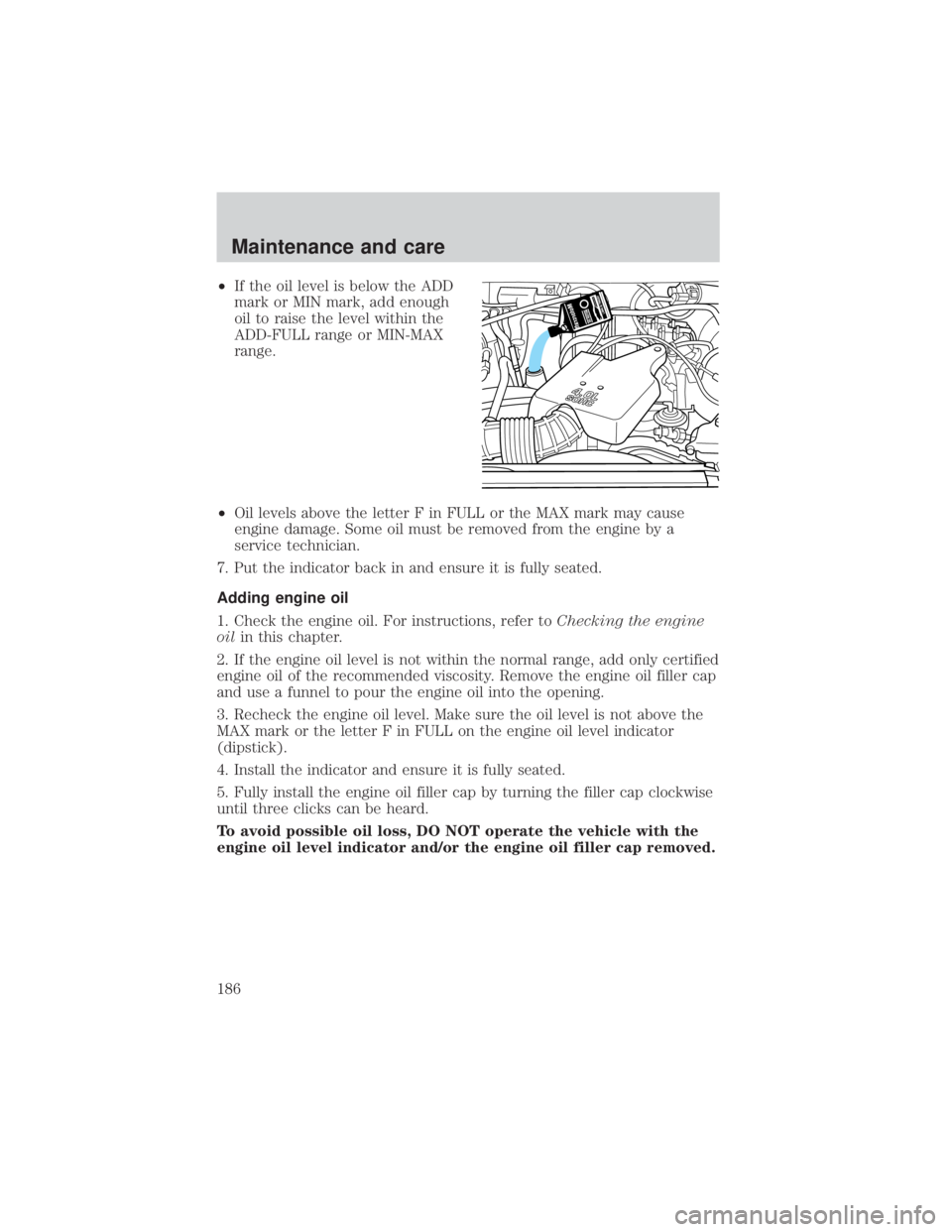

²If the oil level is below the ADD

mark or MIN mark, add enough

oil to raise the level within the

ADD-FULL range or MIN-MAX

range.

²Oil levels above the letter F in FULL or the MAX mark may cause

engine damage. Some oil must be removed from the engine by a

service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark or the letter F in FULL on the engine oil level indicator

(dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

until three clicks can be heard.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Maintenance and care

186

Page 193 of 264

with the factory-filled coolant.Mixing Motorcraft Speciality Orange

Engine Coolant or any orange-colored extended life product with your

factory filled coolant can result in degraded corrosion protection.

