brake FORD F250 2014 Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 2014, Model line: F250, Model: FORD F250 2014Pages: 460, PDF Size: 5.33 MB

Page 267 of 460

Note:

Do not reduce tire pressure

to change the ride characteristics

of the vehicle. If you do not

maintain the inflation pressure at

the levels specified by Ford, your

vehicle may experience a condition

known as shimmy. Shimmy is a

severe vibration and oscillation in

the steering wheel after the vehicle

travels over a bump or dip in the

road that does not dampen out by

itself. Shimmy may result from

significant under-inflation of the

tires, improper tires (load range,

size, or type), or vehicle

modifications such as lift-kits. In

the event that your vehicle

experiences shimmy, you should

slowly reduce speed by either lifting

off the accelerator pedal or lightly

applying the brakes. The shimmy

will cease as the vehicle speed

decreases.

Maximum Inflation Pressure is

the tire manufacturer's maximum

permissible pressure and the

pressure at which the maximum

load can be carried by the tire. This

pressure is normally higher than

the manufacturer ’s recommended

cold inflation pressure which can

be found on the Safety

Compliance Certification Label

(affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch

post, next to the driver's seating

position), or Tire Label located on the B-pillar or the edge of the

driver's door. The cold inflation

pressure should never be set lower

than the recommended pressure

on the Safety Compliance

Certification Label or Tire Label.

When weather temperature

changes occur, tire inflation

pressures also change. A 10°F

(6°C) temperature drop can

cause a corresponding drop of 1

psi (7 kPa) in inflation pressure.

Check your tire pressures

frequently and adjust them to the

proper pressure which can be

found on the Safety Compliance

Certification Label or Tire Label.

To check the pressure in your

tire(s):

1. Make sure the tires are cool,

meaning they are not hot from

driving even a mile.

Note:

If you are checking tire

pressure when the tire is hot, (for

example, driven more than 1 mile

[1.6 kilometers]), never bleed or

reduce air pressure. The tires are

hot from driving and it is normal for

pressures to increase above

recommended cold pressures. A

hot tire at or below recommended

cold inflation pressure could be

significantly under-inflated.

264

Super Duty (TFA) Wheels and Tires

Page 276 of 460

If your vehicle is equipped with

dual rear wheels it is

recommended that the front and

rear tires (in pairs) be rotated only

side to side. We do not

recommend splitting up the dual

rear wheels. Rotate them side to

side as a set. After tire rotation,

inflation pressures must be

adjusted for the tires new

positions in accordance with

vehicle requirements.

Sometimes irregular tire wear can

be corrected by rotating the tires.

USING SNOW CHAINS

WARNING

Snow tires must be the same size,

load index, speed rating as those

originally provided by Ford. Use of

any tire or wheel not recommended by

Ford can affect the safety and

performance of your vehicle, which could

result in an increased risk of loss of vehicle

control, vehicle rollover, personal injury and

death. Additionally, the use of

non-recommended tires and wheels could

cause steering, suspension, axle, transfer

case or power transfer unit failure. Note:

Do not use snow chains on vehicles

with 20 inch wheels and tires.

The tires on your vehicle have all-weather

treads to provide traction in rain and snow.

However, in some climates, you may need

to use snow tires and cables. If you need

to use cables, it is recommended that steel

wheels (of the same size and

specifications) be used, as cables may chip

aluminum wheels. Note:

The suspension insulation and

bumpers will help prevent vehicle damage.

Do not remove these components from your

vehicle when using snow tires and chains.

Follow these guidelines when using snow

tires and chains:

• If possible, avoid fully loading your

vehicle

• Use only SAE Class S chains.

• Install chains securely, verifying that

the chains do not touch any wiring,

brake lines or fuel lines.

• Drive cautiously. If you hear the chains

rub or bang against your vehicle, stop

and retighten the chains. If this does

not work, remove the chains to prevent

damage to your vehicle.

• Remove the tire chains when they are

no longer needed. Do not use tire

chains on dry roads.

If you have any questions regarding snow

chains or cables, please contact your

authorized dealer.

TIRE PRESSURE MONITORING

SYSTEM WARNING

The tire pressure monitoring system

is not a substitute for manually

checking tire pressure. The tire

pressure should be checked periodically

(at least monthly) using a tire gauge, see

Inflating your tires in this chapter. Failure

to properly maintain your tire pressure

could increase the risk of tire failure, loss

of control, vehicle rollover and personal

injury. 273

Super Duty (TFA) Wheels and Tires

Page 282 of 460

11.

Set all four tires to the recommended

air pressure as indicated on the

Safety Compliance Certification

Label (affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver's seating position)

or Tire Label located on the B-Pillar

or the edge of the driver's door.

CHANGING A ROAD WHEEL WARNINGS

The use of tire sealants may damage

your tire pressure monitoring system

and should not be used. However, if

you must use a sealant, the tire pressure

monitoring system sensor and valve stem

on the wheel must be replaced by an

authorized dealer. If the tire pressure monitor sensor

becomes damaged, it will no longer

function. See Tire Pressure

Monitoring System (page 273). Note:

If your vehicle is equipped with the

tire pressure monitoring system, the

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not

apply the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe

place on the side of the road. If your vehicle is equipped with the tire

pressure monitoring system, have a flat

serviced by an authorized dealer in order

to prevent damage to the system sensors.

See

Tire Pressure Monitoring System

(page 273). Replace the spare tire with a

road tire as soon as possible. During

repairing or replacing of the flat tire, have

the authorized dealer inspect the system

sensor for damage.

Dissimilar Spare Wheel and Tire

Assembly Information WARNING

Failure to follow these guidelines

could result in an increased risk of

loss of vehicle control, injury or death.

If you have a dissimilar spare wheel and

tire, then it is intended for temporary use

only. This means that if you need to use it,

you should replace it as soon as possible

with a road wheel and tire assembly that

is the same size and type as the road tires

and wheels that were originally provided

by Ford. If the dissimilar spare tire or wheel

is damaged, it should be replaced rather

than repaired.

A dissimilar spare wheel and tire assembly

is defined as a spare wheel and tire

assembly that is different in brand, size or

appearance from the road tires and wheels

and can be one of three types:

1.

T-type mini-spare:

This spare tire

begins with the letter T for tire size and

may have Temporary Use Only molded in

the sidewall.

2. Full-size dissimilar spare with label

on wheel:

This spare tire has a label on

the wheel that states: THIS WHEEL AND

TIRE ASSEMBLY FOR TEMPORARY USE

ONLY

When driving with one of the dissimilar

spare tires listed above, do not:

279

Super Duty (TFA) Wheels and Tires

Page 285 of 460

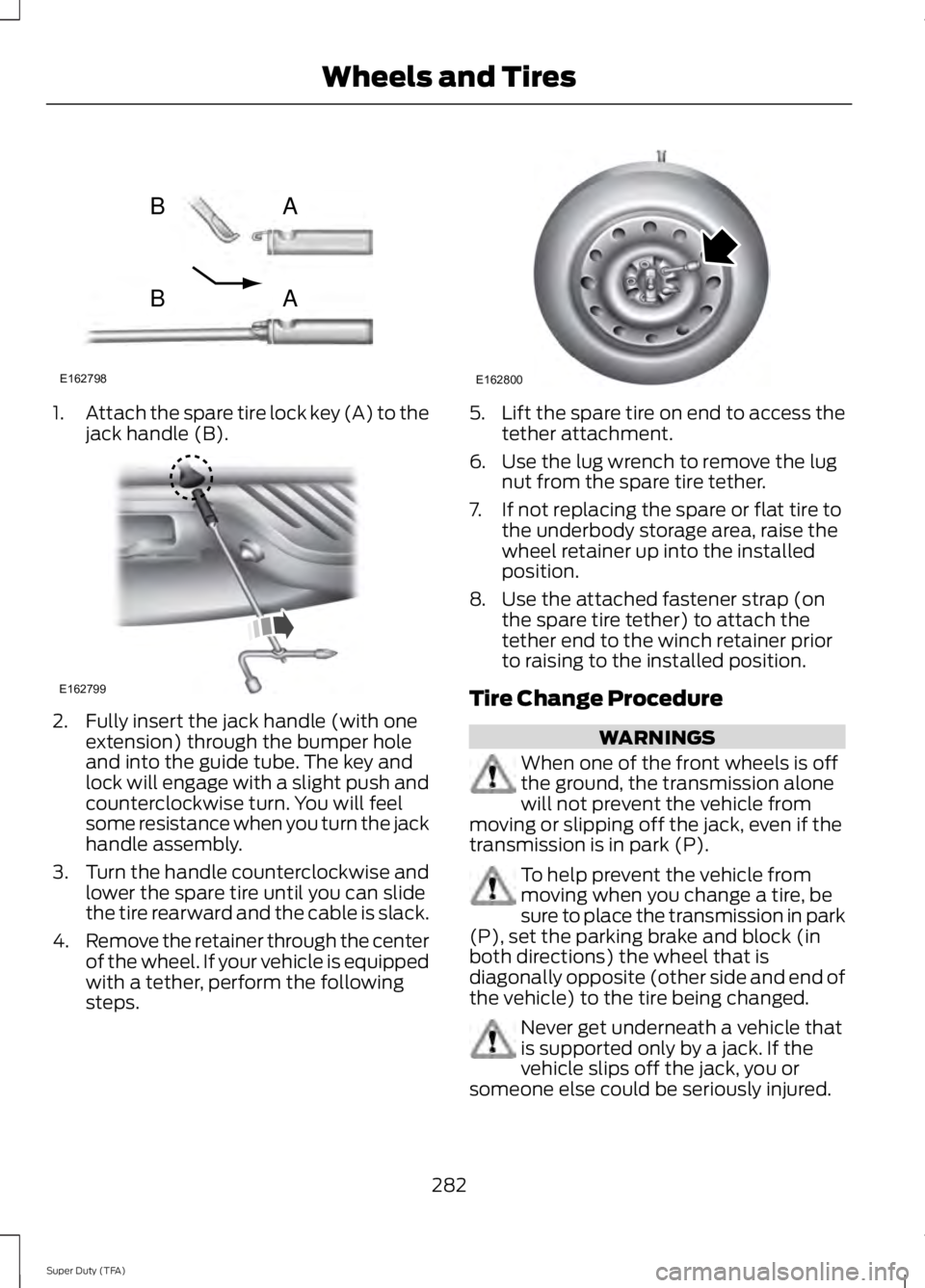

1.

Attach the spare tire lock key (A) to the

jack handle (B). 2. Fully insert the jack handle (with one

extension) through the bumper hole

and into the guide tube. The key and

lock will engage with a slight push and

counterclockwise turn. You will feel

some resistance when you turn the jack

handle assembly.

3. Turn the handle counterclockwise and

lower the spare tire until you can slide

the tire rearward and the cable is slack.

4. Remove the retainer through the center

of the wheel. If your vehicle is equipped

with a tether, perform the following

steps. 5.

Lift the spare tire on end to access the

tether attachment.

