height FORD F250 2006 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: F250, Model: FORD F250 2006Pages: 312, PDF Size: 3.19 MB

Page 42 of 312

Vertical and horizontal aim adjustment (sealed beam headlamps)

The headlamps on your vehicle are intended to be aimed using

mechanical aimers. If mechanical aimers are used and the cross-car sight

line is in any way blocked, set the legs of the universal adaptor all to the

same setting, such that the cross-car sight line is no longer blocked, per

the instructions for the brand of mechanical aimer used. You can also

aim the headlamps visually using the procedure below.

To adjust the headlamps:

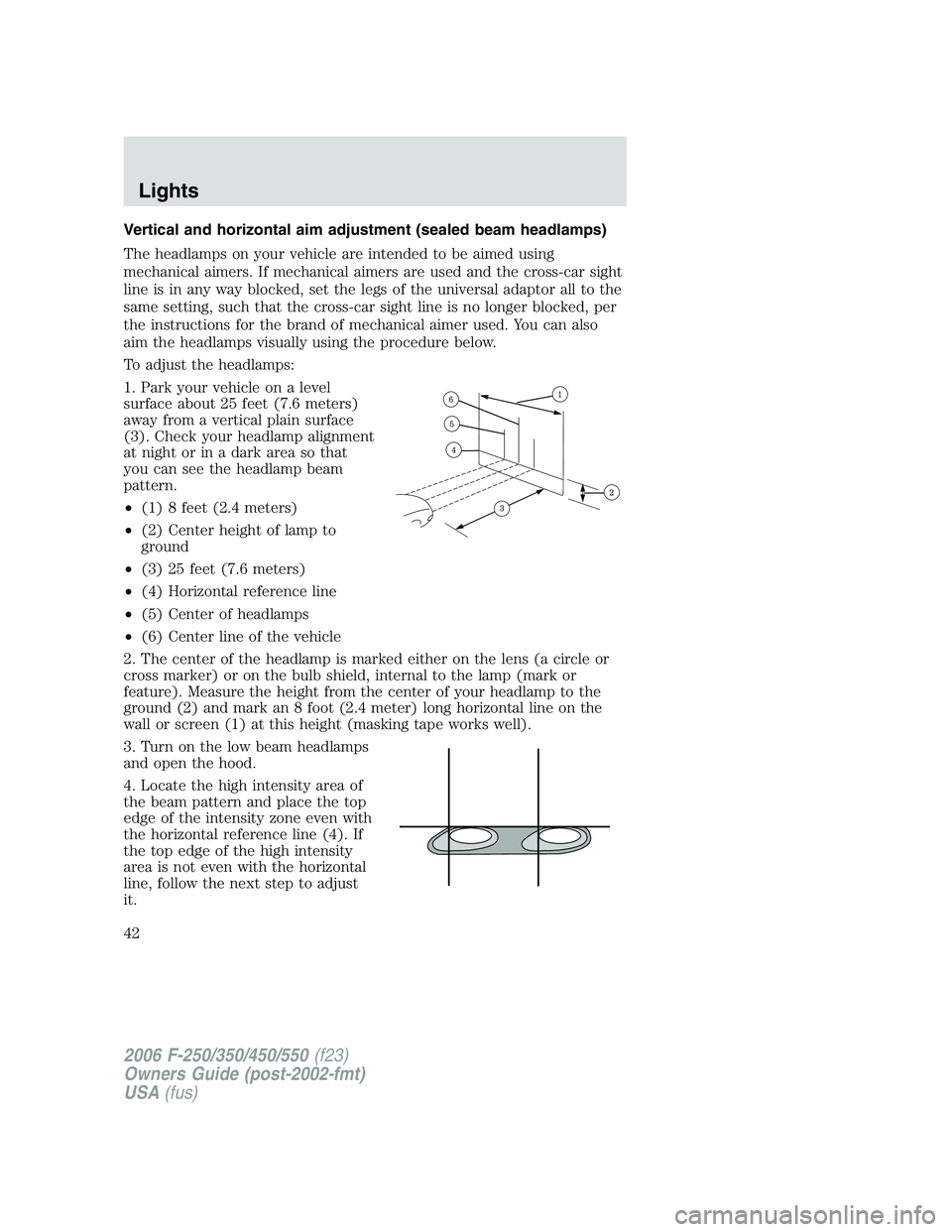

1. Park your vehicle on a level

surface about 25 feet (7.6 meters)

away from a vertical plain surface

(3). Check your headlamp alignment

at night or in a dark area so that

you can see the headlamp beam

pattern.

•(1) 8 feet (2.4 meters)

•(2) Center height of lamp to

ground

•(3) 25 feet (7.6 meters)

•(4) Horizontal reference line

•(5) Center of headlamps

•(6) Center line of the vehicle

2. The center of the headlamp is marked either on the lens (a circle or

cross marker) or on the bulb shield, internal to the lamp (mark or

feature). Measure the height from the center of your headlamp to the

ground (2) and mark an 8 foot (2.4 meter) long horizontal line on the

wall or screen (1) at this height (masking tape works well).

3. Turn on the low beam headlamps

and open the hood.

4. Locate the high intensity area of

the beam pattern and place the top

edge of the intensity zone even with

the horizontal reference line (4). If

the top edge of the high intensity

area is not even with the horizontal

line, follow the next step to adjust

it.

