maintenance reset FORD F-550 2018 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2018, Model line: F-550, Model: FORD F-550 2018Pages: 660, PDF Size: 11.64 MB

Page 7 of 660

Cruise Control

Principle of Operation

...............................243

Using Cruise Control ..................................

243

Using Adaptive Cruise Control ..............

244

Driving Aids

Lane Keeping System ...............................

250

Blind Spot Information System .............

252

Cross Traffic Alert ........................................

257

Steering ..........................................................

259

Collision Warning System ........................

261

Load Carrying

Load Limit .....................................................

264

Bed Ramps ...................................................

268

Towing

Towing a Trailer ............................................

272

Trailer Reversing Aids ................................

274

Trailer Sway Control ...................................

281

Recommended Towing Weights ..........

282

Essential Towing Checks .........................

286

Towing the Vehicle on Four Wheels .....

295

Driving Hints

Breaking-In ...................................................

298

Economical Driving ....................................

298

Driving Through Water .............................

299

Floor Mats .....................................................

299

Snowplowing ...............................................

300

Roadside Emergencies

Roadside Assistance .................................

303

Hazard Flashers ..........................................

304

Fuel Shutoff .................................................

304

Jump Starting the Vehicle .......................

305

Post-Crash Alert System .........................

307

Transporting the Vehicle ..........................

307

Towing Points ..............................................

308Customer Assistance

Getting the Services You Need

..............

310

In California (U.S. Only) ..............................

311

The Better Business Bureau (BBB) Auto Line Program (U.S. Only) ......................

312

Utilizing the Mediation/Arbitration Program (Canada Only) .......................

313

Getting Assistance Outside the U.S. and Canada ........................................................

313

Ordering Additional Owner's Literature ........................................................................\

.

314

Reporting Safety Defects (U.S. Only) ........................................................................\

.

315

Reporting Safety Defects (Canada Only) ........................................................................\

.

315

Fuses

Fuse Specification Chart ...........................

317

Changing a Fuse .........................................

326

Maintenance

General Information ..................................

328

Opening and Closing the Hood .............

328

Under Hood Overview - 6.2L ..................

329

Under Hood Overview - 6.7L Diesel .....

330

Under Hood Overview - 6.8L ...................

331

Engine Oil Dipstick - 6.2L/6.8L ..............

333

Engine Oil Dipstick - 6.7L Diesel ............

333

Engine Oil Check - 6.2L/6.8L ..................

333

Engine Oil Check - 6.7L Diesel ...............

334

Changing the Engine Oil and Oil Filter ........................................................................\

335

Changing the Crankcase Vent Filter Element ......................................................

336

Oil Change Indicator Reset ......................

337

Engine Coolant Check - 6.2L/6.8L .......

338

Engine Coolant Check - 6.7L Diesel ......

342

Automatic Transmission Fluid Check ........................................................................\

346

Transfer Case Fluid Check ......................

349

Brake Fluid Check .......................................

349

4

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Table of Contents

Page 185 of 660

We recommend the following cold

weather idling guidelines:

•

You can use Motorcraft® cetane

improvers or non-alcohol-based

cetane improvers from a reputable

manufacturer as needed.

• Maintain the engine cooling system

properly.

• Avoid shutting the engine down after

an extensive idling period. Drive your

vehicle for several miles with the

engine at normal operating

temperatures under a moderate load.

• Consider using an engine block heater.

• For extended idle times use an

approved idle speed increase device.

Winter Operating Tips for Arctic

Operation -20°F (-29°C) and Below

The following information is a guideline

only and is not to be the only source of

possible solutions in resolving extreme

cold temperature issues.

Starting Aids WARNING

Do not use starting fluid, for example

ether, in the air intake system. Such

fluid could cause immediate

explosive damage to the engine and

possible personal injury. The use of the factory engine block heater

assists in engine starting in extreme cold

ambient temperatures See Engine Block

Heater (page 183). Idle Control

Your vehicle may have a factory option for

a stationary elevated idle control through

the upfitter switches in the overhead

console. This allows the operator to

elevate the idle RPM for extended idle

periods, as well as aftermarket equipment

such as PTO operation. You must configure

this feature even if ordered from the

factory. See your authorized dealer for

required upfitting.

