FORD F-250 2021 Owners Manual

Manufacturer: FORD, Model Year: 2021, Model line: F-250, Model: FORD F-250 2021Pages: 666, PDF Size: 11.3 MB

Page 421 of 666

Replacing a Tire That is

Greenhouse Gas Certified

The tires installed on this vehicle

at the factory as original

equipment are certified for

Greenhouse Gas and Fuel

Efficiency regulations.

Replacement tires must be of

equal or lower rolling resistance

level (TRRL or Crr). Consult with

your tire supplier(s) for

appropriate replacement tires.

Safety Practices

WARNING: If your vehicle

is stuck in snow, mud or sand, do

not rapidly spin the tires;

spinning the tires can tear the

tire and cause an explosion. A

tire can explode in as little as

three to five seconds. WARNING:

Do not spin the

wheels at over 34 mph

(55 km/h). The tires may fail and

injure a passenger or bystander.

Driving habits have a great deal

to do with your tire mileage and

safety.

*Observe posted speed limits.

*Avoid fast starts, stops and turns.

*Avoid potholes and objects on

the road.

*Do not run over curbs or hit the

tire against a curb when parking. Highway Hazards

No matter how carefully you drive

there

’s always the possibility that

you may eventually have a flat tire

on the highway. Drive slowly to the

closest safe area out of traffic.

This may further damage the flat

tire, but your safety is more

important.

If you feel a sudden vibration or

ride disturbance while driving, or

you suspect your tire or vehicle

has been damaged, immediately

reduce your speed. Drive with

caution until you can safely pull

off the road. Stop and inspect the

tires for damage. If a tire is

under-inflated or damaged,

deflate it, remove wheel and

replace it with your spare tire and

wheel. If you cannot detect a

cause, have the vehicle towed to

the nearest repair facility or tire

dealer to have the vehicle

inspected.

Tire and Wheel Alignment

A bad jolt from hitting a curb or

pothole can cause the front end

of your vehicle to become

misaligned or cause damage to

your tires. If your vehicle seems to

pull to one side when you’re

driving, the wheels may be out of

alignment. Have an authorized

dealer check the wheel alignment

periodically.

418

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 422 of 666

Wheel misalignment in the front

or the rear can cause uneven and

rapid treadwear of your tires and

should be corrected by an

authorized dealer. Front-wheel

drive vehicles and those with an

independent rear suspension may

require alignment of all four

wheels.

The tires should also be balanced

periodically. An unbalanced tire

and wheel assembly may result in

irregular tire wear.

Tire Rotation

WARNING: If the tire label

shows different tire pressures for

the front and rear tires and the

vehicle has a tire pressure

monitoring system, then you

need to update the settings for

the system sensors. Always

perform the system reset

procedure after tire rotation. If

you do not reset the system, it

may not provide a low tire

pressure warning when

necessary.

Note: If your tires show uneven

wear ask an authorized dealer to

check for and correct any wheel

misalignment, tire imbalance or

mechanical problem involved

before tire rotation. Note:

Your vehicle may be

equipped with a dissimilar spare

wheel and tire assembly. A

dissimilar spare wheel and tire

assembly is defined as a spare

wheel and tire assembly that is

different in brand, size or

appearance from the road tires and

wheels. If you have a dissimilar

spare wheel and tire assembly it is

intended for temporary use only

and should not be used in a tire

rotation.

Note: After having your tires

rotated, inflation pressure must be

checked and adjusted to the

vehicle requirements.