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Lights

42

Page 43 of 312

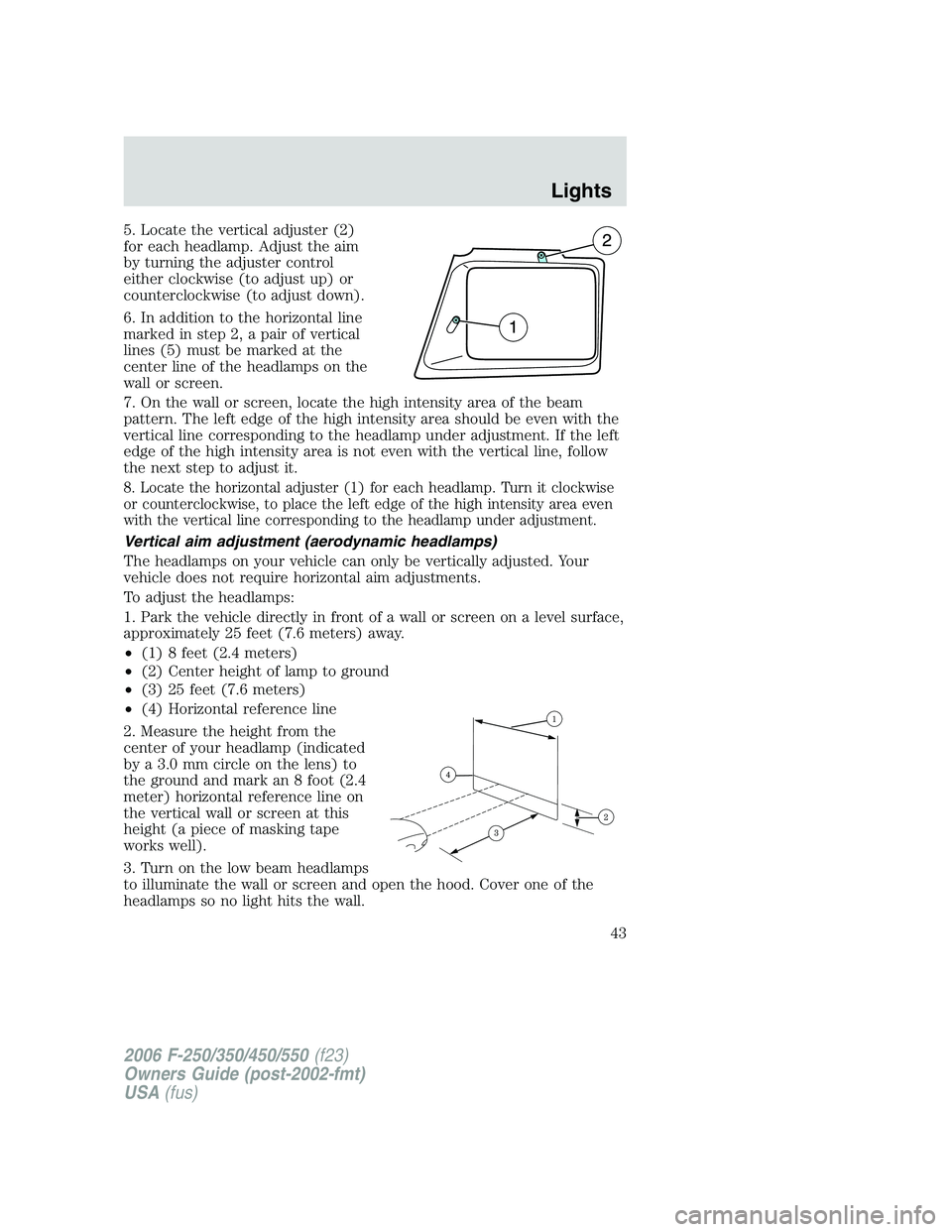

5. Locate the vertical adjuster (2)

for each headlamp. Adjust the aim

by turning the adjuster control

either clockwise (to adjust up) or

counterclockwise (to adjust down).

6. In addition to the horizontal line

marked in step 2, a pair of vertical

lines (5) must be marked at the

center line of the headlamps on the

wall or screen.

7. On the wall or screen, locate the high intensity area of the beam

pattern. The left edge of the high intensity area should be even with the

vertical line corresponding to the headlamp under adjustment. If the left

edge of the high intensity area is not even with the vertical line, follow

the next step to adjust it.

8. Locate the horizontal adjuster (1) for each headlamp. Turn it clockwise

or counterclockwise, to place the left edge of the high intensity area even

with the vertical line corresponding to the headlamp under adjustment.

Vertical aim adjustment (aerodynamic headlamps)

The headlamps on your vehicle can only be vertically adjusted. Your

vehicle does not require horizontal aim adjustments.

To adjust the headlamps:

1. Park the vehicle directly in front of a wall or screen on a level surface,

approximately 25 feet (7.6 meters) away.

•(1) 8 feet (2.4 meters)

•(2) Center height of lamp to ground

•(3) 25 feet (7.6 meters)

•(4) Horizontal reference line

2. Measure the height from the

center of your headlamp (indicated

by a 3.0 mm circle on the lens) to

the ground and mark an 8 foot (2.4

meter) horizontal reference line on

the vertical wall or screen at this

height (a piece of masking tape

works well).

3. Turn on the low beam headlamps

to illuminate the wall or screen and open the hood. Cover one of the

headlamps so no light hits the wall.

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Lights

43

Page 44 of 312

4. On the wall or screen you will

observe a light pattern with a

distinct horizontal edge towards the

right. If this edge is not at the

horizontal reference line, the beam will need to be adjusted so the edge

is at the same height as the horizontal reference line.

5. Locate the vertical adjuster on

each headlamp, then use a E5 Torx

socket to turn the adjuster either

counterclockwise (to adjust down)

or clockwise (to adjust up) aligning

the upper edge of the light pattern

up to the horizontal line.

6. Repeat Steps 3–5 for the other

headlamp.

7. Close the hood and turn off the

lamps.

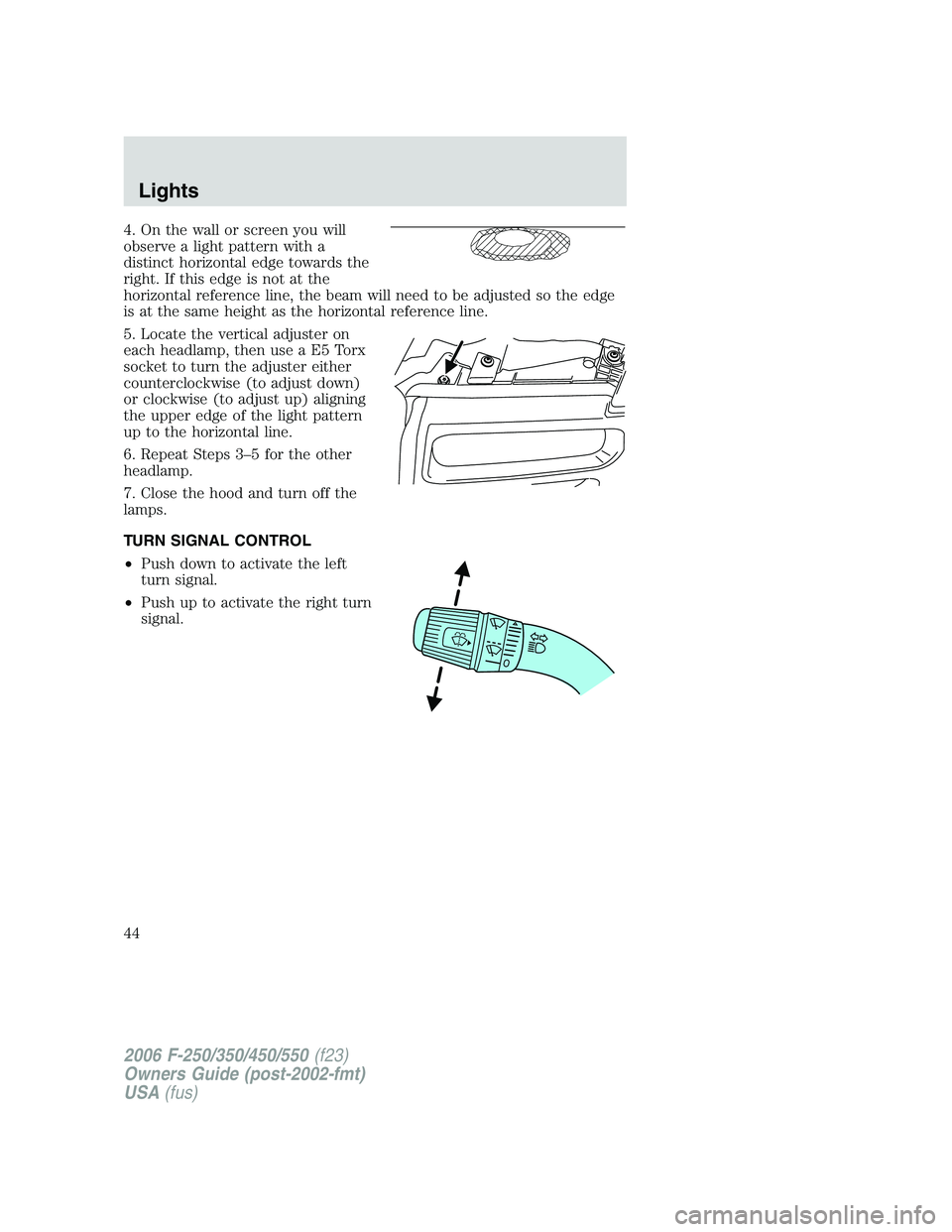

TURN SIGNAL CONTROL

•Push down to activate the left

turn signal.

•Push up to activate the right turn

signal.

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Lights

44

Page 101 of 312

BELT AND RETRACTOR ASSEMBLY MUST BE REPLACED if

the seat belt assembly “automatic locking retractor” feature or

any other seat belt function is not operating properly when checked

according to the procedures in theWorkshop Manual. Failure to

replace the belt and retractor assembly could increase the risk of

injury in collisions.

Energy Management Feature

•This vehicle has a seat belt system with an energy management

feature at the front outboard seating positions to help further reduce

the risk of injury in the event of a head-on collision.

•The front outboard seat belt systems have a retractor assembly that is

designed to pay out webbing in a controlled manner. This feature is

designed to help reduce the belt force acting on the occupant’s chest.

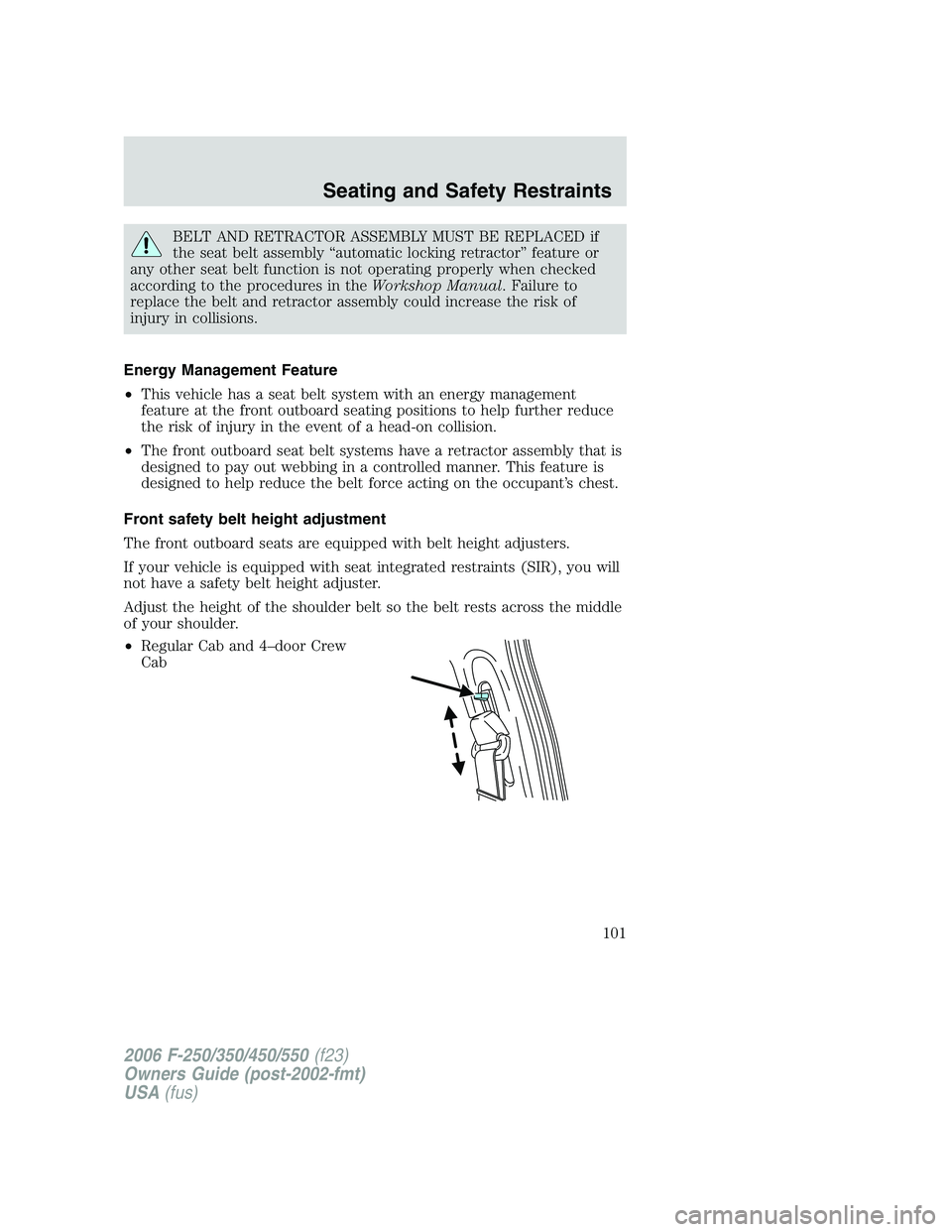

Front safety belt height adjustment

The front outboard seats are equipped with belt height adjusters.

If your vehicle is equipped with seat integrated restraints (SIR), you will

not have a safety belt height adjuster.

Adjust the height of the shoulder belt so the belt rests across the middle

of your shoulder.

•Regular Cab and 4–door Crew

Cab

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Seating and Safety Restraints

101

Page 102 of 312

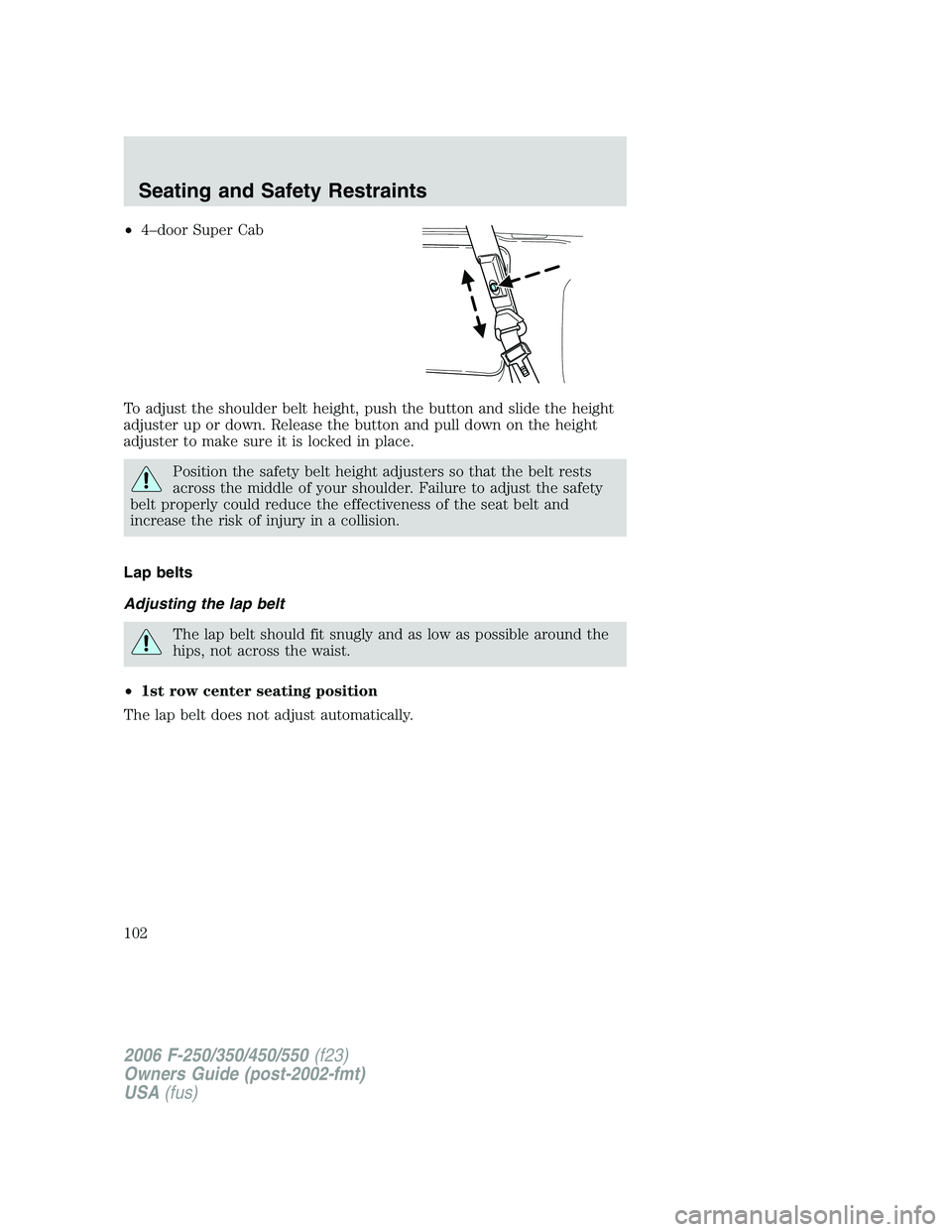

•4–door Super Cab

To adjust the shoulder belt height, push the button and slide the height

adjuster up or down. Release the button and pull down on the height

adjuster to make sure it is locked in place.

Position the safety belt height adjusters so that the belt rests

across the middle of your shoulder. Failure to adjust the safety

belt properly could reduce the effectiveness of the seat belt and

increase the risk of injury in a collision.

Lap belts

Adjusting the lap belt

The lap belt should fit snugly and as low as possible around the

hips, not across the waist.

•1st row center seating position

The lap belt does not adjust automatically.

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Seating and Safety Restraints

102

Page 108 of 312

the label. Also, use the safety belt extension only if the safety belt is too

short for you when fully extended.

Do not use extensions to change the fit of the shoulder belt

across the torso.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, tears or cuts. Replace if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), shoulder belt guide on seatback (if

equipped), child safety seat LATCH and tether anchors, and attaching

hardware, should be inspected after a collision. Ford Motor Company

recommends that all safety belt assemblies in use in vehicles involved in

a collision be replaced. However, if the collision was minor and your

authorized dealer finds that the belts do not show damage and continue

to operate properly, they do not need to be replaced. Safety belt

assemblies not in use during a collision should also be inspected and

replaced if either damage or improper operation is noted.

Failure to inspect and if necessary replace the safety belt

assembly under the above conditions could result in severe

personal injuries in the event of a collision.

For proper care of soiled safety belts, refer toInteriorin theCleaning

chapter.

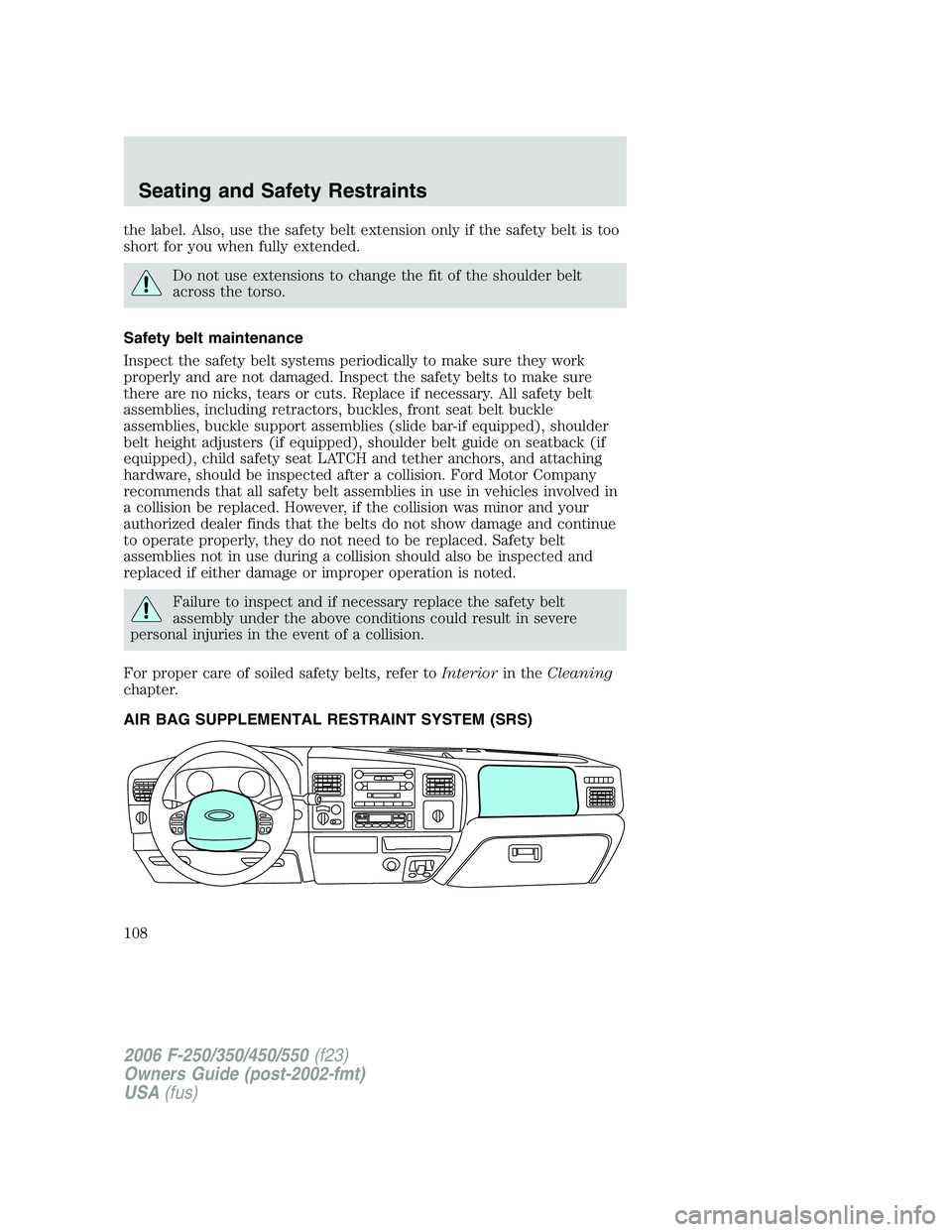

AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Seating and Safety Restraints

108

Page 138 of 312

Improper or inadequate vehicle maintenance can cause tires to wear

abnormally. Inspect all your tires, including the spare, frequently, and

replace them if one or more of the following conditions exist:

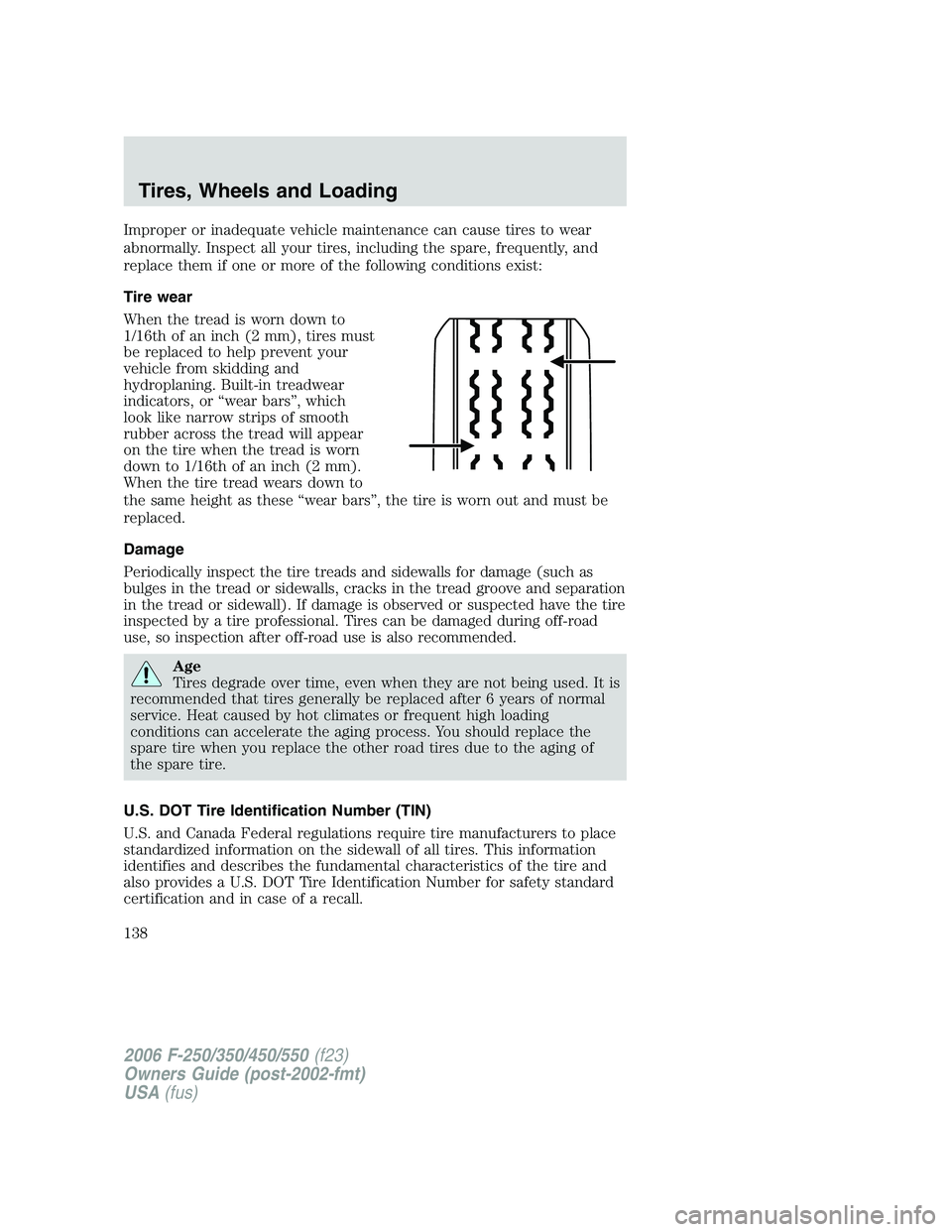

Tire wear

When the tread is worn down to

1/16th of an inch (2 mm), tires must

be replaced to help prevent your

vehicle from skidding and

hydroplaning. Built-in treadwear

indicators, or “wear bars”, which

look like narrow strips of smooth

rubber across the tread will appear

on the tire when the tread is worn

down to 1/16th of an inch (2 mm).

When the tire tread wears down to

the same height as these “wear bars”, the tire is worn out and must be

replaced.

Damage

Periodically inspect the tire treads and sidewalls for damage (such as

bulges in the tread or sidewalls, cracks in the tread groove and separation

in the tread or sidewall). If damage is observed or suspected have the tire

inspected by a tire professional. Tires can be damaged during off-road

use, so inspection after off-road use is also recommended.

Age

Tires degrade over time, even when they are not being used. It is

recommended that tires generally be replaced after 6 years of normal

service. Heat caused by hot climates or frequent high loading

conditions can accelerate the aging process. You should replace the

spare tire when you replace the other road tires due to the aging of

the spare tire.

U.S. DOT Tire Identification Number (TIN)

U.S. and Canada Federal regulations require tire manufacturers to place

standardized information on the sidewall of all tires. This information

identifies and describes the fundamental characteristics of the tire and

also provides a U.S. DOT Tire Identification Number for safety standard

certification and in case of a recall.

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

138

Page 143 of 312

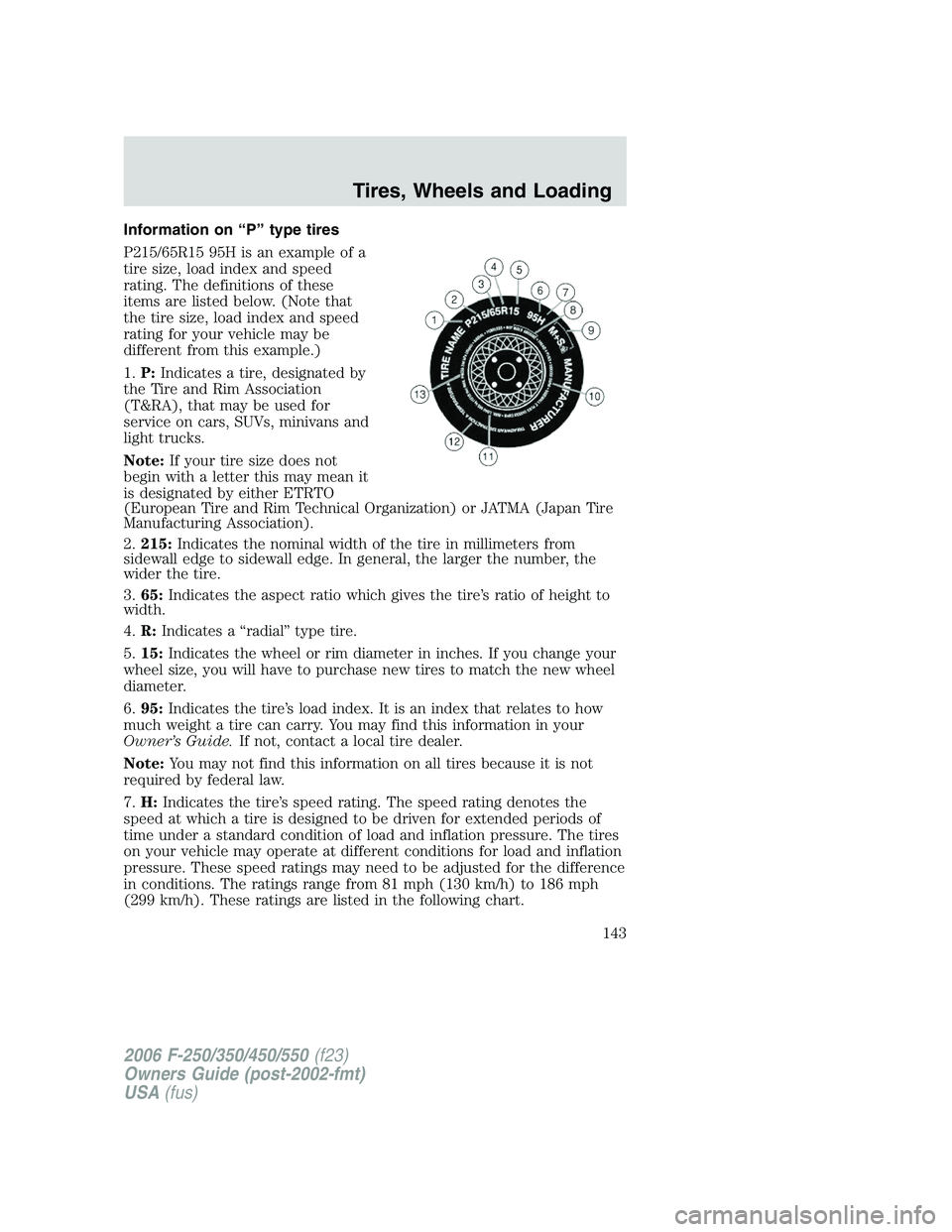

Information on “P” type tires

P215/65R15 95H is an example of a

tire size, load index and speed

rating. The definitions of these

items are listed below. (Note that

the tire size, load index and speed

rating for your vehicle may be

different from this example.)

1.P:Indicates a tire, designated by

the Tire and Rim Association

(T&RA), that may be used for

service on cars, SUVs, minivans and

light trucks.

Note:If your tire size does not

begin with a letter this may mean it

is designated by either ETRTO

(European Tire and Rim Technical Organization) or JATMA (Japan Tire

Manufacturing Association).

2.215:Indicates the nominal width of the tire in millimeters from

sidewall edge to sidewall edge. In general, the larger the number, the

wider the tire.

3.65:Indicates the aspect ratio which gives the tire’s ratio of height to

width.

4.R:Indicates a “radial” type tire.

5.15:Indicates the wheel or rim diameter in inches. If you change your

wheel size, you will have to purchase new tires to match the new wheel

diameter.

6.95:Indicates the tire’s load index. It is an index that relates to how

much weight a tire can carry. You may find this information in your

Owner’s Guide.If not, contact a local tire dealer.

Note:You may not find this information on all tires because it is not

required by federal law.

7.H:Indicates the tire’s speed rating. The speed rating denotes the

speed at which a tire is designed to be driven for extended periods of

time under a standard condition of load and inflation pressure. The tires

on your vehicle may operate at different conditions for load and inflation

pressure. These speed ratings may need to be adjusted for the difference

in conditions. The ratings range from 81 mph (130 km/h) to 186 mph

(299 km/h). These ratings are listed in the following chart.