Operation in Snow and Rain

Vehicle operation in heavy snowfall or

extreme rain conditions may feed

excessive amounts of snow or water into

the air intake system. This could plug the

air filter with snow and may cause the

engine to lose power and possibly shut

down.

We recommend the following actions after

operating your vehicle up to

200 mi

(320 km) in snowfall or extreme rain:

• Snow: At the earliest opportunity, open

the hood and clear all the snow and ice

from the air filter housing inlet (do not

remove the foam filter) and reset the

air filter restriction gauge.

Note: Removal of the foam filter degrades

your vehicle performance during snow and

hot weather conditions.

• Extreme rain: The air filter dries after

about 15– 30 minutes at highway

speeds. At the earliest opportunity,

open the hood and reset the air filter

restriction gauge.

Refer to Air filter and restriction gauge in

the Maintenance chapter for more

information. See

Changing the Engine

Air Filter (page 363).

182

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Starting and Stopping the Engine

Page 339 of 660

4. Refill the engine with new oil. See

Capacities and Specifications (page

432).

5. For diesel engines, you need to reset the Intelligent Oil Life Monitor™. See

Information Displays

(page 113).

Engine lubrication for severe

service operation

The following conditions define severe

operation for which engine operation with

SAE 5W-40 API CJ-4 is recommended. Oil

and oil filter change intervals will be

determined by the Intelligent Oil Life

Monitor™ as noted previously.

• Frequent or extended idling (over 10

minutes per hour of normal driving).

• Low-speed operation/stationary use.

• If vehicle is operated in sustained

ambient temperatures below

-9°F

(-23°C) or above 100°F (38°C).

• Frequent low-speed operation,

consistent heavy traffic less than

25 mph (40 km/h)

.

• Operating in severe dust conditions.

• Operating the vehicle off road.

• Towing a trailer over

1,000 mi

(1,600 km).

• Sustained, high-speed driving at Gross

Vehicle Weight Rating (maximum

loaded weight for vehicle operation).

• Use of fuels with sulfur content other

than ultra-low sulfur diesel (ULSD).

• Use of high-sulfur diesel fuel. CHANGING THE CRANKCASE

VENT FILTER ELEMENT

(If

Equipped) WARNING

Do not dispose of engine oil or oil

filters in the household refuse or the

public sewage system. Use an

authorized waste disposal facility. Do not clean or recondition the filter

element.

We recommend that you demand the use

of genuine Ford and Motorcraft® parts

whenever your vehicle requires scheduled

maintenance or repair. Use the correct

specification filter element. See

Capacities and Specifications

(page

432).

Note: Operating your vehicle without a filter

element or with an unapproved filter

element may result in damage to the turbo

charger or exchanger and could lead to

engine damage that may not be covered by

the vehicle Warranty.

336

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Maintenance

Page 340 of 660

Filter cover.

A

Filter element.

B

Filter housing.

C

1. Clean the filter cover and remove the bolts.

2. Carefully remove the filter cover.

3. Remove used filter element from the filter housing and carefully dispose of

it.

4. Make sure that the sealing surfaces on

the filter housing and cover are clean

and free of debris.

5. Install the new filter element.

6. Install the filter cover.

7. Install the bolts finger-tight. 8.

Fully tighten all of the bolts to between

3–4 lb.ft (4.5–6 Nm) in the sequence

shown.

9. Record the engine mileage and update

the service log accordingly.

OIL CHANGE INDICATOR

RESET

Use the information display controls on

the steering wheel to reset the oil change

indicator.

From the main menu scroll to: Action and description

Message

Press the right arrow button,

then from this menu scroll

to the following message.

Settings

Press the right arrow button,

then from this menu scroll

to the following message.

Conveni-

ence

Press the right arrow button,

then from this menu scroll

to the following message.

Oil Life

Reset

337

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing MaintenanceE211403

A

B

C E211404

165

4

32

7

Page 341 of 660

Action and description

Message

Press and hold the OK

button until the instrument

cluster displays the

following message.

Hold OK to

Reset

Reset Successful

When the oil change indic-

ator resets the instrument

cluster displays 100%.

Remaining Life

{00}%

If the instrument cluster

displays one of the following

messages, repeat the

process.

Not Reset

Reset Cancelled

ENGINE COOLANT CHECK -

6.2L/6.8L WARNINGS

Never remove the coolant reservoir

cap when the engine is running or

hot.

Do not put coolant in the windshield

washer reservoir. If sprayed on the

windshield, coolant could make it

difficult to see through the windshield. To reduce the risk of personal injury,

make sure the engine is cool before

unscrewing the coolant pressure

relief cap. The cooling system is under

pressure. Steam and hot liquid can come

out forcefully when you loosen the cap

slightly. Do not add coolant further than the

MAX

mark. When the engine is cold, check the

concentration and level of the coolant at

the intervals listed in the scheduled

maintenance information. See Scheduled

Maintenance

(page 581).

Note: Make sure that the coolant level is

between the

MIN and the MAX marks on

the coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the

MAX mark.

Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C). Coolant concentration should be

checked using a refractometer. We

recommend, Robinair® Coolant and

Battery Refractometer 75240 (Rotunda

tool part number: ROB75240). We do not

recommend the use of hydrometers or

coolant test strips for measuring coolant

concentration.

Note: Automotive fluids are not

interchangeable. Do not use coolant or

windshield washer fluid outside of its

specified function and vehicle location.

Note: Do not use stop leak pellets, cooling

system sealants, or non-specified additives

as they can cause damage to the engine

cooling or heating systems. Resulting

component damage may not be covered by

the vehicle Warranty.

Adding Coolant WARNING

Never remove the coolant reservoir

cap when the engine is running or

hot.

338

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Maintenance

Page 343 of 660

Severe Climates

If you drive in extremely cold climates:

•

It may be necessary to increase the

coolant concentration above 50%.

• A coolant concentration of 60%

provides improved freeze point

protection. Coolant concentrations

above 60% decrease the overheat

protection characteristics of the

coolant and may cause engine

damage.

If you drive in extremely hot climates:

• It may be necessary to decrease the

coolant concentration to 40%.

• A coolant concentration of 40%

provides improved overheat

protection. Coolant concentrations

below 40% decrease the freeze and

corrosion protection characteristics of

the coolant and may cause engine

damage.

Vehicles driven year-round in non-extreme

climates should use prediluted coolant for

optimum cooling system and engine

protection.

Fail-Safe Cooling

Fail-safe cooling allows you to temporarily

drive your vehicle before any incremental

component damage occurs. The fail-safe

distance depends on ambient

temperature, vehicle load and terrain.

How Fail-Safe Cooling Works

If the engine begins to overheat, the

coolant temperature gauge moves toward

the red zone: A warning lamp illuminates and

a message may appear in the

information display. If the engine reaches a preset

over-temperature condition, the engine

automatically switches to alternating

cylinder operation. Each disabled cylinder

acts as an air pump and cools the engine.

When this occurs, your vehicle still

operates, however:

•

Engine power is limited.

• The air conditioning system turns off.

Continued operation increases the engine

temperature, causing the engine to

completely shut down. Your steering and

braking effort increases in this situation.

When the engine temperature cools, you

can re-start the engine. Have your vehicle

checked as soon as possible to minimize

engine damage.

When Fail-Safe Mode Is Activated WARNINGS

Fail-safe mode is for use during

emergencies only. Operate your

vehicle in fail-safe mode only as long

as necessary to bring your vehicle to rest

in a safe location and seek immediate

repairs. When in fail-safe mode, your

vehicle will have limited power, will not be

able to maintain high-speed operation, and

may completely shut down without

warning, potentially losing engine power,

power steering assist, and power brake

assist, which may increase the possibility

of a crash resulting in serious injury. Never remove the coolant reservoir

cap when the engine is running or

hot.

