wheel FORD F-150 2020 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2020, Model line: F-150, Model: FORD F-150 2020Pages: 625, PDF Size: 7.98 MB

Page 422 of 625

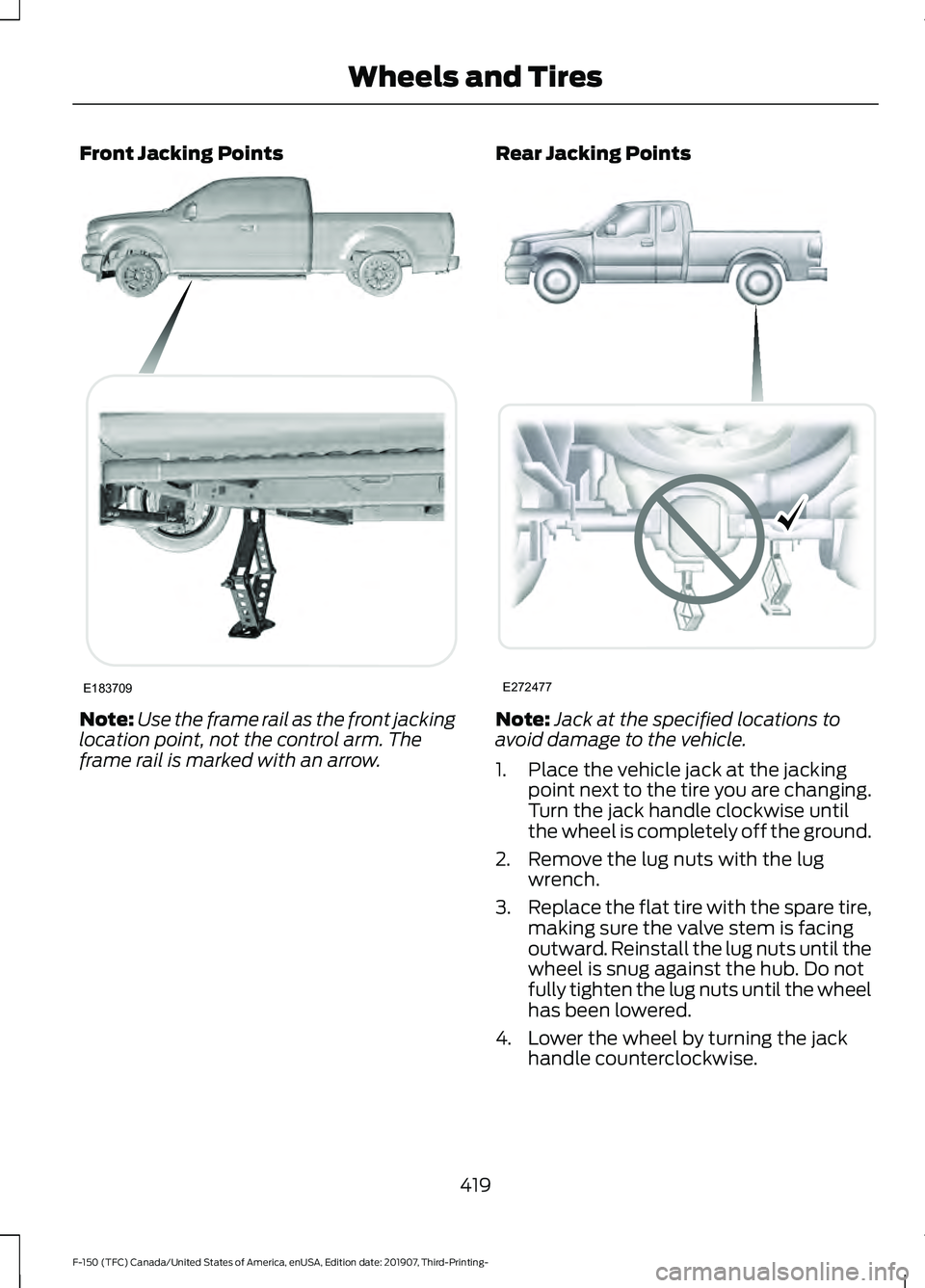

Front Jacking Points

Note:

Use the frame rail as the front jacking

location point, not the control arm. The

frame rail is marked with an arrow. Rear Jacking Points

Note:

Jack at the specified locations to

avoid damage to the vehicle.

1. Place the vehicle jack at the jacking point next to the tire you are changing.

Turn the jack handle clockwise until

the wheel is completely off the ground.

2. Remove the lug nuts with the lug wrench.

3. Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward. Reinstall the lug nuts until the

wheel is snug against the hub. Do not

fully tighten the lug nuts until the wheel

has been lowered.

4. Lower the wheel by turning the jack handle counterclockwise.

419

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Wheels and TiresE183709 E272477