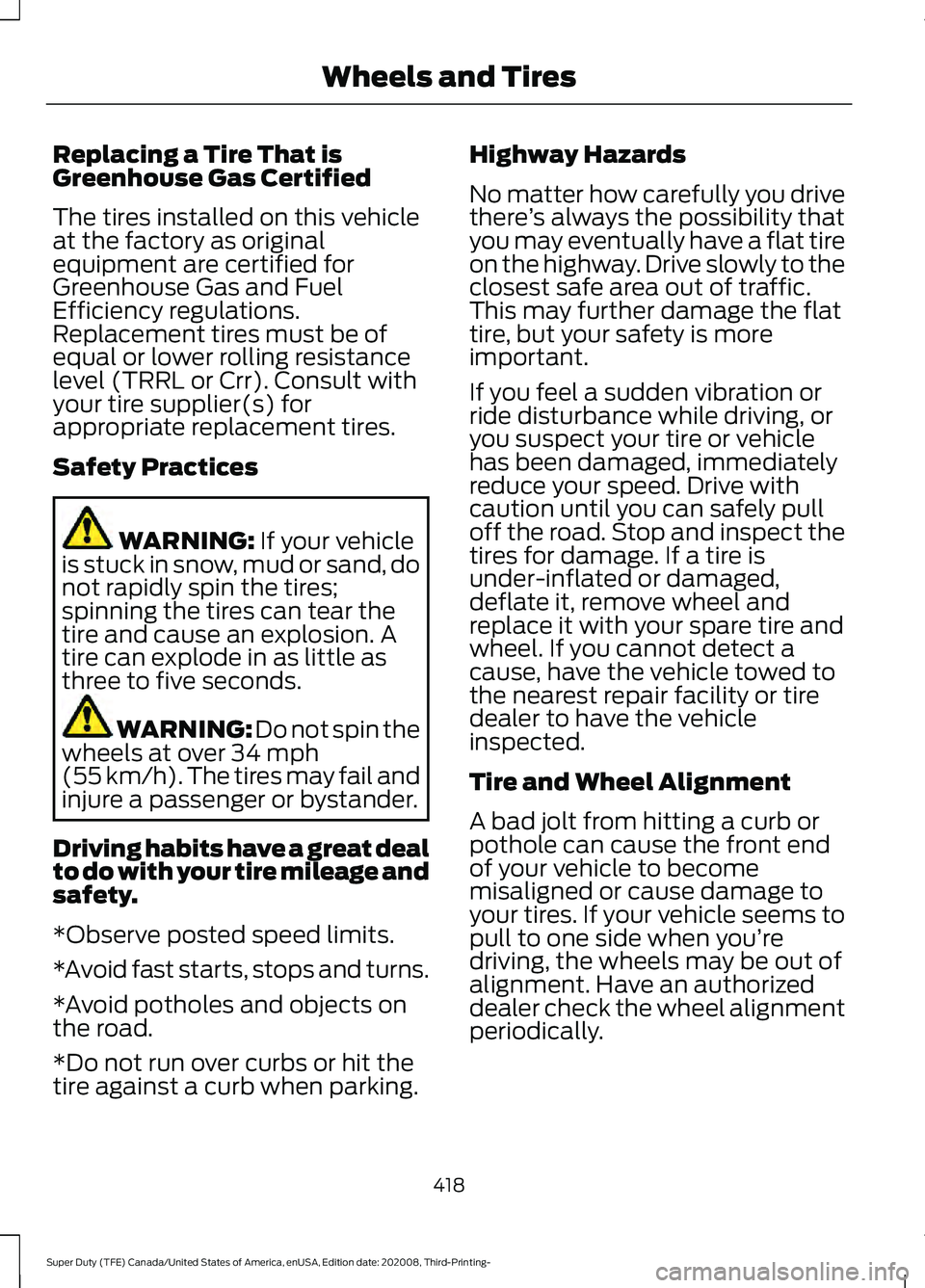

Rotating your tires at the

recommended interval (as

indicated in the Scheduled

Maintenance chapter) will help

your tires wear more evenly,

providing better tire performance

and longer tire life. Sometime

irregular tire wear can be

corrected by rotating the tires. Rear-wheel drive vehicles and

four-wheel drive vehicles (front

tires at left of diagram).

419

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE142548

Page 423 of 666

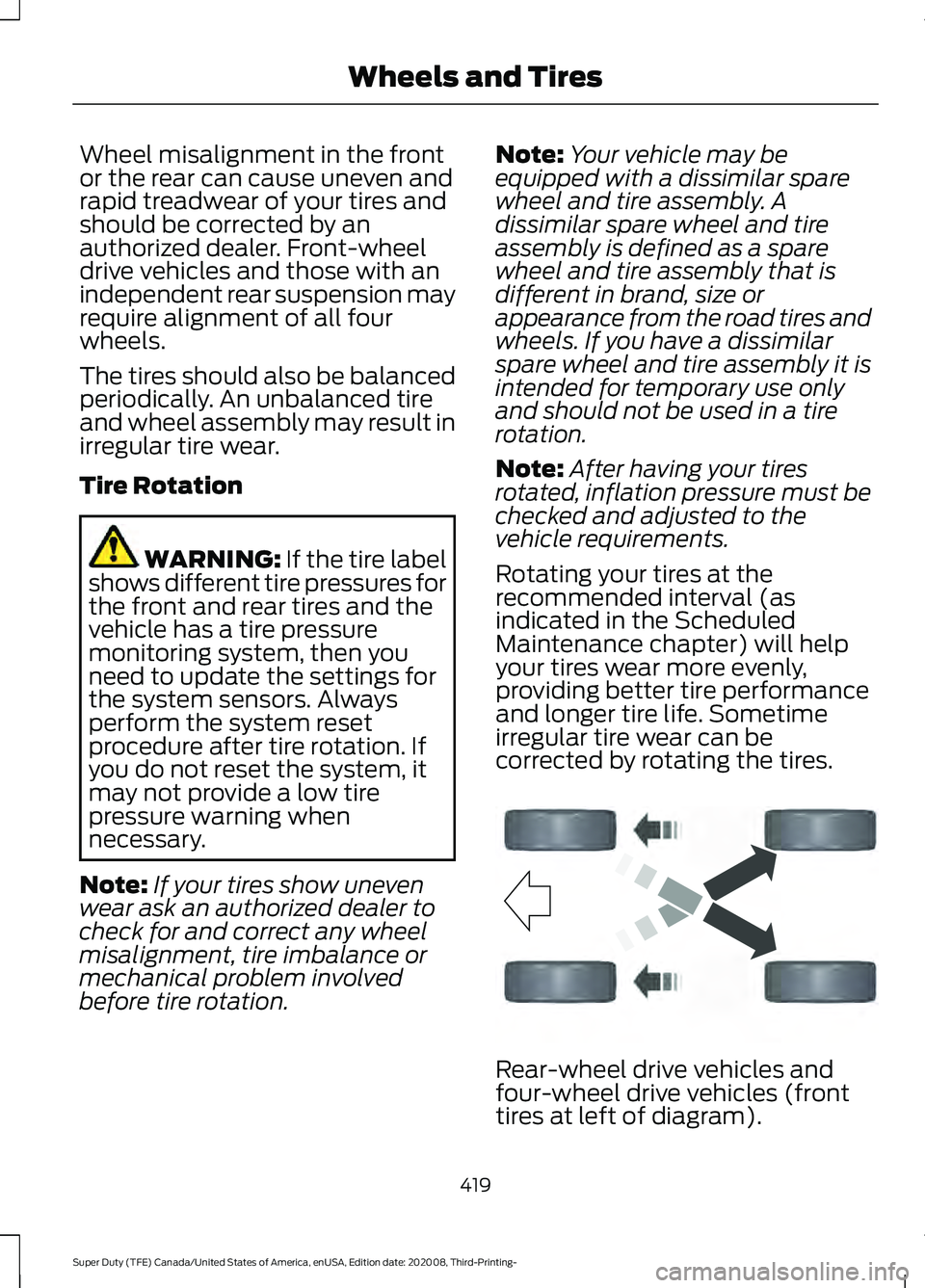

Dual rear wheel drive vehicle - six

tire rotation (front tires at top of

diagram).

If your vehicle is equipped with

dual rear wheels it is

recommended that the front and

rear tires (in pairs) be rotated only

side to side. We do not

recommend splitting up the dual

rear wheels. Rotate them side to

side as a set. After tire rotation,

inflation pressures must be

adjusted for the tires new

positions in accordance with

vehicle requirements.