Your vehicle has limited engine power

when in the fail-safe mode, drive your

vehicle with caution. Your vehicle does not

maintain high-speed operation and the

engine may operate poorly.

340

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Maintenance

Page 357 of 660

5. Run the engine until it reaches normal

operating temperature. While the

engine is warming up, complete the

following: Reset the clock. Reset the

power windows bounce-back feature.

See Windows and Mirrors (page 98).

Reset the radio station presets. See

Audio System (page 445).

6. Allow the engine to idle for at least one

minute.

7. Drive the vehicle at least 10 mi (16 km)

to completely relearn the idle trim and

fuel trim strategy.

Note: If you do not allow the engine to

relearn the idle and fuel trim strategy, the

idle quality of your vehicle may be adversely

affected until the engine computer

eventually relearns the idle trim and fuel

trim strategy.

Note: For flexible fuel vehicles, if you are

operating on E85, you may experience poor

starts or an inability to start the engine and

driveability problems until the fuel trim and

ethanol content have been relearned.

Make sure that you dispose of old batteries

in an environmentally friendly way. Seek

advice from your local authority about

recycling old batteries.

If storing your vehicle for more than 30

days without recharging the battery, we

recommend that you disconnect the

battery cables to maintain battery charge

for quick starting.

Battery Management System

(If

Equipped)

The battery management system monitors

battery conditions and takes actions to

extend battery life. If excessive battery

drain is detected, the system temporarily

disables some electrical systems to

protect the battery. Systems included are:

•

Heated rear window.

• Heated seats.

• Climate control.

• Heated steering wheel.

• Audio unit.

• Navigation system.

A message may appear in the information

displays to alert you that battery

protection actions are active. These

messages are only for notification that an

action is taking place, and not intended to

indicate an electrical problem or that the

battery requires replacement.

After battery replacement, or in some

cases after charging the battery with an

external charger, the battery management

system requires eight hours of vehicle sleep

time to relearn the battery state of charge.

During this time your vehicle must remain

fully locked with the ignition switched off.

Note: Prior to relearning the battery state

of charge, the battery management system

may temporarily disable some electrical

systems.

Electrical Accessory Installation

To make sure the battery management

system works correctly, do not connect an

electrical device ground connection

directly to the battery negative post. This

can cause inaccurate measurements of

the battery condition and potential

incorrect system operation.

Note: If you add electrical accessories or

components to the vehicle, it may adversely

affect battery performance and durability.

This may also affect the performance of

other electrical systems in the vehicle.

354

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Maintenance

Page 368 of 660

Operating your vehicle in heavy snowfall

or extreme rain conditions may allow

excessive amounts of snow or water into

the air intake system. This could restrict air

flow and cause the engine to lose power

or shut down.

After installing a new air filter element, you

must reset the gauge by pressing the reset

button.

After operating your vehicle during heavy

snowfall or extreme rain, do the following:

•

Snow: At the earliest opportunity, open

the hood and clear any snow and ice

from the air filter housing inlet and

reset the air filter restriction gauge.

• Extreme rain: The air filter element

dries out after approximately 15– 30

minutes of driving at highway speeds.

At the earliest opportunity, open the

hood and reset the air filter restriction

gauge.

Note: Do not remove the foam filter.

CHANGING THE ENGINE-

MOUNTED AND DIESEL FUEL

CONDITIONER MODULE FUEL

FILTERS - 6.7L DIESEL WARNING

Do not dispose of fuel in the

household refuse or the public

sewage system. Use an authorized

waste disposal facility. Your vehicle has two fuel filters. The first

filter mounts on top of the engine on the

left-hand side. The second filter is inside

the diesel fuel conditioner module. The

module is attached to the fuel tank in

different locations depending on the

configuration of your truck. See table

below for configurations.

Note:

The module is at the front of the fuel

tank or at the front of the aft-axle fuel tank

on some models.

Regular fuel filter changes are an

important part of engine maintenance;

failing to keep with the scheduled

maintenance could lead to engine

performance issues and fuel injection

system damage. See Scheduled

Maintenance (page 581).

Use only recommended service parts

conforming to specifications. See

Motorcraft Parts

(page 422).

Note: Using fuel that has high levels of

impurities may require more frequent filter

replacements than the service interval

specifies.

Diesel Fuel Conditioner Module

Filter

Filter Location

Use the tables below to find the location

of your filter.

365

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Maintenance

Page 401 of 660

Tire Rotation

WARNING

If the tire label shows

different tire pressures for the

front and rear tires and the vehicle

has a tire pressure monitoring

system, then you need to update

the settings for the system

sensors. Always perform the

system reset procedure after tire

rotation. If you do not reset the

system, it may not provide a low

tire pressure warning when

necessary. Note:

If your tires show uneven

wear ask an authorized dealer to

check for and correct any wheel

misalignment, tire imbalance or

mechanical problem involved

before tire rotation.

Note: Your vehicle may be

equipped with a dissimilar spare

wheel and tire assembly. A

dissimilar spare wheel and tire

assembly is defined as a spare

wheel and tire assembly that is

different in brand, size or

appearance from the road tires and

wheels. If you have a dissimilar

spare wheel and tire assembly it is

intended for temporary use only

and should not be used in a tire

rotation.

Note: After having your tires

rotated, inflation pressure must be

checked and adjusted to the

vehicle requirements. Rotating your tires at the

recommended interval (as

indicated in the Scheduled

Maintenance chapter) will help

your tires wear more evenly,

providing better tire performance

and longer tire life. Sometime

irregular tire wear can be

corrected by rotating the tires.

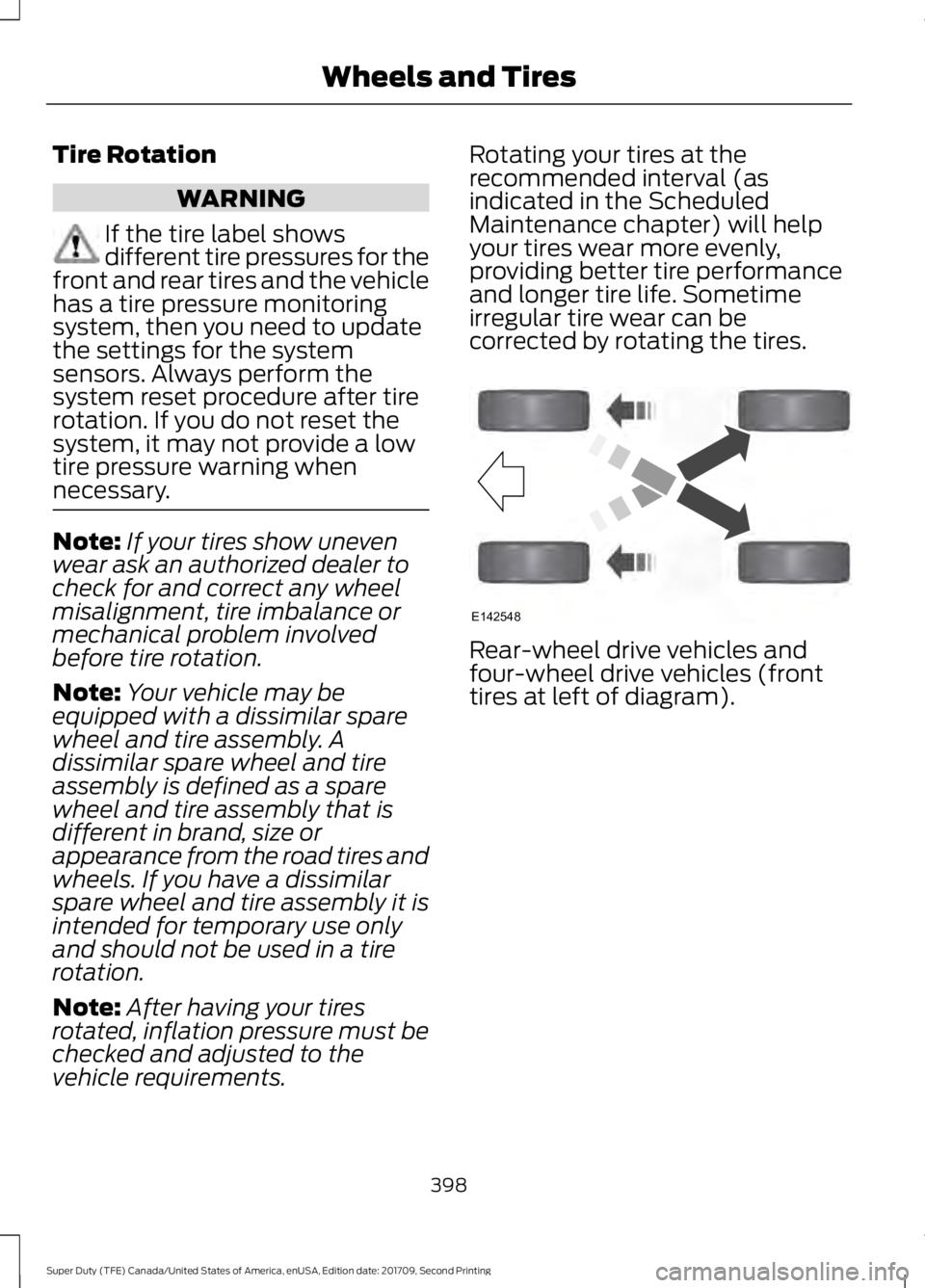

Rear-wheel drive vehicles and

four-wheel drive vehicles (front

tires at left of diagram).

398

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Wheels and TiresE142548

Page 410 of 660

12.

Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

13. Set all six tires to the recommended air pressure as indicated on the

Safety Compliance Certification

Label (affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver's seating position)

or Tire Label located on the B-Pillar

or the edge of the driver's door.

Trailer Tire Pressure Monitoring

System (If Equipped)

Note: Additional equipment may be

required for your vehicle to support trailer

tire pressure monitoring. See your authorized

dealer for more information.

Note: The trailer tire pressure monitoring

system is not a substitute for proper tire

maintenance. It is your responsibility to

maintain correct tire pressures at all times.

Note: If a trailer tire is repaired, replaced or

broken down for service, the screw and valve

on the trailer tire pressure sensor should be

replaced. See your authorized dealer for

details. The trailer tire pressure monitoring system

is an added safety feature that allows you

to view your trailer tire pressures through

the information display. See

General

Information (page 113). Tire pressure

sensors are mounted into each tire on your

trailer. The sensors send a message to your

vehicle indicating the current trailer tire

pressure.

If the trailer tire pressure monitoring

system detects that a tire is low, a warning

message appears in the information

display. The trailer tire pressure status

screen in the information display highlights

the tire with a low pressure.

The main function of the trailer tire

pressure monitoring system is to warn you

when your trailer tires need air. It can also

warn you in the event the system is no

longer capable of functioning as intended.

See

Information Messages (page 129).

When a Temporary Spare or New Tire

is Installed

If you have replaced a trailer tire with a new

or spare tire, a warning message appears

and pressure readings are no longer

displayed for that tire.

To restore the full function of the trailer

tire pressure monitoring system:

• Have the damaged wheel and tire

assembly repaired and remounted to

your trailer.

• Install the trailer tire pressure

monitoring sensor into the new wheel

and tire assembly.

• Perform the trailer tire pressure

monitoring system reset procedure.

Trailer Tire Pressure Monitoring

System Reset Procedure

Note: You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation, or when a new trailer tire

pressure sensor is installed into a trailer tire.

407

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Wheels and TiresE235807