clock FORD F250 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: F250, Model: FORD F250 2007Pages: 312, PDF Size: 3.23 MB

Page 58 of 312

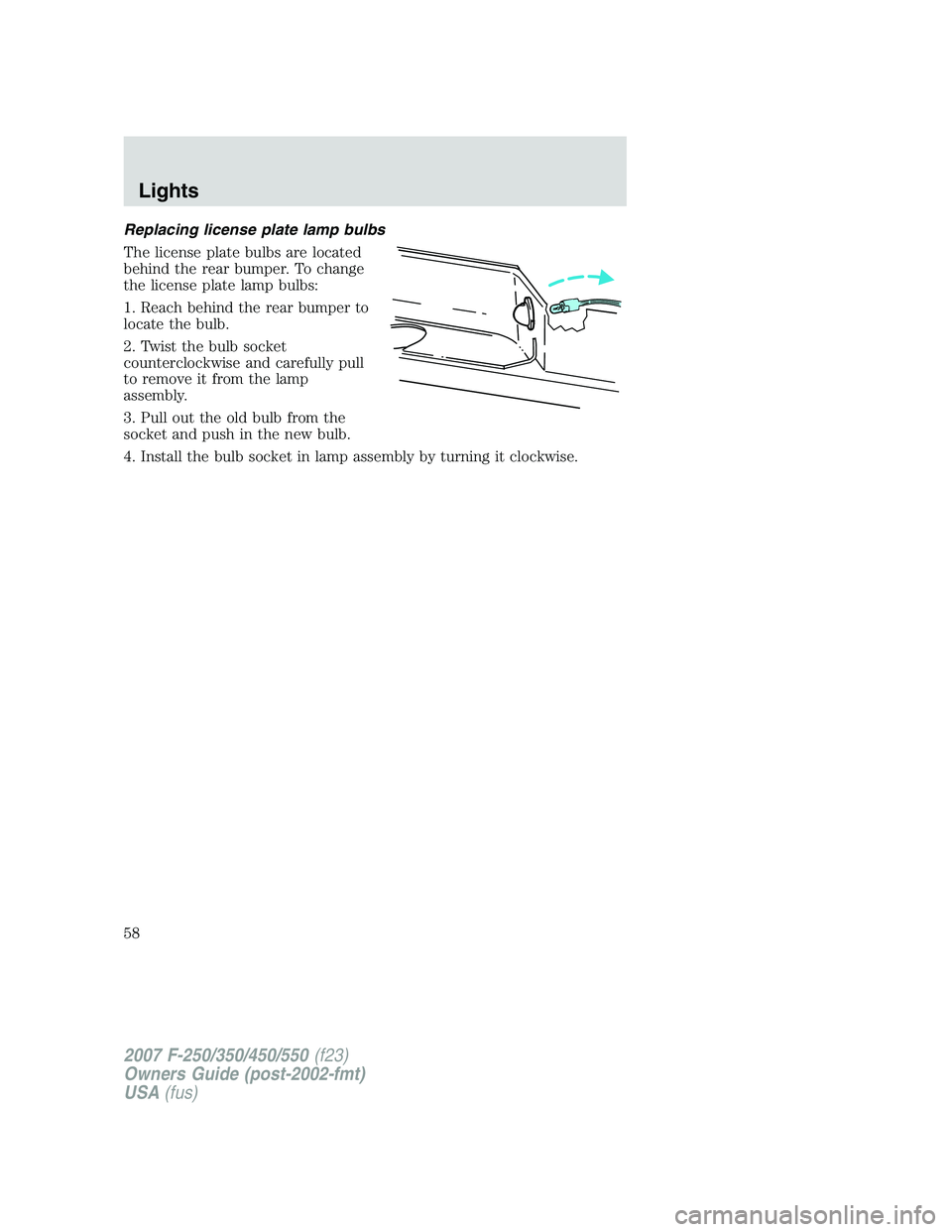

Replacing license plate lamp bulbs

The license plate bulbs are located

behind the rear bumper. To change

the license plate lamp bulbs:

1. Reach behind the rear bumper to

locate the bulb.

2. Twist the bulb socket

counterclockwise and carefully pull

to remove it from the lamp

assembly.

3. Pull out the old bulb from the

socket and push in the new bulb.

4. Install the bulb socket in lamp assembly by turning it clockwise.

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Lights

58

Page 64 of 312

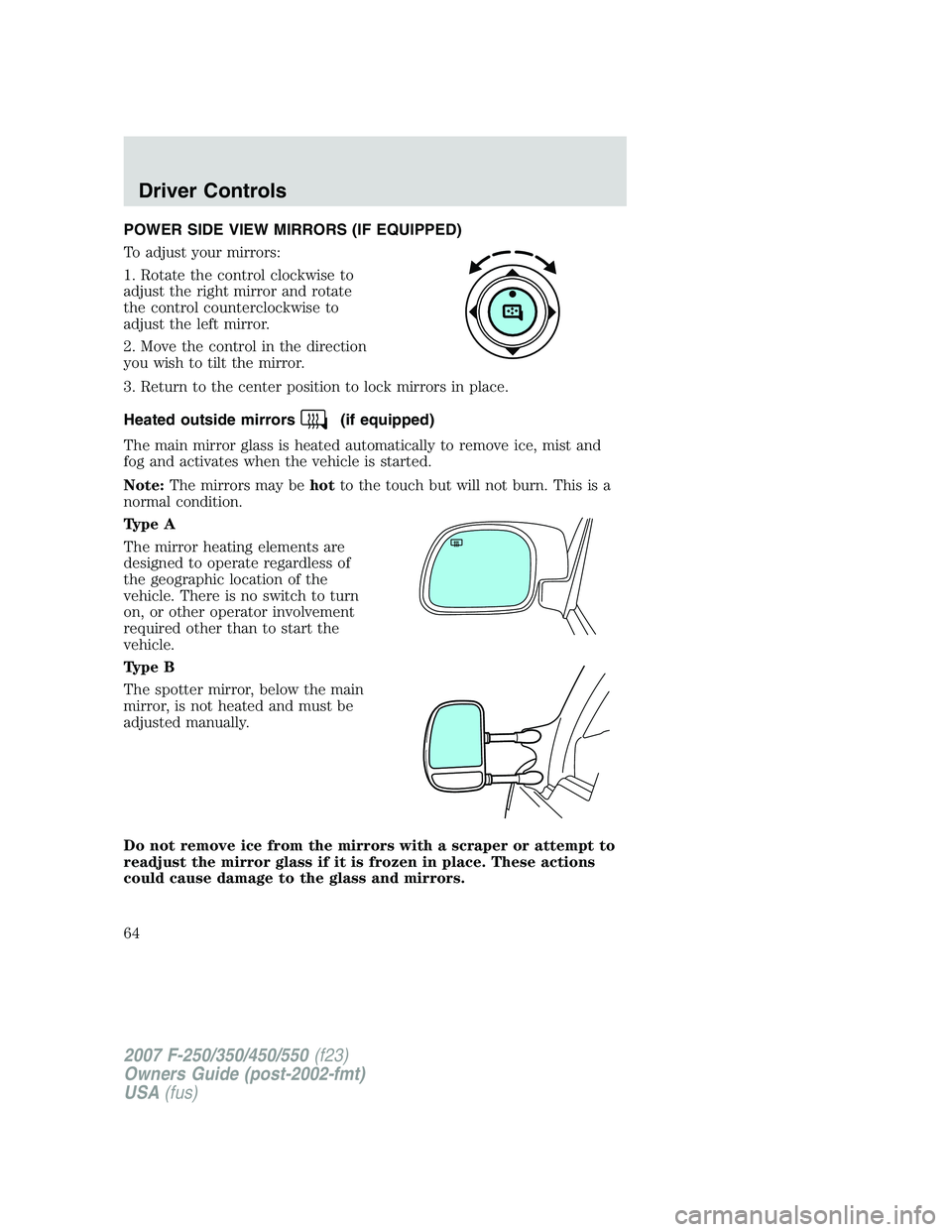

POWER SIDE VIEW MIRRORS (IF EQUIPPED)

To adjust your mirrors:

1. Rotate the control clockwise to

adjust the right mirror and rotate

the control counterclockwise to

adjust the left mirror.

2. Move the control in the direction

you wish to tilt the mirror.

3. Return to the center position to lock mirrors in place.

Heated outside mirrors

(if equipped)

The main mirror glass is heated automatically to remove ice, mist and

fog and activates when the vehicle is started.

Note:The mirrors may behotto the touch but will not burn. This is a

normal condition.

Type A

The mirror heating elements are

designed to operate regardless of

the geographic location of the

vehicle. There is no switch to turn

on, or other operator involvement

required other than to start the

vehicle.

Type B

The spotter mirror, below the main

mirror, is not heated and must be

adjusted manually.

Do not remove ice from the mirrors with a scraper or attempt to

readjust the mirror glass if it is frozen in place. These actions

could cause damage to the glass and mirrors.

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Driver Controls

64

Page 190 of 312

If your vehicle sustains damage to the rear bumper/fascia, leaving

it misaligned or bent, the sensing zone may be altered causing

inaccurate measurement of obstacles or false alarms.

FOUR-WHEEL DRIVE (4WD) OPERATION (IF EQUIPPED)

For important information regarding safe operation of this type

of vehicle, seePreparing to drive your vehiclein this chapter.

When four–wheel drive (4WD) is engaged, power is supplied to all four

wheels through a transfer case. 4WD can be selected when additional

traction is desired.

4WD operation is not recommended on dry pavement. Doing so could

result in difficult disengagement of the transfer case, increased tire wear

and decreased fuel economy.

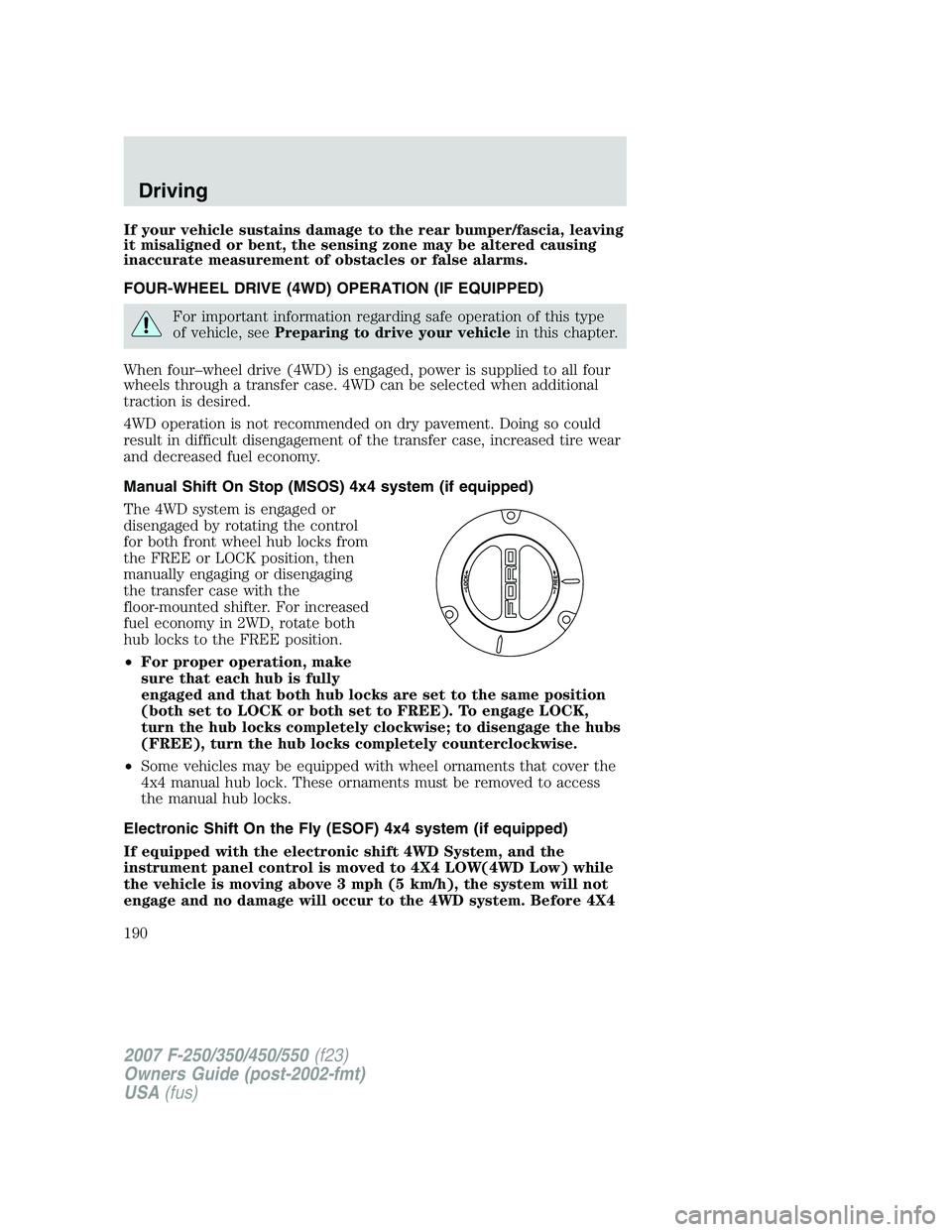

Manual Shift On Stop (MSOS) 4x4 system (if equipped)

The 4WD system is engaged or

disengaged by rotating the control

for both front wheel hub locks from

the FREE or LOCK position, then

manually engaging or disengaging

the transfer case with the

floor-mounted shifter. For increased

fuel economy in 2WD, rotate both

hub locks to the FREE position.

•For proper operation, make

sure that each hub is fully

engaged and that both hub locks are set to the same position

(both set to LOCK or both set to FREE). To engage LOCK,

turn the hub locks completely clockwise; to disengage the hubs

(FREE), turn the hub locks completely counterclockwise.

•Some vehicles may be equipped with wheel ornaments that cover the

4x4 manual hub lock. These ornaments must be removed to access

the manual hub locks.

Electronic Shift On the Fly (ESOF) 4x4 system (if equipped)

If equipped with the electronic shift 4WD System, and the

instrument panel control is moved to 4X4 LOW(4WD Low) while

the vehicle is moving above 3 mph (5 km/h), the system will not

engage and no damage will occur to the 4WD system. Before 4X4

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Driving

190

Page 191 of 312

LOW (4WD Low) can be engaged, the vehicle speed must be

below 3 mph (5 km/h) with the brake pedal depressed and the

transmission in N (Neutral). This vehicle is equipped with a

non-synchronous low range gearset which will not allow the

transfer case to shift into 4X4 LOW (4WD Low) if vehicle speed

is above 3 mph (5 km/h). It is recommended that a shift to 4X4

LOW (4WD Low) is performed while the vehicle is rolling at a

speed below 3 mph (5 km/h).

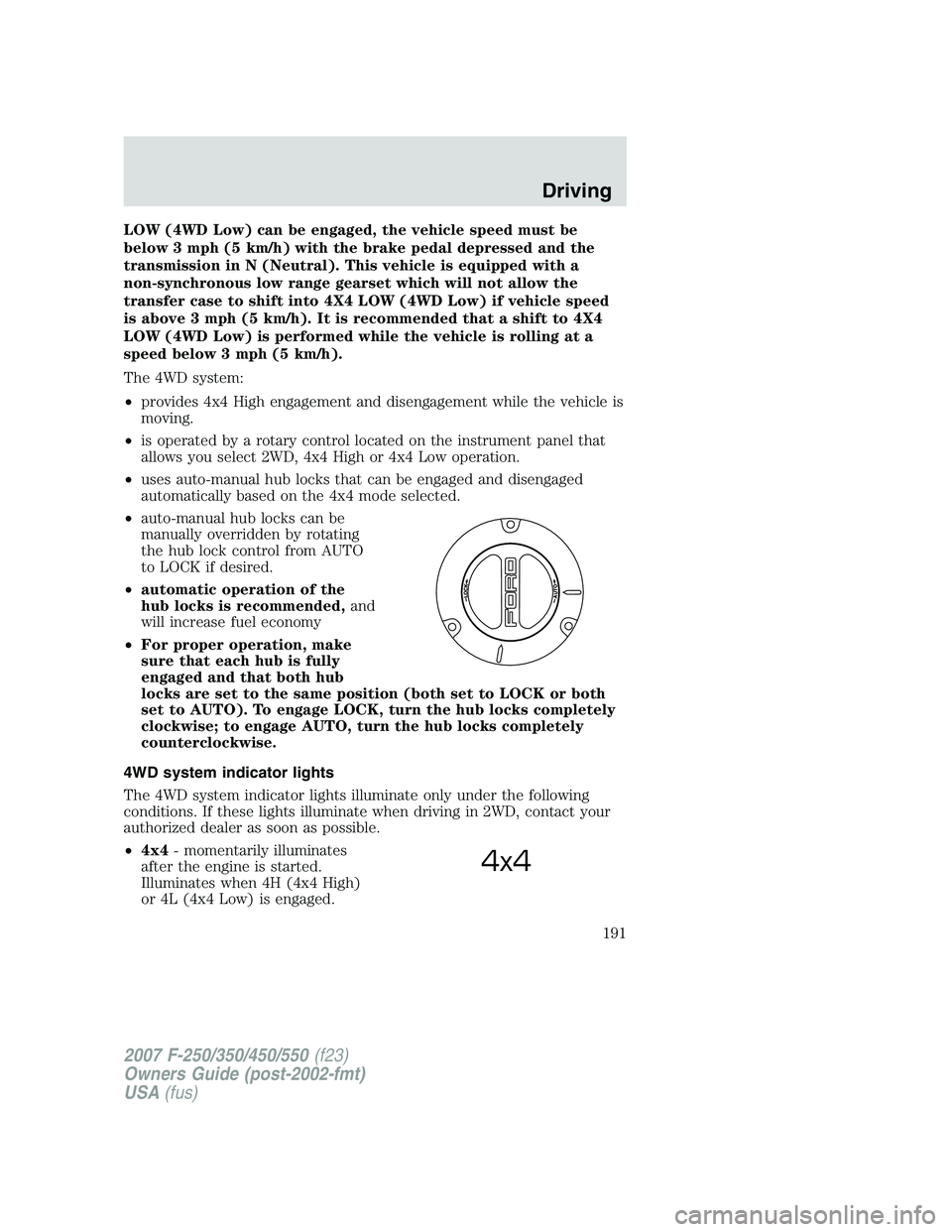

The 4WD system:

•provides 4x4 High engagement and disengagement while the vehicle is

moving.

•is operated by a rotary control located on the instrument panel that

allows you select 2WD, 4x4 High or 4x4 Low operation.

•uses auto-manual hub locks that can be engaged and disengaged

automatically based on the 4x4 mode selected.

•auto-manual hub locks can be

manually overridden by rotating

the hub lock control from AUTO

to LOCK if desired.

•automatic operation of the

hub locks is recommended,and

will increase fuel economy

•For proper operation, make

sure that each hub is fully

engaged and that both hub

locks are set to the same position (both set to LOCK or both

set to AUTO). To engage LOCK, turn the hub locks completely

clockwise; to engage AUTO, turn the hub locks completely

counterclockwise.

4WD system indicator lights

The 4WD system indicator lights illuminate only under the following

conditions. If these lights illuminate when driving in 2WD, contact your

authorized dealer as soon as possible.

•4x4- momentarily illuminates

after the engine is started.

Illuminates when 4H (4x4 High)

or 4L (4x4 Low) is engaged.

4x4

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Driving

191

Page 224 of 312

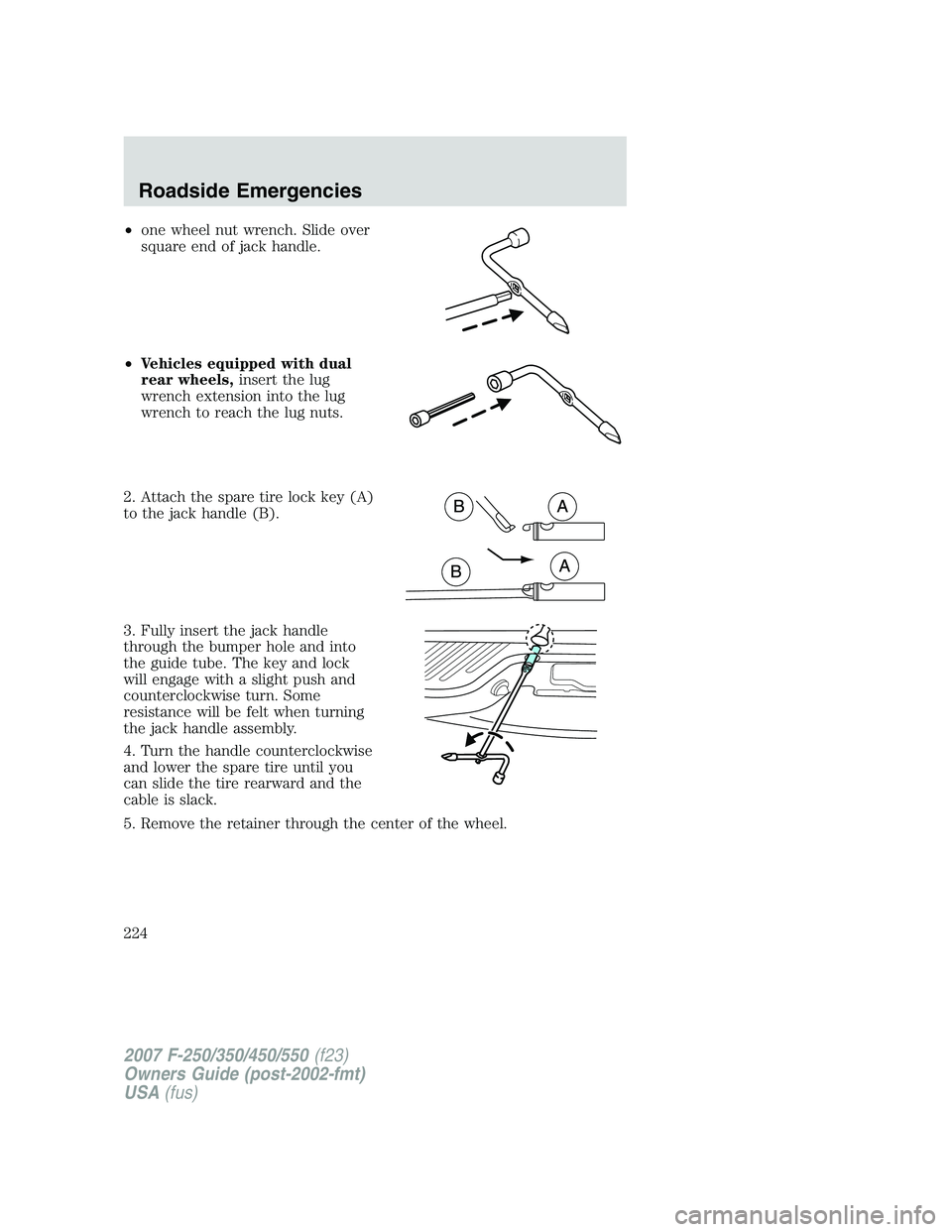

•one wheel nut wrench. Slide over

square end of jack handle.

•Vehicles equipped with dual

rear wheels,insert the lug

wrench extension into the lug

wrench to reach the lug nuts.

2. Attach the spare tire lock key (A)

to the jack handle (B).

3. Fully insert the jack handle

through the bumper hole and into

the guide tube. The key and lock

will engage with a slight push and

counterclockwise turn. Some

resistance will be felt when turning

the jack handle assembly.

4. Turn the handle counterclockwise

and lower the spare tire until you

can slide the tire rearward and the

cable is slack.

5. Remove the retainer through the center of the wheel.

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

224

Page 225 of 312

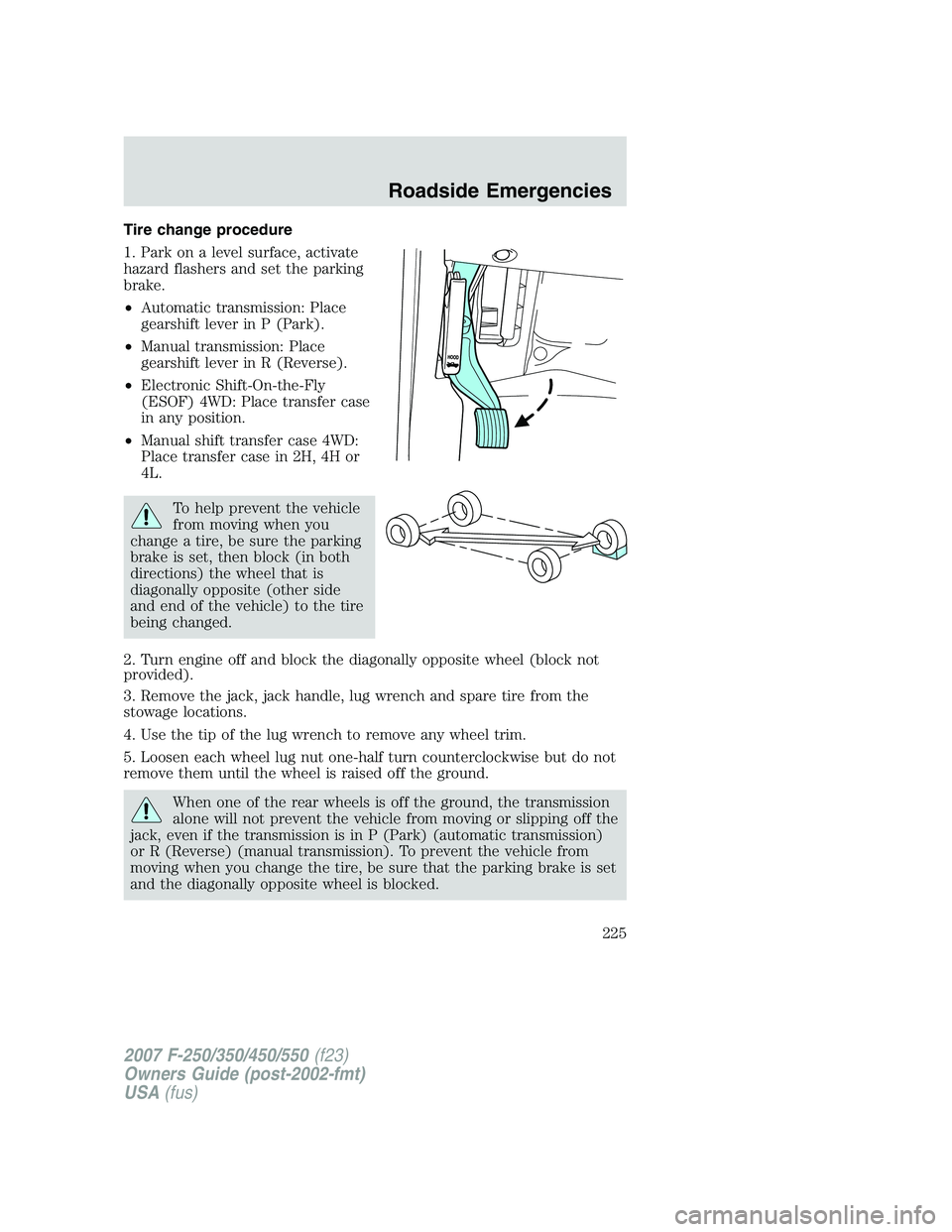

Tire change procedure

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

•Automatic transmission: Place

gearshift lever in P (Park).

•Manual transmission: Place

gearshift lever in R (Reverse).

•Electronic Shift-On-the-Fly

(ESOF) 4WD: Place transfer case

in any position.

•Manual shift transfer case 4WD:

Place transfer case in 2H, 4H or

4L.

To help prevent the vehicle

from moving when you

change a tire, be sure the parking

brake is set, then block (in both

directions) the wheel that is

diagonally opposite (other side

and end of the vehicle) to the tire

being changed.

2. Turn engine off and block the diagonally opposite wheel (block not

provided).

3. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

4. Use the tip of the lug wrench to remove any wheel trim.

5. Loosen each wheel lug nut one-half turn counterclockwise but do not

remove them until the wheel is raised off the ground.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park) (automatic transmission)

or R (Reverse) (manual transmission). To prevent the vehicle from

moving when you change the tire, be sure that the parking brake is set

and the diagonally opposite wheel is blocked.

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

225

Page 227 of 312

![FORD F250 2007 User Guide •Front passenger side (4x4)

Note:View shown from the rear of

the vehicle to clearly identify the

jack point. Place the jack directly

under the axle.

•Rear (including F-350 Dual Rear

wheel [DRW] ve FORD F250 2007 User Guide •Front passenger side (4x4)

Note:View shown from the rear of

the vehicle to clearly identify the

jack point. Place the jack directly

under the axle.

•Rear (including F-350 Dual Rear

wheel [DRW] ve](/img/11/58768/w960_58768-226.png)

•Front passenger side (4x4)

Note:View shown from the rear of

the vehicle to clearly identify the

jack point. Place the jack directly

under the axle.

•Rear (including F-350 Dual Rear

wheel [DRW] vehicles)

Never use the front or rear

differential as a jacking point.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

8. Turn the jack handle clockwise

until the wheel is completely off the

ground and high enough to install

the spare tire.

9. Remove the lug nuts with the lug

wrench.

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

227

Page 228 of 312

10. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward for all front wheels and single rear wheel vehicles. If

replacing an inboard rear tire on dual rear wheel vehicles, the valve stem

must be facing outward. If replacing the outboard wheel, the valve stem

must be facing inward. Reinstall the lug nuts until the wheel is snug against

the hub. Do not fully tighten the lug nuts until the wheel has been lowered.

11. Lower the wheel by turning the jack handle counterclockwise.

Go to step 19.

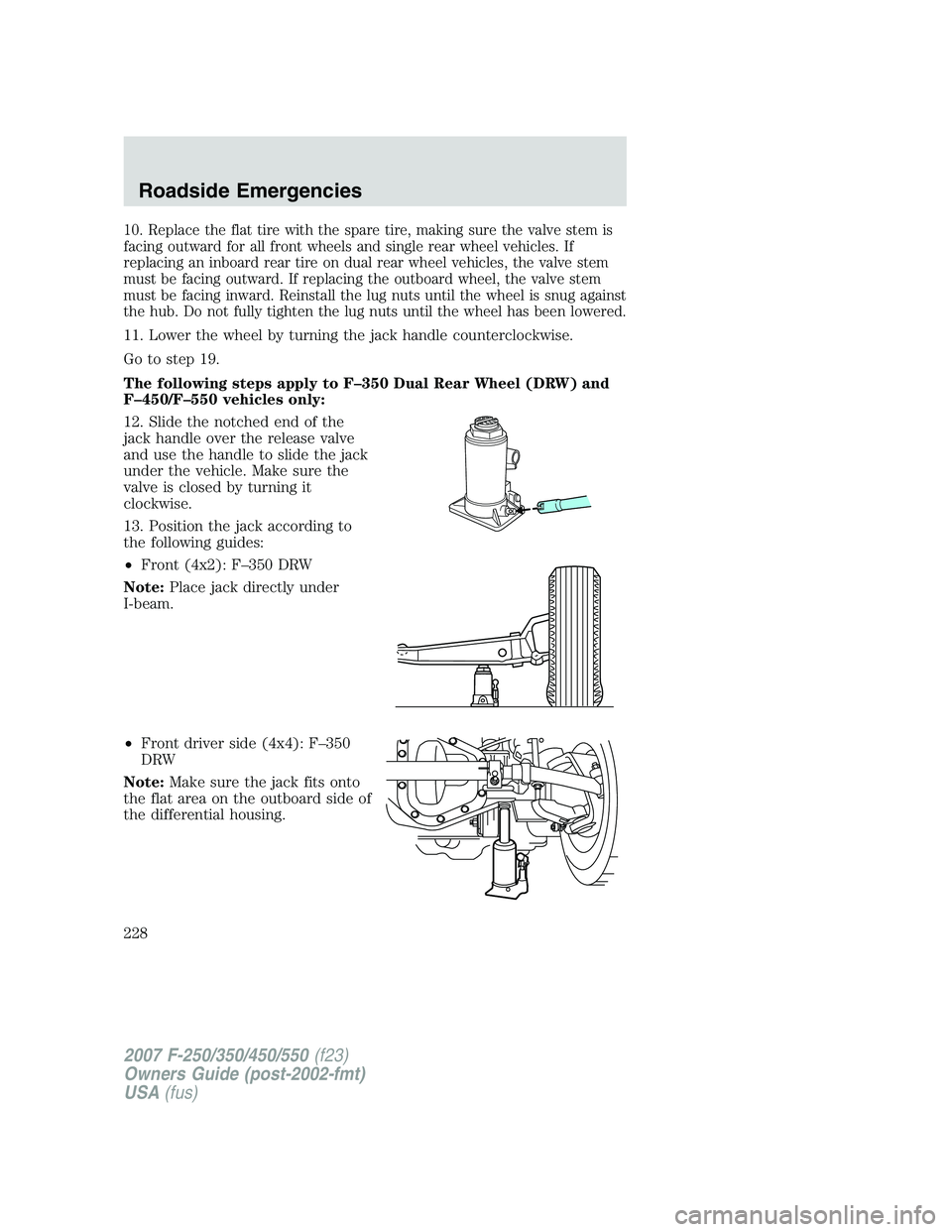

The following steps apply to F–350 Dual Rear Wheel (DRW) and

F–450/F–550 vehicles only:

12. Slide the notched end of the

jack handle over the release valve

and use the handle to slide the jack

under the vehicle. Make sure the

valve is closed by turning it

clockwise.

13. Position the jack according to

the following guides:

•Front (4x2): F–350 DRW

Note:Place jack directly under

I-beam.

•Front driver side (4x4): F–350

DRW

Note:Make sure the jack fits onto

the flat area on the outboard side of

the differential housing.

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

228

Page 230 of 312

17. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward on all front an inboard rear wheels. If replacing the

outboard wheel, the valve stem must be facing inward. Reinstall the lug

nuts until the wheel is snug against the hub. Do not fully tighten the lug

nuts until the wheel has been lowered.

18. Lower the wheel by slowly turning the release valve

counterclockwise. Opening the release valve slowly will provide a more

controlled rate of descent.

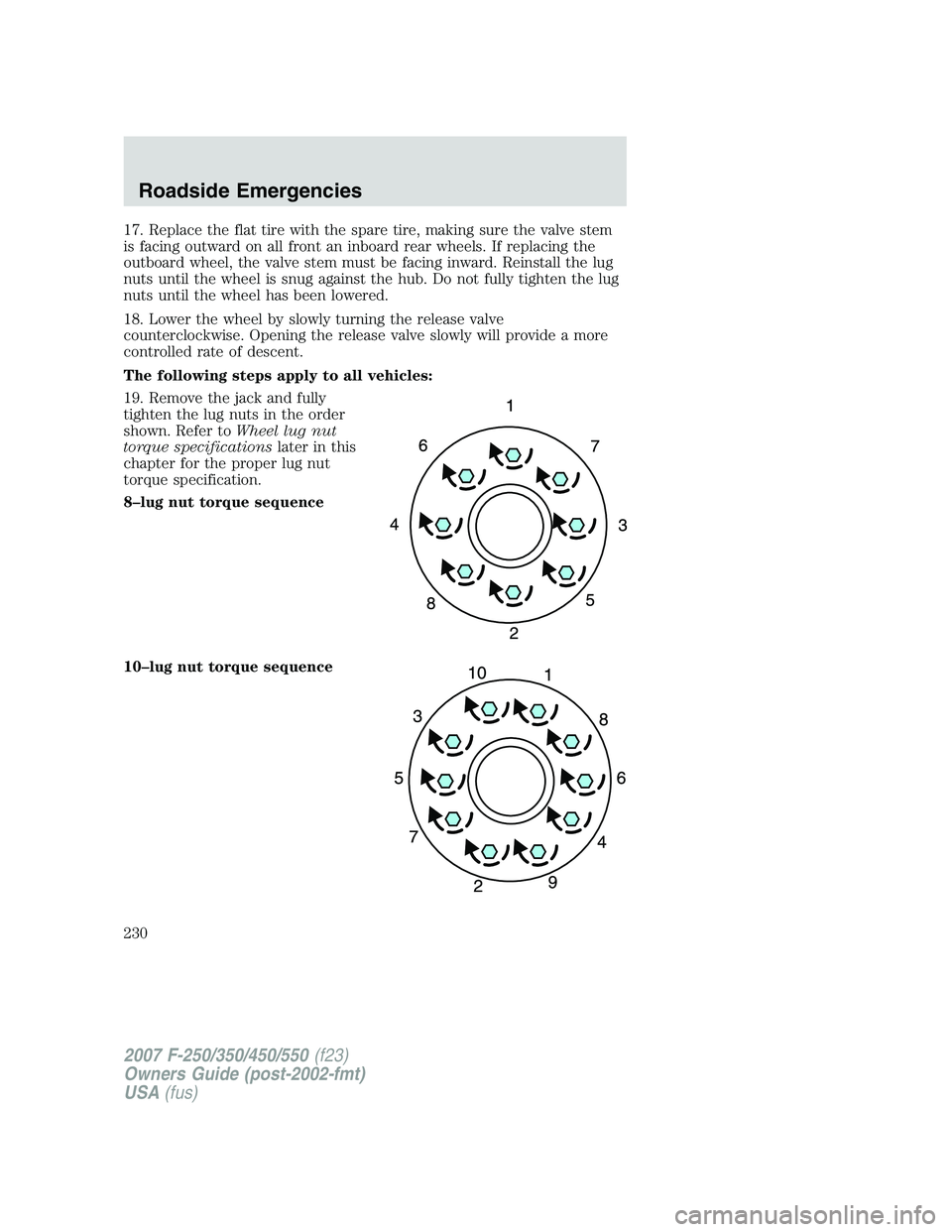

The following steps apply to all vehicles:

19. Remove the jack and fully

tighten the lug nuts in the order

shown. Refer toWheel lug nut

torque specificationslater in this

chapter for the proper lug nut

torque specification.

8–lug nut torque sequence

10–lug nut torque sequence

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

230

Page 231 of 312

20. Stow the flat tire. Refer toStowing the flat/spare tireif the vehicle

is equipped with a spare tire carrier.

Note:Do not stow the Harley-Davidson flat tire and wheel using the

spare tire winch mechanism; store the flat in the bed of the truck.

21. Stow the jack, jack handle and lug wrench. Make sure the jack is

securely fastened so it does not rattle when driving.

22. Unblock the wheels.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located in the glove box.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your authorized

dealer for assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, perscheduled maintenance information),

or at any time that the spare tire is disturbed through service of other

components.

6. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.

2007 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

231