Page 423 of 625

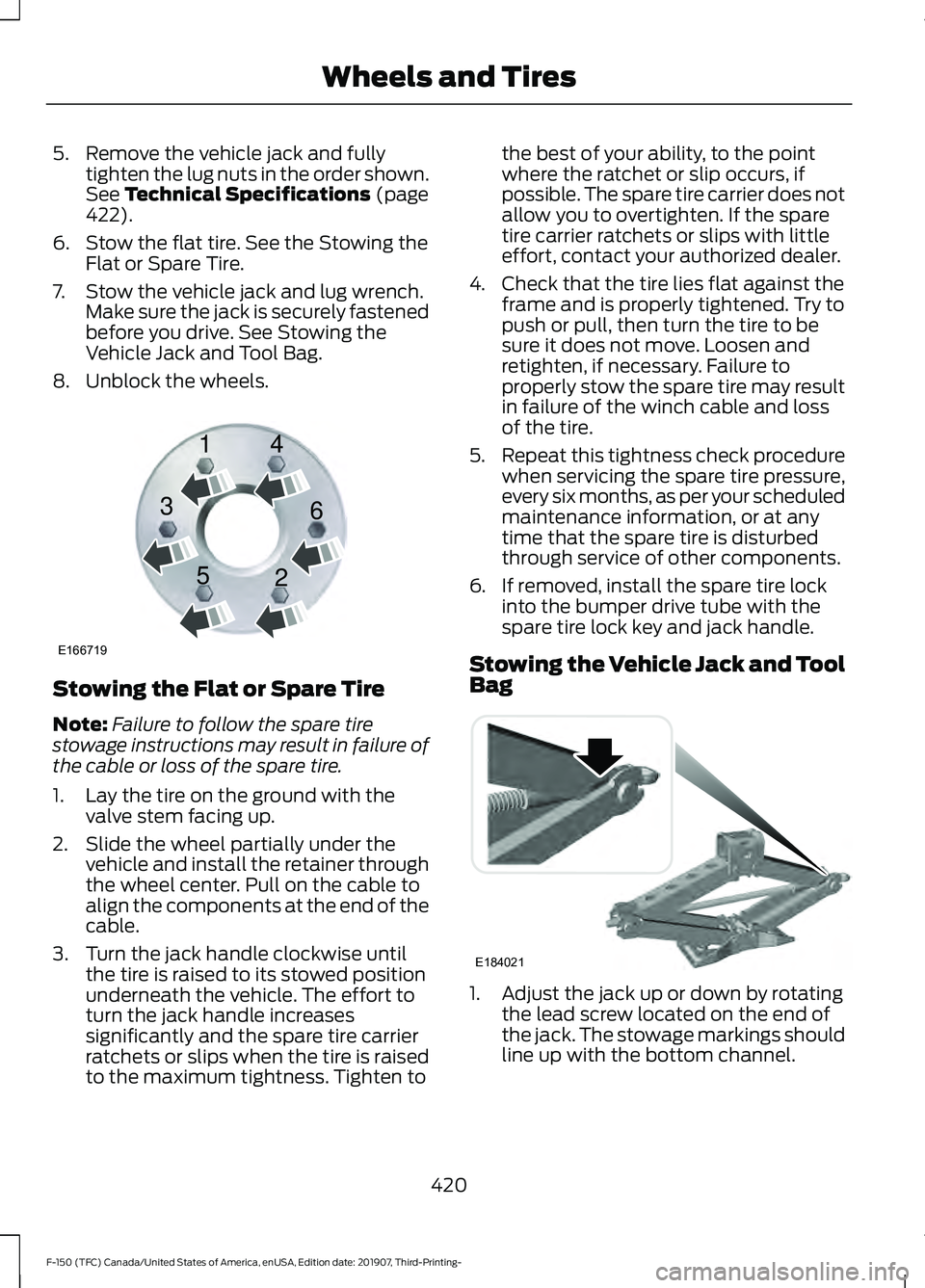

5. Remove the vehicle jack and fully

tighten the lug nuts in the order shown.

See Technical Specifications (page

422).

6. Stow the flat tire. See the Stowing the Flat or Spare Tire.

7. Stow the vehicle jack and lug wrench. Make sure the jack is securely fastened

before you drive. See Stowing the

Vehicle Jack and Tool Bag.

8. Unblock the wheels. Stowing the Flat or Spare Tire

Note:

Failure to follow the spare tire

stowage instructions may result in failure of

the cable or loss of the spare tire.

1. Lay the tire on the ground with the valve stem facing up.

2. Slide the wheel partially under the vehicle and install the retainer through

the wheel center. Pull on the cable to

align the components at the end of the

cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed position

underneath the vehicle. The effort to

turn the jack handle increases

significantly and the spare tire carrier

ratchets or slips when the tire is raised

to the maximum tightness. Tighten to the best of your ability, to the point

where the ratchet or slip occurs, if

possible. The spare tire carrier does not

allow you to overtighten. If the spare

tire carrier ratchets or slips with little

effort, contact your authorized dealer.

4. Check that the tire lies flat against the frame and is properly tightened. Try to

push or pull, then turn the tire to be

sure it does not move. Loosen and

retighten, if necessary. Failure to

properly stow the spare tire may result

in failure of the winch cable and loss

of the tire.

5. Repeat this tightness check procedure

when servicing the spare tire pressure,

every six months, as per your scheduled

maintenance information, or at any

time that the spare tire is disturbed

through service of other components.

6. If removed, install the spare tire lock into the bumper drive tube with the

spare tire lock key and jack handle.

