FORD F250 2008 Owners Manual

Manufacturer: FORD, Model Year: 2008, Model line: F250, Model: FORD F250 2008Pages: 400, PDF Size: 3.5 MB

Page 231 of 400

3. Press and hold the brake pedal for two (2) seconds, then release.

4. Turn the ignition to OFF/LOCK (DO NOTremove the key.)

5. Cycle the ignition from OFF/LOCK to RUN three (3) times ending in

RUN.DO NOTstart the engine.

If reset mode has been entered successfully, the horn will sound once,

the TPMS indicator will flash and the message center will displayTRAIN

LF TIRE.

If after repeated attempts to enter reset mode, the horn does not sound,

the TPMS indicator does not flash and the message center does not

display TRAIN LF TIRE, seek service from your authorized dealer.

TPMS reset sequence

The TPMS system needs to be reset starting with the left front tire in

the following clockwise order:

1. Left front tire

2. Right front tire

3. Right rear tire

4. Left rear tire

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

231

Page 232 of 400

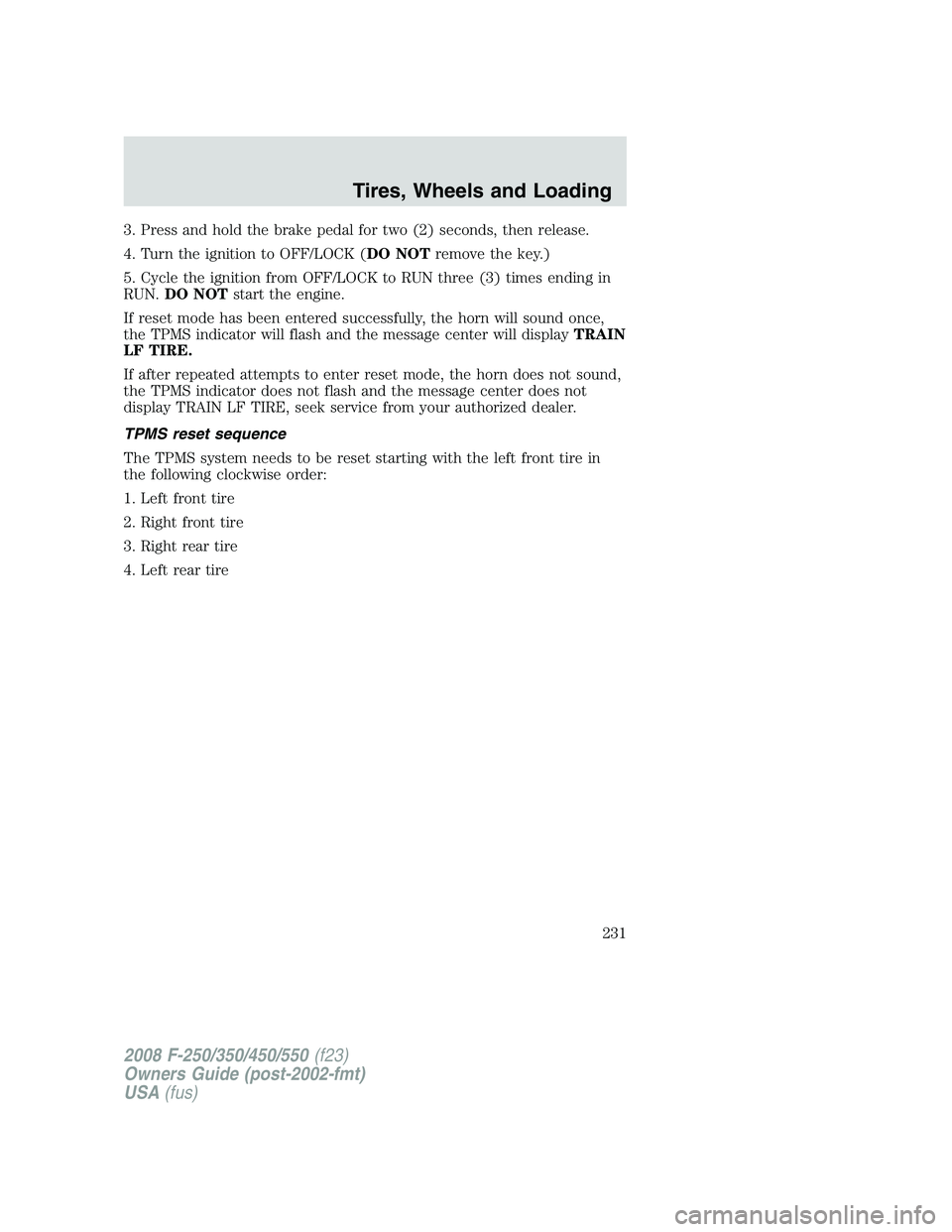

1.Left front tire:Place the TPMS reset tool against the left front tire

where the tire meets the rim, opposite from the valve stem (1) as shown.

This is where the sensor is located inside the rim.

The tool needs to be held against the tire sidewall opposite the

valve stem as illustrated with the arrow on the tool pointing

towards the rim; do not use the tool with the arrow pointing away

from the rim as it may not activate the sensor.

2. Press and release the green button and hold the tool to the tire

sidewall until the horn sounds. The red light on the TPMS reset tool will

illuminate while the tool is active. The horn will sound once within 10

seconds to indicate the process was successful.

Note:If a double horn chirp is heard, repeat the procedure. If a single

horn chirp is not heard, move the vehicle to rotate the wheels at least a

1�4-turn and repeat the procedure. If the horn does not sound while

attempting to reset any wheel, seek service from your authorized dealer.

3. Perform Steps 1 and 2 on the right front, right rear and finally the left

rear tires.

Successful completion of the reset procedure can be verified by turning

the ignition to OFF without the horn sounding. If two short beeps are

heard, the reset procedure was unsuccessful and must be repeated.

If after repeating the procedure two short beeps are heard when the key

is turned to OFF, seek assistance from your authorized dealer.

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

232

Page 233 of 400

Rotation, pressure adjustment and TPMS reset example

The following example describes all the major steps involved in rotating

tires on a vehicle with different front and rear tire pressures. It

illustrates that the TPMS reset procedure needs to follow tire rotation

and pressure adjustment to avoid a possible false low tire warning.

Example:

A particular vehicle has the following recommended tire pressures: 50 psi

(345 kPa) front; 80 psi (552 kPa) rear.

Note:For your vehicle’s pressure, refer to the Safety Compliance

Certification Label located on the B-Pillar or the edge of your vehicle’s

driver’s door.

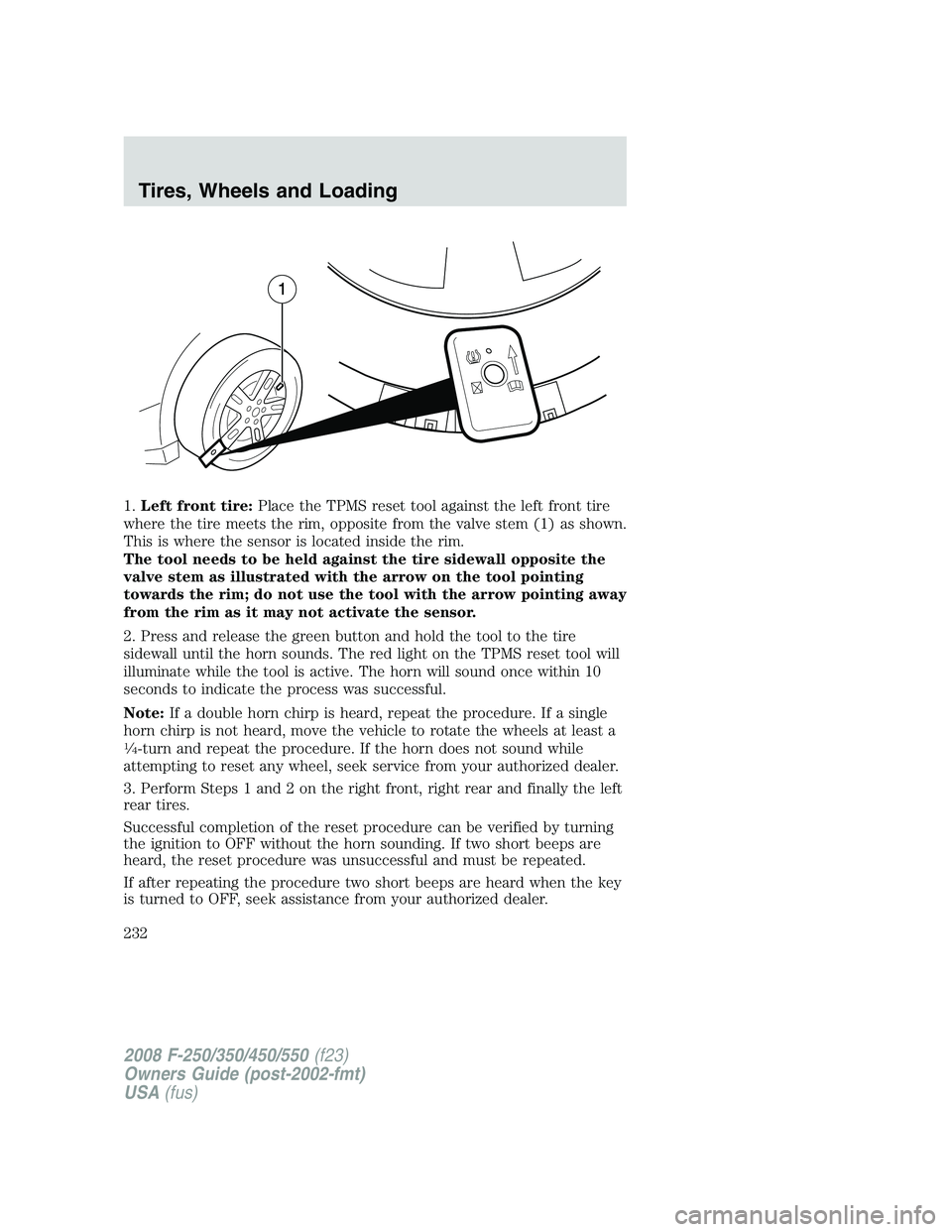

Before tire rotation

Sensor 1: 50 psi

Sensor 2: 50 psi

Sensor 3: 80 psi

Sensor 4: 80 psi

Tire rotation using the

recommended sequence (front

tires at top of diagram)

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

233

Page 234 of 400

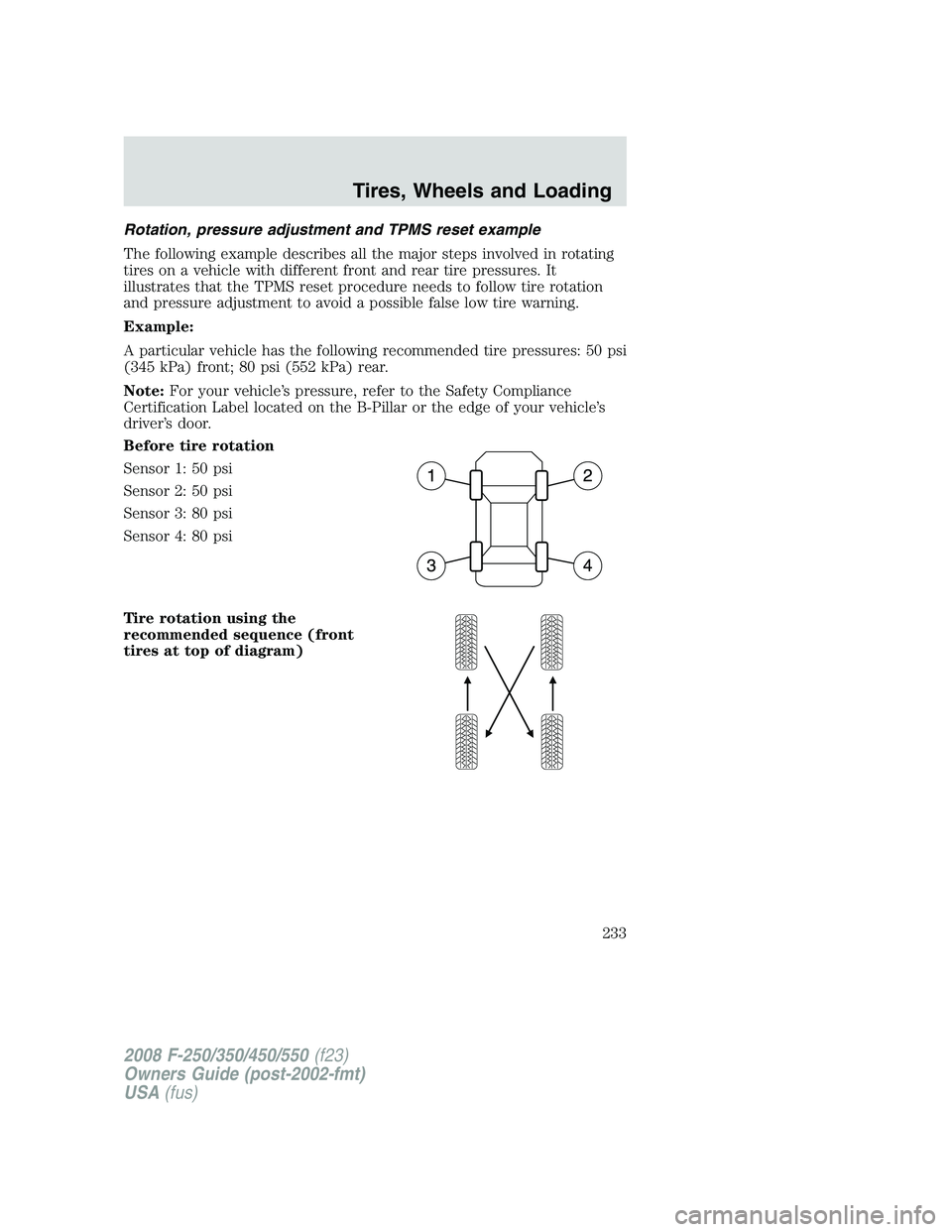

Sensor position following tire

rotation

Sensor 1: 50 psi

Sensor 2: 50 psi

Sensor 3: 80 psi

Sensor 4: 80 psi

Pressure adjustment without the

required TPMS reset procedure

Sensor 1: 80 psi

Sensor 2: 80 psi

Sensor 3: 50 psi

Sensor 4: 50 psi

In this situation, the TPMS warning

light will come on.

If the TPMS reset procedure is not performed after tire rotation and air

pressure adjustment, the TPMS telltale may illuminate for a false low tire

pressure condition.

As in this example, the rear tires rotated to the front and properly

inflated to 50 psi (345 kPa) for the front axle would falsely illuminate the

low tire warning indicator as they are still trained for the rear positions

which require 80 psi (552 kPa).

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

234

Page 235 of 400

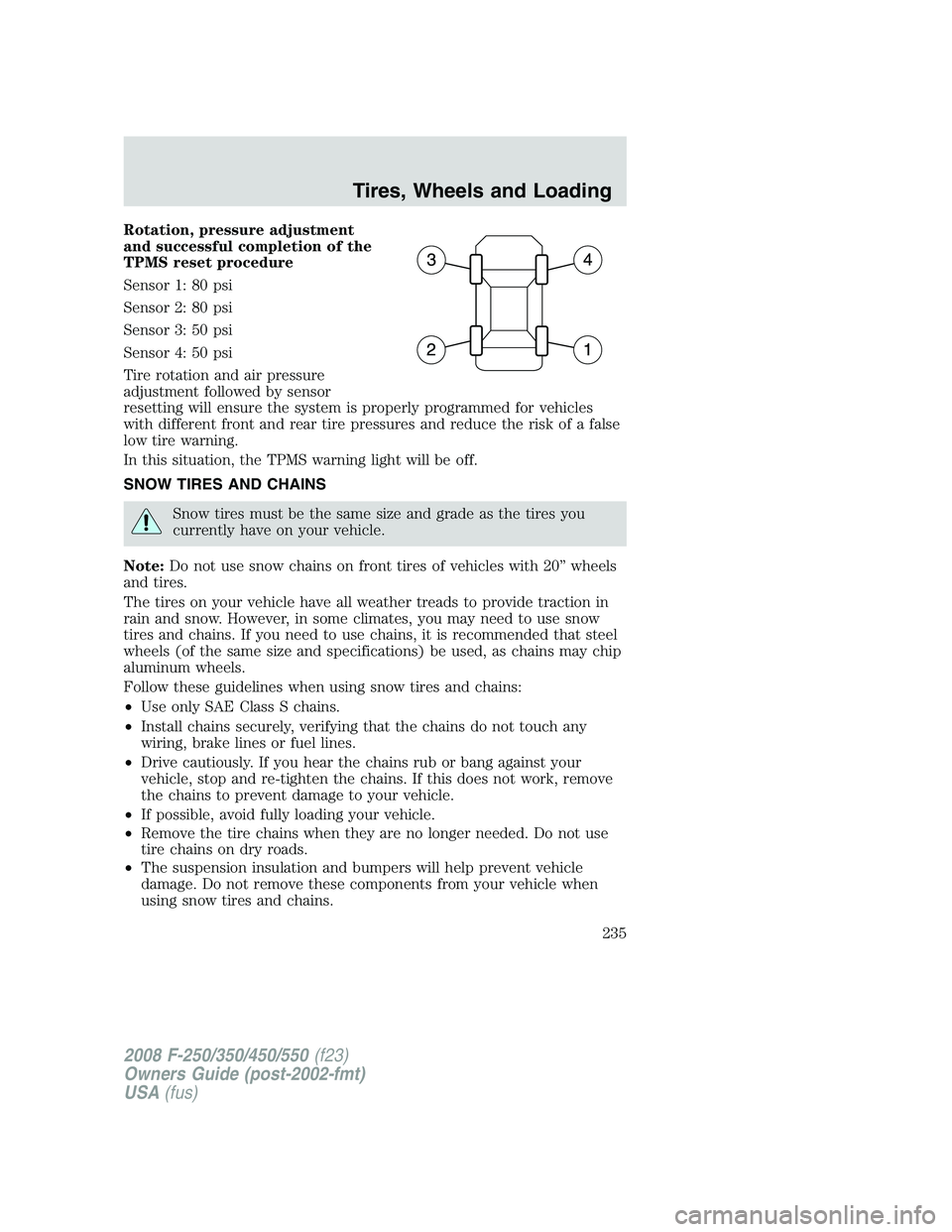

Rotation, pressure adjustment

and successful completion of the

TPMS reset procedure

Sensor 1: 80 psi

Sensor 2: 80 psi

Sensor 3: 50 psi

Sensor 4: 50 psi

Tire rotation and air pressure

adjustment followed by sensor

resetting will ensure the system is properly programmed for vehicles

with different front and rear tire pressures and reduce the risk of a false

low tire warning.

In this situation, the TPMS warning light will be off.

SNOW TIRES AND CHAINS

Snow tires must be the same size and grade as the tires you

currently have on your vehicle.

Note:Do not use snow chains on front tires of vehicles with 20” wheels

and tires.

The tires on your vehicle have all weather treads to provide traction in

rain and snow. However, in some climates, you may need to use snow

tires and chains. If you need to use chains, it is recommended that steel

wheels (of the same size and specifications) be used, as chains may chip

aluminum wheels.

Follow these guidelines when using snow tires and chains:

•Use only SAE Class S chains.

•Install chains securely, verifying that the chains do not touch any

wiring, brake lines or fuel lines.

•Drive cautiously. If you hear the chains rub or bang against your

vehicle, stop and re-tighten the chains. If this does not work, remove

the chains to prevent damage to your vehicle.

•If possible, avoid fully loading your vehicle.

•Remove the tire chains when they are no longer needed. Do not use

tire chains on dry roads.

•The suspension insulation and bumpers will help prevent vehicle

damage. Do not remove these components from your vehicle when

using snow tires and chains.

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

235

Page 236 of 400

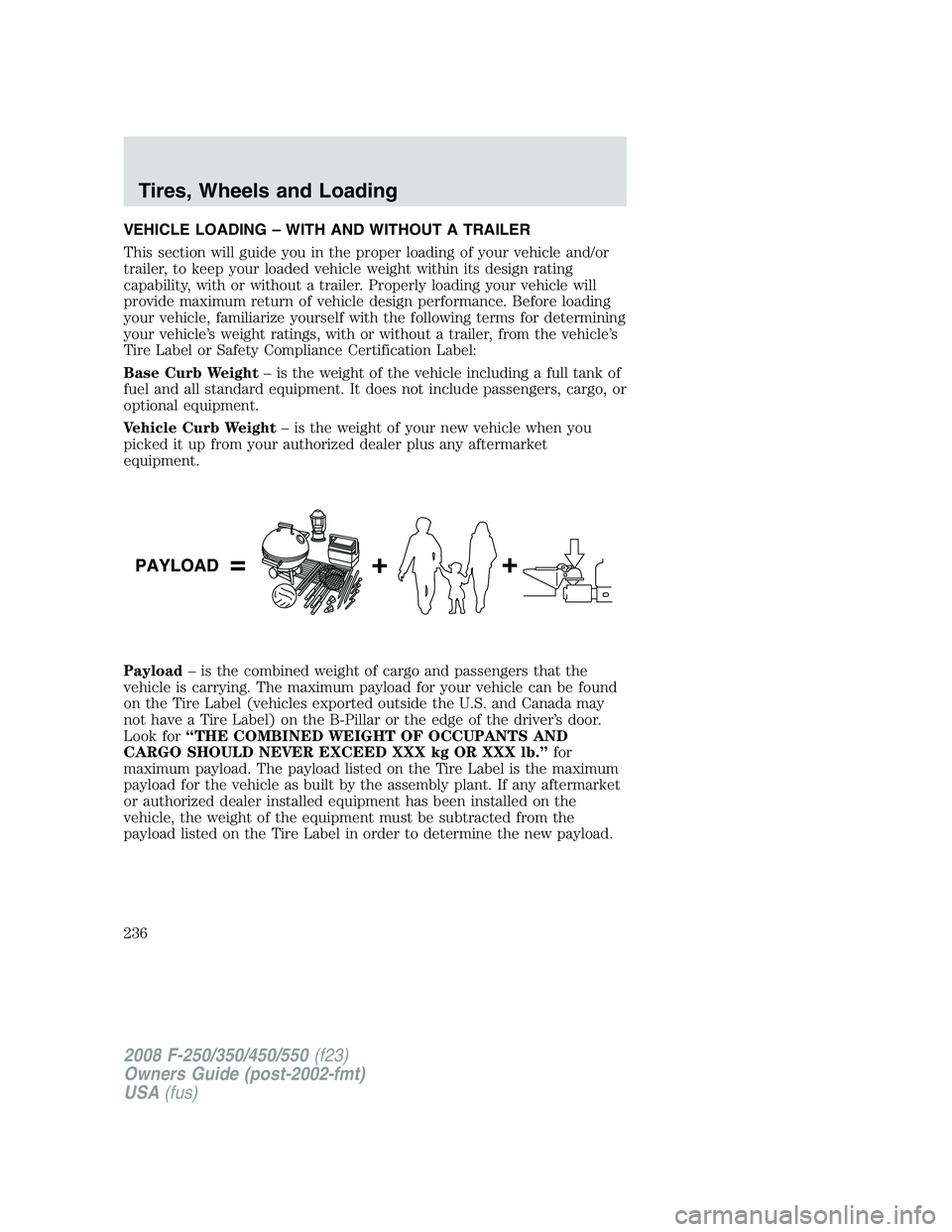

VEHICLE LOADING – WITH AND WITHOUT A TRAILER

This section will guide you in the proper loading of your vehicle and/or

trailer, to keep your loaded vehicle weight within its design rating

capability, with or without a trailer. Properly loading your vehicle will

provide maximum return of vehicle design performance. Before loading

your vehicle, familiarize yourself with the following terms for determining

your vehicle’s weight ratings, with or without a trailer, from the vehicle’s

Tire Label or Safety Compliance Certification Label:

Base Curb Weight– is the weight of the vehicle including a full tank of

fuel and all standard equipment. It does not include passengers, cargo, or

optional equipment.

Vehicle Curb Weight– is the weight of your new vehicle when you

picked it up from your authorized dealer plus any aftermarket

equipment.

Payload– is the combined weight of cargo and passengers that the

vehicle is carrying. The maximum payload for your vehicle can be found

on the Tire Label (vehicles exported outside the U.S. and Canada may

not have a Tire Label) on the B-Pillar or the edge of the driver’s door.

Look for“THE COMBINED WEIGHT OF OCCUPANTS AND

CARGO SHOULD NEVER EXCEED XXX kg OR XXX lb.”for

maximum payload. The payload listed on the Tire Label is the maximum

payload for the vehicle as built by the assembly plant. If any aftermarket

or authorized dealer installed equipment has been installed on the

vehicle, the weight of the equipment must be subtracted from the

payload listed on the Tire Label in order to determine the new payload.

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

236

Page 237 of 400

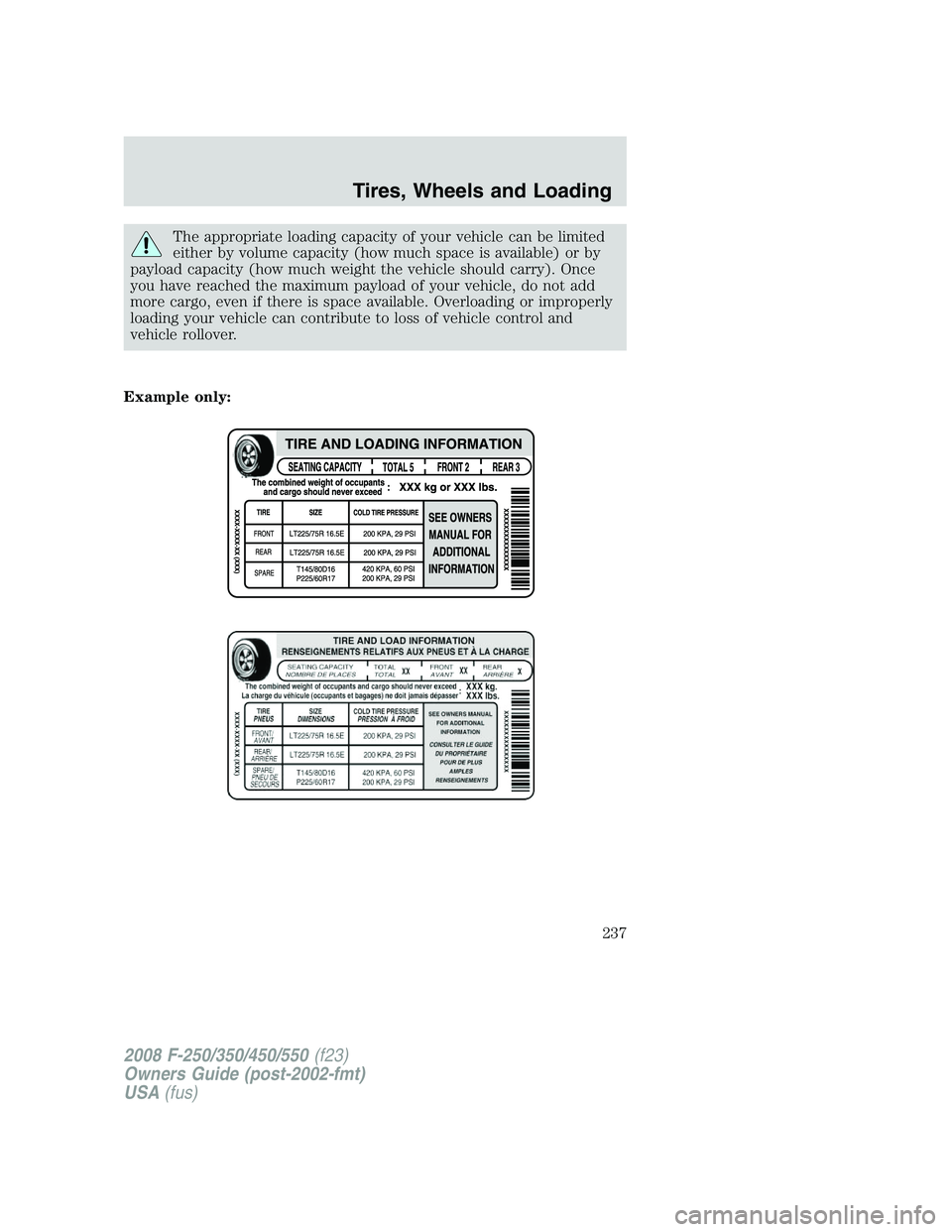

The appropriate loading capacity of your vehicle can be limited

either by volume capacity (how much space is available) or by

payload capacity (how much weight the vehicle should carry). Once

you have reached the maximum payload of your vehicle, do not add

more cargo, even if there is space available. Overloading or improperly

loading your vehicle can contribute to loss of vehicle control and

vehicle rollover.

Example only:

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

237

Page 238 of 400

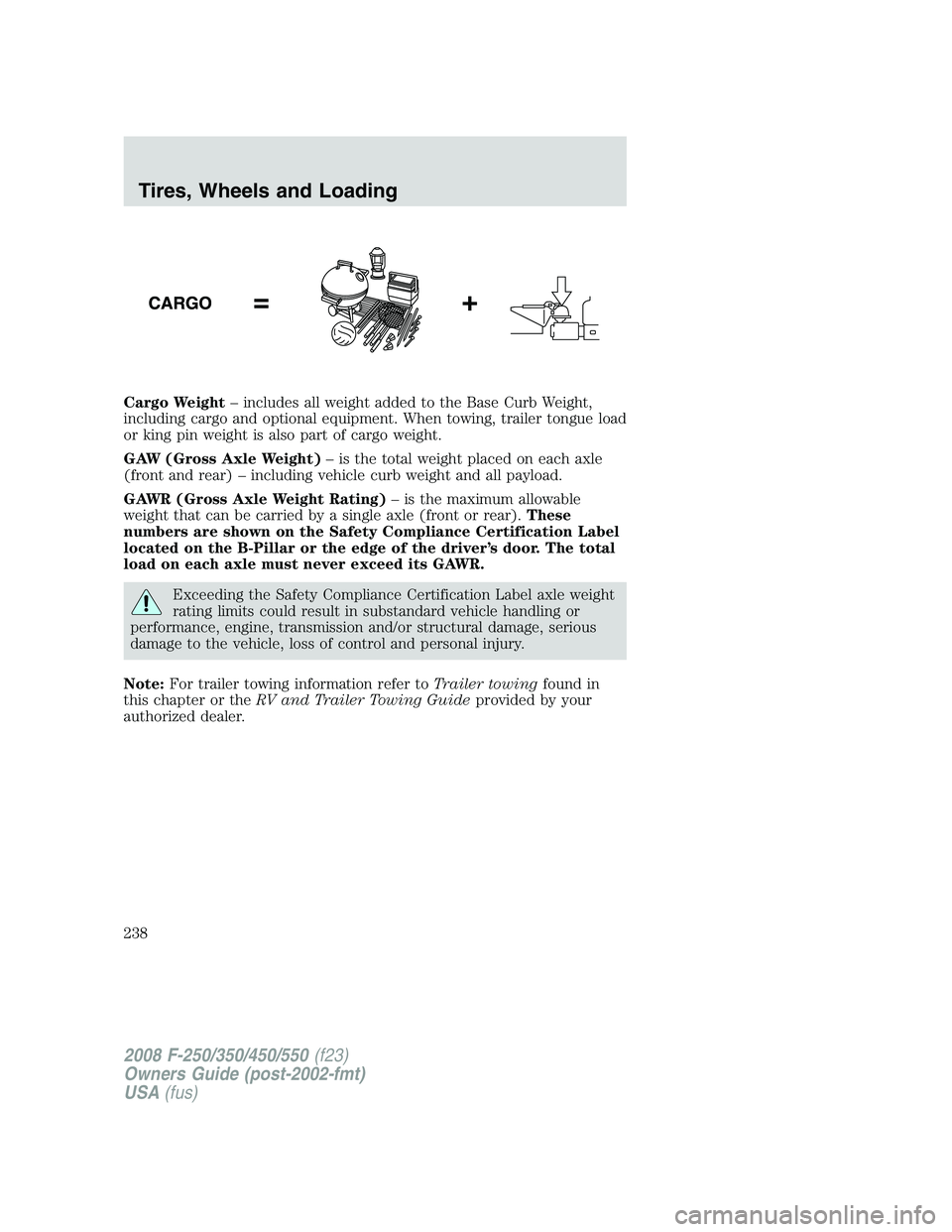

Cargo Weight– includes all weight added to the Base Curb Weight,

including cargo and optional equipment. When towing, trailer tongue load

or king pin weight is also part of cargo weight.

GAW (Gross Axle Weight)– is the total weight placed on each axle

(front and rear) – including vehicle curb weight and all payload.

GAWR (Gross Axle Weight Rating)– is the maximum allowable

weight that can be carried by a single axle (front or rear).These

numbers are shown on the Safety Compliance Certification Label

located on the B-Pillar or the edge of the driver’s door. The total

load on each axle must never exceed its GAWR.

Exceeding the Safety Compliance Certification Label axle weight

rating limits could result in substandard vehicle handling or

performance, engine, transmission and/or structural damage, serious

damage to the vehicle, loss of control and personal injury.

Note:For trailer towing information refer toTrailer towingfound in

this chapter or theRV and Trailer Towing Guideprovided by your

authorized dealer.

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

238

Page 239 of 400

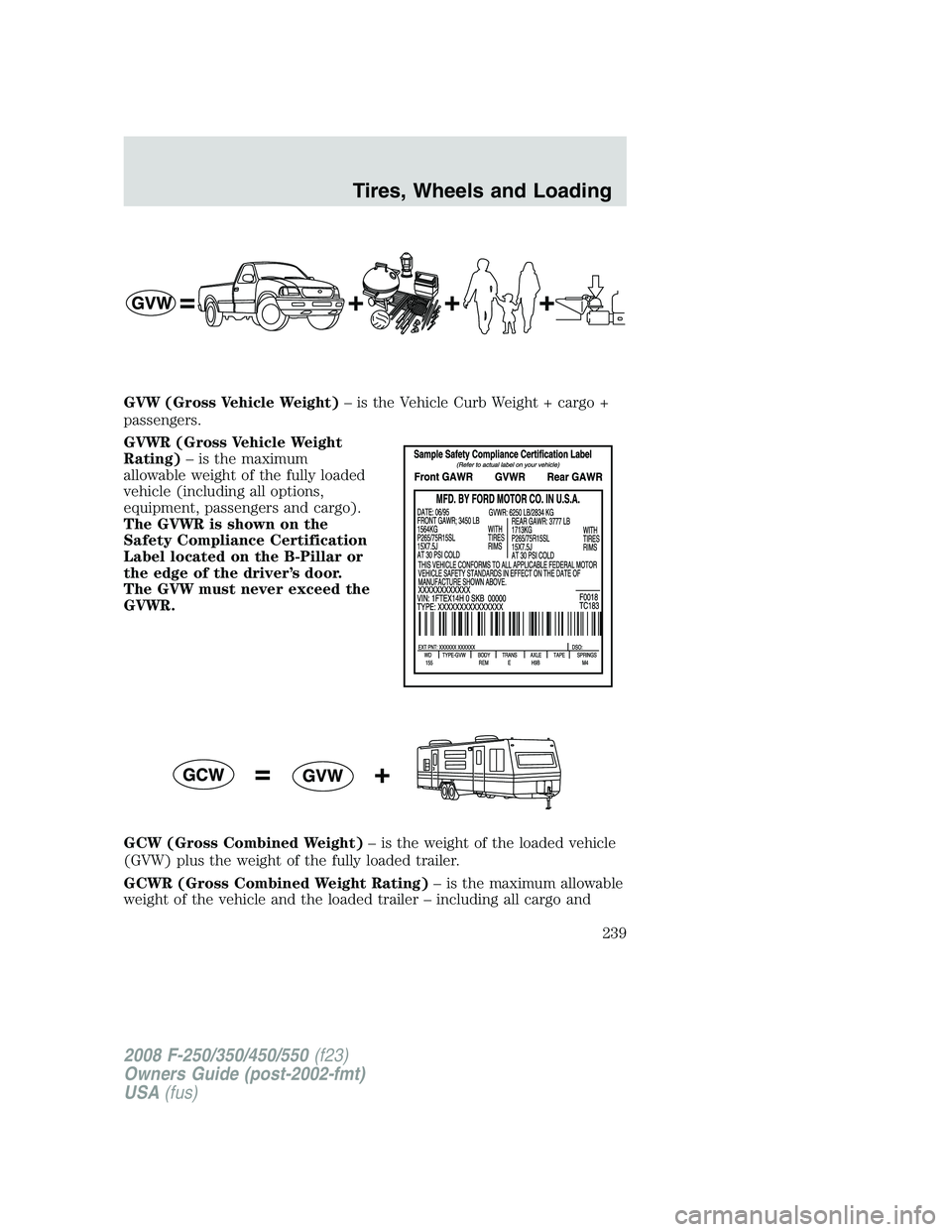

GVW (Gross Vehicle Weight)– is the Vehicle Curb Weight + cargo +

passengers.

GVWR (Gross Vehicle Weight

Rating)– is the maximum

allowable weight of the fully loaded

vehicle (including all options,

equipment, passengers and cargo).

The GVWR is shown on the

Safety Compliance Certification

Label located on the B-Pillar or

the edge of the driver’s door.

The GVW must never exceed the

GVWR.

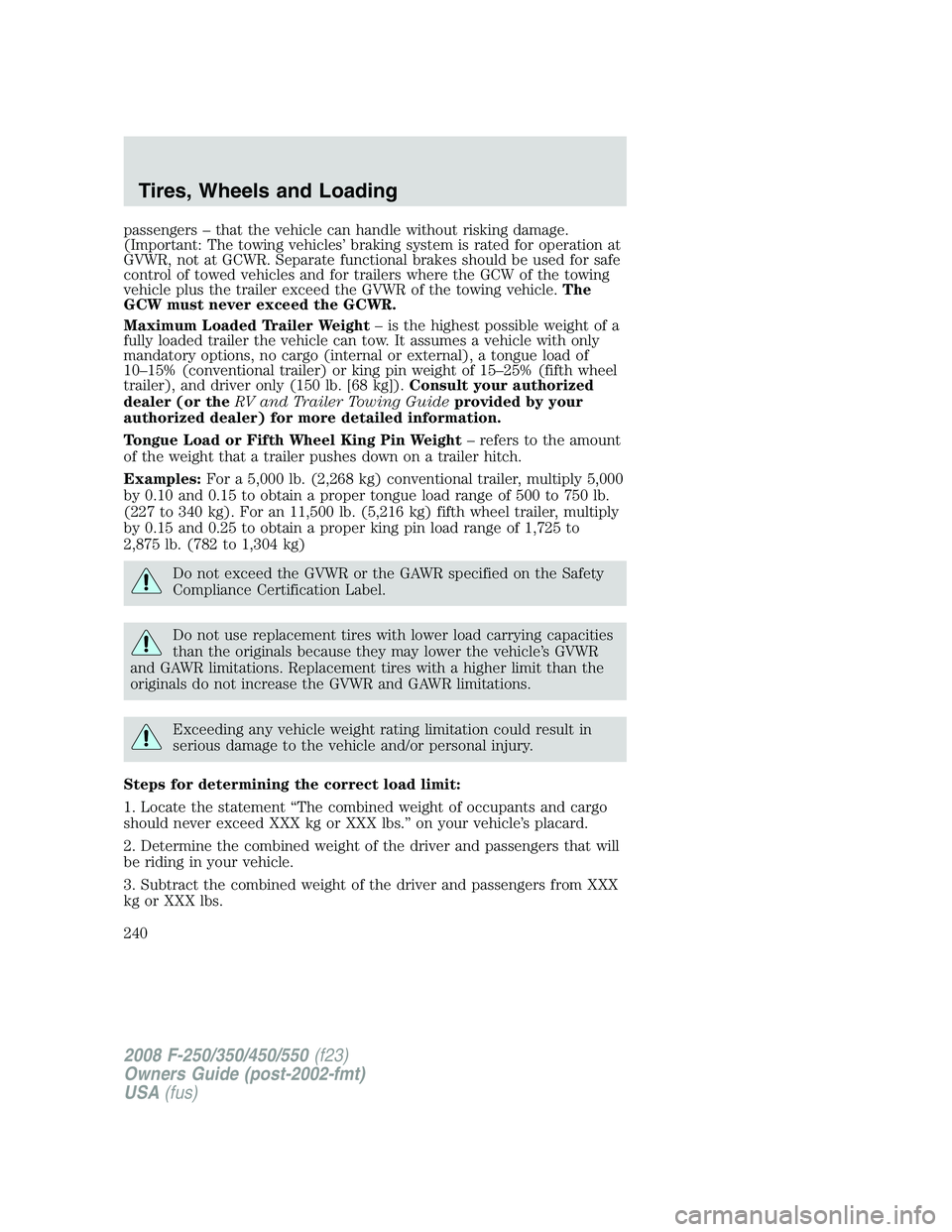

GCW (Gross Combined Weight)– is the weight of the loaded vehicle

(GVW) plus the weight of the fully loaded trailer.

GCWR (Gross Combined Weight Rating)– is the maximum allowable

weight of the vehicle and the loaded trailer – including all cargo and

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

239

Page 240 of 400

passengers – that the vehicle can handle without risking damage.

(Important: The towing vehicles’ braking system is rated for operation at

GVWR, not at GCWR. Separate functional brakes should be used for safe

control of towed vehicles and for trailers where the GCW of the towing

vehicle plus the trailer exceed the GVWR of the towing vehicle.The

GCW must never exceed the GCWR.

Maximum Loaded Trailer Weight– is the highest possible weight of a

fully loaded trailer the vehicle can tow. It assumes a vehicle with only

mandatory options, no cargo (internal or external), a tongue load of

10–15% (conventional trailer) or king pin weight of 15–25% (fifth wheel

trailer), and driver only (150 lb. [68 kg]).Consult your authorized

dealer (or theRV and Trailer Towing Guideprovided by your

authorized dealer) for more detailed information.

Tongue Load or Fifth Wheel King Pin Weight– refers to the amount

of the weight that a trailer pushes down on a trailer hitch.

Examples:For a 5,000 lb. (2,268 kg) conventional trailer, multiply 5,000

by 0.10 and 0.15 to obtain a proper tongue load range of 500 to 750 lb.

(227 to 340 kg). For an 11,500 lb. (5,216 kg) fifth wheel trailer, multiply

by 0.15 and 0.25 to obtain a proper king pin load range of 1,725 to

2,875 lb. (782 to 1,304 kg)

Do not exceed the GVWR or the GAWR specified on the Safety

Compliance Certification Label.

Do not use replacement tires with lower load carrying capacities

than the originals because they may lower the vehicle’s GVWR

and GAWR limitations. Replacement tires with a higher limit than the

originals do not increase the GVWR and GAWR limitations.

Exceeding any vehicle weight rating limitation could result in

serious damage to the vehicle and/or personal injury.

Steps for determining the correct load limit:

1. Locate the statement “The combined weight of occupants and cargo

should never exceed XXX kg or XXX lbs.” on your vehicle’s placard.

2. Determine the combined weight of the driver and passengers that will

be riding in your vehicle.

3. Subtract the combined weight of the driver and passengers from XXX

kg or XXX lbs.

2008 F-250/350/450/550(f23)

Owners Guide (post-2002-fmt)

USA(fus)

Tires, Wheels and Loading

240