²A large amount of water without engine coolant may be added, in case

of emergency, to reach a vehicle service location. In this instance, the

cooling system must be drained and refilled with a 50/50 mixture of

engine coolant and distilled water as soon as possible. Water alone

(without engine coolant) can cause engine damage from corrosion,

overheating or freezing.

²Do not use alcohol, methanol or brine or any engine coolants

mixed with alcohol or methanol antifreeze (coolant).Alcohol

and other liquids can cause engine damage from overheating or

freezing.

²Do not add extra inhibitors or additives to the coolant.These

can be harmful and compromise the corrosion protection of the engine

coolant.

²Do not mix with recycled coolant unless from a Ford-approved

recycling process (seeUse of Recycled Engine Coolantsection).

For vehicles with overflow coolant systems with a non-pressurized cap

on the coolant recovery system, add coolant to the coolant recovery

reservoir when the engine is cool. Add the proper mixture of coolant and

water to the ªcold fullº level. For all other vehicles, which have a coolant

degas system with a pressurized cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator of a vehicle with an overflow

system, follow these steps to add engine coolant.

To avoid personal injury, make sure the engine is cool before

unscrewing the coolant pressure relief cap. The cooling system is

under pressure; steam and hot liquid can come out forcefully when the

cap is loosened slightly.

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (an opaque plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

Maintenance and care

193

Page 201 of 264

When lifting a plastic-cased battery, excessive pressure on the

end walls could cause acid to flow through the vent caps,

resulting in personal injury and/or damage to the vehicle or battery.

Lift the battery with a battery carrier or with your hands on opposite

corners.

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

Battery posts, terminals and related accessories contain lead and

lead compounds.Wash hands after handling.

Because your vehicle's engine is electronically controlled by a computer,

some control conditions are maintained by power from the battery. When

the battery is disconnected or a new battery is installed, the engine must

relearn its idle and fuel trim strategy for optimum driveability and

performance. To begin this process:

1. With the vehicle at a complete stop, set the parking brake.

2. Put the gearshift in P (Park), turn off all accessories and start the

engine.

3. Run the engine until it reaches normal operating temperature.

4. Allow the engine to idle for at least one minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

6. Drive the vehicle to complete the relearning process.

²The vehicle may need to be driven 16 km (10 miles) or more to

relearn the idle and fuel trim strategy.

²If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

Maintenance and care

201

Page 214 of 264

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a 1/8 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8 of a turn until it

stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it stops.

If the ªCheck Fuel Capº indicator comes on and stays on after you start

the engine, the fuel filler cap may not be properly installed. Turn off the

engine, remove the fuel filler cap, align the cap properly and reinstall it.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If the fuel filler cap is

venting vapor or if you hear a hissing sound, wait until it stops

before completely removing the fuel filler cap. Otherwise, fuel may

spray out and injure you or others.

If you do not use the proper fuel filler cap, excessive pressure or

vacuum in the fuel tank may damage the fuel system or cause

the fuel cap to disengage in a collision, which may result in possible

personal injury.