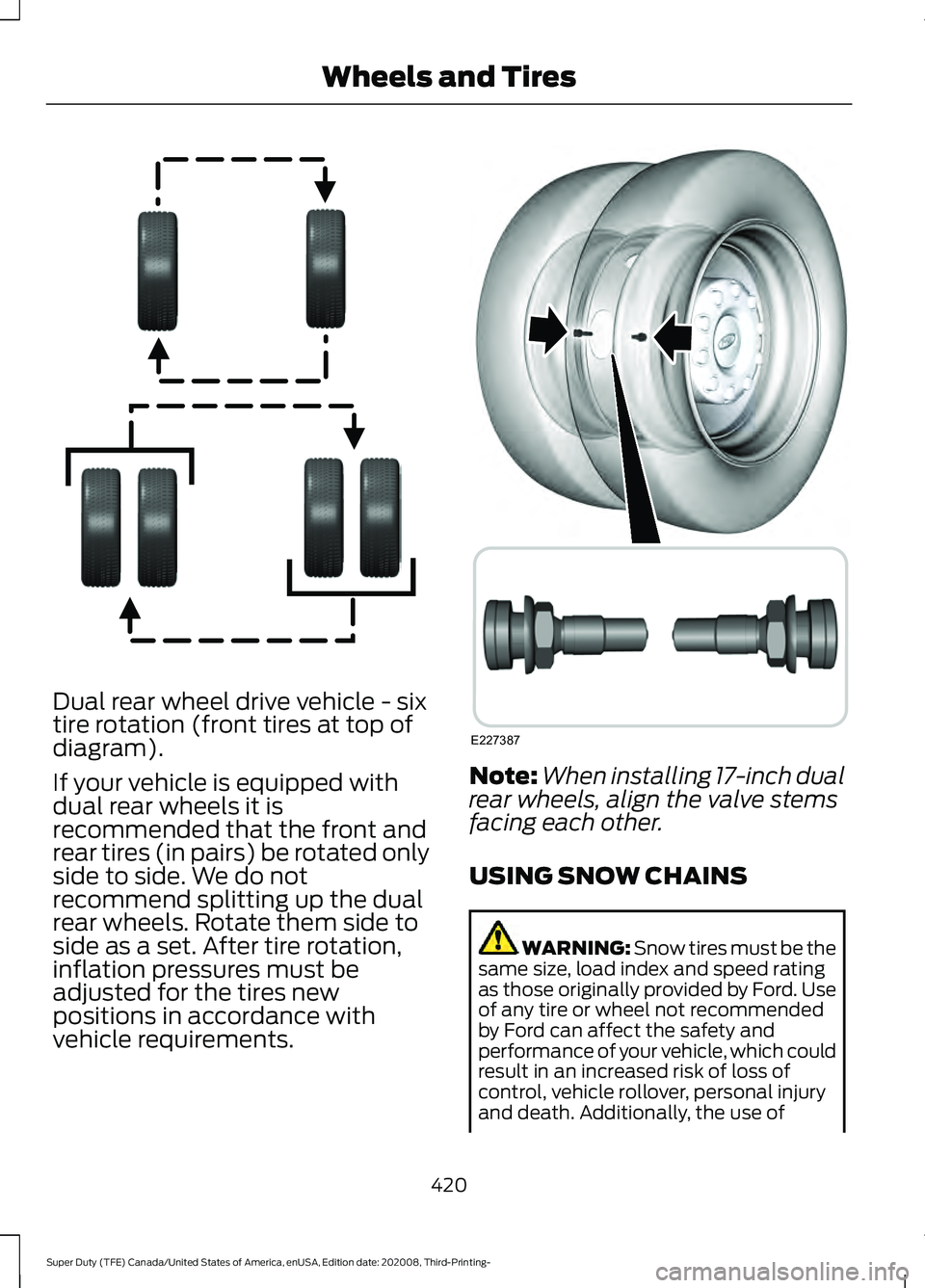

Note:

When installing 17-inch dual

rear wheels, align the valve stems

facing each other.

USING SNOW CHAINS WARNING: Snow tires must be the

same size, load index and speed rating

as those originally provided by Ford. Use

of any tire or wheel not recommended

by Ford can affect the safety and

performance of your vehicle, which could

result in an increased risk of loss of

control, vehicle rollover, personal injury

and death. Additionally, the use of

420

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE166988 E227387

Page 424 of 666

non-recommended tires and wheels can

cause steering, suspension, axle, transfer

case or power transfer unit failure.

Follow the Ford recommended tire

inflation pressure found on the Safety

Compliance Certification Label (on the

door hinge pillar, door latch post or the

door edge that meets the door latch

post, next to the driver seat), or Tire

Label on the B-Pillar or the edge of the

driver door. Failure to follow the tire

pressure recommendations can cause

uneven treadwear patterns and

adversely affect the way your vehicle

handles.

WARNING: Do not use snow chains

on snow-free roads.

Note: Do not use snow chains on vehicles

with LT275/65R20 or LT 285/75R18 sized

tires.

The tires on your vehicle have all-weather

treads to provide traction in rain and snow.

However, in some climates, you may need

to use snow tires and cables. If you need

to use cables, we recommend that you use

steel wheels of the same size and

specification, as cables may chip

aluminum wheels.

Note: The suspension insulation and

bumpers will help prevent vehicle damage.

Do not remove these components from your

vehicle when using snow tires and chains.

Follow these guidelines when using snow

tires and chains:

• If possible, avoid fully loading your

vehicle.

• Use only SAE Class S chains.

• Install chains securely, verifying that

the chains do not touch any wiring,

brake lines or fuel lines.

• Only install snow chains on the rear

axle. •

For Dual Rear Wheel (DRW) vehicles,

only install snow chains on the outer

wheel of each pair.

• Drive cautiously. If you hear the chains

rub or bang against your vehicle, stop

and retighten the chains. If this does

not work, remove the chains to prevent

damage to your vehicle.

• Remove the tire chains when you no

longer need them. Do not use tire

chains on dry roads.

If you have any questions regarding snow

chains or cables, please contact your

authorized dealer.

TIRE PRESSURE MONITORING

SYSTEM

Vehicle Tire Pressure Monitoring

System WARNING:

The tire pressure

monitoring system is not a substitute for

manually checking tire pressures. You

should periodically check tire pressures

using a pressure gauge. Failure to

correctly maintain tire pressures could

increase the risk of tire failure, loss of

control, vehicle rollover and personal

injury. Check each tire, including the

spare, if provided, monthly when

cold and inflated to the inflation

pressure recommended by the vehicle

manufacturer on the vehicle placard or tire

inflation pressure label. If your vehicle has

tires of a different size than the size

indicated on the vehicle placard or tire

inflation pressure label, you should

determine the proper tire inflation pressure

for those tires.

421

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 425 of 666

As an added safety feature, your vehicle

has been equipped with a Tire Pressure

Monitoring System (TPMS) that

illuminates a low tire pressure telltale

when one or more of your tires is

significantly under-inflated. Accordingly,

when the low tire pressure telltale

illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly under-inflated tire causes the

tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency

and tire tread life, and may affect the

vehicle

’s handling and stopping ability.

Please note that the TPMS is not a

substitute for proper tire maintenance, and

it is the driver's responsibility to maintain

correct tire pressure, even if under-inflation

has not reached the level to trigger

illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with

a TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is

combined with the low tire pressure

telltale. When the system detects a

malfunction, the telltale flashes for

approximately one minute and then

remains continuously illuminated. This

sequence continues upon subsequent

vehicle start-ups as long as the

malfunction exists.

When the malfunction indicator is

illuminated, the system may not be able

to detect or signal low tire pressure as

intended. TPMS malfunctions may occur

for a variety of reasons, including the

installation of replacement or alternate

tires or wheels on the vehicle that prevent

the TPMS from functioning properly. Always check the TPMS malfunction

telltale after replacing one or more tires or

wheels on your vehicle to ensure that the

replacement or alternate tires and wheels

allow the TPMS to continue to function

properly.

This device complies with Part 15 of the

FCC Rules and with Industry Canada

license-exempt RSS standard(s).

Operation is subject to the following two

conditions:

•

This device may not cause harmful

interference.

• This device must accept any

interference received, including

interference that may cause undesired

operation.

Note: Changes or modifications not

expressively approved by the party

responsible for compliance could void the

user's authority to operate the equipment.

The term "IC" before the radio certification

number only signifies that Industry Canada

technical specifications were met.

Changing Tires with a Tire Pressure

Monitoring System 422

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE142549

Page 426 of 666

Note:

Each road tire is equipped with a tire

pressure sensor located inside the wheel

and tire assembly cavity. The pressure

sensor is attached to the valve stem. The

pressure sensor is covered by the tire and is

not visible unless the tire is removed. Take

care when changing the tire to avoid

damaging the sensor.

You should always have your tires serviced

by an authorized dealer.

Periodically check the tire pressure, at least

monthly, using an accurate tire gauge. See

Inflating Your Tires in this chapter.