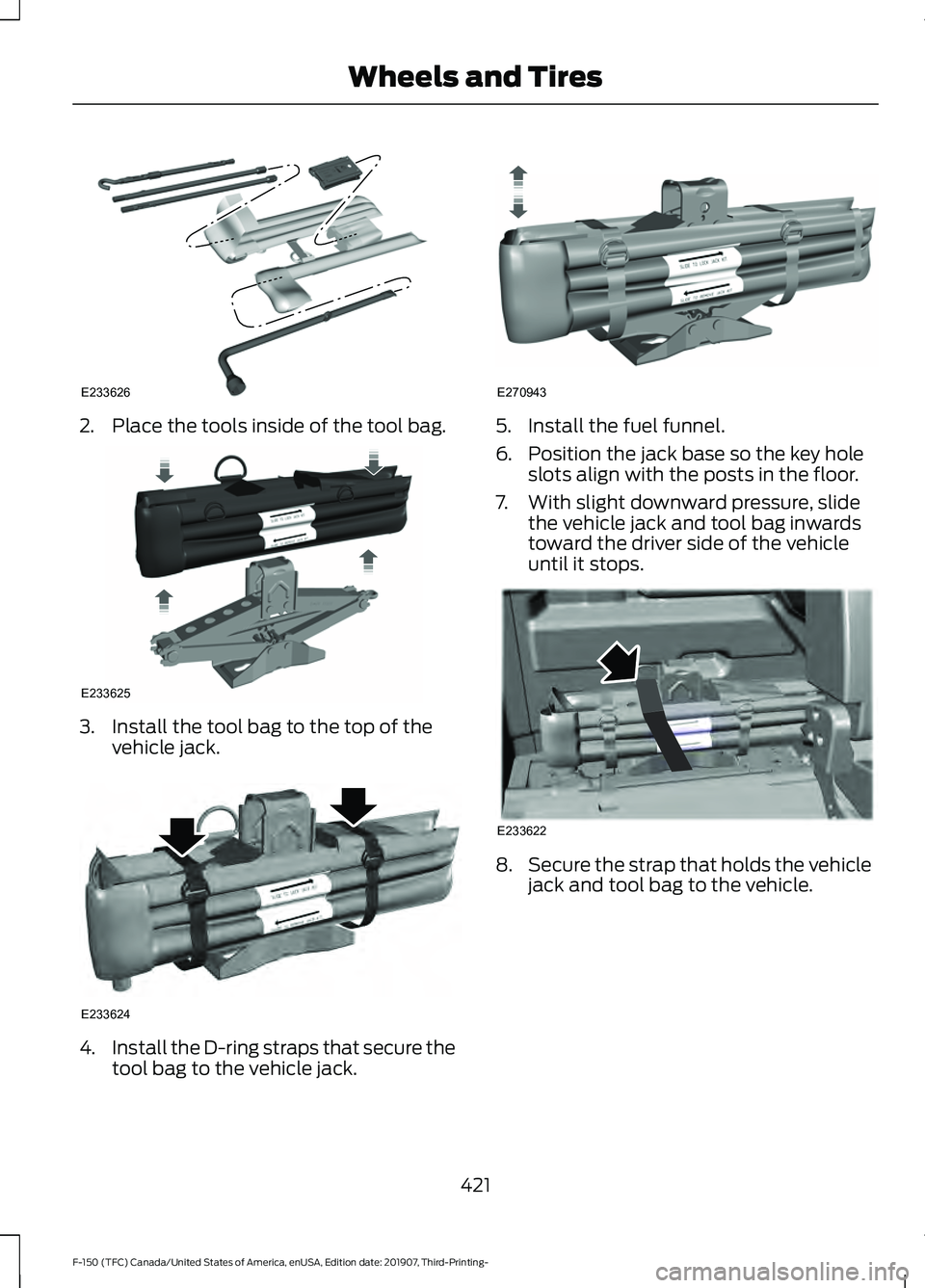

Stowing the Vehicle Jack and Tool

Bag 1. Adjust the jack up or down by rotating

the lead screw located on the end of

the jack. The stowage markings should

line up with the bottom channel.

420

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Wheels and TiresE166719

1

3

5 4

6

2 E184021

Page 424 of 625

2. Place the tools inside of the tool bag.

3. Install the tool bag to the top of the

vehicle jack. 4.

Install the D-ring straps that secure the

tool bag to the vehicle jack. 5. Install the fuel funnel.

6. Position the jack base so the key hole

slots align with the posts in the floor.

7. With slight downward pressure, slide the vehicle jack and tool bag inwards

toward the driver side of the vehicle

until it stops. 8.

Secure the strap that holds the vehicle

jack and tool bag to the vehicle.

421

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Wheels and TiresE233626 E233625 E233624 E270943 E233622

Page 425 of 625

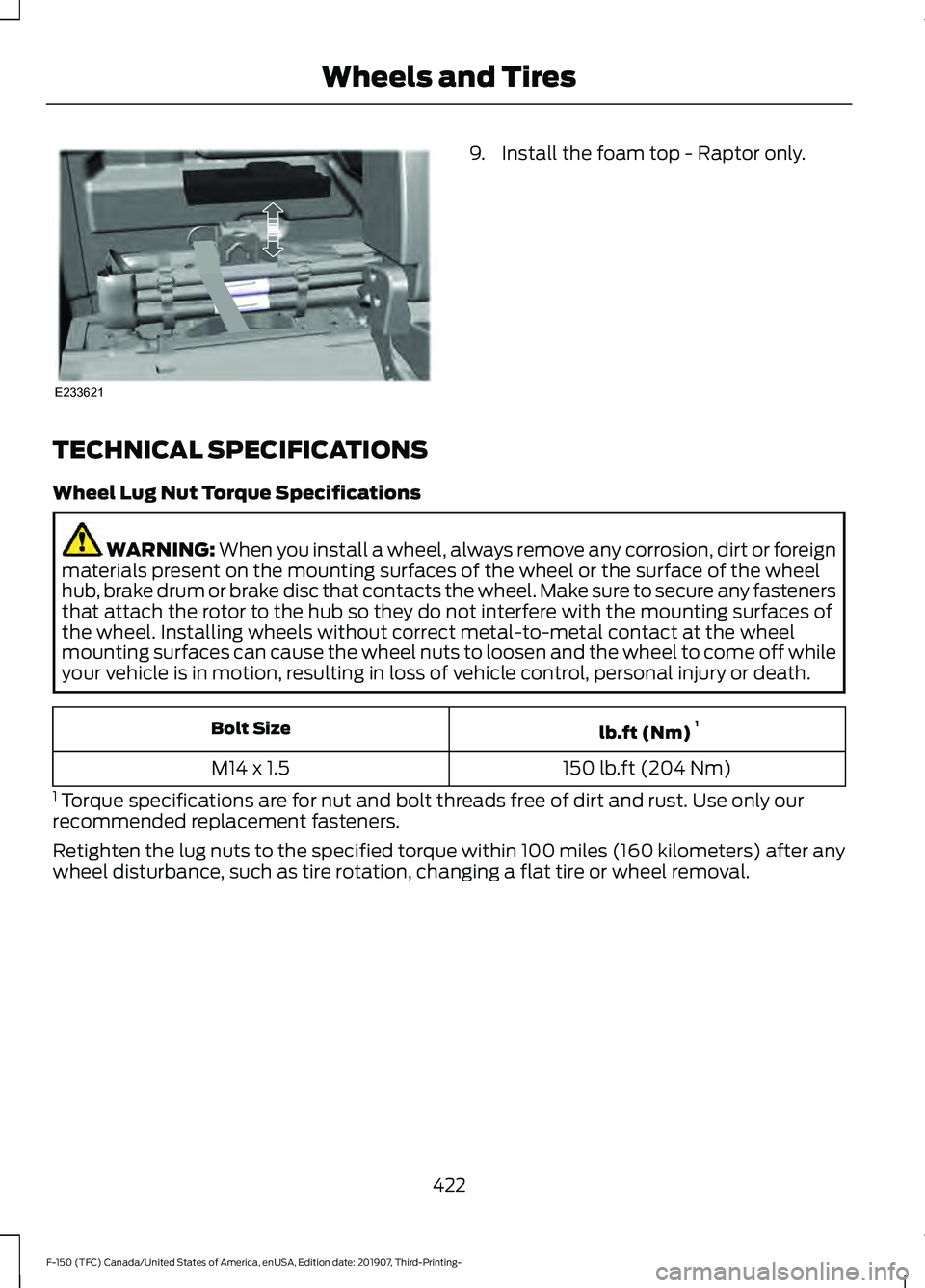

9. Install the foam top - Raptor only.

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications WARNING: When you install a wheel, always remove any corrosion, dirt or foreign

materials present on the mounting surfaces of the wheel or the surface of the wheel

hub, brake drum or brake disc that contacts the wheel. Make sure to secure any fasteners

that attach the rotor to the hub so they do not interfere with the mounting surfaces of

the wheel. Installing wheels without correct metal-to-metal contact at the wheel

mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while

your vehicle is in motion, resulting in loss of vehicle control, personal injury or death. lb.ft (Nm)