Maintenance and care

214

Page 221 of 264

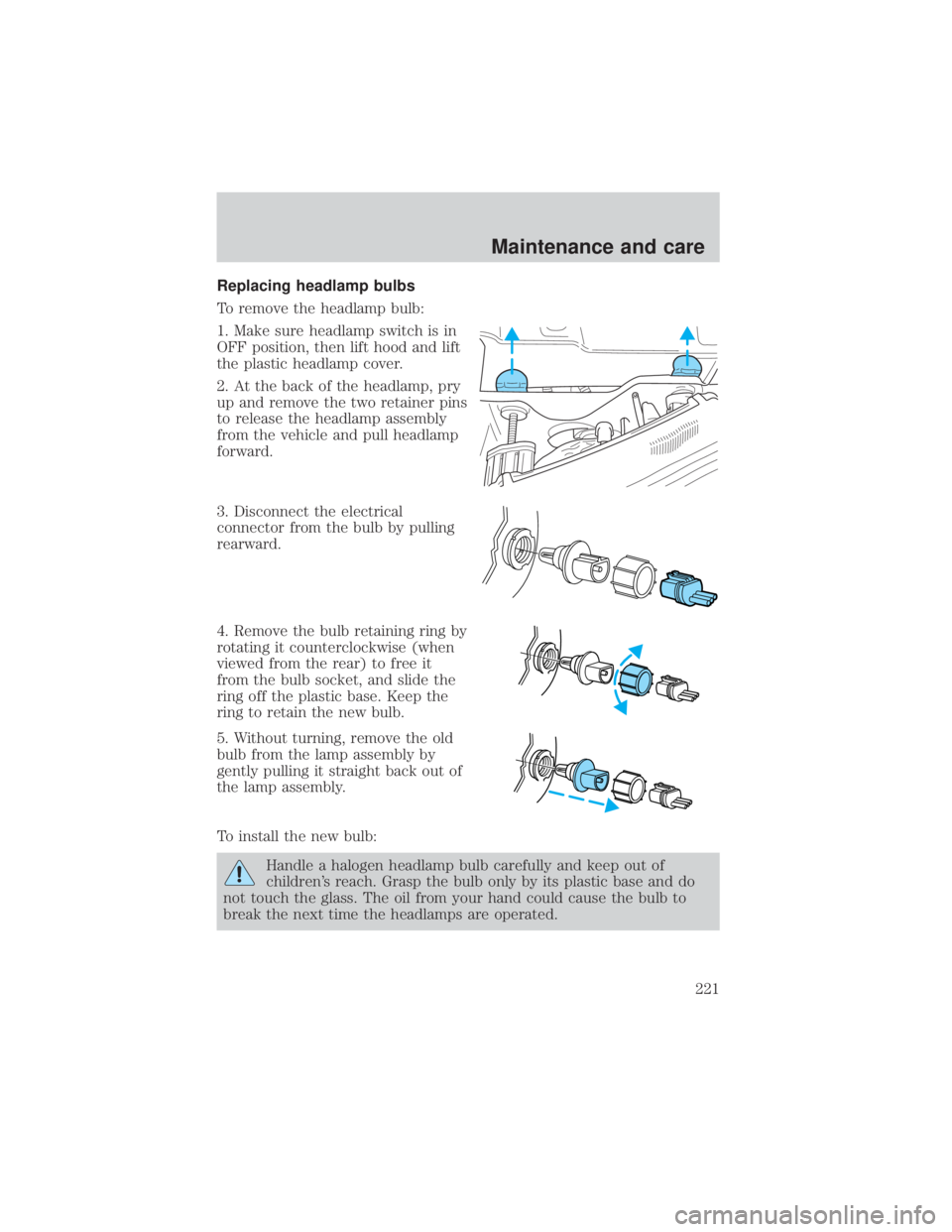

Replacing headlamp bulbs

To remove the headlamp bulb:

1. Make sure headlamp switch is in

OFF position, then lift hood and lift

the plastic headlamp cover.

2. At the back of the headlamp, pry

up and remove the two retainer pins

to release the headlamp assembly

from the vehicle and pull headlamp

forward.

3. Disconnect the electrical

connector from the bulb by pulling

rearward.

4. Remove the bulb retaining ring by

rotating it counterclockwise (when

viewed from the rear) to free it

from the bulb socket, and slide the

ring off the plastic base. Keep the

ring to retain the new bulb.

5. Without turning, remove the old

bulb from the lamp assembly by

gently pulling it straight back out of

the lamp assembly.

To install the new bulb:

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

Maintenance and care

221

Page 222 of 264

1. With the flat side of the new bulb's plastic base facing upward, insert

the glass end of the bulb into the lamp assembly. Turn the bulb left or

right to align the grooves in the plastic base with the tabs in the lamp

assembly. When the grooves are aligned, push the bulb into the lamp

assembly until the plastic base contacts the rear of the lamp assembly.

2. Install the bulb retaining ring over the plastic base until it contacts the

rear of the socket by rotating it clockwise until you feel a ªstop.º

3. Connect the electrical connector into the rear of the plastic base until

it snaps, locking it into position.

4. Install the headlamp on vehicle by aligning the lamp on the vehicle,

push rearward and secure with two retainer pins.

5. Install the protective cover over headlamps locking it in place.

6. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

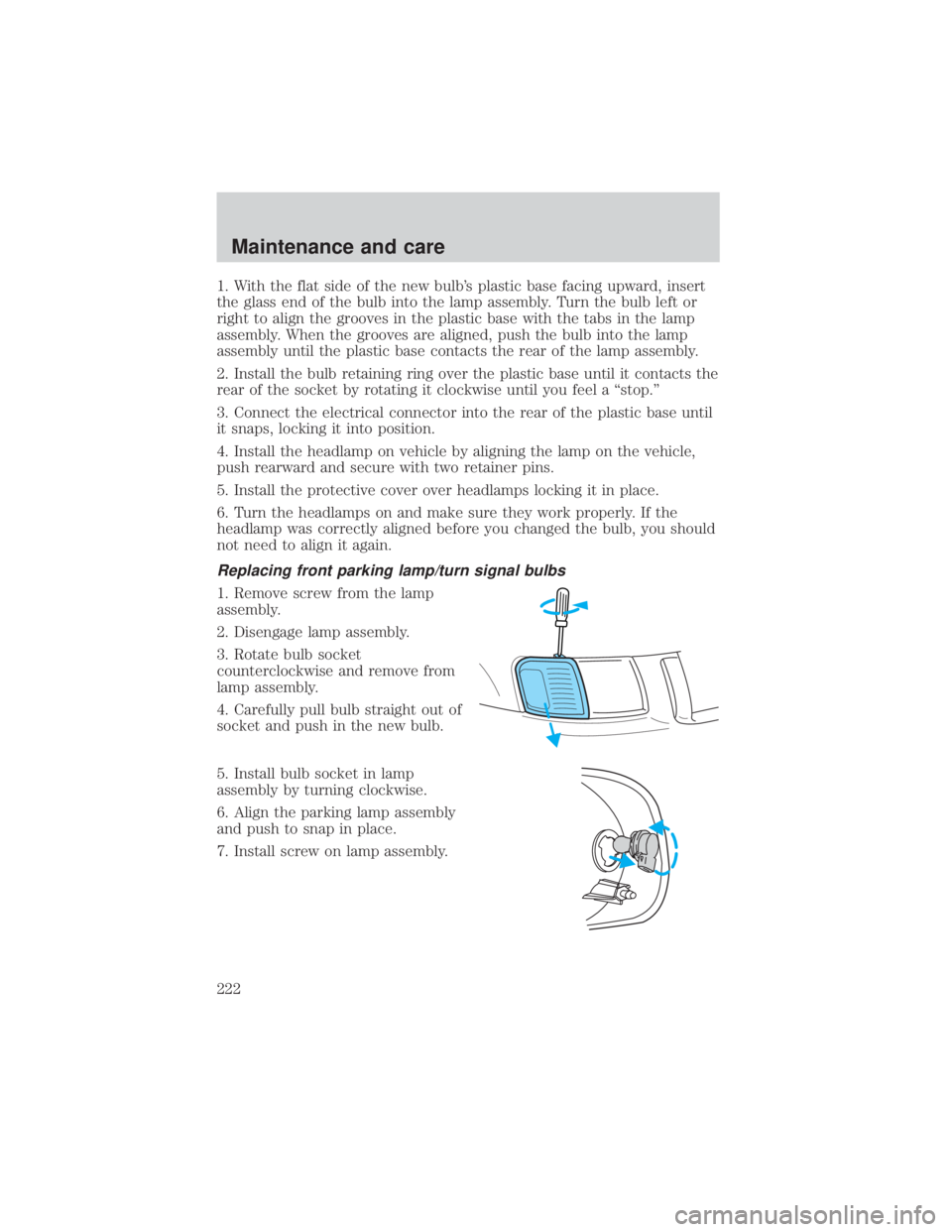

Replacing front parking lamp/turn signal bulbs

1. Remove screw from the lamp

assembly.

2. Disengage lamp assembly.

3. Rotate bulb socket

counterclockwise and remove from

lamp assembly.

4. Carefully pull bulb straight out of

socket and push in the new bulb.

5. Install bulb socket in lamp

assembly by turning clockwise.

6. Align the parking lamp assembly

and push to snap in place.

7. Install screw on lamp assembly.

Maintenance and care

222

Page 223 of 264

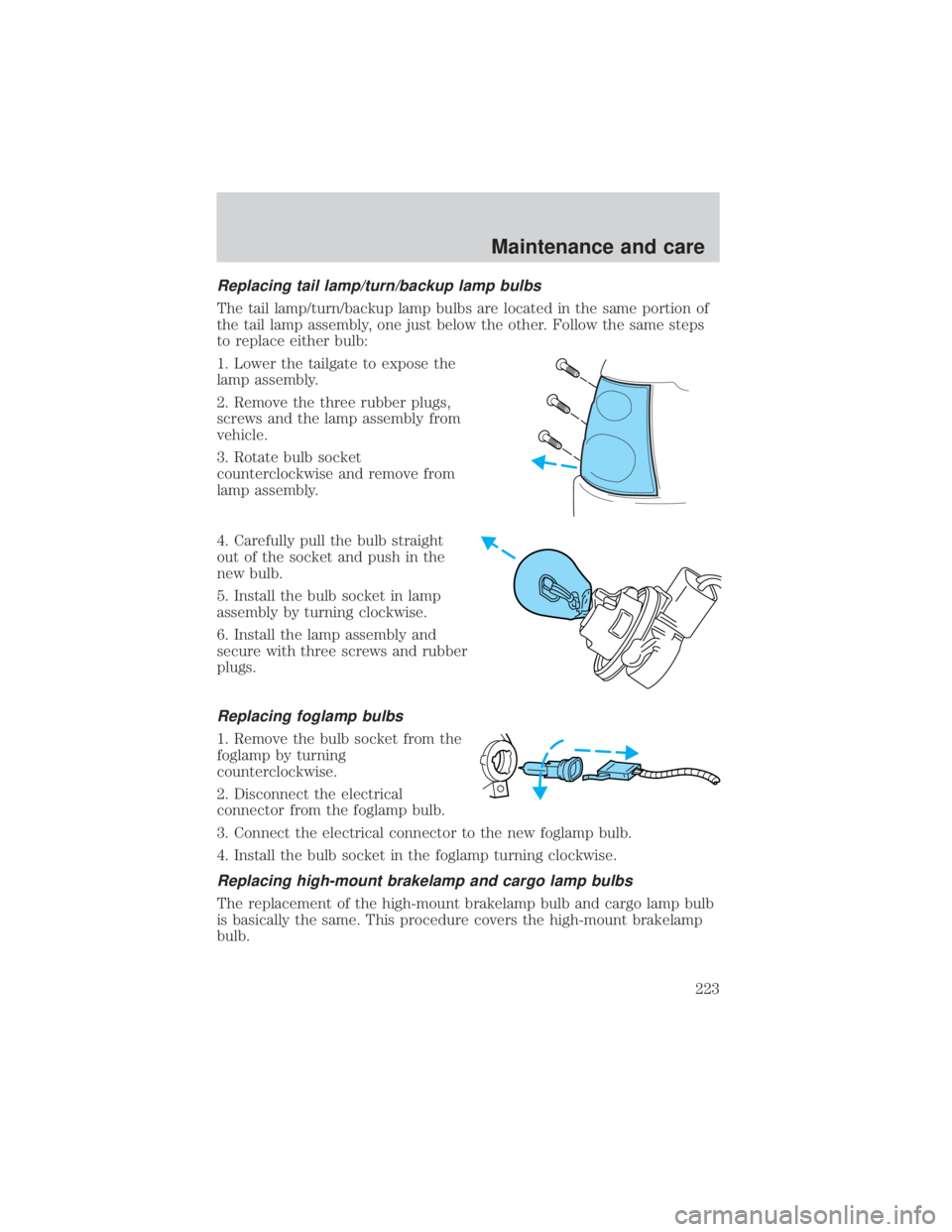

Replacing tail lamp/turn/backup lamp bulbs

The tail lamp/turn/backup lamp bulbs are located in the same portion of

the tail lamp assembly, one just below the other. Follow the same steps

to replace either bulb:

1. Lower the tailgate to expose the

lamp assembly.

2. Remove the three rubber plugs,

screws and the lamp assembly from

vehicle.

3. Rotate bulb socket

counterclockwise and remove from

lamp assembly.

4. Carefully pull the bulb straight

out of the socket and push in the

new bulb.

5. Install the bulb socket in lamp

assembly by turning clockwise.

6. Install the lamp assembly and

secure with three screws and rubber

plugs.

Replacing foglamp bulbs

1. Remove the bulb socket from the

foglamp by turning

counterclockwise.

2. Disconnect the electrical

connector from the foglamp bulb.

3. Connect the electrical connector to the new foglamp bulb.

4. Install the bulb socket in the foglamp turning clockwise.

Replacing high-mount brakelamp and cargo lamp bulbs

The replacement of the high-mount brakelamp bulb and cargo lamp bulb

is basically the same. This procedure covers the high-mount brakelamp

bulb.

Maintenance and care

223

Page 224 of 264

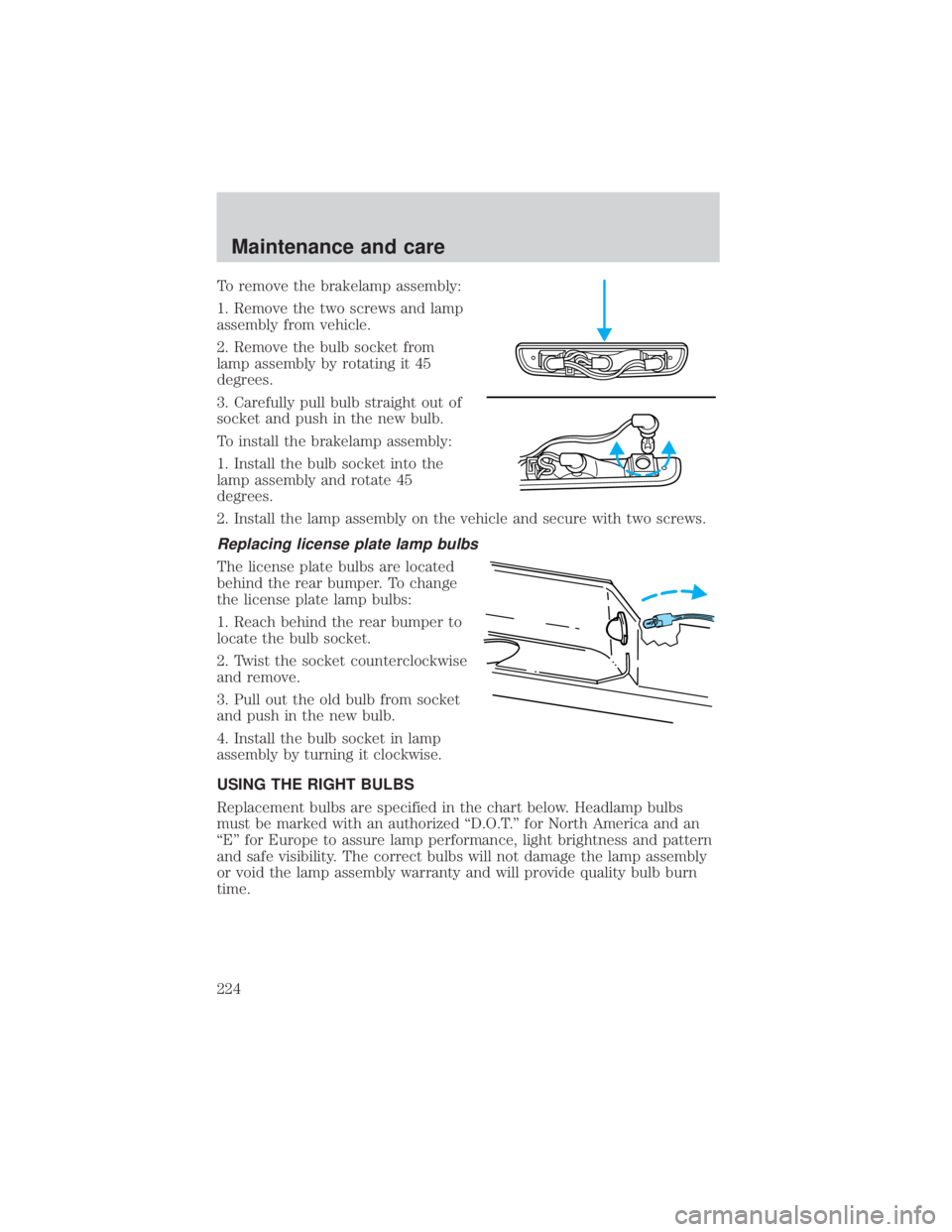

To remove the brakelamp assembly:

1. Remove the two screws and lamp

assembly from vehicle.

2. Remove the bulb socket from

lamp assembly by rotating it 45

degrees.

3. Carefully pull bulb straight out of

socket and push in the new bulb.

To install the brakelamp assembly:

1. Install the bulb socket into the

lamp assembly and rotate 45

degrees.

2. Install the lamp assembly on the vehicle and secure with two screws.

Replacing license plate lamp bulbs

The license plate bulbs are located

behind the rear bumper. To change

the license plate lamp bulbs:

1. Reach behind the rear bumper to

locate the bulb socket.

2. Twist the socket counterclockwise

and remove.

3. Pull out the old bulb from socket

and push in the new bulb.

4. Install the bulb socket in lamp

assembly by turning it clockwise.

USING THE RIGHT BULBS

Replacement bulbs are specified in the chart below. Headlamp bulbs

must be marked with an authorized ªD.O.T.º for North America and an

ªEº for Europe to assure lamp performance, light brightness and pattern

and safe visibility. The correct bulbs will not damage the lamp assembly

or void the lamp assembly warranty and will provide quality bulb burn

time.

Maintenance and care

224