6. Use the lug wrench to remove the lug nut from the spare tire tether.

7. If not replacing the spare or flat tire to the underbody storage area, raise the

wheel retainer up into the installed

position.

8. Use the attached fastener strap (on the spare tire tether) to attach the

tether end to the winch retainer prior

to raising to the installed position.

Tire Change Procedure WARNINGS

When one of the front wheels is off

the ground, the transmission alone

will not prevent the vehicle from

moving or slipping off the jack, even if the

transmission is in park (P). To help prevent the vehicle from

moving when you change a tire, be

sure to place the transmission in park

(P), set the parking brake and block (in

both directions) the wheel that is

diagonally opposite (other side and end of

the vehicle) to the tire being changed. Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured.

282

Super Duty (TFA) Wheels and TiresE162798

AB

AB E162799 E162800

Page 286 of 460

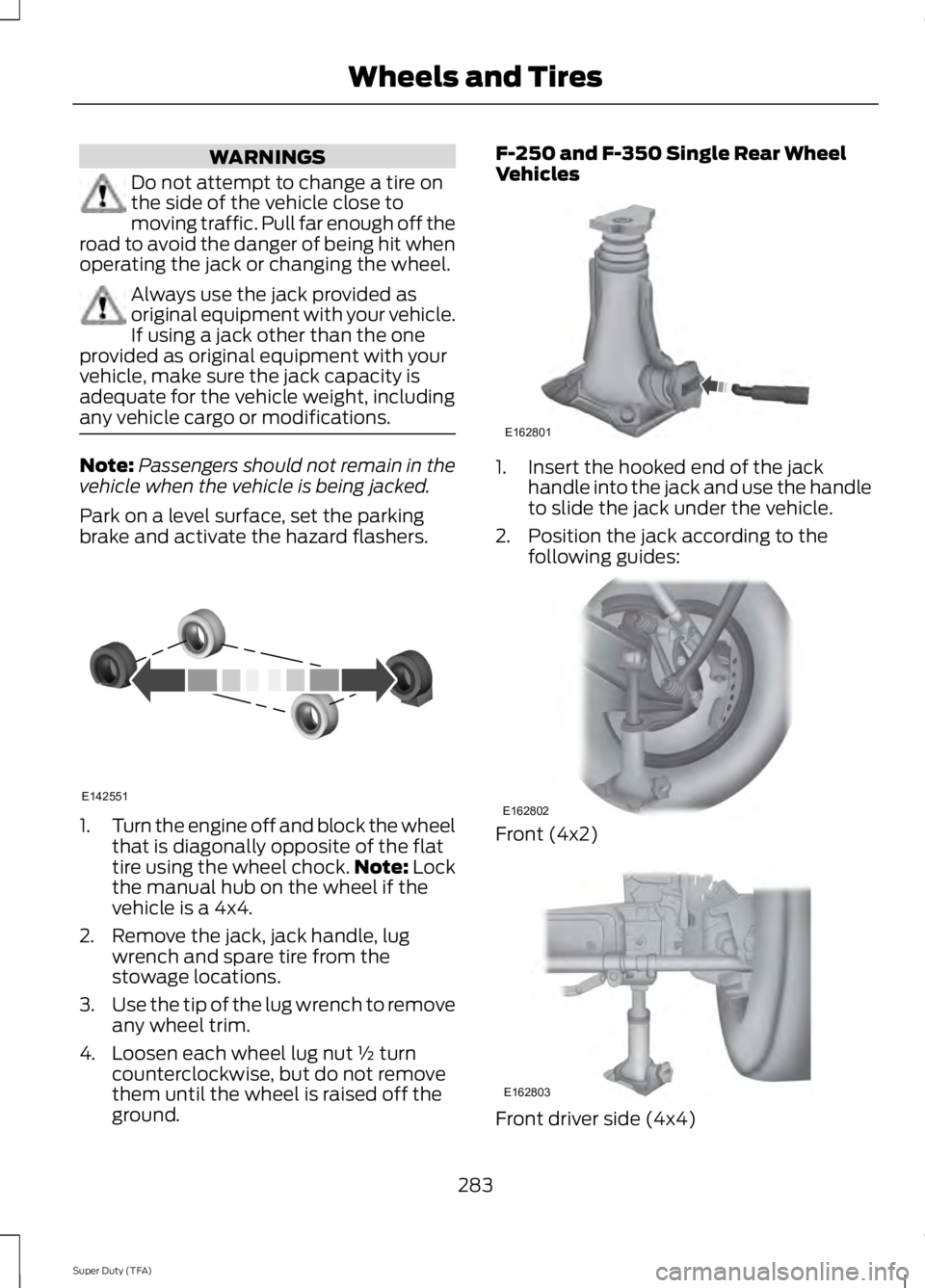

WARNINGS

Do not attempt to change a tire on

the side of the vehicle close to

moving traffic. Pull far enough off the

road to avoid the danger of being hit when

operating the jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one

provided as original equipment with your

vehicle, make sure the jack capacity is

adequate for the vehicle weight, including

any vehicle cargo or modifications. Note:

Passengers should not remain in the

vehicle when the vehicle is being jacked.

Park on a level surface, set the parking

brake and activate the hazard flashers. 1.

Turn the engine off and block the wheel

that is diagonally opposite of the flat

tire using the wheel chock. Note: Lock

the manual hub on the wheel if the

vehicle is a 4x4.

2. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

3. Use the tip of the lug wrench to remove

any wheel trim.

4. Loosen each wheel lug nut ½ turn counterclockwise, but do not remove

them until the wheel is raised off the

ground. F-250 and F-350 Single Rear Wheel

Vehicles

1. Insert the hooked end of the jack

handle into the jack and use the handle

to slide the jack under the vehicle.

2. Position the jack according to the following guides: Front (4x2)

Front driver side (4x4)

283

Super Duty (TFA) Wheels and TiresE142551 E162801 E162802 E162803

Page 293 of 460

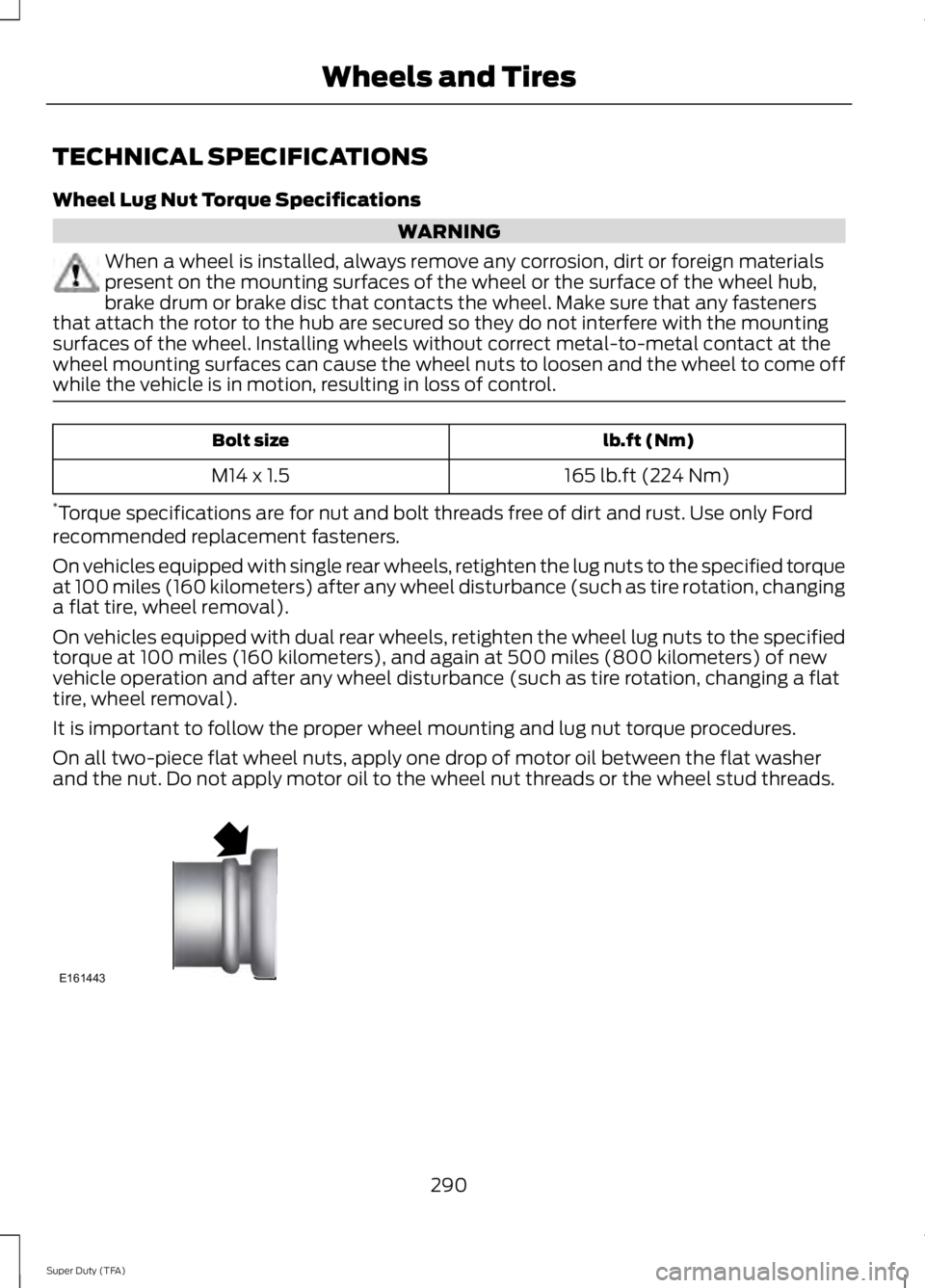

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign materials

present on the mounting surfaces of the wheel or the surface of the wheel hub,

brake drum or brake disc that contacts the wheel. Make sure that any fasteners

that attach the rotor to the hub are secured so they do not interfere with the mounting

surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off

while the vehicle is in motion, resulting in loss of control. lb.ft (Nm)

Bolt size

165 lb.ft (224 Nm)

M14 x 1.5

* Torque specifications are for nut and bolt threads free of dirt and rust. Use only Ford

recommended replacement fasteners.

On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque

at 100 miles (160 kilometers) after any wheel disturbance (such as tire rotation, changing

a flat tire, wheel removal).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts to the specified

torque at 100 miles (160 kilometers), and again at 500 miles (800 kilometers) of new

vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat

tire, wheel removal).

It is important to follow the proper wheel mounting and lug nut torque procedures.

On all two-piece flat wheel nuts, apply one drop of motor oil between the flat washer

and the nut. Do not apply motor oil to the wheel nut threads or the wheel stud threads. 290

Super Duty (TFA) Wheels and TiresE161443

Page 297 of 460

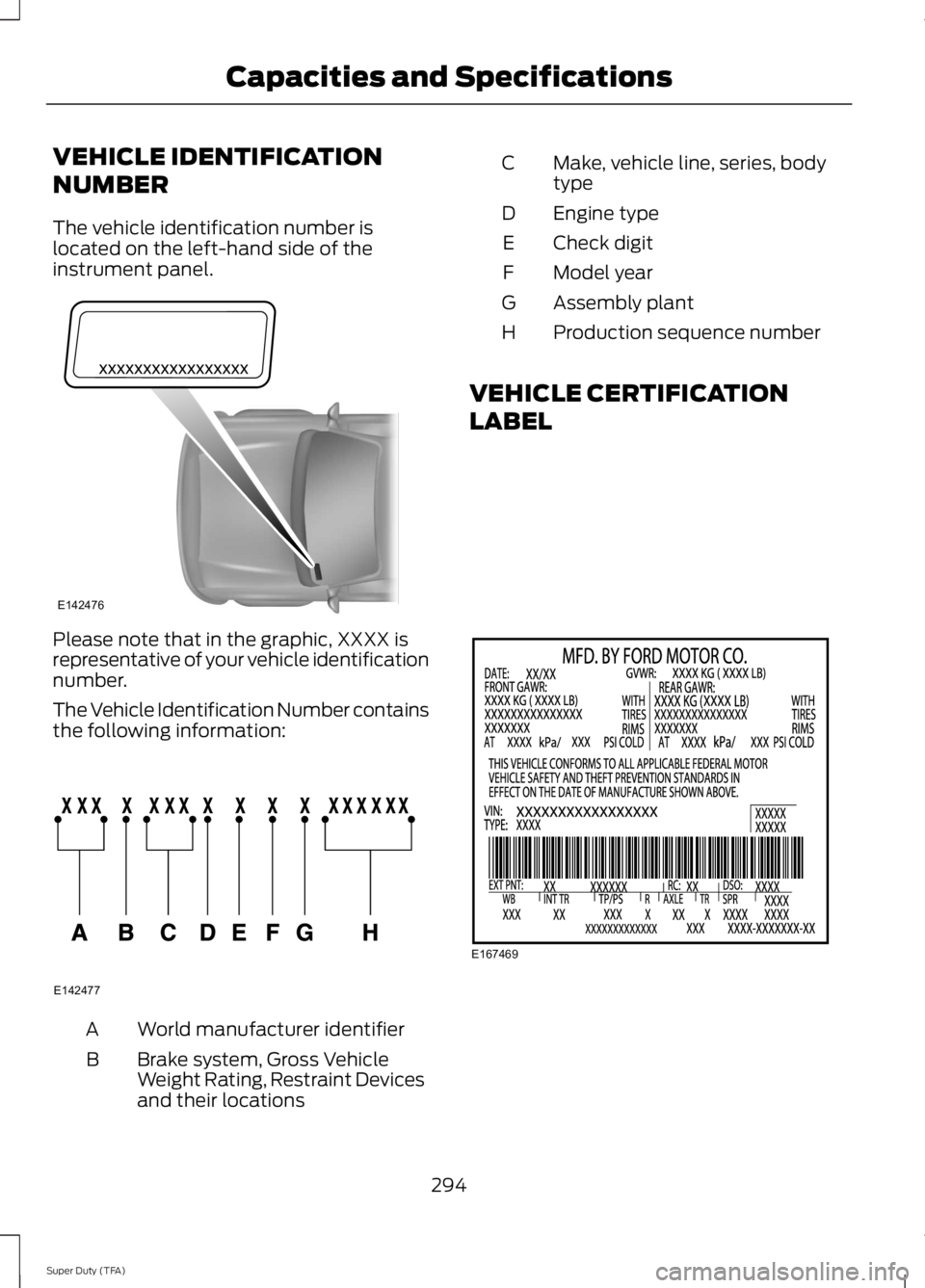

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number is

located on the left-hand side of the

instrument panel.

Please note that in the graphic, XXXX is

representative of your vehicle identification

number.

The Vehicle Identification Number contains

the following information:

World manufacturer identifier

A

Brake system, Gross Vehicle

Weight Rating, Restraint Devices

and their locations

B Make, vehicle line, series, body

type

C

Engine type

D

Check digit

E

Model year

F

Assembly plant

G

Production sequence number

H

VEHICLE CERTIFICATION

LABEL 294

Super Duty (TFA) Capacities and SpecificationsE142476 E142477 E167469

Page 299 of 460

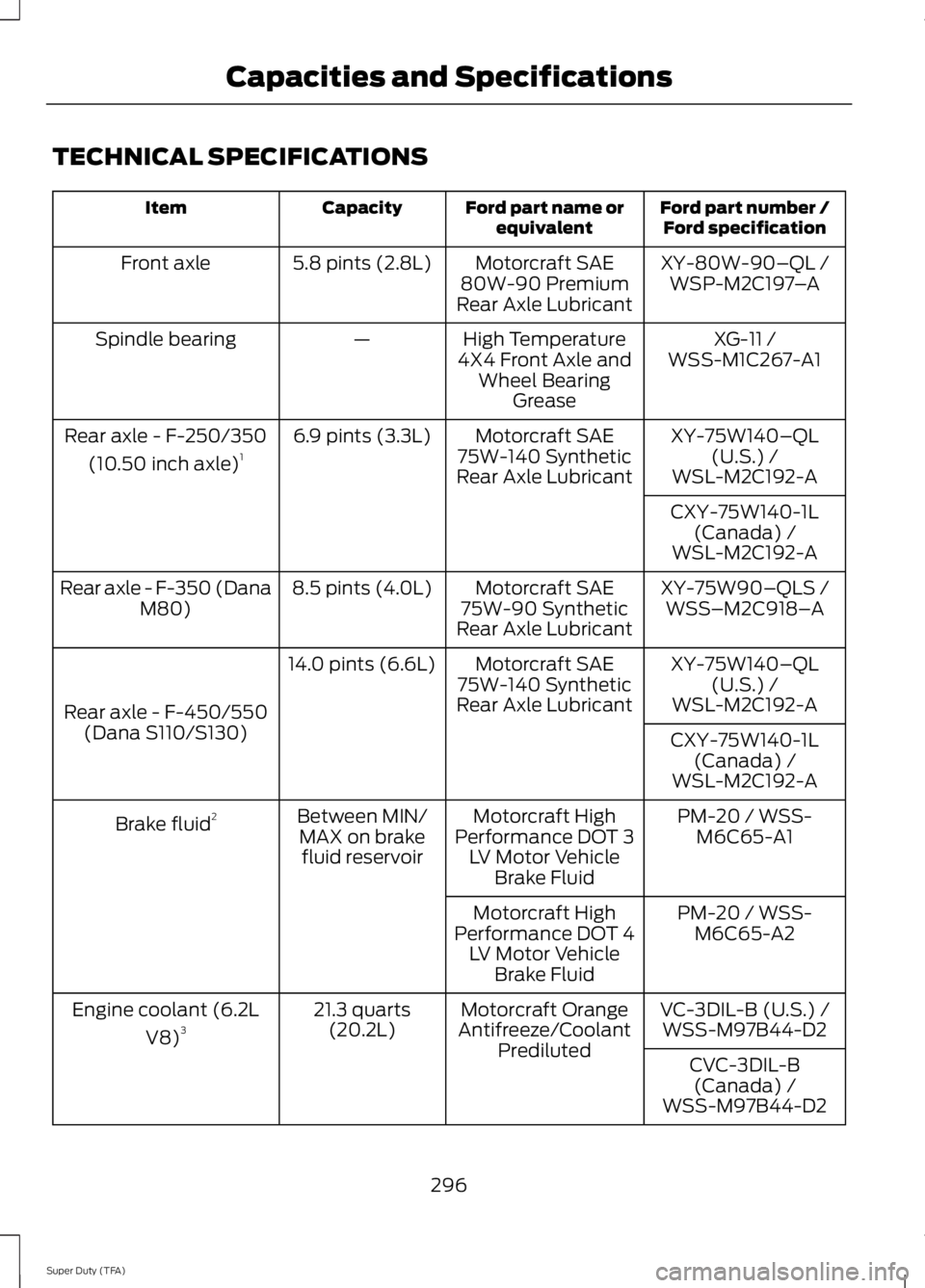

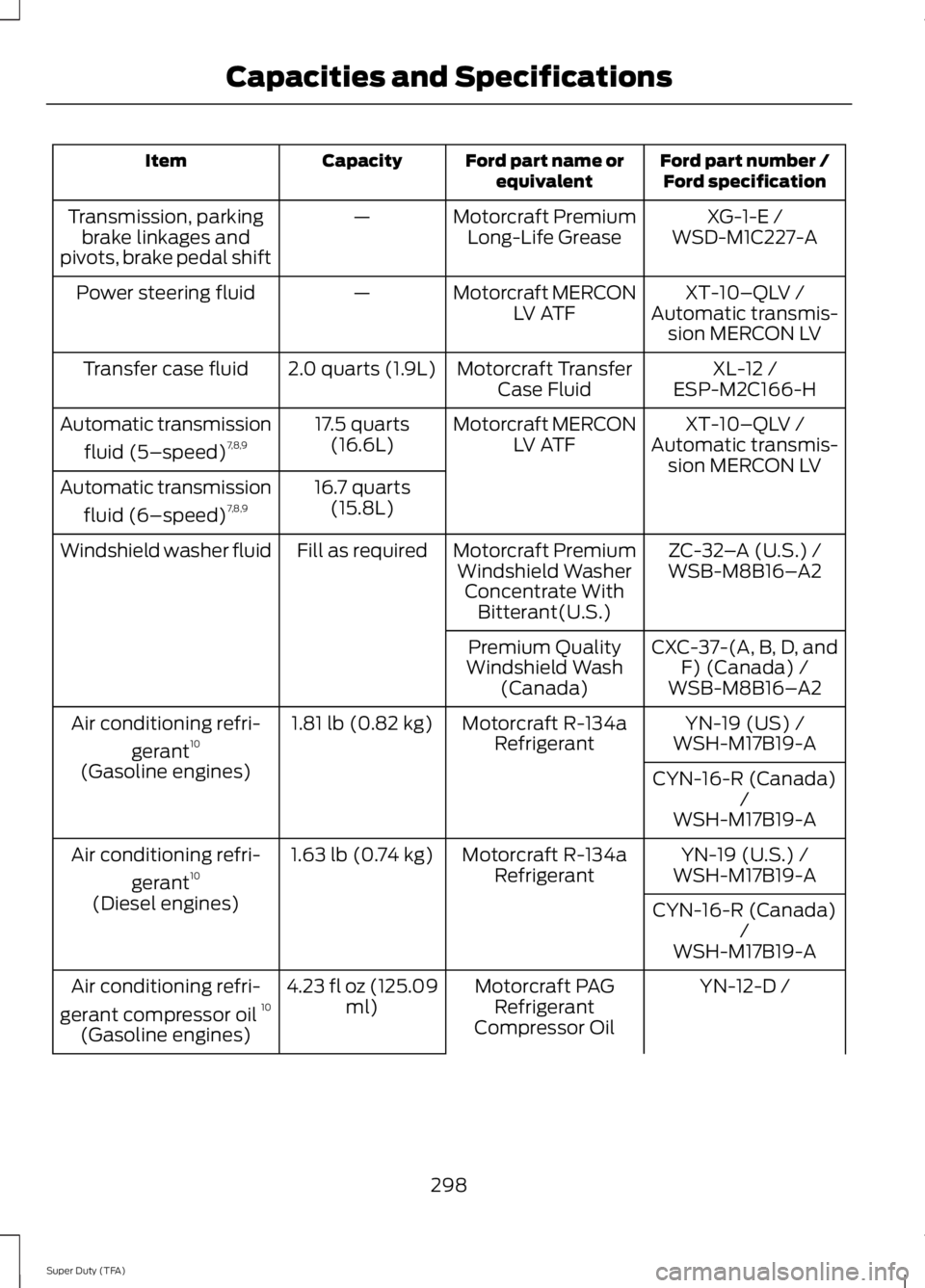

TECHNICAL SPECIFICATIONS

Ford part number /

Ford specification

Ford part name or

equivalent

Capacity

Item

XY-80W-90–QL /

Motorcraft SAE

80W-90 Premium

Rear Axle Lubricant

5.8 pints (2.8L)

Front axle

WSP-M2C197–A

XG-11 /

High Temperature

4X4 Front Axle and Wheel Bearing Grease

—

Spindle bearing

WSS-M1C267-A1

XY-75W140–QL (U.S.) /

Motorcraft SAE

75W-140 Synthetic

Rear Axle Lubricant

6.9 pints (3.3L)

Rear axle - F-250/350

(10.50 inch axle) 1

WSL-M2C192-A

CXY-75W140-1L (Canada) /

WSL-M2C192-A

XY-75W90–QLS /

Motorcraft SAE

75W-90 Synthetic

Rear Axle Lubricant

8.5 pints (4.0L)

Rear axle - F-350 (Dana

M80) WSS–M2C918–A

XY-75W140–QL (U.S.) /

Motorcraft SAE

75W-140 Synthetic

Rear Axle Lubricant

14.0 pints (6.6L)

Rear axle - F-450/550 (Dana S110/S130) WSL-M2C192-A

CXY-75W140-1L (Canada) /

WSL-M2C192-A

PM-20 / WSS- M6C65-A1

Motorcraft High

Performance DOT 3 LV Motor Vehicle Brake Fluid

Between MIN/

MAX on brakefluid reservoir

Brake fluid

2

PM-20 / WSS-M6C65-A2

Motorcraft High

Performance DOT 4 LV Motor Vehicle Brake Fluid

VC-3DIL-B (U.S.) /

Motorcraft Orange

Antifreeze/Coolant Prediluted

21.3 quarts

(20.2L)

Engine coolant (6.2L

V8)3

WSS-M97B44-D2

CVC-3DIL-B(Canada) /

WSS-M97B44-D2

296

Super Duty (TFA) Capacities and Specifications

Page 301 of 460

Ford part number /

Ford specification

Ford part name or

equivalent

Capacity

Item

XG-1-E /

Motorcraft Premium

Long-Life Grease

—

Transmission, parking

brake linkages and

pivots, brake pedal shift WSD-M1C227-A

XT-10–QLV /

Motorcraft MERCON

LV ATF

—

Power steering fluid

Automatic transmis-sion MERCON LV

XL-12 /

Motorcraft Transfer

Case Fluid

2.0 quarts (1.9L)

Transfer case fluid

ESP-M2C166-H

XT-10–QLV /

Motorcraft MERCON

LV ATF

17.5 quarts

(16.6L)

Automatic transmission

fluid (5–speed) 7,8,9

Automatic transmis-

sion MERCON LV

16.7 quarts (15.8L)

Automatic transmission

fluid (6–speed) 7,8,9

ZC-32–A (U.S.) /

Motorcraft Premium

Windshield Washer Concentrate With Bitterant(U.S.)

Fill as required

Windshield washer fluid

WSB-M8B16–A2

CXC-37-(A, B, D, and F) (Canada) /

Premium Quality

Windshield Wash (Canada) WSB-M8B16– A2

YN-19 (US) /

Motorcraft R-134a

Refrigerant

1.81 lb (0.82 kg)

Air conditioning refri-

gerant10

WSH-M17B19-A

(Gasoline engines) CYN-16-R (Canada)

/

WSH-M17B19-A

YN-19 (U.S.) /

Motorcraft R-134a

Refrigerant

1.63 lb (0.74 kg)

Air conditioning refri-

gerant10

WSH-M17B19-A

(Diesel engines) CYN-16-R (Canada)

/

WSH-M17B19-A

YN-12-D /

Motorcraft PAG

Refrigerant

Compressor Oil

4.23 fl oz (125.09

ml)

Air conditioning refri-

gerant compressor oil 10

(Gasoline engines)

298

Super Duty (TFA) Capacities and Specifications

Page 303 of 460

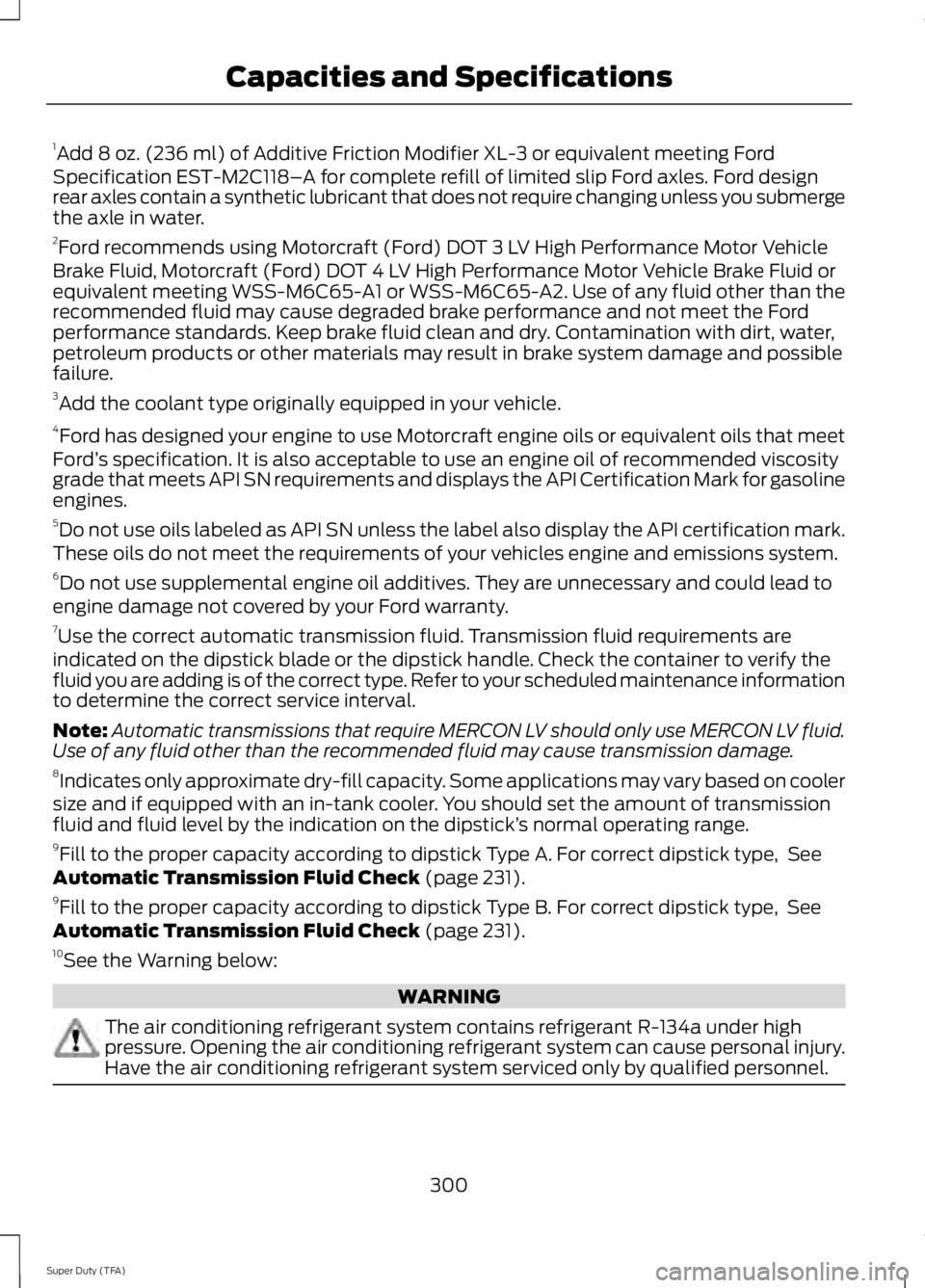

1

Add 8 oz. (236 ml) of Additive Friction Modifier XL-3 or equivalent meeting Ford

Specification EST-M2C118– A for complete refill of limited slip Ford axles. Ford design

rear axles contain a synthetic lubricant that does not require changing unless you submerge

the axle in water.

2 Ford recommends using Motorcraft (Ford) DOT 3 LV High Performance Motor Vehicle

Brake Fluid, Motorcraft (Ford) DOT 4 LV High Performance Motor Vehicle Brake Fluid or

equivalent meeting WSS-M6C65-A1 or WSS-M6C65-A2. Use of any fluid other than the

recommended fluid may cause degraded brake performance and not meet the Ford

performance standards. Keep brake fluid clean and dry. Contamination with dirt, water,

petroleum products or other materials may result in brake system damage and possible

failure.

3 Add the coolant type originally equipped in your vehicle.

4 Ford has designed your engine to use Motorcraft engine oils or equivalent oils that meet

Ford ’s specification. It is also acceptable to use an engine oil of recommended viscosity

grade that meets API SN requirements and displays the API Certification Mark for gasoline

engines.

5 Do not use oils labeled as API SN unless the label also display the API certification mark.

These oils do not meet the requirements of your vehicles engine and emissions system.

6 Do not use supplemental engine oil additives. They are unnecessary and could lead to

engine damage not covered by your Ford warranty.

7 Use the correct automatic transmission fluid. Transmission fluid requirements are

indicated on the dipstick blade or the dipstick handle. Check the container to verify the

fluid you are adding is of the correct type. Refer to your scheduled maintenance information

to determine the correct service interval.

Note: Automatic transmissions that require MERCON LV should only use MERCON LV fluid.

Use of any fluid other than the recommended fluid may cause transmission damage.

8 Indicates only approximate dry-fill capacity. Some applications may vary based on cooler

size and if equipped with an in-tank cooler. You should set the amount of transmission

fluid and fluid level by the indication on the dipstick’ s normal operating range.

9 Fill to the proper capacity according to dipstick Type A. For correct dipstick type, See

Automatic Transmission Fluid Check (page 231).

9 Fill to the proper capacity according to dipstick Type B. For correct dipstick type, See

Automatic Transmission Fluid Check

(page 231).

10 See the Warning below: WARNING

The air conditioning refrigerant system contains refrigerant R-134a under high

pressure. Opening the air conditioning refrigerant system can cause personal injury.

Have the air conditioning refrigerant system serviced only by qualified personnel.

300

Super Duty (TFA) Capacities and Specifications