1

Bolt Size

150 lb.ft (204 Nm)

M14 x 1.5

1 Torque specifications are for nut and bolt threads free of dirt and rust. Use only our

recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kilometers) after any

wheel disturbance, such as tire rotation, changing a flat tire or wheel removal.

422

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Wheels and TiresE233621

Page 426 of 625

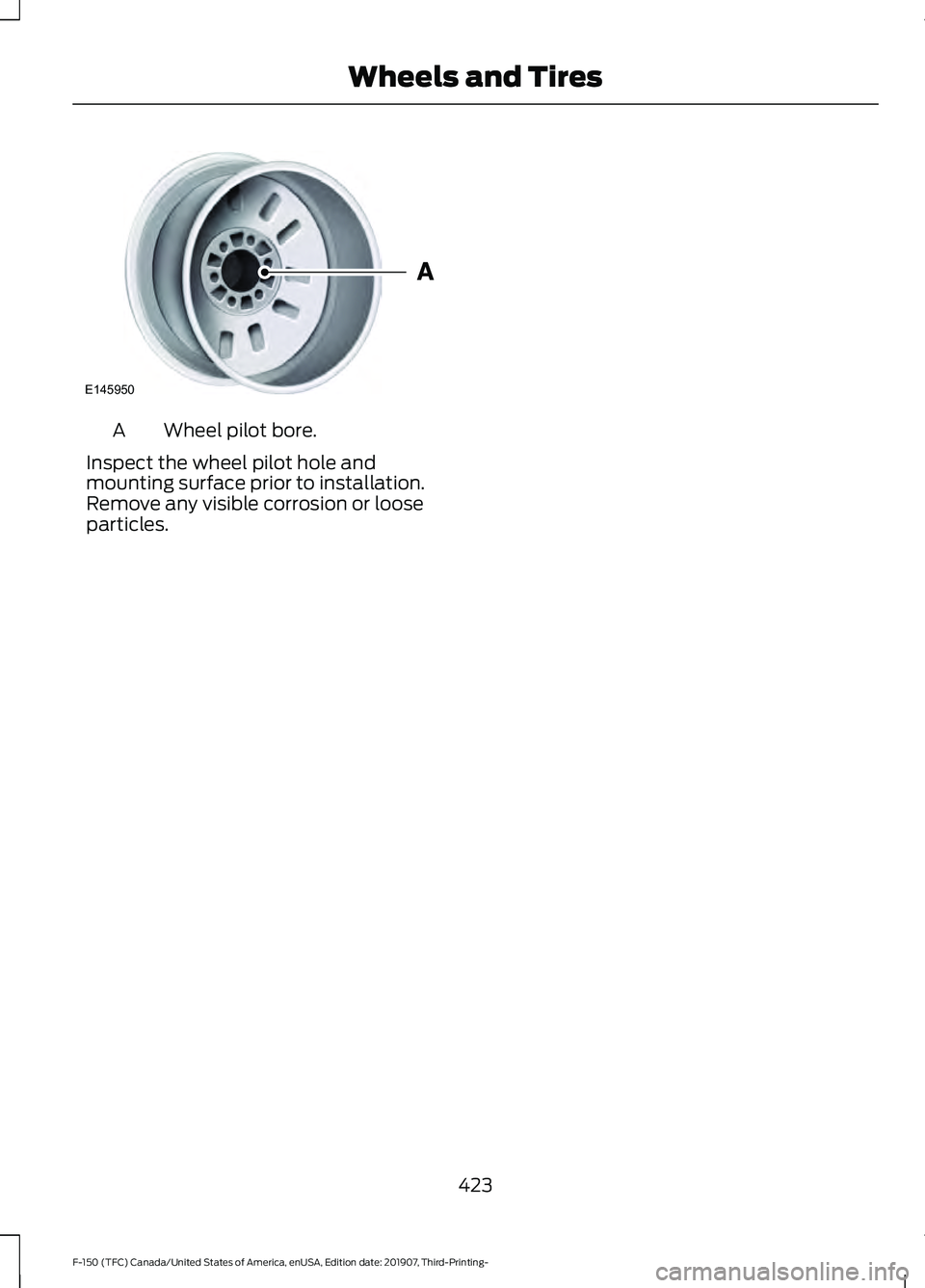

Wheel pilot bore.

A

Inspect the wheel pilot hole and

mounting surface prior to installation.

Remove any visible corrosion or loose

particles.

423

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Wheels and TiresE145950

Page 441 of 625

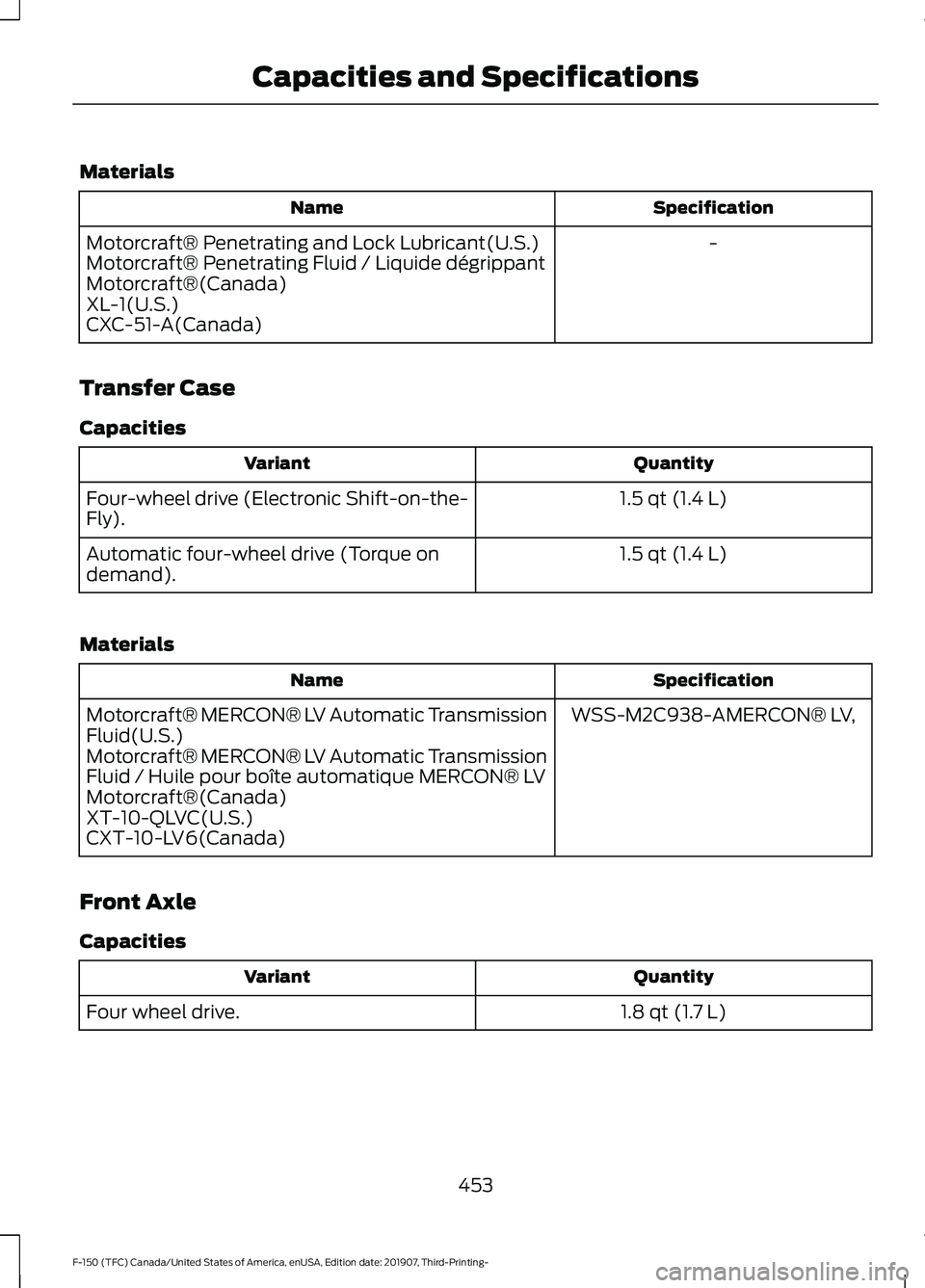

Materials

Specification

Name

-

Motorcraft® Penetrating and Lock Lubricant(U.S.)

Motorcraft® Penetrating Fluid / Liquide dégrippant

Motorcraft®(Canada)

XL-1(U.S.)

CXC-51-A(Canada)

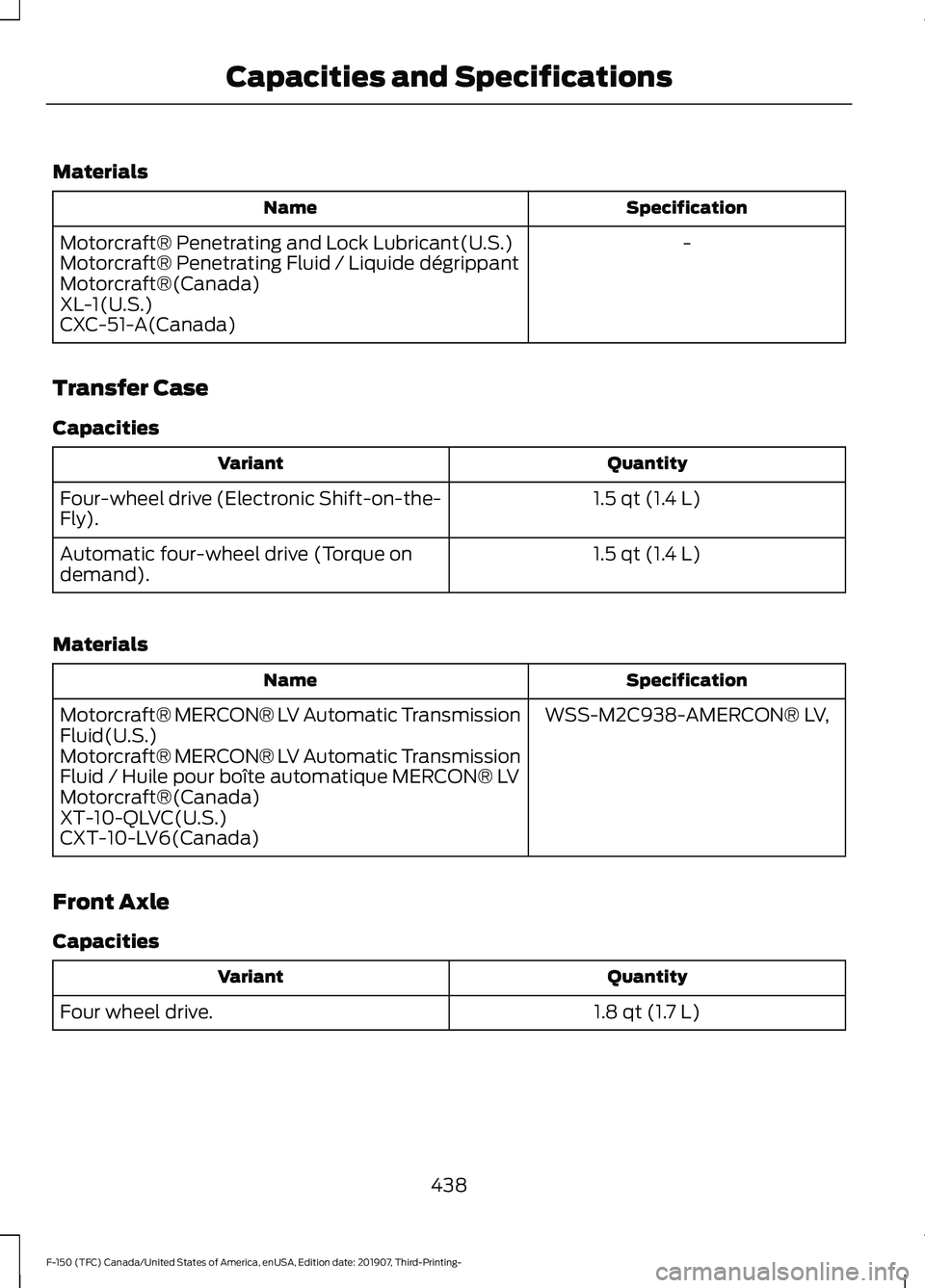

Transfer Case

Capacities Quantity

Variant

1.5 qt (1.4 L)

Four-wheel drive (Electronic Shift-on-the-

Fly).

1.5 qt (1.4 L)

Automatic four-wheel drive (Torque on

demand).

Materials Specification

Name

WSS-M2C938-AMERCON® LV,

Motorcraft® MERCON® LV Automatic Transmission

Fluid(U.S.)

Motorcraft® MERCON® LV Automatic Transmission

Fluid / Huile pour boîte automatique MERCON® LV

Motorcraft®(Canada)

XT-10-QLVC(U.S.)

CXT-10-LV6(Canada)

Front Axle

Capacities Quantity

Variant

1.8 qt (1.7 L)

Four wheel drive.

438

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Capacities and Specifications

Page 448 of 625

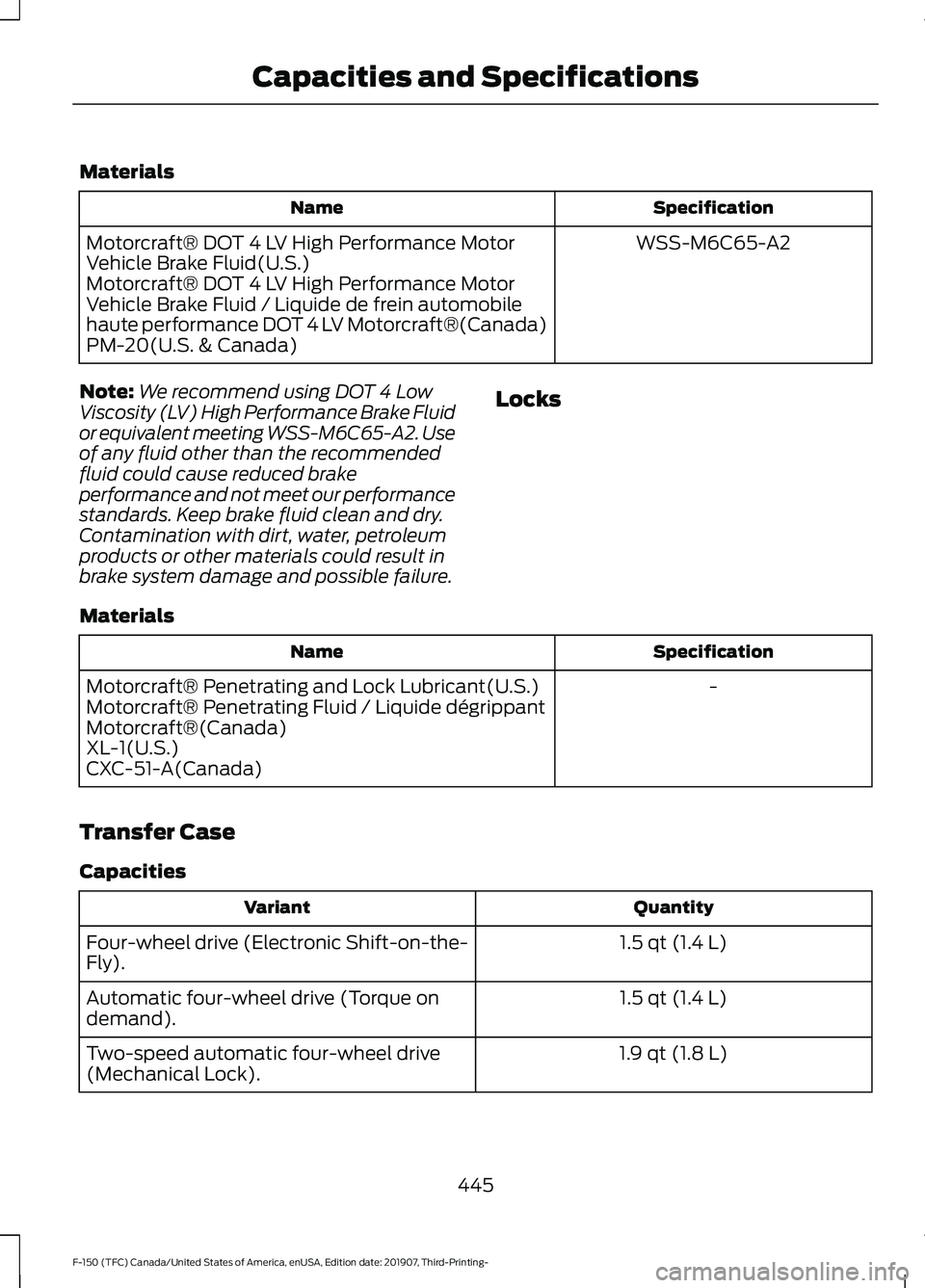

Materials

Specification

Name

WSS-M6C65-A2

Motorcraft® DOT 4 LV High Performance Motor

Vehicle Brake Fluid(U.S.)

Motorcraft® DOT 4 LV High Performance Motor

Vehicle Brake Fluid / Liquide de frein automobile

haute performance DOT 4 LV Motorcraft®(Canada)

PM-20(U.S. & Canada)

Note: We recommend using DOT 4 Low

Viscosity (LV) High Performance Brake Fluid

or equivalent meeting WSS-M6C65-A2. Use

of any fluid other than the recommended

fluid could cause reduced brake

performance and not meet our performance

standards. Keep brake fluid clean and dry.

Contamination with dirt, water, petroleum

products or other materials could result in

brake system damage and possible failure. Locks

Materials Specification

Name

-

Motorcraft® Penetrating and Lock Lubricant(U.S.)

Motorcraft® Penetrating Fluid / Liquide dégrippant

Motorcraft®(Canada)

XL-1(U.S.)

CXC-51-A(Canada)

Transfer Case

Capacities Quantity

Variant

1.5 qt (1.4 L)

Four-wheel drive (Electronic Shift-on-the-

Fly).

1.5 qt (1.4 L)

Automatic four-wheel drive (Torque on

demand).

1.9 qt (1.8 L)

Two-speed automatic four-wheel drive

(Mechanical Lock).

445

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Capacities and Specifications

Page 449 of 625

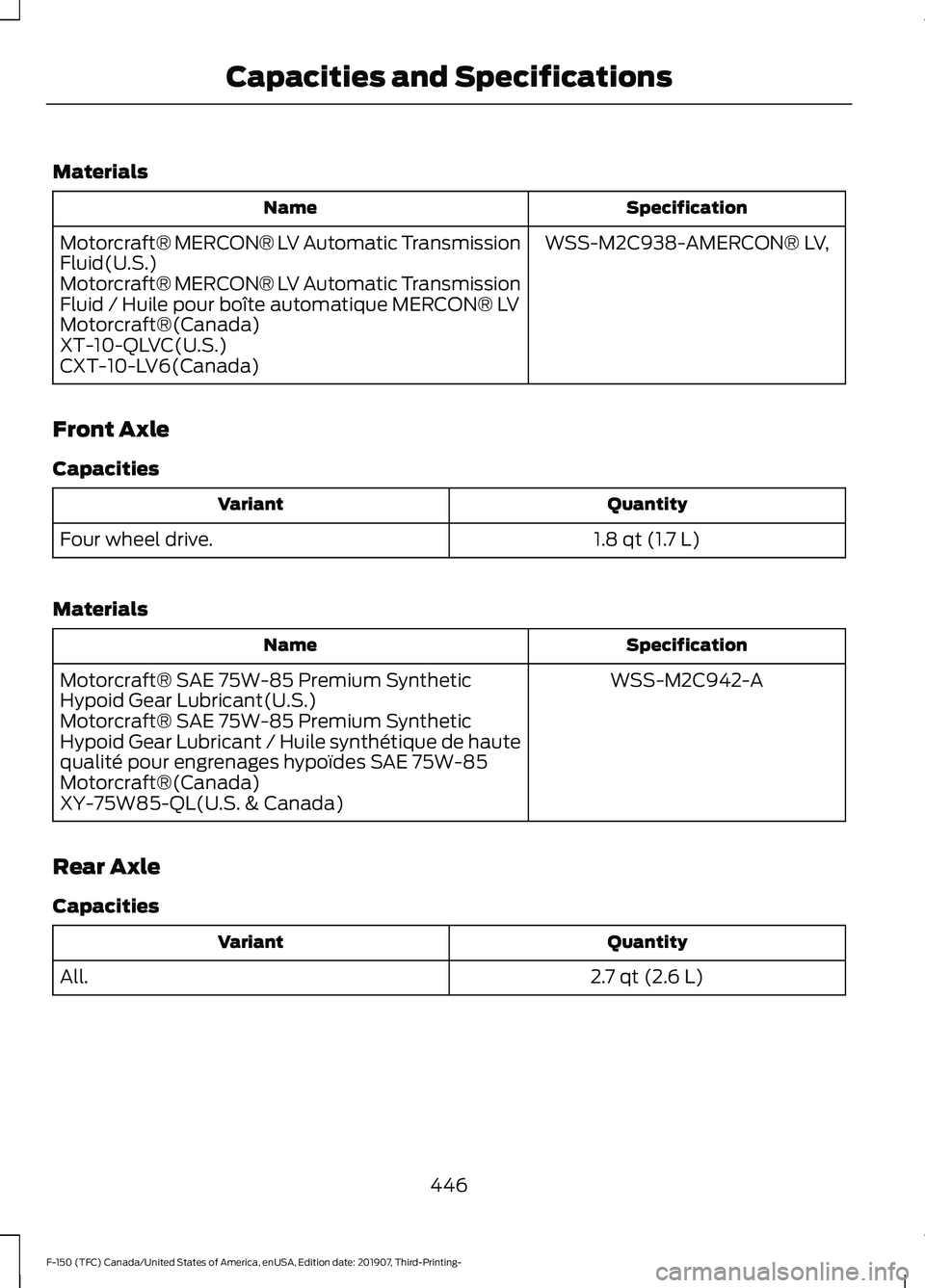

Materials

Specification

Name

WSS-M2C938-AMERCON® LV,

Motorcraft® MERCON® LV Automatic Transmission

Fluid(U.S.)

Motorcraft® MERCON® LV Automatic Transmission

Fluid / Huile pour boîte automatique MERCON® LV

Motorcraft®(Canada)

XT-10-QLVC(U.S.)

CXT-10-LV6(Canada)

Front Axle

Capacities Quantity

Variant

1.8 qt (1.7 L)

Four wheel drive.

Materials Specification

Name

WSS-M2C942-A

Motorcraft® SAE 75W-85 Premium Synthetic

Hypoid Gear Lubricant(U.S.)

Motorcraft® SAE 75W-85 Premium Synthetic

Hypoid Gear Lubricant / Huile synthétique de haute

qualité pour engrenages hypoïdes SAE 75W-85

Motorcraft®(Canada)

XY-75W85-QL(U.S. & Canada)

Rear Axle

Capacities Quantity

Variant

2.7 qt (2.6 L)

All.

446

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Capacities and Specifications

Page 456 of 625

Materials

Specification

Name

-

Motorcraft® Penetrating and Lock Lubricant(U.S.)

Motorcraft® Penetrating Fluid / Liquide dégrippant

Motorcraft®(Canada)

XL-1(U.S.)

CXC-51-A(Canada)

Transfer Case

Capacities Quantity

Variant

1.5 qt (1.4 L)

Four-wheel drive (Electronic Shift-on-the-

Fly).

1.5 qt (1.4 L)

Automatic four-wheel drive (Torque on

demand).

Materials Specification

Name

WSS-M2C938-AMERCON® LV,

Motorcraft® MERCON® LV Automatic Transmission

Fluid(U.S.)

Motorcraft® MERCON® LV Automatic Transmission

Fluid / Huile pour boîte automatique MERCON® LV

Motorcraft®(Canada)

XT-10-QLVC(U.S.)

CXT-10-LV6(Canada)

Front Axle

Capacities Quantity

Variant

1.8 qt (1.7 L)

Four wheel drive.

453

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Capacities and Specifications

Page 463 of 625

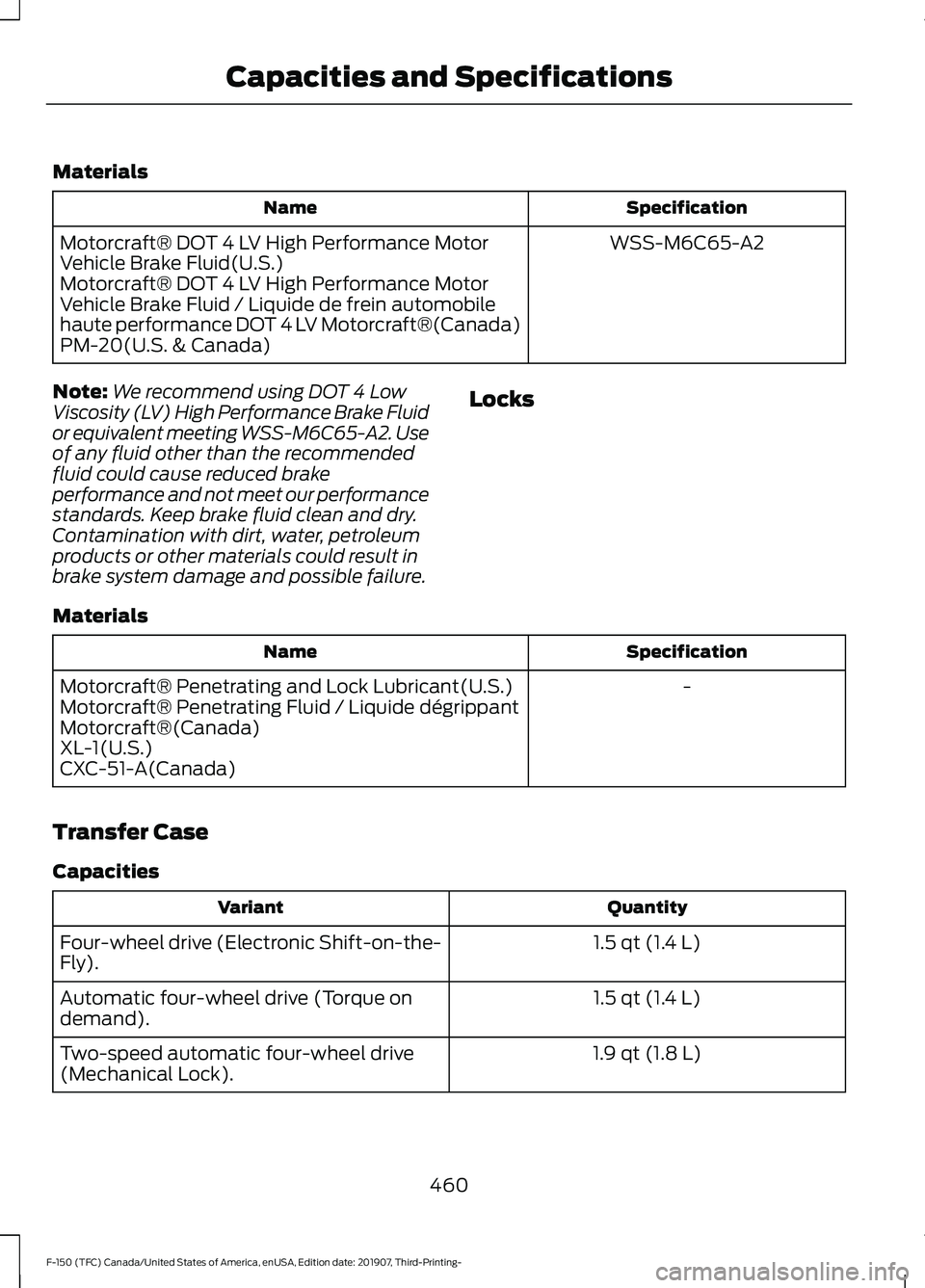

Materials

Specification

Name

WSS-M6C65-A2

Motorcraft® DOT 4 LV High Performance Motor

Vehicle Brake Fluid(U.S.)

Motorcraft® DOT 4 LV High Performance Motor

Vehicle Brake Fluid / Liquide de frein automobile

haute performance DOT 4 LV Motorcraft®(Canada)

PM-20(U.S. & Canada)

Note: We recommend using DOT 4 Low

Viscosity (LV) High Performance Brake Fluid

or equivalent meeting WSS-M6C65-A2. Use

of any fluid other than the recommended

fluid could cause reduced brake

performance and not meet our performance

standards. Keep brake fluid clean and dry.

Contamination with dirt, water, petroleum

products or other materials could result in

brake system damage and possible failure. Locks

Materials Specification

Name

-

Motorcraft® Penetrating and Lock Lubricant(U.S.)

Motorcraft® Penetrating Fluid / Liquide dégrippant

Motorcraft®(Canada)

XL-1(U.S.)

CXC-51-A(Canada)

Transfer Case

Capacities Quantity

Variant

1.5 qt (1.4 L)

Four-wheel drive (Electronic Shift-on-the-

Fly).

1.5 qt (1.4 L)

Automatic four-wheel drive (Torque on

demand).

1.9 qt (1.8 L)

Two-speed automatic four-wheel drive

(Mechanical Lock).

460

F-150 (TFC) Canada/United States of America, enUSA, Edition date: 201907, Third-Printing- Capacities and Specifications