service indicator FORD F-350 2021 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2021, Model line: F-350, Model: FORD F-350 2021Pages: 666, PDF Size: 11.3 MB

Page 230 of 666

PRINCIPLE OF OPERATION

The traction control system helps avoid

drive wheel spin and loss of traction.

If your vehicle begins to slide, the system

applies the brakes to individual wheels

and, when needed, reduces engine power

at the same time. If the wheels spin when

accelerating on slippery or loose surfaces,

the system reduces engine power in order

to increase traction.

USING TRACTION CONTROL

WARNING: The stability and

traction control light illuminates steadily

if the system detects a failure. Make sure

you did not manually disable the traction

control system using the information

display controls or the switch. If the

stability control and traction control light

is still illuminating steadily, have the

system serviced by an authorized dealer

immediately. Operating your vehicle with

the traction control disabled could lead

to an increased risk of loss of vehicle

control, vehicle rollover, personal injury

and death.

The system automatically turns on each

time you switch the ignition on.

If your vehicle is stuck in mud or snow,

switching traction control off may be

beneficial as this allows the wheels to spin.

Note: When you switch traction control off,

stability control remains fully active.

Note: For additional information on the

traction and stability control systems. See

Using Stability Control

(page 229). Switching the System Off

When you switch the system off or on, a

message appears in the information

display showing system status.

Use the traction and stability control

switch on the instrument panel to switch

the system off or on.

The switch illuminates when traction

control is off.

When you place your vehicle into

four-wheel drive low mode the traction

control disables. Traction control resumes

full operation when you put your vehicle

back into two-wheel drive mode.

System Indicator Lights and

Messages

The stability and traction control

light:

• Temporarily illuminates on engine

start-up.

• Flashes when a driving condition

activates either of the systems.

• Illuminates if a problem occurs in either

of the systems. The stability and traction control

off light temporarily illuminates

on engine start-up and stays on

when you switch the traction control

system off.

227

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Traction ControlE225465 E225466

Page 319 of 666

Note:

You can check four-wheel-down

towing status at any time by opening the

driver's door or turning the ignition to the

accessory or on position. A message

displays in the information display

confirming your vehicle is in neutral tow.

When finished towing with all four wheels

on the ground return the transfer case to

its 2H position:

1. With your vehicle still properly secured

to the tow vehicle, put the ignition in

the on position, but do not start the

engine. If your vehicle has an ignition

key, switch the key to on. If your vehicle

has intelligent access, switch the

vehicle into accessory mode. See

Starting and Stopping the Engine

(page

174).

2. Press and hold the brake pedal.

3. Shift out of neutral (N).

4. Release the brake pedal.

Note: If completed successfully, the

instrument cluster displays 2H and Neutral

Tow Disabled

.

Note: If the indicator light and message do

not display, you must perform the procedure

again from the beginning.

Note: If

Shift Delayed Pull Forward

displays in the instrument cluster, a transfer

case blockage is present. See resolving the

shift delayed pull forward message

instructions after this section.

5. Apply the parking brake and disconnect

the vehicle from the tow vehicle.

6. Release the parking brake, start the engine and shift the transmission to

drive (D) to make sure the transfer

case is out of neutral (N).

7. If the transfer case does not successfully shift out of neutral (N),

set the parking brake until you can have

your vehicle serviced. Resolving the

Shift Delayed Pull Forward

Message

1. Press and hold the brake pedal.

2. Put the transmission into neutral (N),

and then start the engine.

3. With the engine running, shift the transmission to drive (D) and let the

vehicle roll forward, up to

3 ft (1 m).

4. Make sure the instrument cluster displays that neutral tow is disabled.

316

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Towing

Page 329 of 666

Vehicles Sold in Canada: Getting

Roadside Assistance

To fully assist you should you have a

vehicle concern, Ford Motor Company of

Canada, Limited offers a complimentary

roadside assistance program. This program

is eligible within Canada or the continental

United States.

The service is available 24 hours a day,

seven days a week.

This program is separate from the New

Vehicle Limited Warranty, but the coverage

is concurrent with the powertrain coverage

period of your vehicle. Canadian roadside

coverage and benefits may differ from the

U.S. coverage.