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

143

Page 147 of 312

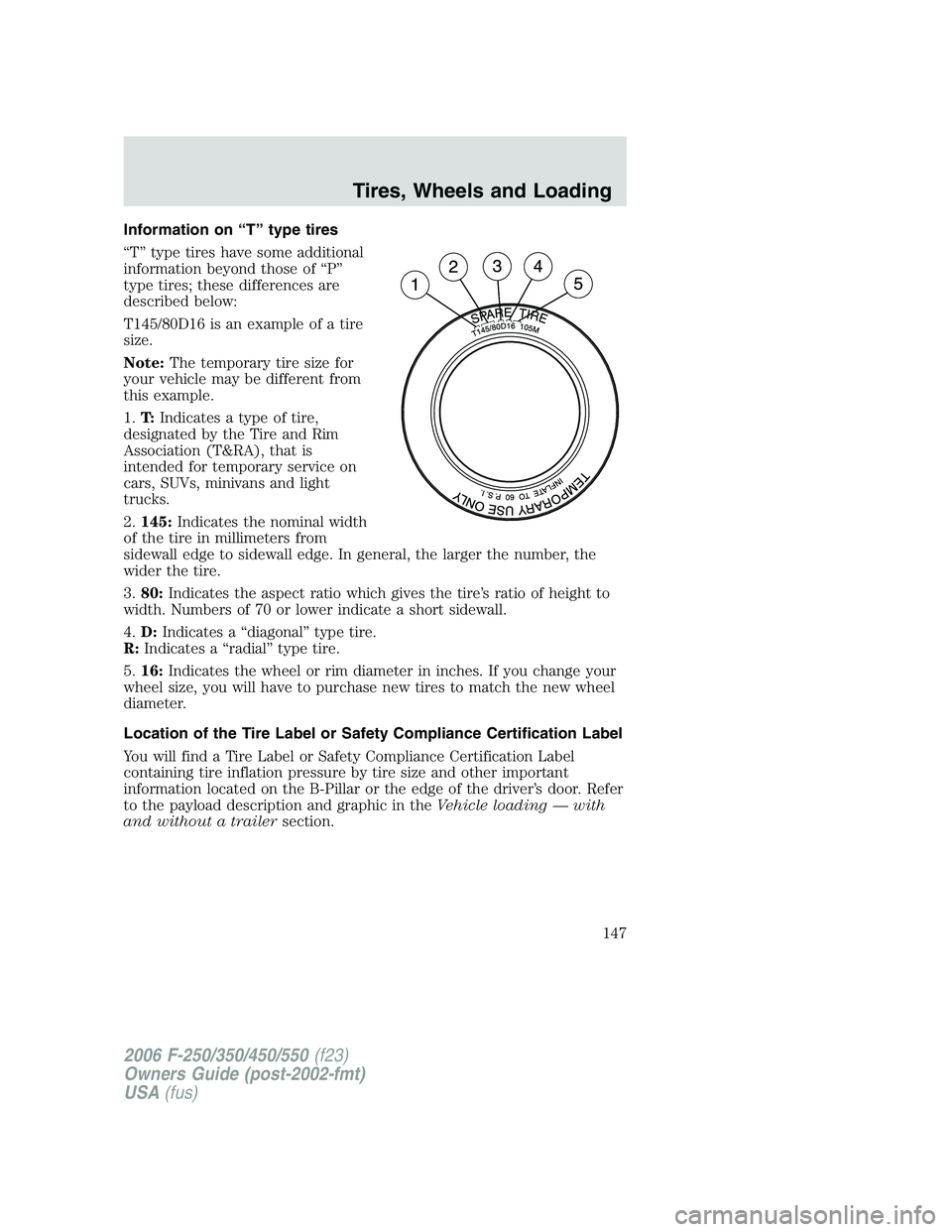

Information on “T” type tires

“T” type tires have some additional

information beyond those of “P”

type tires; these differences are

described below:

T145/80D16 is an example of a tire

size.

Note:The temporary tire size for

your vehicle may be different from

this example.

1.T:Indicates a type of tire,

designated by the Tire and Rim

Association (T&RA), that is

intended for temporary service on

cars, SUVs, minivans and light

trucks.

2.145:Indicates the nominal width

of the tire in millimeters from

sidewall edge to sidewall edge. In general, the larger the number, the

wider the tire.

3.80:Indicates the aspect ratio which gives the tire’s ratio of height to

width. Numbers of 70 or lower indicate a short sidewall.

4.D:Indicates a “diagonal” type tire.

R:Indicates a “radial” type tire.

5.16:Indicates the wheel or rim diameter in inches. If you change your

wheel size, you will have to purchase new tires to match the new wheel

diameter.

Location of the Tire Label or Safety Compliance Certification Label

You will find a Tire Label or Safety Compliance Certification Label

containing tire inflation pressure by tire size and other important

information located on the B-Pillar or the edge of the driver’s door. Refer

to the payload description and graphic in theVehicle loading — with

and without a trailersection.

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

147

Page 158 of 312

Towing trailers beyond the maximum tongue weight exceeds the

limit of the towing system and could result in vehicle structural

damage, loss of vehicle control and personal injury.

Load equalizing hitch

When hooking up a trailer using a load equalizing hitch, always use the

following procedure:

1. Park the unloaded vehicle on a level surface. With the ignition on and

all doors closed, allow the vehicle to stand for several minutes so that it

can level.

2. Measure the height of a reference point on the front and rear bumpers

at the center of the vehicle.

3. Attach the trailer to the vehicle and adjust the hitch equalizers so that

the front bumper height is within

1�2” (13 mm) of the reference point.

After proper adjustment, the rear bumper should be no higher than in

Step 2.

Note:Adjusting an equalizing hitch so the rear bumper of the vehicle is

higher than it was unloaded will defeat the function of the load

equalizing hitch and may cause unpredictable handling.

Safety chains

Always connect the trailer’s safety chains to the frame or hook retainers

of the vehicle hitch. To connect the trailer’s safety chains, cross the

chains under the trailer tongue and allow slack for turning corners.

If you use a rental trailer, follow the instructions that the rental agency

gives to you.

Do not attach safety chains to the bumper.

Trailer brakes

Electric brakes and manual, automatic or surge-type trailer brakes are safe

if installed properly and adjusted to the manufacturer’s specifications. The

trailer brakes must meet local and Federal regulations.

If you own a trailer with a hydraulic brake system, do not

connect the trailer’s hydraulic brake system directly to your

vehicle’s brake system. The vehicle’s brake system is only designed to

carry the appropriate amount of brake fluid for the vehicle alone.

Connecting a hydraulic trailer braking system could adversely affect

your vehicle’s braking performance.

2006 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

158