FORD F250 2003 Owners Manual

Manufacturer: FORD, Model Year: 2003, Model line: F250, Model: FORD F250 2003Pages: 280, PDF Size: 3.73 MB

Page 181 of 280

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

113 30A** Starter motor

114 30A** Right-hand power seats

115 20A** Trailer tow battery charge

116 30A** Ignition switch

601 30A CB*** Window motors, Moonroof

602 60A** 4WABS module

210—Not used

211—Backup lamps relay (Diesel engine

only)

212—Not used

301—Front blower motor relay

302—Powertrain Control Module (PCM)

relay

303—Fuel heater relay (Diesel engine

only)

304—Heated backlight relay

305—Trailer tow battery charge relay

306—Delayed accessory relay

307—Starter relay

* Mini Fuses ** Maxi Fuses ***Circuit Breaker

Note: (Diesel engine only)The Fuel Injection Control Module (FICM)

logic 15A mini-fuse is located in the underhood relay block.

CHANGING A FLAT TIRE

If you get a flat tire while driving:

•do not brake heavily.

•gradually decrease the vehicle’s speed.

•hold the steering wheel firmly.

•slowly move to a safe place on the side of the road.

The use of tire sealants is not recommended and may

compromise the integrity of your tires.

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

181

Page 182 of 280

Spare tire information

Your vehicle may be equipped with a spare tire that can be used as

either a spare or a regular tire. The spare tire is not equipped with wheel

trim. The wheel trim from the original wheel/tire may be used on the

spare.

If your vehicle is equipped with 4WD, a spare tire of a different

size than the road tires should not be used. Use of such a tire

could result in damage to driveline components and an increased risk

of loss of vehicle control, vehicle rollover, personal injury or death.

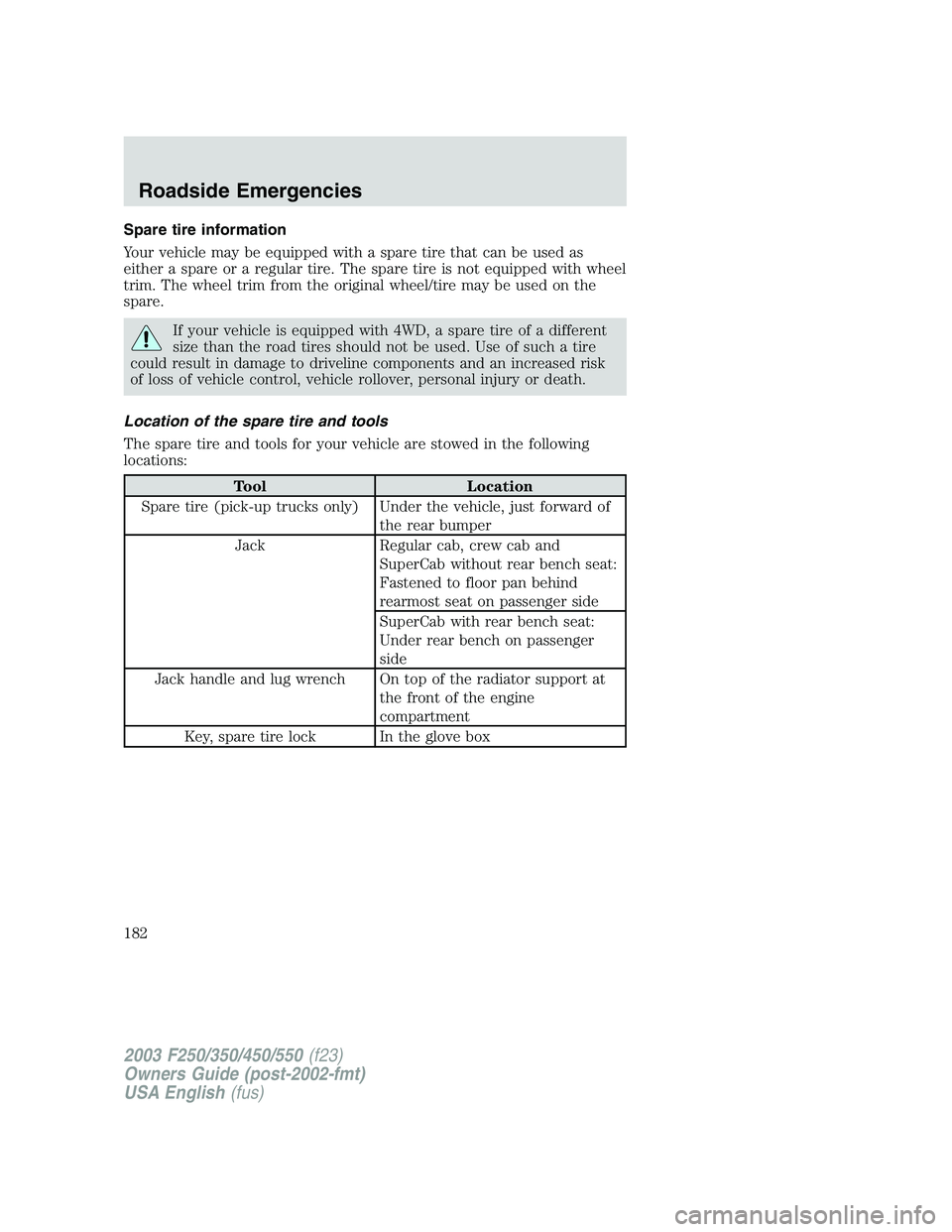

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Tool Location

Spare tire (pick-up trucks only) Under the vehicle, just forward of

the rear bumper

Jack Regular cab, crew cab and

SuperCab without rear bench seat:

Fastened to floor pan behind

rearmost seat on passenger side

SuperCab with rear bench seat:

Under rear bench on passenger

side

Jack handle and lug wrench On top of the radiator support at

the front of the engine

compartment

Key, spare tire lock In the glove box

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

182

Page 183 of 280

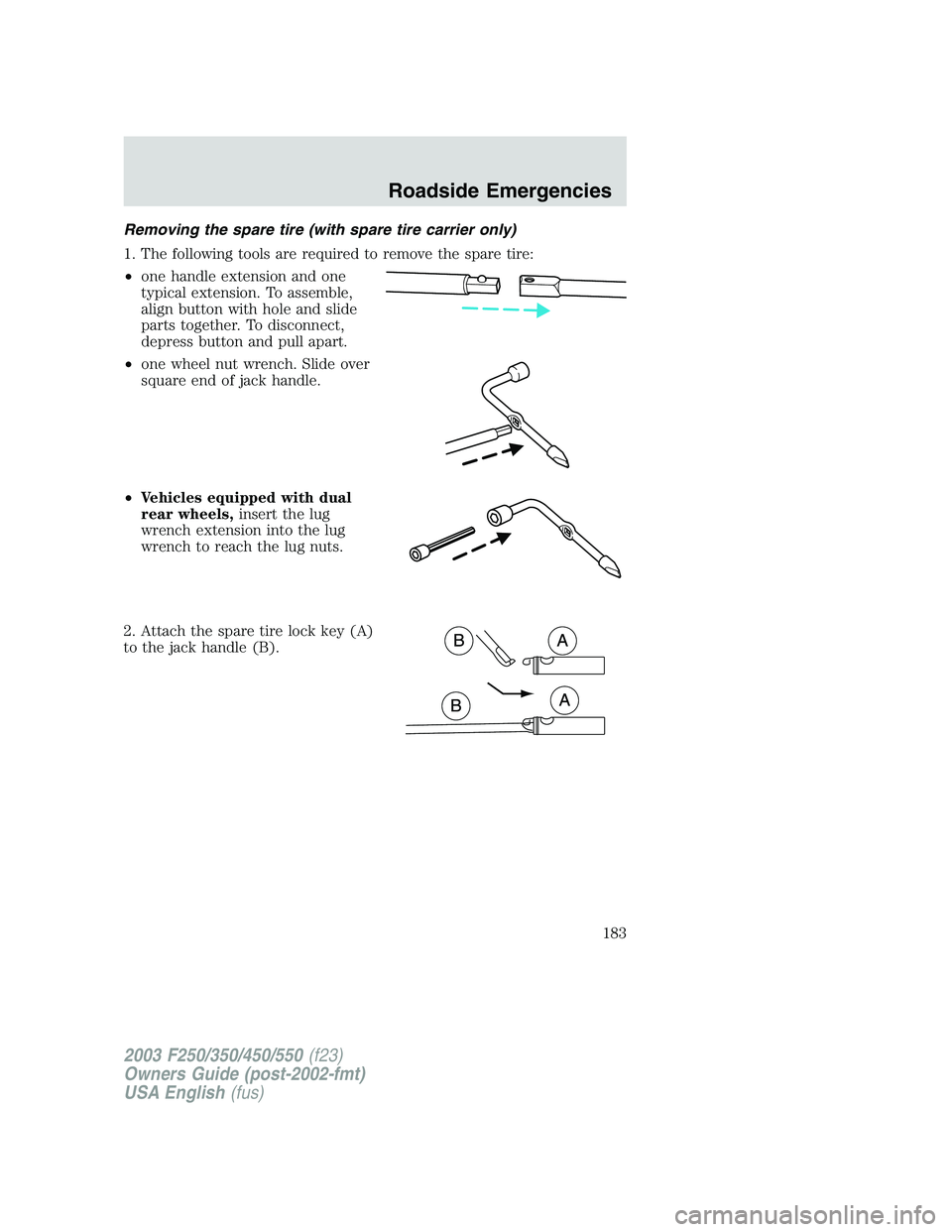

Removing the spare tire (with spare tire carrier only)

1. The following tools are required to remove the spare tire:

•one handle extension and one

typical extension. To assemble,

align button with hole and slide

parts together. To disconnect,

depress button and pull apart.

•one wheel nut wrench. Slide over

square end of jack handle.

•Vehicles equipped with dual

rear wheels,insert the lug

wrench extension into the lug

wrench to reach the lug nuts.

2. Attach the spare tire lock key (A)

to the jack handle (B).

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

183

Page 184 of 280

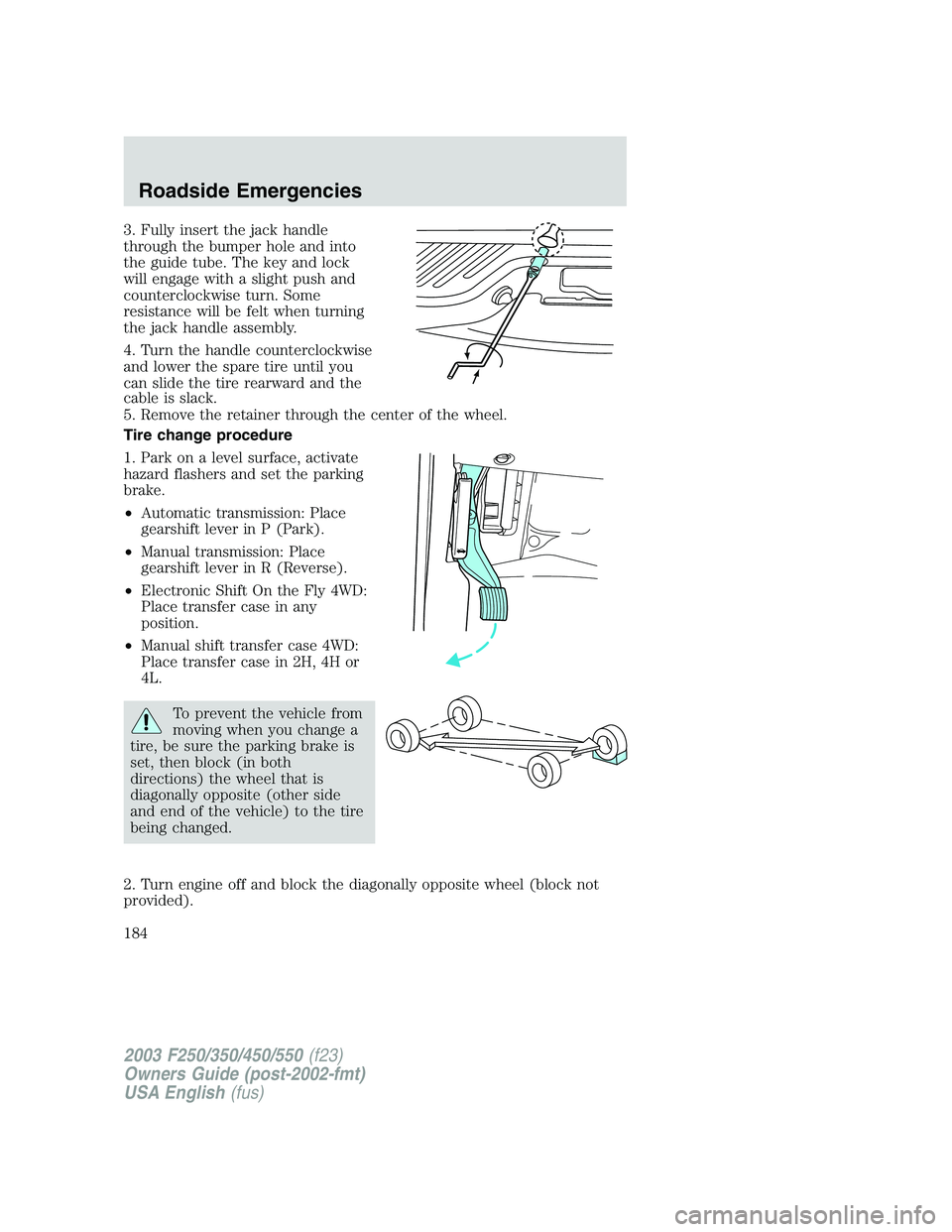

3. Fully insert the jack handle

through the bumper hole and into

the guide tube. The key and lock

will engage with a slight push and

counterclockwise turn. Some

resistance will be felt when turning

the jack handle assembly.

4. Turn the handle counterclockwise

and lower the spare tire until you

can slide the tire rearward and the

cable is slack.

5. Remove the retainer through the center of the wheel.

Tire change procedure

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

•Automatic transmission: Place

gearshift lever in P (Park).

•Manual transmission: Place

gearshift lever in R (Reverse).

•Electronic Shift On the Fly 4WD:

Place transfer case in any

position.

•Manual shift transfer case 4WD:

Place transfer case in 2H, 4H or

4L.

To prevent the vehicle from

moving when you change a

tire, be sure the parking brake is

set, then block (in both

directions) the wheel that is

diagonally opposite (other side

and end of the vehicle) to the tire

being changed.

2. Turn engine off and block the diagonally opposite wheel (block not

provided).

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

184

Page 185 of 280

3. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

4. Use the tip of the lug wrench to remove any wheel trim.

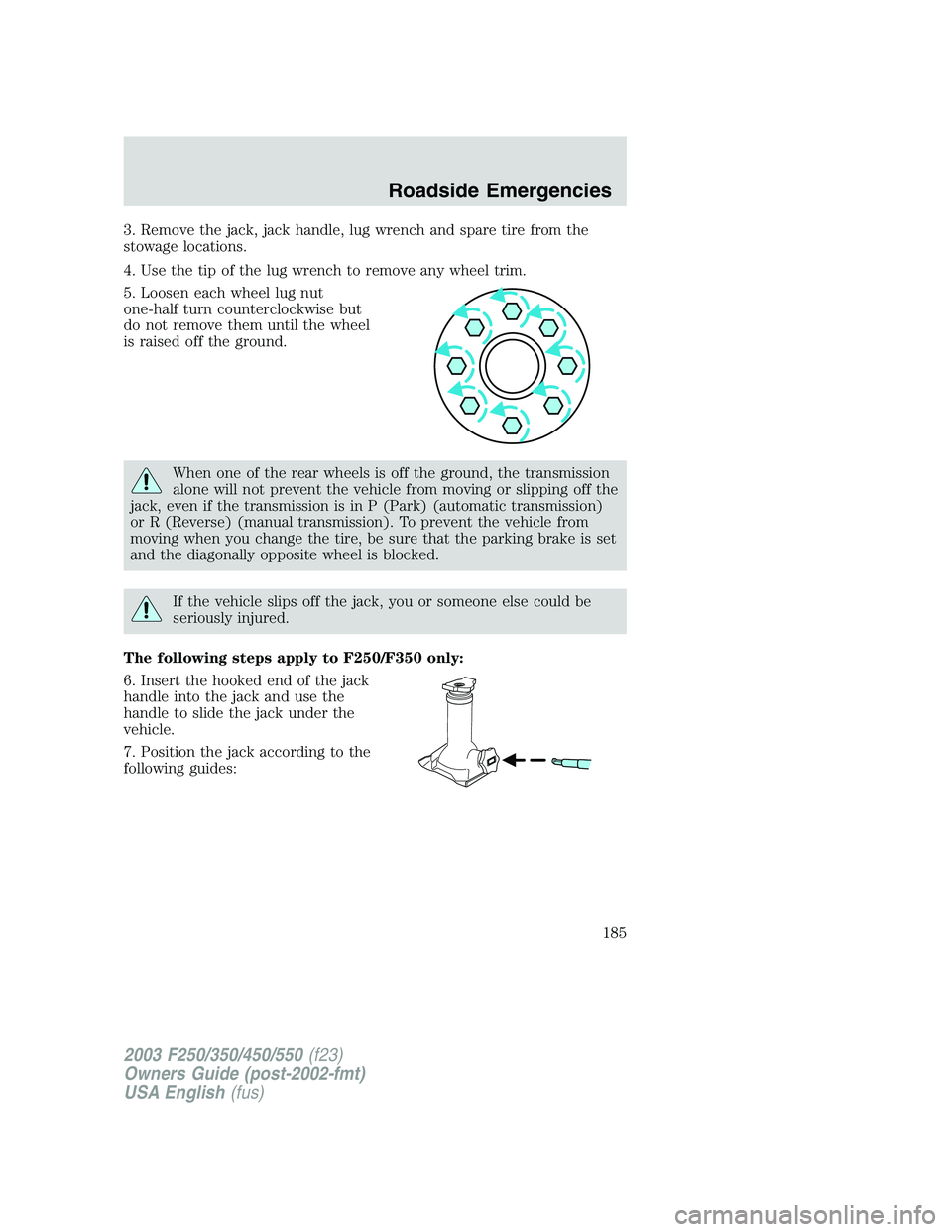

5. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park) (automatic transmission)

or R (Reverse) (manual transmission). To prevent the vehicle from

moving when you change the tire, be sure that the parking brake is set

and the diagonally opposite wheel is blocked.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

The following steps apply to F250/F350 only:

6. Insert the hooked end of the jack

handle into the jack and use the

handle to slide the jack under the

vehicle.

7. Position the jack according to the

following guides:

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

185

Page 186 of 280

•Front (4x2)

•Front passenger side (4x4)

•Front driver side (4x4)

Make sure the jack fits into the

notched area next to the differential

housing.

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

186

Page 187 of 280

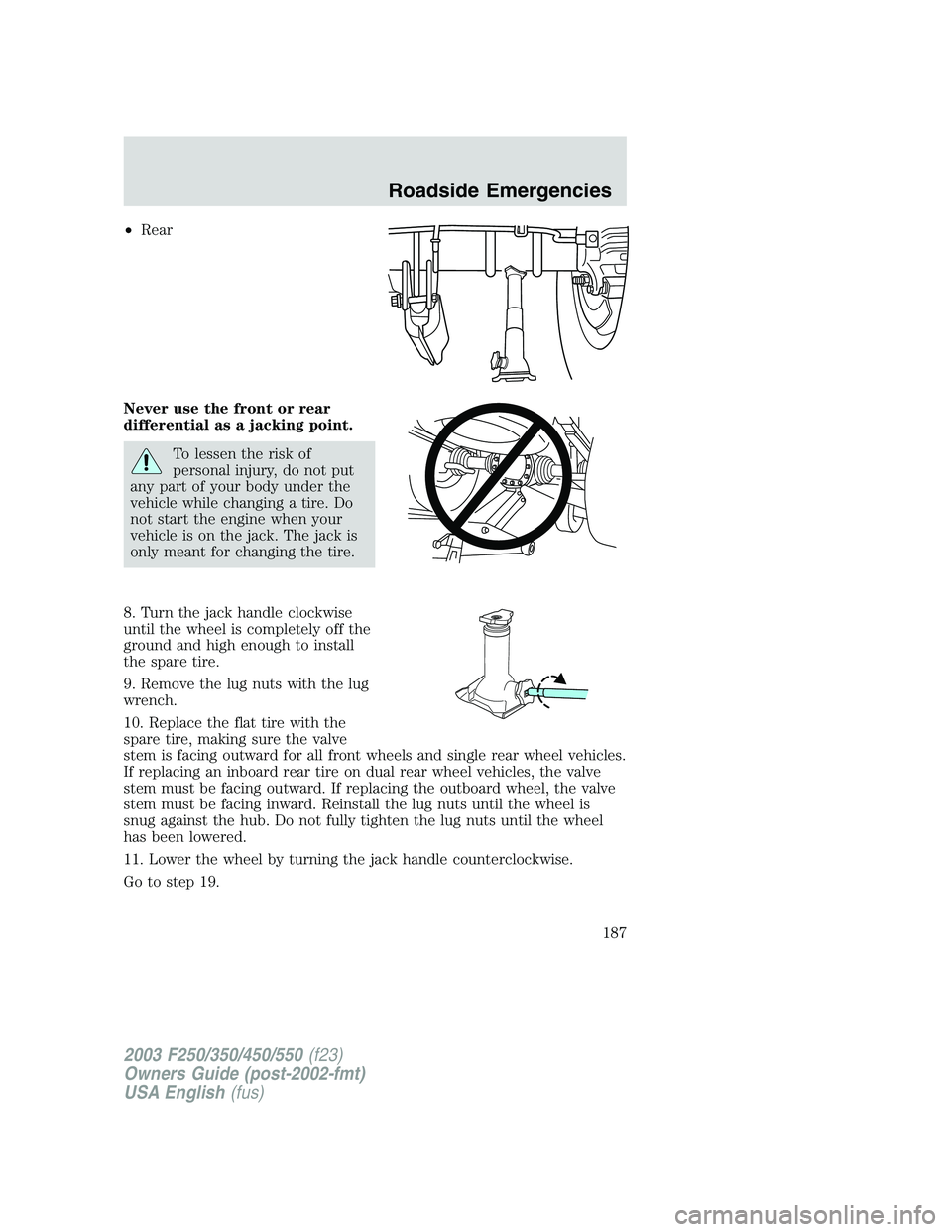

•Rear

Never use the front or rear

differential as a jacking point.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

8. Turn the jack handle clockwise

until the wheel is completely off the

ground and high enough to install

the spare tire.

9. Remove the lug nuts with the lug

wrench.

10. Replace the flat tire with the

spare tire, making sure the valve

stem is facing outward for all front wheels and single rear wheel vehicles.

If replacing an inboard rear tire on dual rear wheel vehicles, the valve

stem must be facing outward. If replacing the outboard wheel, the valve

stem must be facing inward. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

11. Lower the wheel by turning the jack handle counterclockwise.

Go to step 19.

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

187

Page 188 of 280

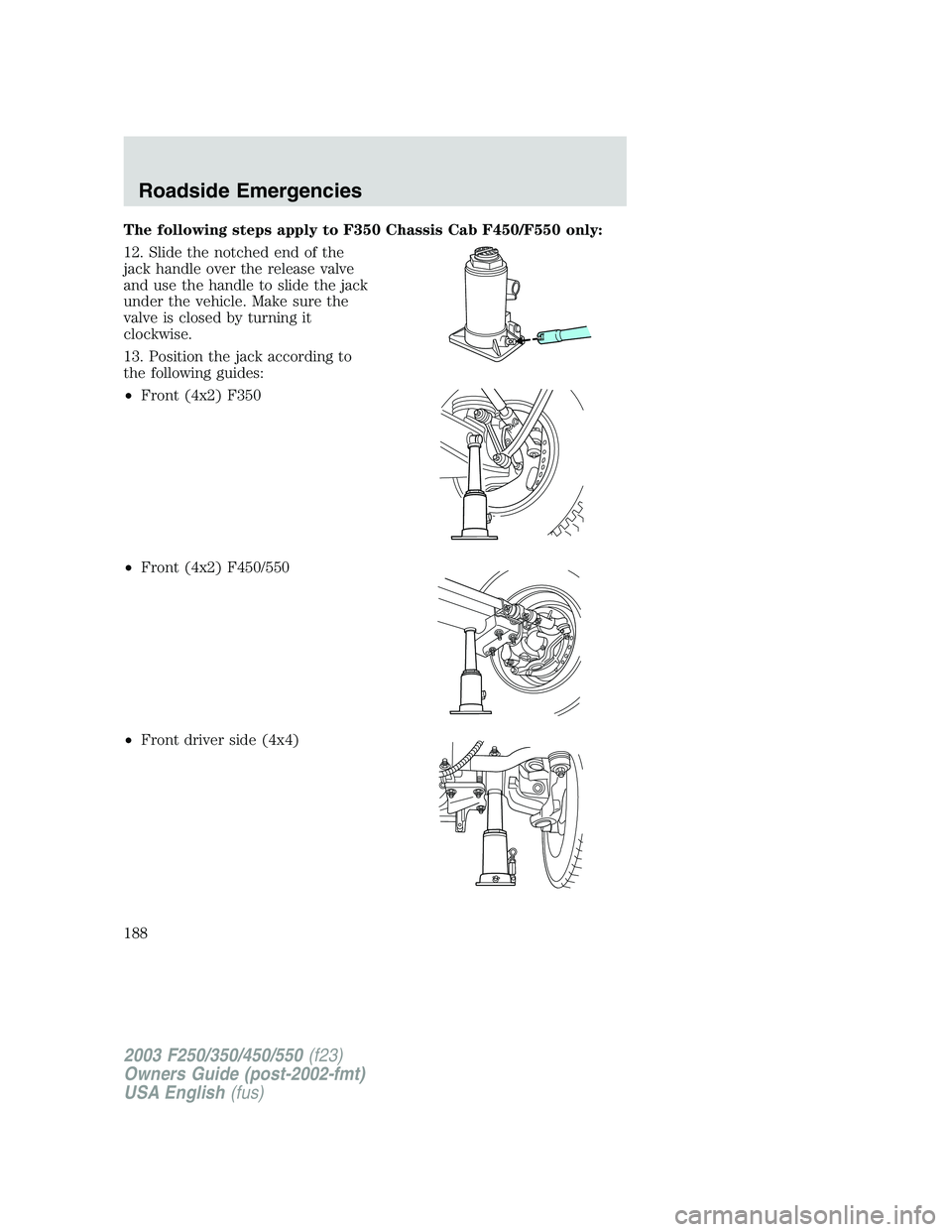

The following steps apply to F350 Chassis Cab F450/F550 only:

12. Slide the notched end of the

jack handle over the release valve

and use the handle to slide the jack

under the vehicle. Make sure the

valve is closed by turning it

clockwise.

13. Position the jack according to

the following guides:

•Front (4x2) F350

•Front (4x2) F450/550

•Front driver side (4x4)

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

188

Page 189 of 280

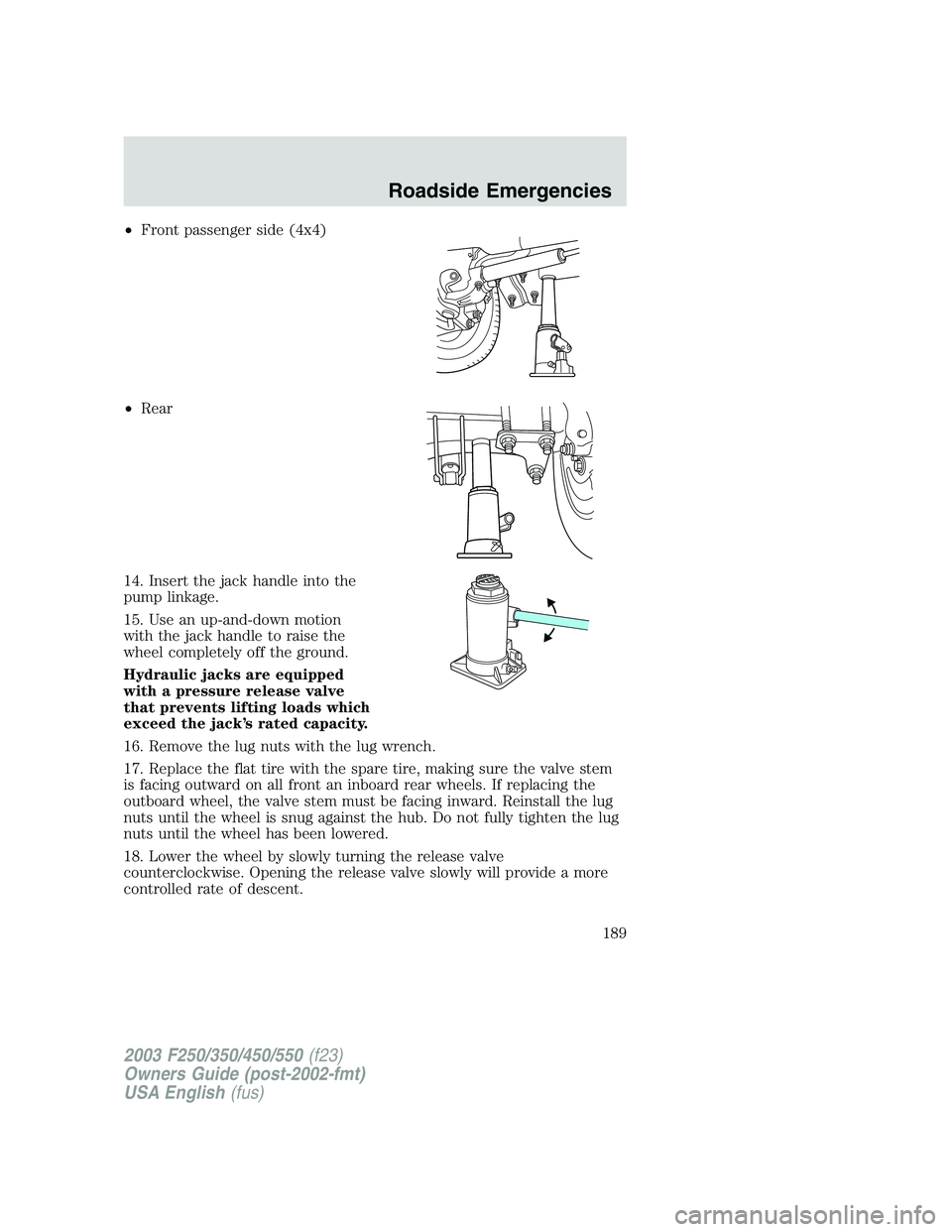

•Front passenger side (4x4)

•Rear

14. Insert the jack handle into the

pump linkage.

15. Use an up-and-down motion

with the jack handle to raise the

wheel completely off the ground.

Hydraulic jacks are equipped

with a pressure release valve

that prevents lifting loads which

exceed the jack’s rated capacity.

16. Remove the lug nuts with the lug wrench.

17. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward on all front an inboard rear wheels. If replacing the

outboard wheel, the valve stem must be facing inward. Reinstall the lug

nuts until the wheel is snug against the hub. Do not fully tighten the lug

nuts until the wheel has been lowered.

18. Lower the wheel by slowly turning the release valve

counterclockwise. Opening the release valve slowly will provide a more

controlled rate of descent.

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

189

Page 190 of 280

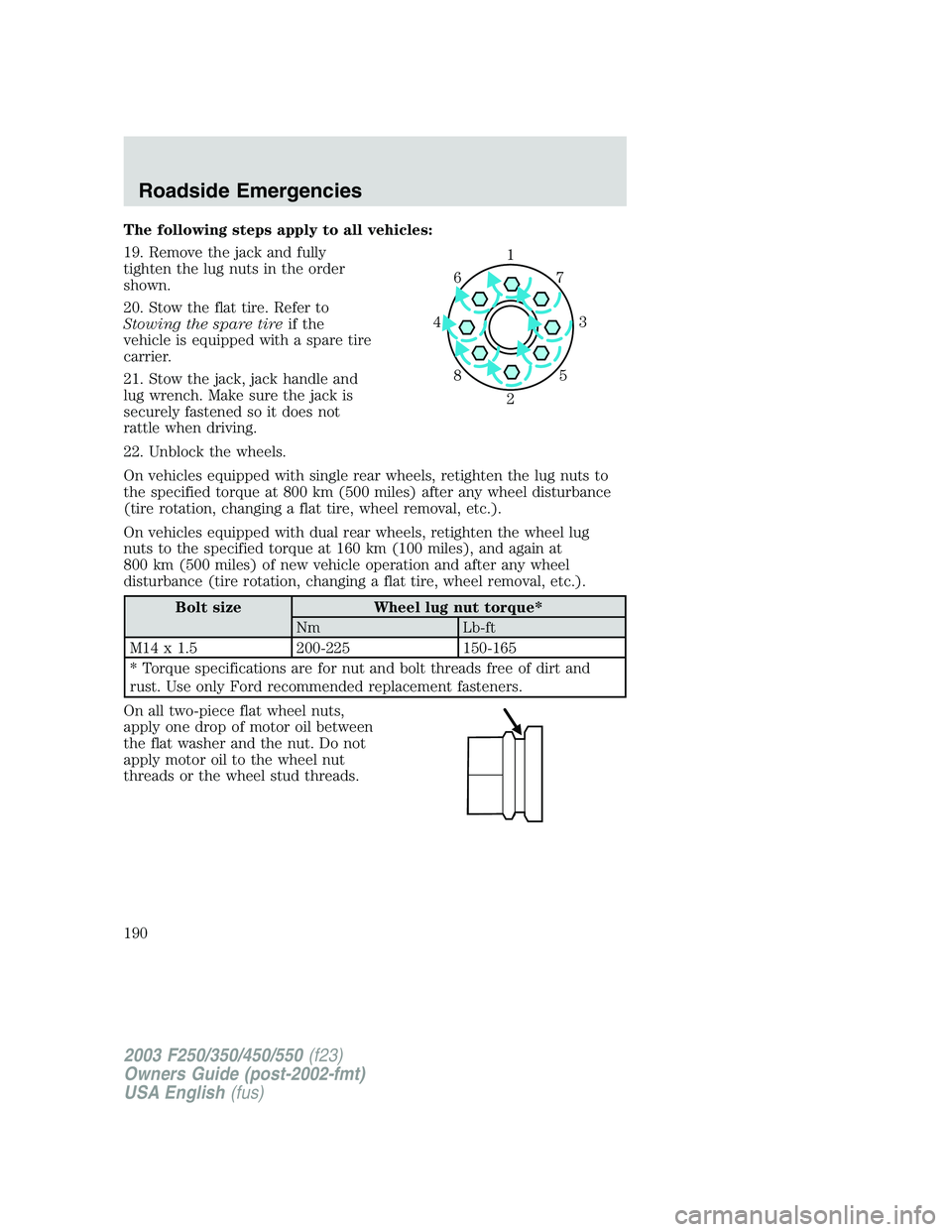

The following steps apply to all vehicles:

19. Remove the jack and fully

tighten the lug nuts in the order

shown.

20. Stow the flat tire. Refer to

Stowing the spare tireif the

vehicle is equipped with a spare tire

carrier.

21. Stow the jack, jack handle and

lug wrench. Make sure the jack is

securely fastened so it does not

rattle when driving.

22. Unblock the wheels.

On vehicles equipped with single rear wheels, retighten the lug nuts to

the specified torque at 800 km (500 miles) after any wheel disturbance

(tire rotation, changing a flat tire, wheel removal, etc.).

On vehicles equipped with dual rear wheels, retighten the wheel lug

nuts to the specified torque at 160 km (100 miles), and again at

800 km (500 miles) of new vehicle operation and after any wheel

disturbance (tire rotation, changing a flat tire, wheel removal, etc.).

Bolt size Wheel lug nut torque*

Nm Lb-ft

M14 x 1.5 200-225 150-165

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

On all two-piece flat wheel nuts,

apply one drop of motor oil between

the flat washer and the nut. Do not

apply motor oil to the wheel nut

threads or the wheel stud threads.

1

3 4

27 6

5 8

2003 F250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

190