If you require more information, please call

us in Canada at 1-800-665-2006, or visit

our website at www.ford.ca.

HAZARD FLASHERS

Note:

The hazard flashers operate when

the ignition is in any position, or if the key is

not in the ignition. If used when the vehicle

is not running, the battery loses charge. As

a result, there may be insufficient power to

restart your vehicle. The flasher control is on the

instrument panel. Use your

hazard flashers when your

vehicle is creating a safety hazard for other

motorists.

• Press the flasher control and all front

and rear direction indicators flash.

• Press the button again to switch them

off. FUEL SHUTOFF WARNING: If your vehicle has been

involved in a crash, have the fuel system

checked. Failure to follow this instruction

could result in fire, personal injury or

death.

Note: When you try to restart your vehicle

after a fuel shutoff, the vehicle makes sure

that various systems are safe to restart.

Once the vehicle determines the systems

are safe, then the vehicle allows you to

restart.

Note: In the event that your vehicle does

not restart after your third attempt, contact

a qualified technician.

The fuel pump shutoff stops the flow of

fuel to the engine in the event of a

moderate to severe crash. Not every

impact causes a shutoff.

Should your vehicle shut off after a crash,

you may restart your vehicle.

If your vehicle has a key system:

1. Switch off the ignition.

2. Switch to start position.

3. Switch off the ignition.

4. Switch on the ignition to re-enable the

fuel pump.

5. If the vehicle does not start, repeat steps 1 through 4.

If your vehicle has a push button start

system:

1. Press START/STOP to switch off your

vehicle.

2. Press the brake pedal and START/STOP

to switch on your

vehicle.

3. Remove your foot from the brake pedal

and press

START/STOP to switch off

your vehicle.

326

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Roadside Emergencies

Page 332 of 666

2. Remove the jumper cable on the

negative (-) terminal of the booster

vehicle battery.

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle battery.

4. Remove the jumper cable from the positive (+) terminal of the disabled

vehicle battery.

5. Allow the engine to idle for at least one

minute.

POST-CRASH ALERT SYSTEM

The system flashes the direction indicators

and sounds the horn (intermittently) in the

event of a serious impact that deploys an

airbag (front, side, side curtain or Safety

Canopy) or the seatbelt pretensioners.

The horn and indicators turn off when:

• You press the hazard control button.

• You press the panic button on the

remote entry transmitter (if equipped).

• Your vehicle runs out of power.

• Sounding of the horn is only enabled

in specific markets.