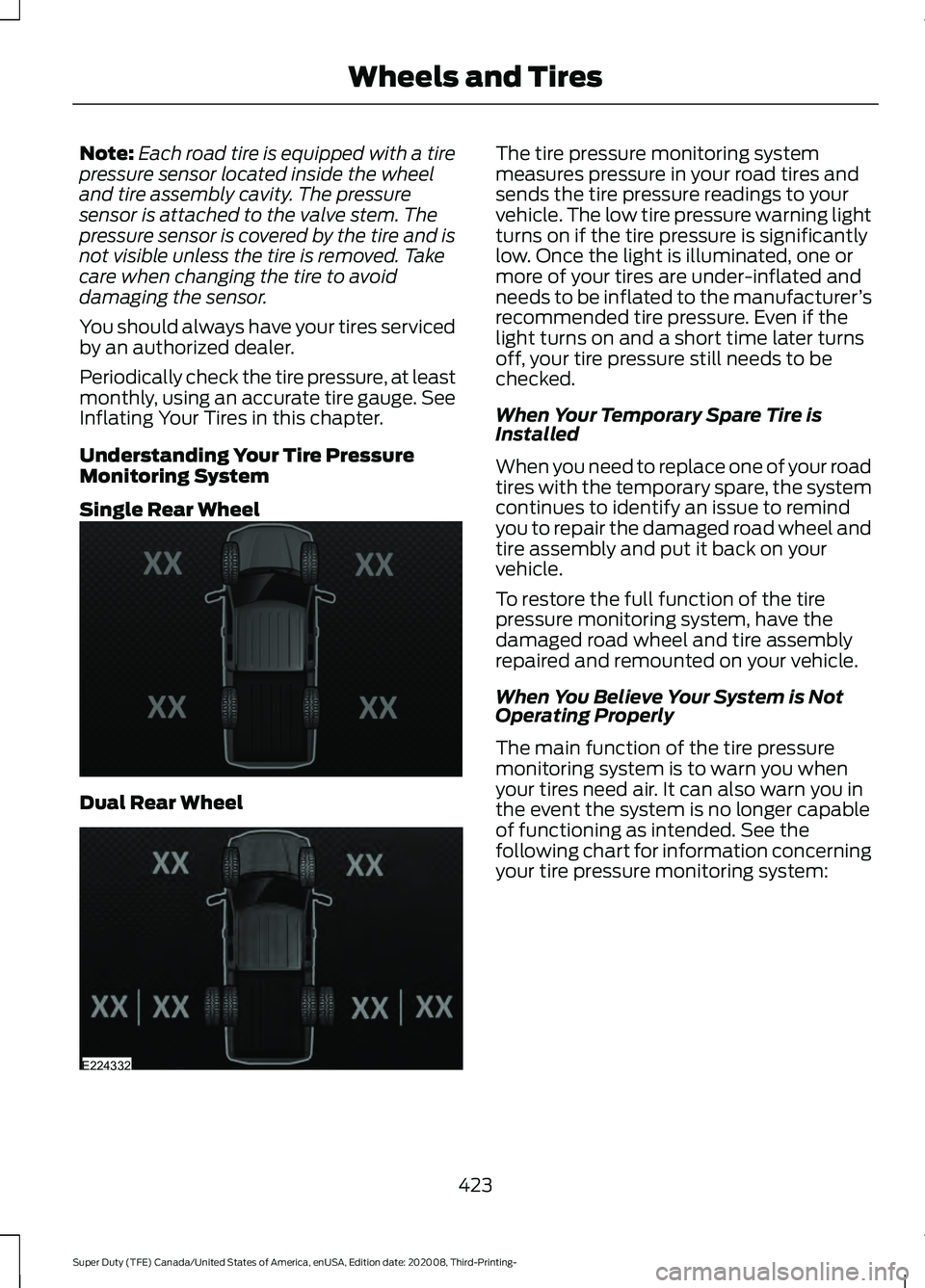

Understanding Your Tire Pressure

Monitoring System

Single Rear Wheel Dual Rear Wheel The tire pressure monitoring system

measures pressure in your road tires and

sends the tire pressure readings to your

vehicle. The low tire pressure warning light

turns on if the tire pressure is significantly

low. Once the light is illuminated, one or

more of your tires are under-inflated and

needs to be inflated to the manufacturer

’s

recommended tire pressure. Even if the

light turns on and a short time later turns

off, your tire pressure still needs to be

checked.

When Your Temporary Spare Tire is

Installed

When you need to replace one of your road

tires with the temporary spare, the system

continues to identify an issue to remind

you to repair the damaged road wheel and

tire assembly and put it back on your

vehicle.

To restore the full function of the tire

pressure monitoring system, have the

damaged road wheel and tire assembly

repaired and remounted on your vehicle.

When You Believe Your System is Not

Operating Properly

The main function of the tire pressure

monitoring system is to warn you when

your tires need air. It can also warn you in

the event the system is no longer capable

of functioning as intended. See the

following chart for information concerning

your tire pressure monitoring system:

423

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE224333 E224332

Page 427 of 666

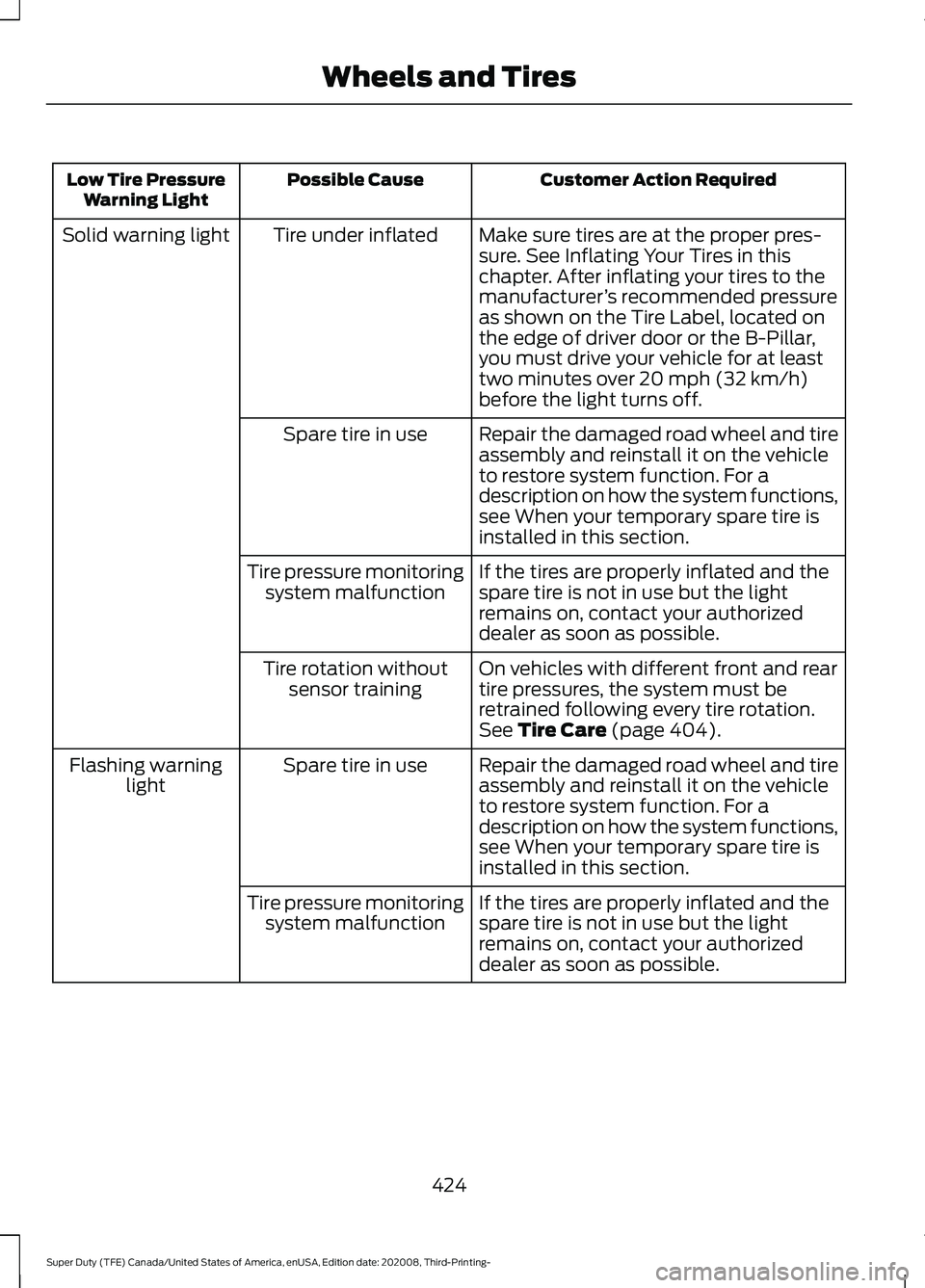

Customer Action Required

Possible Cause

Low Tire Pressure

Warning Light

Make sure tires are at the proper pres-

sure. See Inflating Your Tires in this

chapter. After inflating your tires to the

manufacturer’s recommended pressure

as shown on the Tire Label, located on

the edge of driver door or the B-Pillar,

you must drive your vehicle for at least

two minutes over 20 mph (32 km/h)

before the light turns off.

Tire under inflated

Solid warning light

Repair the damaged road wheel and tire

assembly and reinstall it on the vehicle

to restore system function. For a

description on how the system functions,

see When your temporary spare tire is

installed in this section.

Spare tire in use

If the tires are properly inflated and the

spare tire is not in use but the light

remains on, contact your authorized

dealer as soon as possible.

Tire pressure monitoring

system malfunction

On vehicles with different front and rear

tire pressures, the system must be

retrained following every tire rotation.

See

Tire Care (page 404).

Tire rotation without

sensor training

Repair the damaged road wheel and tire

assembly and reinstall it on the vehicle

to restore system function. For a

description on how the system functions,

see When your temporary spare tire is

installed in this section.

Spare tire in use

Flashing warning

light

If the tires are properly inflated and the

spare tire is not in use but the light

remains on, contact your authorized

dealer as soon as possible.

Tire pressure monitoring

system malfunction

424

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 428 of 666

When Inflating Your Tires

When putting air into your tires, such as at

a gas station or in your garage, the tire

pressure monitoring system may not

respond immediately to the air added to

your tires.

It may take up to two minutes of driving

over 20 mph (32 km/h) for the light to turn

off after you have filled your tires to the

recommended inflation pressure.

How Temperature Affects Your Tire

Pressure

The tire pressure monitoring system

monitors tire pressure in each pneumatic

tire. When driving in a normal manner, a

typical passenger tire inflation pressure

may increase about 2

–4 psi (14– 28 kPa)

from a cold start situation. If the vehicle is

stationary overnight with the outside

temperature significantly lower than the

daytime temperature, the tire pressure may

decrease about 3 psi (21 kPa) for a drop of

30°F (17°C) in ambient temperature. This

lower pressure value may be detected by

the tire pressure monitoring system as

being significantly lower than the

recommended inflation pressure and

activate the system warning light for low

tire pressure.

If the low tire pressure warning light is on,

visually check each tire to verify that no tire

is flat. If one or more tires are flat, repair as

necessary. Check the air pressure in the

road tires. If any tire is under-inflated,

carefully drive the vehicle to the nearest

location where air can be added to the

tires. Inflate all the tires to the

recommended inflation pressure. Tire Pressure Monitoring System Reset

Procedure WARNING:

To determine the

required pressure(s) for your vehicle, see

the Safety Compliance Certification

Label (on the door hinge pillar,

door-latch post or the door edge that

meets the door-latch post, next to the

driver seat) or the Tire Label on the

B-Pillar or the edge of the driver door.

Note: You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation.

To provide the vehicle's load carrying

capability, some vehicles require different

recommended tire pressures in the front

tires as compared to the rear tires. The tire

pressure monitoring system equipped on

these vehicles is designed to illuminate the

low tire pressure warning light at two

different pressures; one for the front tires

and one for the rear tires.

Since tires need to be rotated to provide

consistent performance and maximum tire

life, the tire pressure monitoring system

needs to know when the tires are rotated

to determine which set of tires are on the

front and which are on the rear. With this

information, the system can detect and

properly warn of low tire pressures.

System reset tips:

425

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 429 of 666

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least 3 ft

(1 m) away from another Ford Motor

Company vehicle undergoing the

system reset procedure at the same

time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system can time-out and you have

to repeat the entire procedure on all

four wheels.

• A double horn sounds indicating the

need to repeat the procedure.

Performing the System Reset Procedure

- Single Rear Wheel

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, seek service from your

authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front -

driver side front tire, Right front -

passenger side front tire, Right rear -

passenger side rear tire, Left rear -

driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn tone confirms that

the sensor identification code has been

learned by the module for this position. If a

double horn is heard, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver

side rear tire, the system indicator

stops flashing, and a message shows

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

426

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 430 of 666

11.

Set all four tires to the recommended

air pressure as indicated on the

Safety Compliance Certification

Label, affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver seating position or

Tire Label located on the B-Pillar or

the edge of the driver door.

Performing the System Reset Procedure

- Dual Rear Wheel

For further information see

Understanding Your Tire Pressure

Monitoring System and refer to Dual

Rear Wheel, earlier in this section.

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all six tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, seek service from your

authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following order: Left front - driver side

front tire, Right front - passenger side

front tire, Right outer rear -passenger

side rear outer tire, Right inner rear -

passenger side rear inner tire, Left outer

rear - driver side rear outer tire, Left

inner rear - driver side rear inner tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn chirp confirms that

the sensor identification code has been

learned by the module for this position. If a

double horn is heard, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right outer rear tire.

Decrease the air pressure until the horn

sounds.

9. Remove the valve cap from the valve stem on the right inner rear tire.

Decrease the air pressure until the horn

sounds.

10. Remove the valve cap from the valve

stem on the left outer rear tire.

Decrease the air pressure until the

horn sounds.

11. Remove the valve cap from the valve

stem on the left inner rear tire.

Decrease the air pressure until the

horn sounds. Training is complete

after the horn sounds for the last tire

trained, the system indicator stops

flashing, and a message is shown in

the information display.

427

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires