FORD F250 2013 Owners Manual

Manufacturer: FORD, Model Year: 2013, Model line: F250, Model: FORD F250 2013Pages: 577, PDF Size: 7.74 MB

Page 381 of 577

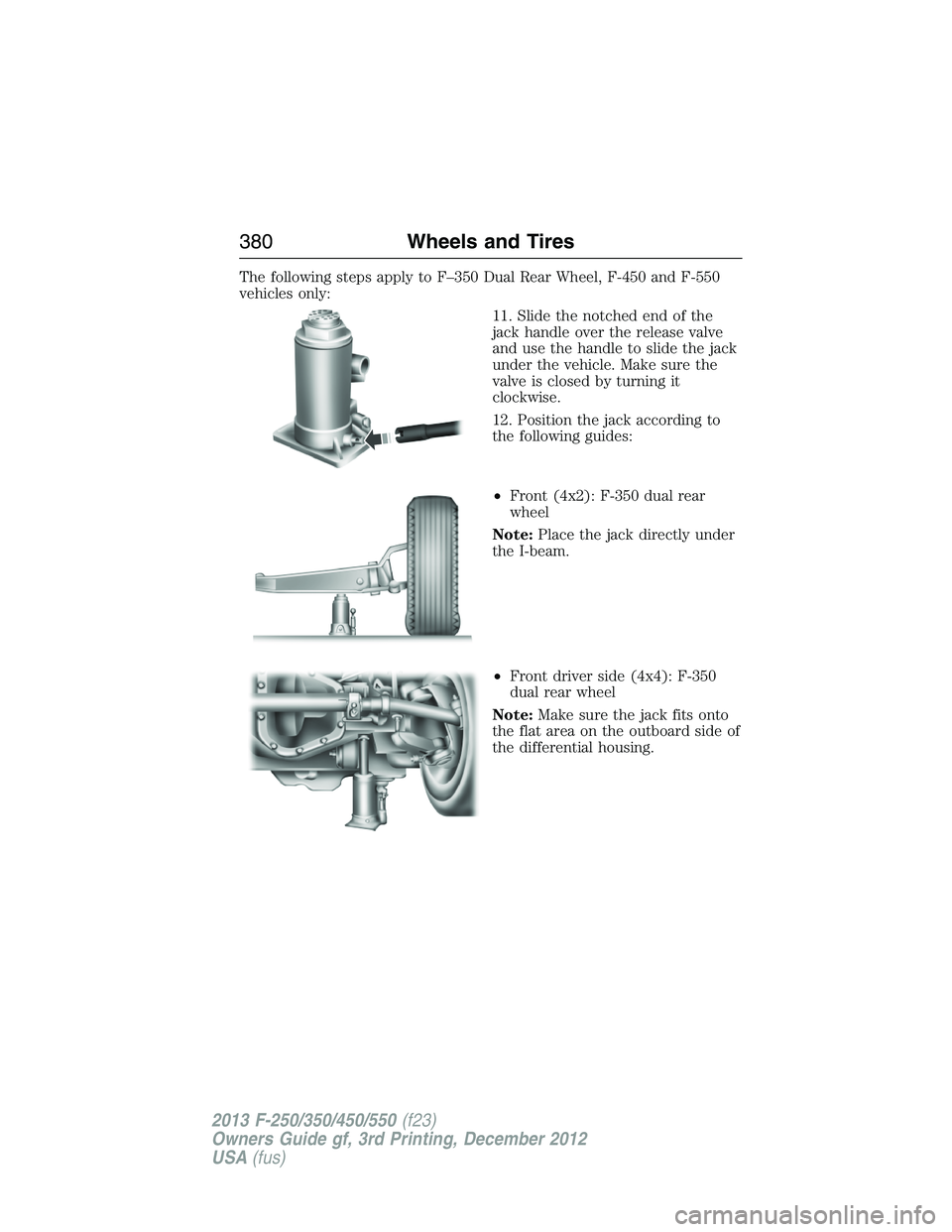

The following steps apply to F–350 Dual Rear Wheel, F-450 and F-550

vehicles only:

11. Slide the notched end of the

jack handle over the release valve

and use the handle to slide the jack

under the vehicle. Make sure the

valve is closed by turning it

clockwise.

12. Position the jack according to

the following guides:

•Front (4x2): F-350 dual rear

wheel

Note:Place the jack directly under

the I-beam.

•Front driver side (4x4): F-350

dual rear wheel

Note:Make sure the jack fits onto

the flat area on the outboard side of

the differential housing.

380Wheels and Tires

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 382 of 577

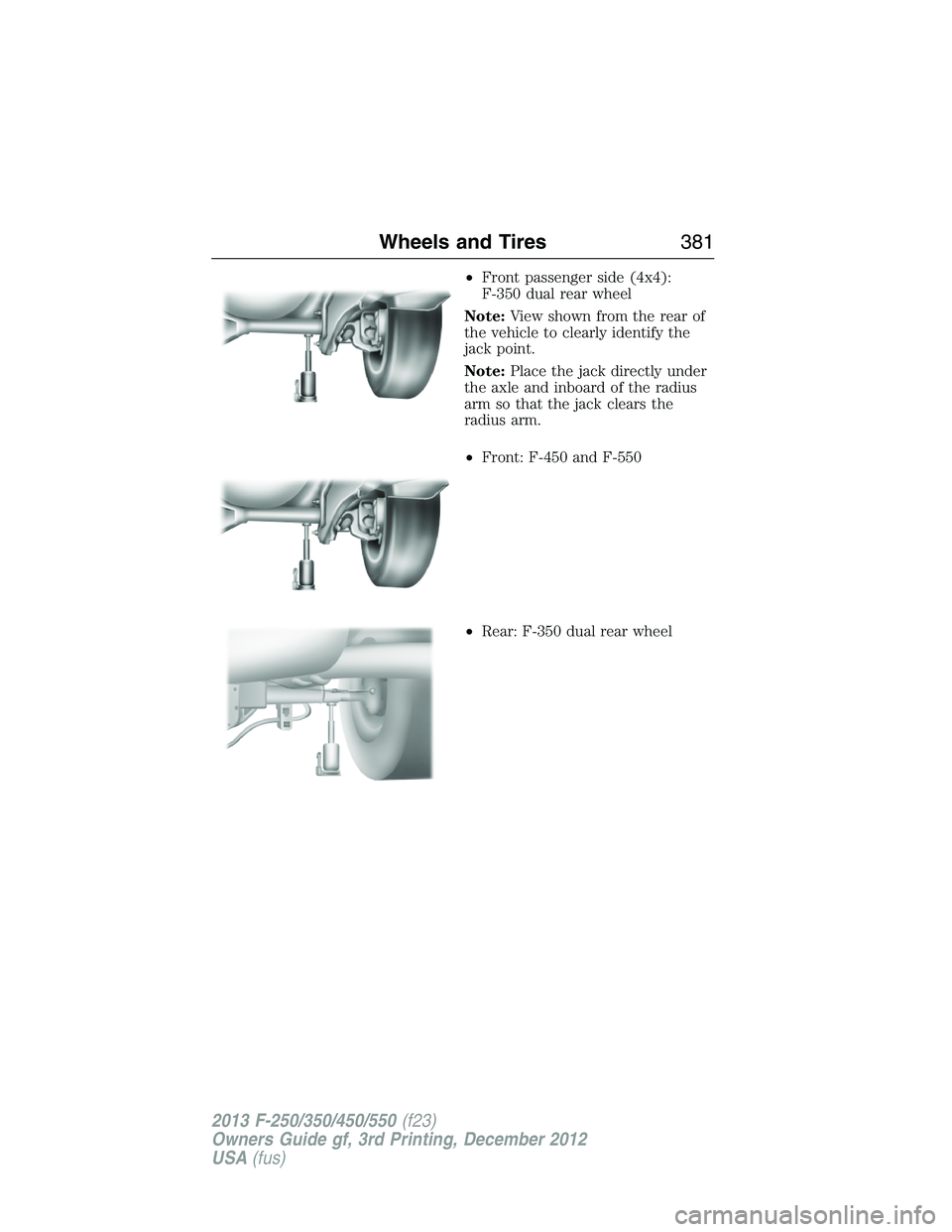

•Front passenger side (4x4):

F-350 dual rear wheel

Note:View shown from the rear of

the vehicle to clearly identify the

jack point.

Note:Place the jack directly under

the axle and inboard of the radius

arm so that the jack clears the

radius arm.

•Front: F-450 and F-550

•Rear: F-350 dual rear wheel

Wheels and Tires381

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 383 of 577

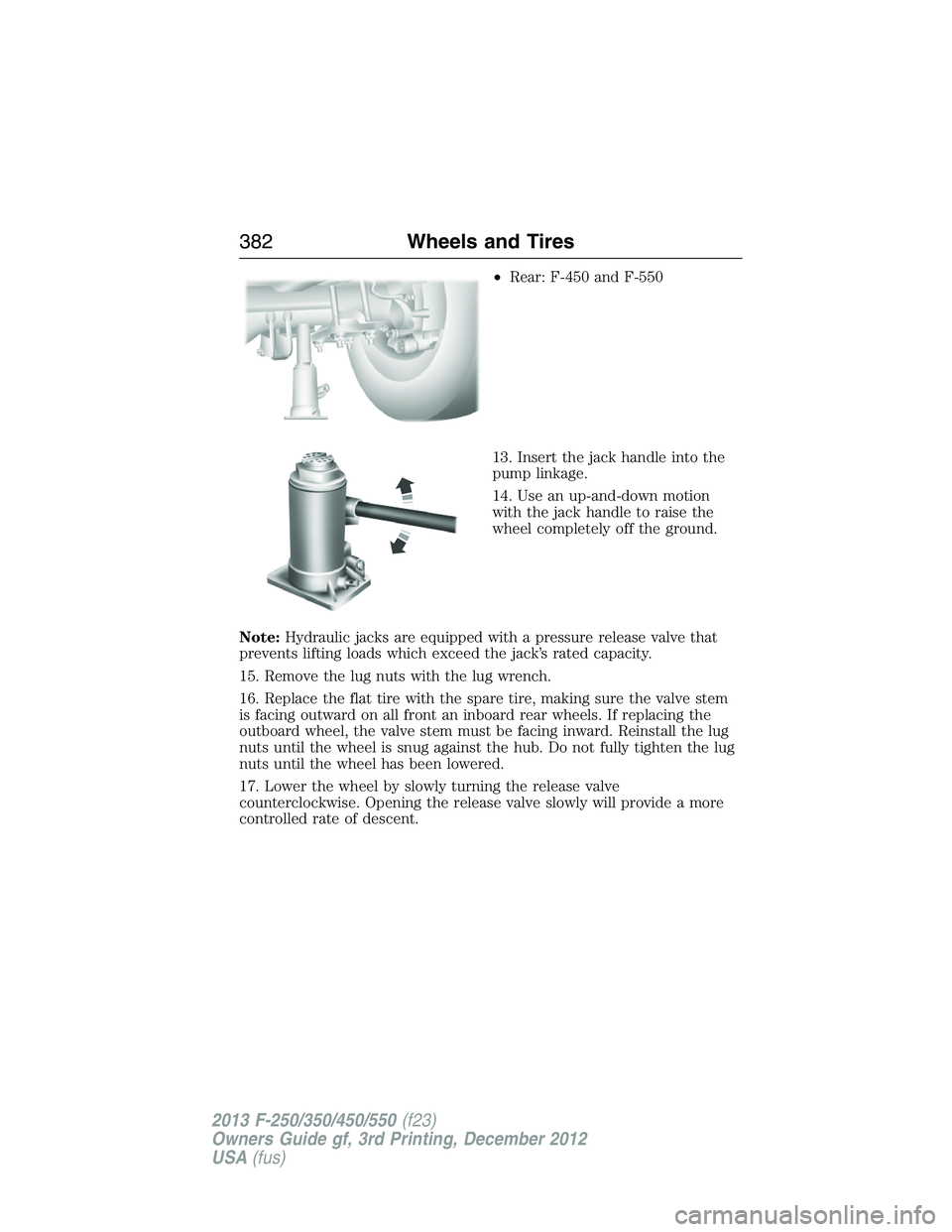

•Rear: F-450 and F-550

13. Insert the jack handle into the

pump linkage.

14. Use an up-and-down motion

with the jack handle to raise the

wheel completely off the ground.

Note:Hydraulic jacks are equipped with a pressure release valve that

prevents lifting loads which exceed the jack’s rated capacity.

15. Remove the lug nuts with the lug wrench.

16. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward on all front an inboard rear wheels. If replacing the

outboard wheel, the valve stem must be facing inward. Reinstall the lug

nuts until the wheel is snug against the hub. Do not fully tighten the lug

nuts until the wheel has been lowered.

17. Lower the wheel by slowly turning the release valve

counterclockwise. Opening the release valve slowly will provide a more

controlled rate of descent.

382Wheels and Tires

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 384 of 577

Note:The following steps apply to all vehicles:

18. Remove the jack and fully

tighten the lug nuts in the order

shown. SeeWheel Lug Nut Torque

Specificationsin this chapter for

the proper lug nut torque

specification.

8-lug nut torque sequence

10-lug nut torque sequence

19. Stow the flat tire. SeeStowing the flat or spare tireif the vehicle is

equipped with a spare tire carrier.

20. Stow the jack, jack handle and lug wrench. Make sure the jack is

securely fastened so it does not rattle when driving.

21. Unblock the wheels.

The following step applies to F-250 and F-350 Single Rear Wheel vehicles

only:

22.

When installing the wheel center

ornaments, ensure that the ornament

retention towers on the back side of

the ornament are aligned with the

studs or lug nuts. The retention

towers are designed to be installed

over the studs or nuts and retain to

the flange on the lug nut.

1

3 4

27 6

5

8

1

2 3

4 5

6

78

9 10

Wheels and Tires383

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 385 of 577

If the ornament retention towers

are aligned between the studs or lug

nuts, the ornament is improperly

installed. This improper installation

may appear and sound correct, but

will not keep the ornament on the

vehicle. Ornaments improperly

installed in this manner will fall off

or become loose with minimal force

or impact.

Installing Dual Rear Wheel Ornaments

1.

Align the ornament with the lug

nuts.

•(A) is the clip and (B) is the flange.

2. Hold the ornament so that all of

the retention clips are sitting on the

flange of the lug nuts.

AB

384Wheels and Tires

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 386 of 577

3. Use your hand or rubber mallet

to tap the ornament in a star

pattern. There should be an even

gap between the ornament and the

wheel.

4. Be sure to install all the clips on the nuts over the flanges so that

there is an even gap all around and the retention clips are fully seated.

A

C

B

D

Wheels and Tires385

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 387 of 577

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

Note:

If you are stowing a tire that requires reattaching it to the vehicle

with a tether, perform these steps first, then proceed with the steps

following.

1. Place the tire on end with the

valve stem facing toward the front

of the vehicle.

2. Place the tether into the bolt

holes in the wheel and attach the

lug nut using the lug winch.

3. Lay the tire on the ground with the valve stem facing up.

4. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

5. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your authorized

dealer for assistance at your earliest convenience.

6. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

7. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, perscheduled maintenance information),

or at any time that the spare tire is disturbed through service of other

components.

8. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.

386Wheels and Tires

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 388 of 577

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING:When a wheel is installed, always remove any

corrosion, dirt or foreign materials present on the mounting

surfaces of the wheel or the surface of the wheel hub, brake drum or

brake disc that contacts the wheel. Make sure that any fasteners that

attach the rotor to the hub are secured so they do not interfere with

the mounting surfaces of the wheel. Installing wheels without correct

metal-to-metal contact at the wheel mounting surfaces can cause the

wheel nuts to loosen and the wheel to come off while the vehicle is in

motion, resulting in loss of control.

On vehicles equipped with single rear wheels, retighten the lug nuts to

the specified torque at 100 miles (160 kilometers) after any wheel

disturbance (such as tire rotation, changing a flat tire, wheel removal).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts

to the specified torque at 100 miles (160 kilometers), and again at

500 miles (800 kilometers) of new vehicle operation and after any wheel

disturbance (such as tire rotation, changing a flat tire, wheel removal).

Wheels and Tires387

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 389 of 577

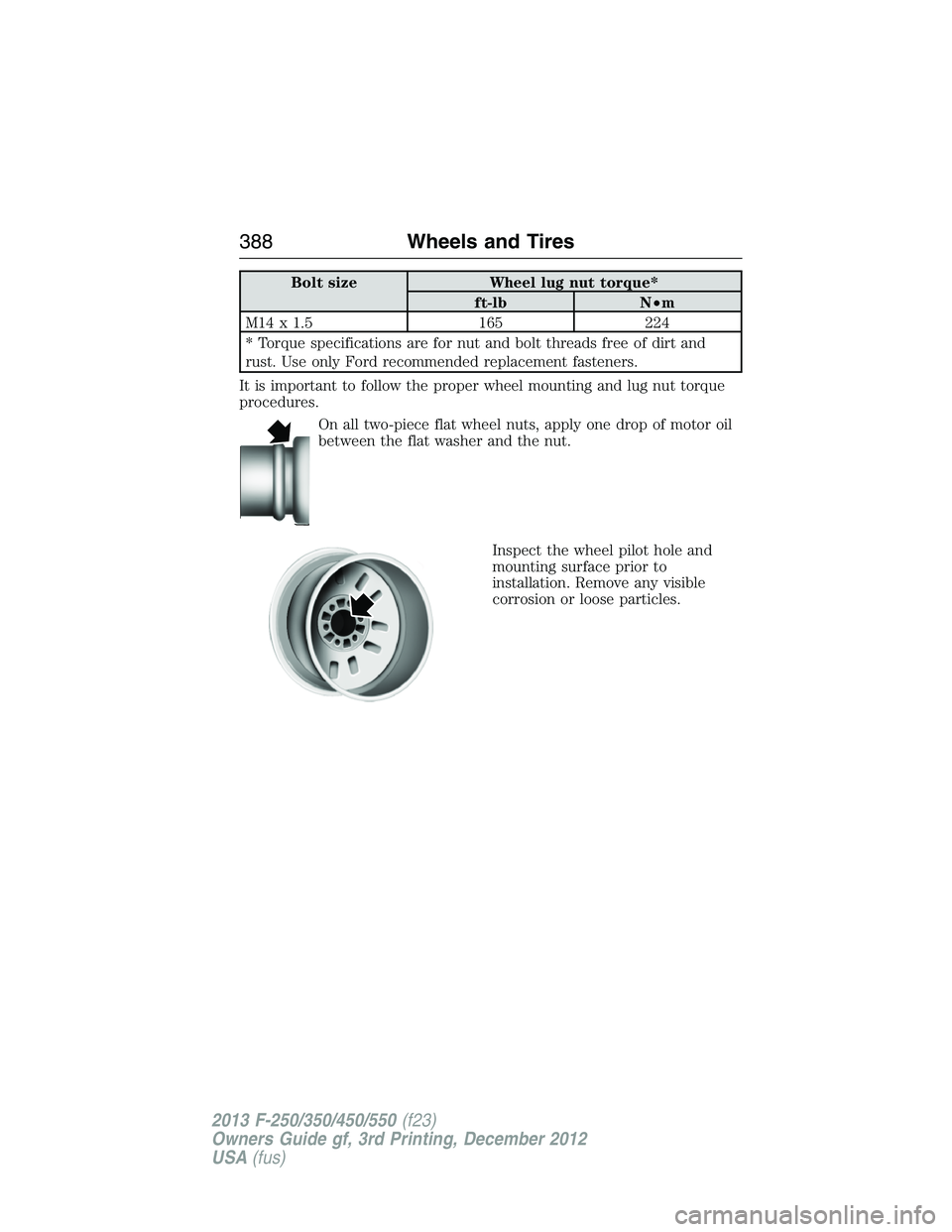

Bolt size Wheel lug nut torque*

ft-lb N•m

M14 x 1.5 165 224

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

It is important to follow the proper wheel mounting and lug nut torque

procedures.

On all two-piece flat wheel nuts, apply one drop of motor oil

between the flat washer and the nut.

Inspect the wheel pilot hole and

mounting surface prior to

installation. Remove any visible

corrosion or loose particles.

388Wheels and Tires

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)

Page 390 of 577

ENGINE SPECIFICATIONS

Engine 6.2L V8 engine 6.8L V10 engine

Cubic inches 378 413

Required fuelMinimum 87 octane or

Ethanol (E85)Minimum 87 octane

Firing order 1-5–4–8–6–3–7–2 1-6-5-10-2-7-3-8-4-9

Spark plug gap0.041–0.047 inch

(1.04–1.20 mm)0.039–0.043 inch

(1.0–1.1 mm)

Ignition system Coil on plug Coil on plug

Compression ratio 9.8:1 9.2:1

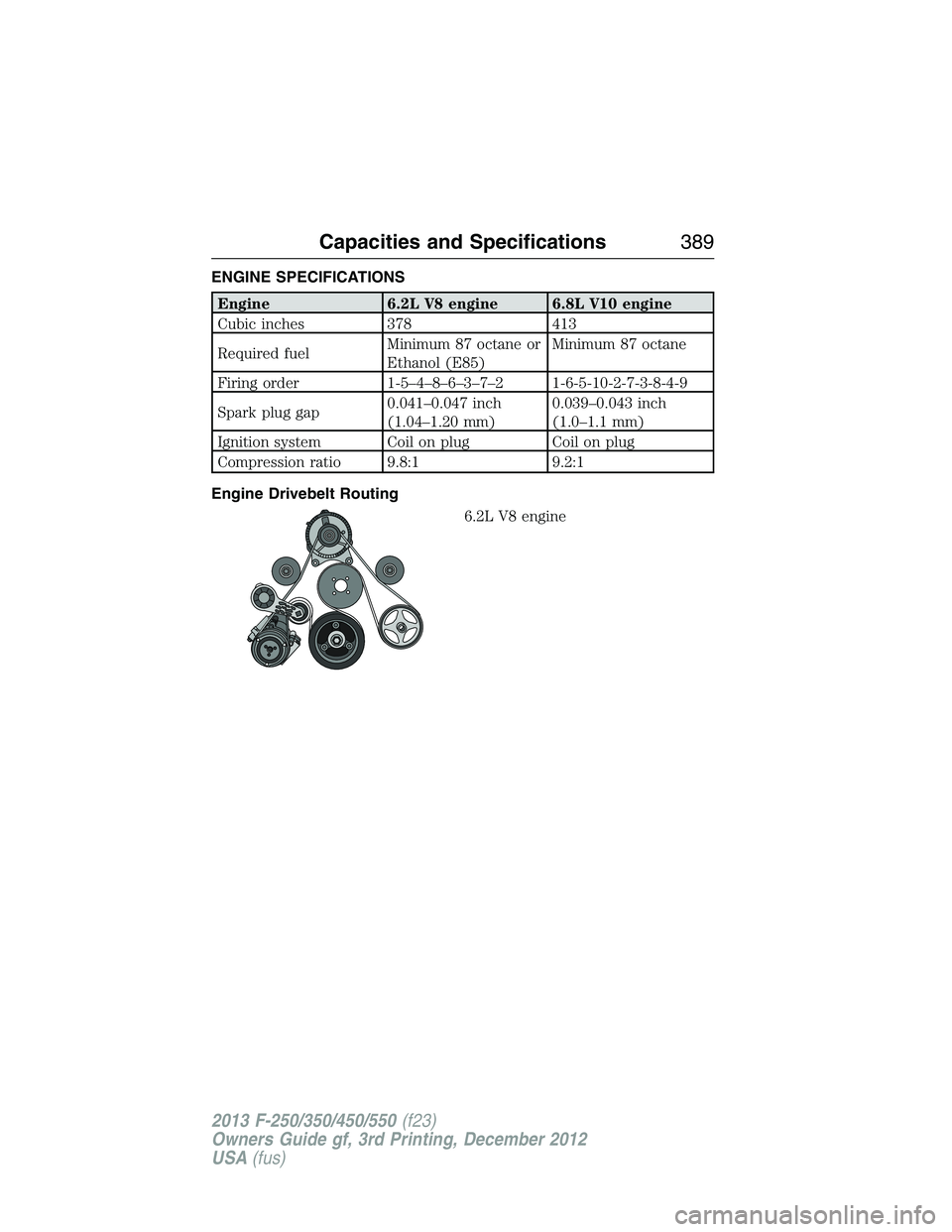

Engine Drivebelt Routing

6.2L V8 engine

Capacities and Specifications389

2013 F-250/350/450/550(f23)

Owners Guide gf, 3rd Printing, December 2012

USA(fus)