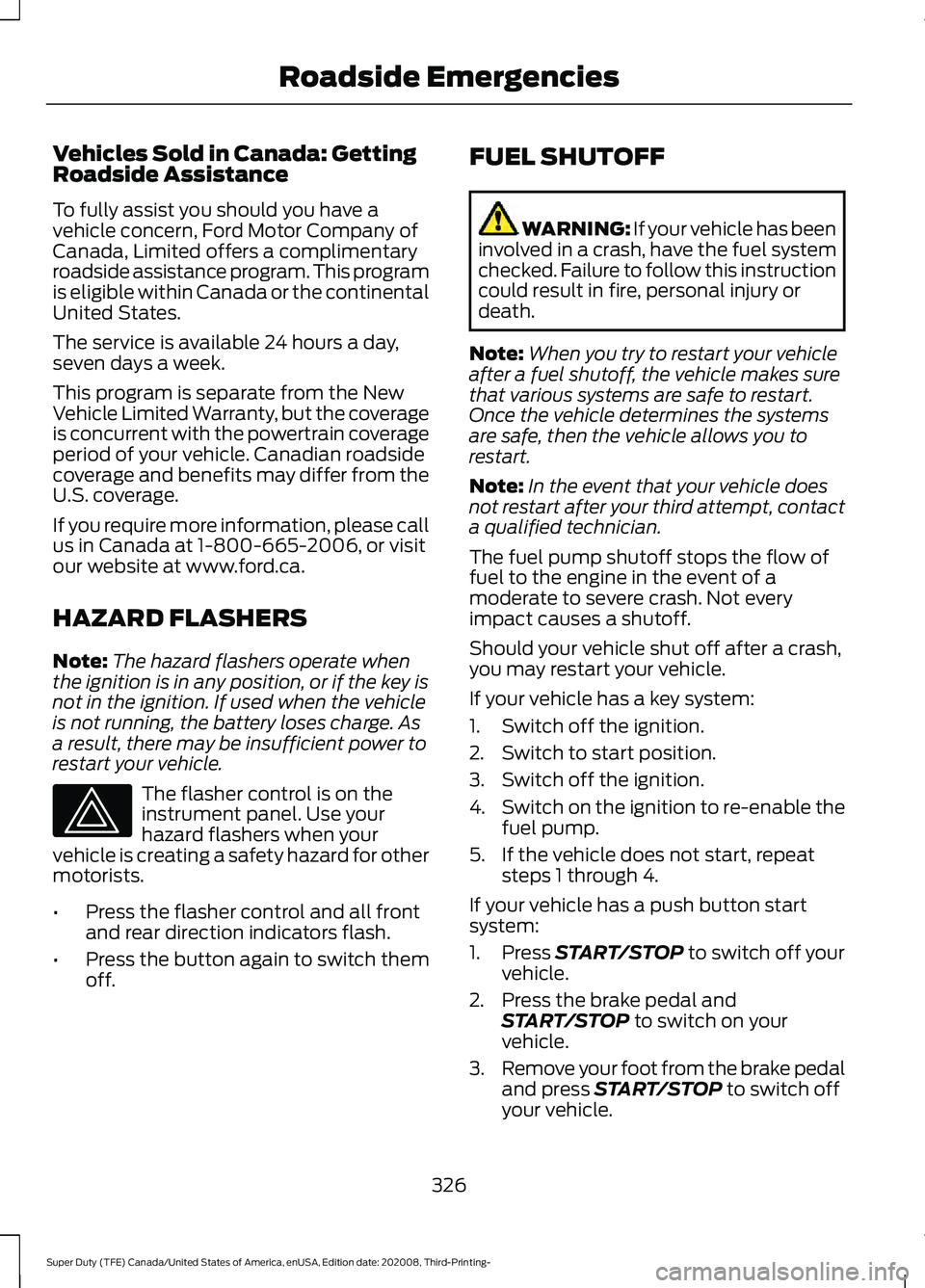

TRANSPORTING THE VEHICLE WARNING: Block the wheels to

help prevent the vehicle from moving. WARNING:

Unexpected and

possibly sudden vehicle movement may

occur if you do not take these

precautions. If you need to tow your vehicle, contact a

professional towing service or, if you are a

member of a roadside assistance program,

your roadside assistance service provider.

We recommend the use of a wheel lift and

dollies or flatbed equipment to tow your

vehicle. Do not tow with a slingbelt. We do

not approve a slingbelt towing procedure.

If you tow your vehicle incorrectly, or by

any other means, vehicle damage may

occur.

We produce a towing manual for all

authorized tow truck operators. Have your

tow truck operator refer to this manual for

proper hook-up and towing procedures for

your vehicle.

It is acceptable to have your two-wheel

drive vehicle towed with the front wheels

on the ground (without dollies) and the

rear wheels off the ground.

329

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Roadside EmergenciesE143886

Page 359 of 666

3. Add engine oil that meets the correct

specification.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap

correctly.

Note: Soak up any spillage with an

absorbent cloth immediately.

CHANGING THE ENGINE OIL

AND OIL FILTER

If your vehicle is equipped with a diesel

engine, an Intelligent Oil Life Monitor™

calculates the proper oil change service

interval. When the information display

indicates: OIL CHANGE REQUIRED, change

the engine oil and oil filter. See

Information Displays (page 110).

The engine oil filter protects your engine

by filtering harmful, abrasive or sludge

particles and particles significantly smaller

than most available will-fit filters. See

Motorcraft Parts

(page 443).

1. Unscrew the oil filter and oil pan drain plug and wait for the oil to drain.

2. Replace the filter.

Note: Do not handle hot oil filter with bare

hands.

3. Reinstall the oil pan drain plug.

4. Refill the engine with new oil. See Engine Oil Capacity and

Specification

(page 449). 5. For diesel engines, you need to reset

the Intelligent Oil Life Monitor™. See

Information Displays

(page 110).

Engine lubrication for severe

service operation

The following conditions define severe

operation for which engine operation with

SAE 5W-40 that meets our specification

WSS-M2C171-F1 is recommended. Oil and

oil filter change intervals will be

determined by the Intelligent Oil Life

Monitor™ as noted previously.

• Frequent or extended idling (over 10

minutes per hour of normal driving).

• Low-speed operation/stationary use.

• If vehicle is operated in sustained

ambient temperatures below

-9°F

(-23°C) or above 100°F (38°C).

• Frequent low-speed operation,

consistent heavy traffic less than

25 mph (40 km/h)

.

• Operating in severe dust conditions.

• Operating the vehicle off road.

• Towing a trailer over

1,000 mi

(1,600 km).

• Sustained, high-speed driving at Gross

Vehicle Weight Rating (maximum

loaded weight for vehicle operation).

• Use of fuels with sulfur content other

than ultra-low sulfur diesel (ULSD).

• Use of high-sulfur diesel fuel.

OIL CHANGE INDICATOR

RESET

Use the information display controls on

the steering wheel to reset the oil change

indicator.

356

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Maintenance

Page 360 of 666

From the main menu scroll to:

Action and description

Message

Press the down arrow

button, then from this menu

scroll to the following

message.

Truck Info

Press the OK button.

Mainten-

ance

Monitor

Press the down arrow

button, then from this menu

scroll to the following

message.

Oil Life:

xxx%

Press the

OK button.

Oil Life

Press and hold the

OK

button until the instrument

cluster displays the

following message.

Oil Life

Hold OK to

Reset

Oil Life: 100%

When the oil change indic-

ator resets the instrument

cluster displays 100%.

Repeat the process if the oil

change indicator does not

reset.

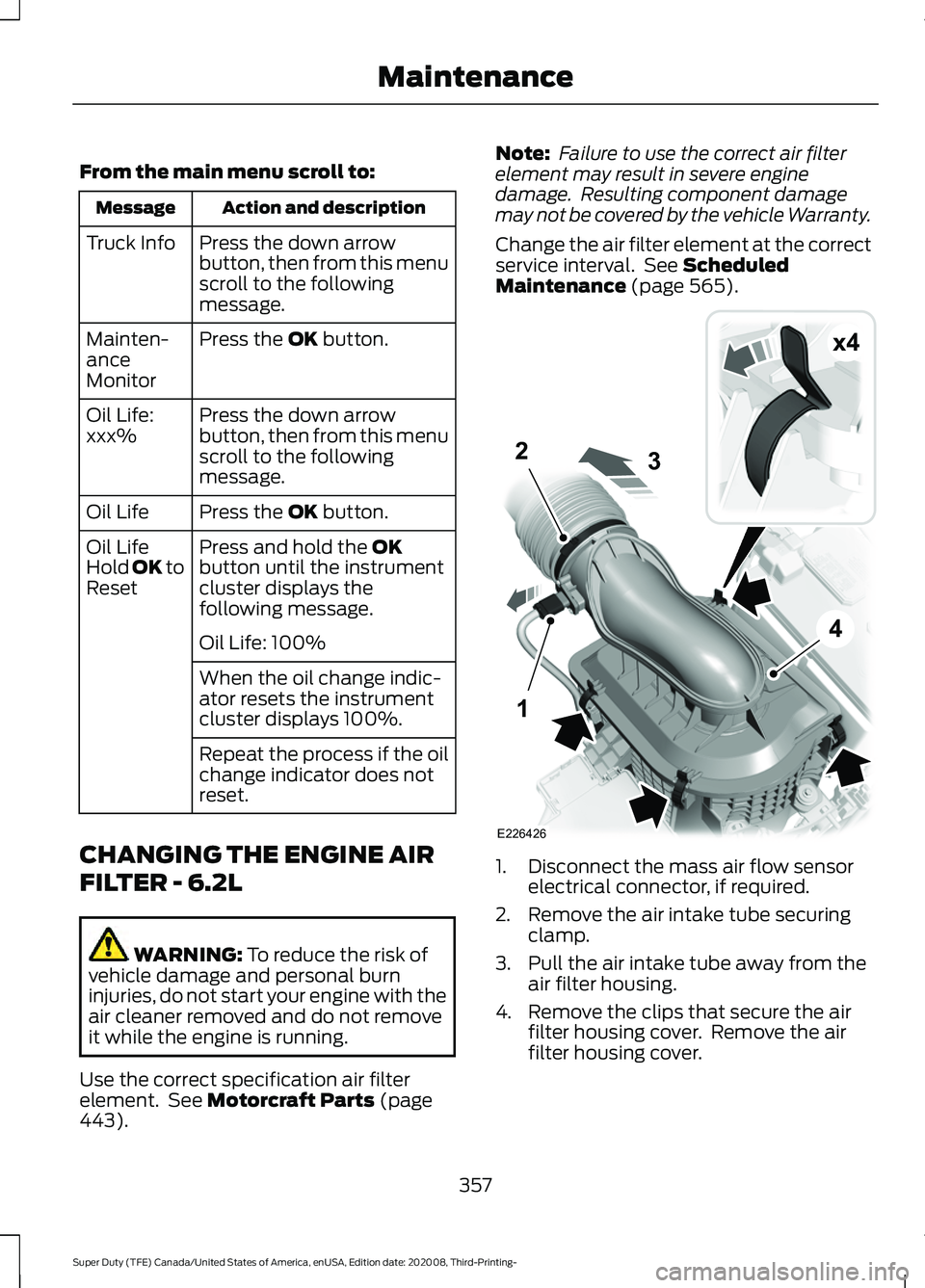

CHANGING THE ENGINE AIR

FILTER - 6.2L WARNING:

To reduce the risk of

vehicle damage and personal burn

injuries, do not start your engine with the

air cleaner removed and do not remove

it while the engine is running.

Use the correct specification air filter

element. See

Motorcraft Parts (page

443). Note:

Failure to use the correct air filter

element may result in severe engine

damage. Resulting component damage

may not be covered by the vehicle Warranty.

Change the air filter element at the correct

service interval. See

Scheduled

Maintenance (page 565). 1. Disconnect the mass air flow sensor

electrical connector, if required.

2. Remove the air intake tube securing clamp.

3. Pull the air intake tube away from the air filter housing.

4. Remove the clips that secure the air filter housing cover. Remove the air

filter housing cover.

357

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- MaintenanceE226426

x4

1

2

4

3

Page 420 of 666

WARNING: To reduce the

risk of serious injury, when

mounting replacement tires and

wheels, you should not exceed

the maximum pressure indicated

on the sidewall of the tire to set

the beads without additional

precautions listed below. If the

beads do not seat at the

maximum pressure indicated,

re-lubricate and try again.

When inflating the tire for

mounting pressures up to 20 psi

(1.38 bar)

greater than the

maximum pressure on the tire

sidewall, the following

precautions must be taken to

protect the person mounting the

tire:

1. Make sure that you have the

correct tire and wheel size.

2. Lubricate the tire bead and

wheel bead seat area again.

3. Stand at a minimum of

12 ft

(3.66 m) away from the wheel

and tire assembly.

4. Use both eye and ear

protection. WARNING: For a mounting

pressure more than

20 psi

(1.38 bar) greater than the

maximum pressure, a Ford

dealer or other tire service

professional should do the

mounting. WARNING:

Always inflate

steel carcass tires with a remote

air fill with the person inflating

standing at a minimum of

12 ft

(3.66 m) away from the wheel

and tire assembly.

Important: Remember to replace

the wheel valve stems when the

road tires are replaced on your

vehicle.

The two front tires or two rear tires

should generally be replaced as a

pair.

The tire pressure sensors mounted

in the wheels are not designed to

be used in aftermarket wheels.

The use of wheels or tires not

recommended by Ford Motor

Company may affect the

operation of your tire pressure

monitoring system.

If the tire pressure monitoring

system indicator is flashing, the

system is malfunctioning. Your

replacement tire might be

incompatible with your tire

pressure monitoring system, or

some component of the system

may be damaged.

417

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 429 of 666

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least 3 ft

(1 m) away from another Ford Motor

Company vehicle undergoing the

system reset procedure at the same

time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system can time-out and you have

to repeat the entire procedure on all

four wheels.

• A double horn sounds indicating the

need to repeat the procedure.

Performing the System Reset Procedure

- Single Rear Wheel

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, seek service from your

authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front -

driver side front tire, Right front -

passenger side front tire, Right rear -

passenger side rear tire, Left rear -

driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn tone confirms that

the sensor identification code has been

learned by the module for this position. If a

double horn is heard, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver

side rear tire, the system indicator

stops flashing, and a message shows

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

426

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 430 of 666

11.

Set all four tires to the recommended

air pressure as indicated on the

Safety Compliance Certification

Label, affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver seating position or

Tire Label located on the B-Pillar or

the edge of the driver door.

Performing the System Reset Procedure

- Dual Rear Wheel

For further information see

Understanding Your Tire Pressure

Monitoring System and refer to Dual

Rear Wheel, earlier in this section.

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all six tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, seek service from your

authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following order: Left front - driver side

front tire, Right front - passenger side

front tire, Right outer rear -passenger

side rear outer tire, Right inner rear -

passenger side rear inner tire, Left outer

rear - driver side rear outer tire, Left

inner rear - driver side rear inner tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn chirp confirms that

the sensor identification code has been

learned by the module for this position. If a

double horn is heard, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right outer rear tire.

Decrease the air pressure until the horn

sounds.

9. Remove the valve cap from the valve stem on the right inner rear tire.

Decrease the air pressure until the horn

sounds.

10. Remove the valve cap from the valve

stem on the left outer rear tire.

Decrease the air pressure until the

horn sounds.

11. Remove the valve cap from the valve

stem on the left inner rear tire.

Decrease the air pressure until the

horn sounds. Training is complete

after the horn sounds for the last tire

trained, the system indicator stops

flashing, and a message is shown in

the information display.

427

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 432 of 666

The trailer tire pressure monitoring system

can be reset through the menu in the

information display. See General

Information (page 110). Performing the

trailer setup process also resets the trailer

tire pressure monitoring system.

CHANGING A ROAD WHEEL WARNING:

If the tire pressure

monitor sensor becomes damaged it

may not function.

Note: If your vehicle is equipped with the

tire pressure monitoring system, the

indicator light illuminates when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

Note: You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

If you get a flat tire when driving, do not

apply the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe

place on the side of the road.

If your vehicle is equipped with the tire

pressure monitoring system, have a flat

serviced by an authorized dealer in order

to prevent damage to the system sensors.

See

Tire Pressure Monitoring System

(page 421). Replace the spare tire with a

road tire as soon as possible. During

repairing or replacing of the flat tire, have

the authorized dealer inspect the system

sensor for damage. Dissimilar Spare Wheel and Tire

Assembly Information WARNING:

Failure to follow these

guidelines could result in an increased

risk of loss of vehicle control, injury or

death.

If you have a dissimilar spare wheel and

tire, then it is intended for temporary use

only. This means that if you need to use it,

you should replace it as soon as possible

with a road wheel and tire assembly that

is the same size and type as the road tires

and wheels that were originally provided

by Ford. If the dissimilar spare tire or wheel

is damaged, it should be replaced rather

than repaired.

A dissimilar spare wheel and tire assembly

is defined as a spare wheel and tire

assembly that is different in brand, size or

appearance from the road tires and

wheels.

Full-size dissimilar spare

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

When driving with the full-size dissimilar

spare wheel and tire assembly, 4WD

functionality may be limited. You may

experience the following:

• Additional noise from the transfer case

or other drive components.

• Difficulty shifting out of a mechanically

locked 4WD mode.

429

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires