lock FORD F250 2016 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: F250, Model: FORD F250 2016Pages: 507, PDF Size: 6.81 MB

Page 253 of 507

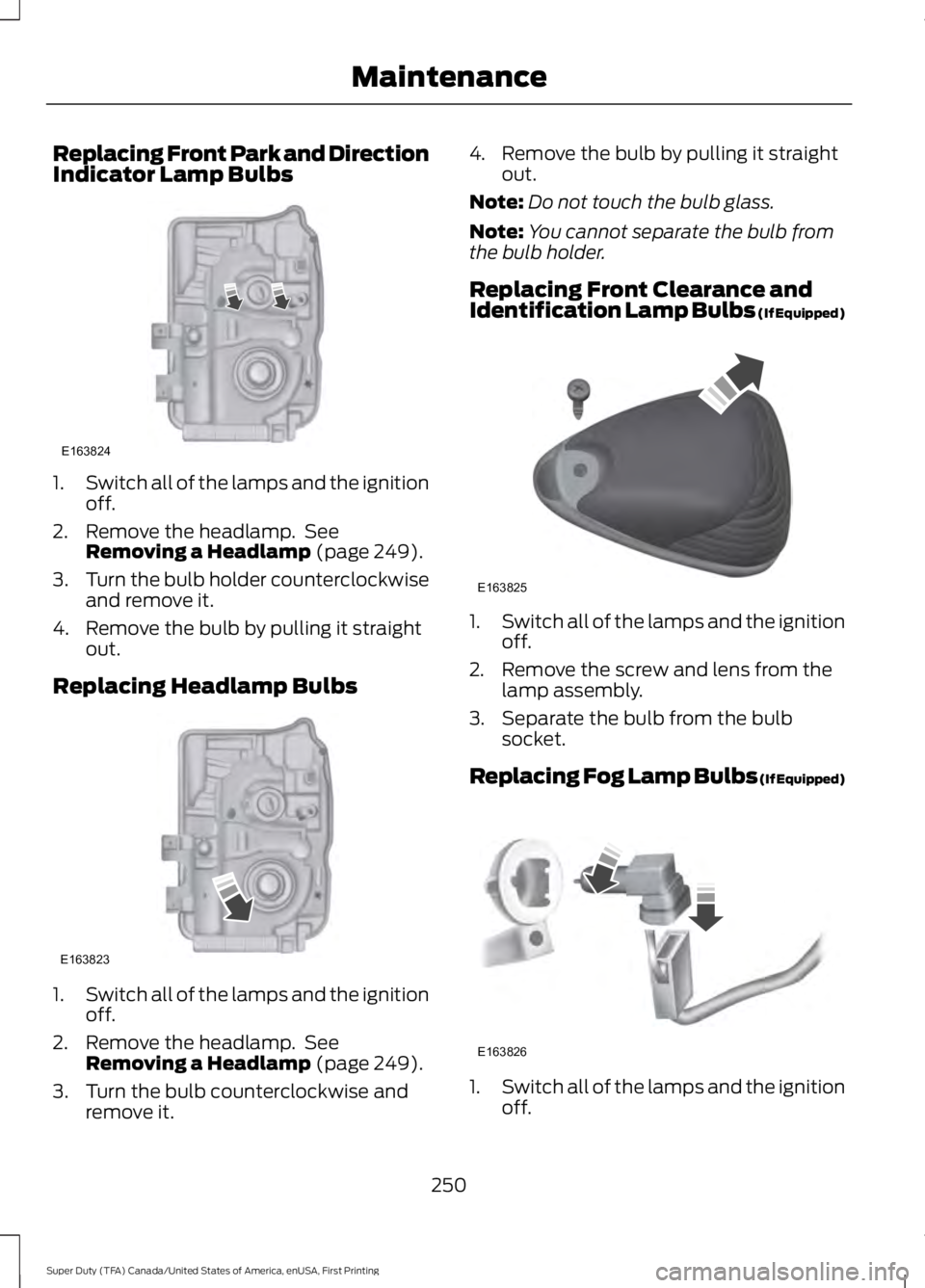

Replacing Front Park and Direction

Indicator Lamp Bulbs

1.

Switch all of the lamps and the ignition

off.

2. Remove the headlamp. See Removing a Headlamp (page 249).

3. Turn the bulb holder counterclockwise

and remove it.

4. Remove the bulb by pulling it straight out.

Replacing Headlamp Bulbs 1.

Switch all of the lamps and the ignition

off.

2. Remove the headlamp. See Removing a Headlamp

(page 249).

3. Turn the bulb counterclockwise and remove it. 4. Remove the bulb by pulling it straight

out.

Note: Do not touch the bulb glass.

Note: You cannot separate the bulb from

the bulb holder.

Replacing Front Clearance and

Identification Lamp Bulbs (If Equipped) 1.

Switch all of the lamps and the ignition

off.

2. Remove the screw and lens from the lamp assembly.

3. Separate the bulb from the bulb socket.

Replacing Fog Lamp Bulbs (If Equipped) 1.

Switch all of the lamps and the ignition

off.

250

Super Duty (TFA) Canada/United States of America, enUSA, First Printing MaintenanceE163824 E163823 E163825 E163826

Page 254 of 507

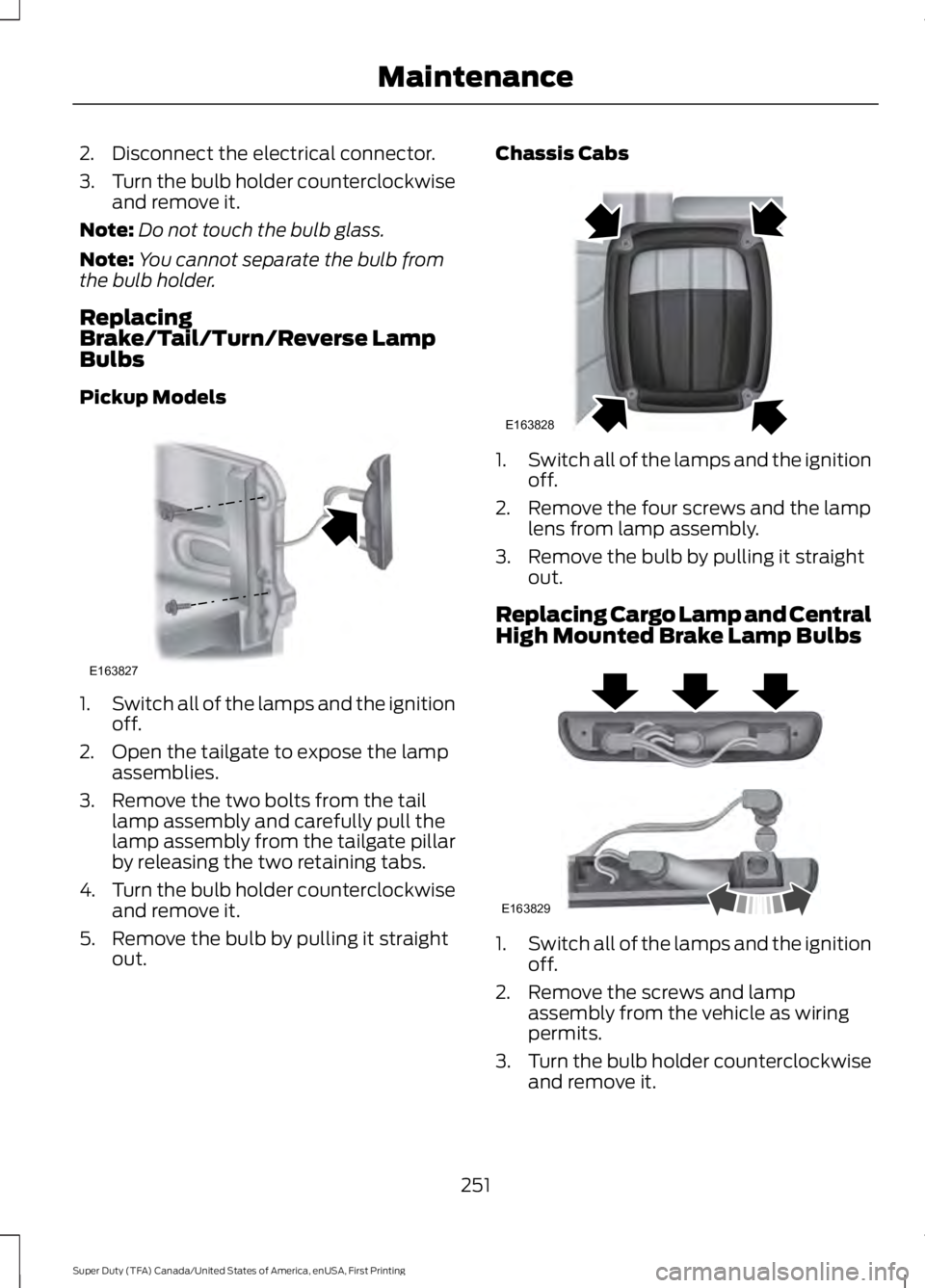

2. Disconnect the electrical connector.

3.

Turn the bulb holder counterclockwise

and remove it.

Note: Do not touch the bulb glass.

Note: You cannot separate the bulb from

the bulb holder.

Replacing

Brake/Tail/Turn/Reverse Lamp

Bulbs

Pickup Models 1.

Switch all of the lamps and the ignition

off.

2. Open the tailgate to expose the lamp assemblies.

3. Remove the two bolts from the tail lamp assembly and carefully pull the

lamp assembly from the tailgate pillar

by releasing the two retaining tabs.

4. Turn the bulb holder counterclockwise

and remove it.

5. Remove the bulb by pulling it straight out. Chassis Cabs

1.

Switch all of the lamps and the ignition

off.

2. Remove the four screws and the lamp lens from lamp assembly.

3. Remove the bulb by pulling it straight out.

Replacing Cargo Lamp and Central

High Mounted Brake Lamp Bulbs 1.

Switch all of the lamps and the ignition

off.

2. Remove the screws and lamp assembly from the vehicle as wiring

permits.

3. Turn the bulb holder counterclockwise

and remove it.

251

Super Duty (TFA) Canada/United States of America, enUSA, First Printing MaintenanceE163827 E163828 E163829

Page 255 of 507

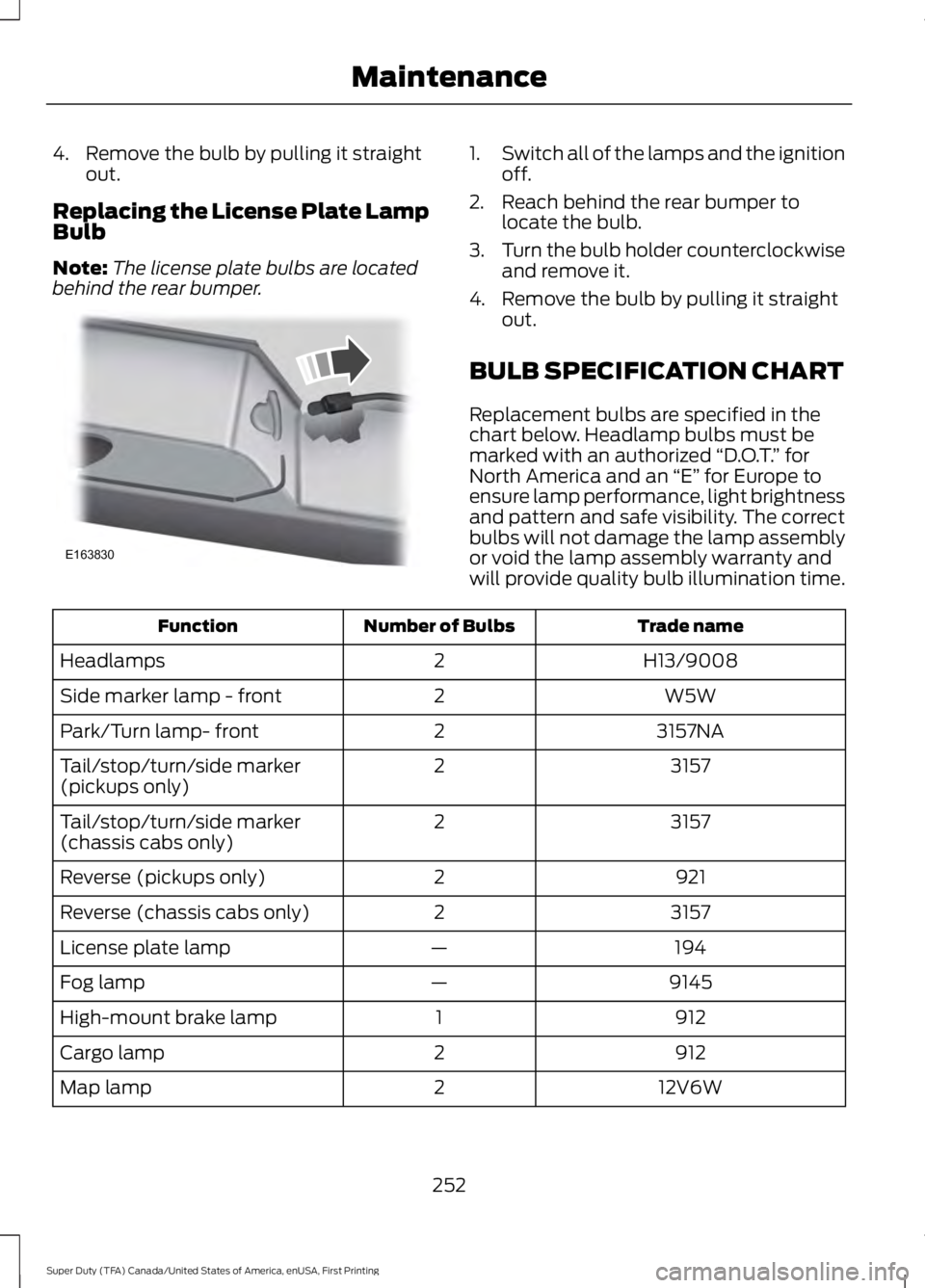

4. Remove the bulb by pulling it straight

out.

Replacing the License Plate Lamp

Bulb

Note: The license plate bulbs are located

behind the rear bumper. 1.

Switch all of the lamps and the ignition

off.

2. Reach behind the rear bumper to locate the bulb.

3. Turn the bulb holder counterclockwise

and remove it.

4. Remove the bulb by pulling it straight out.

BULB SPECIFICATION CHART

Replacement bulbs are specified in the

chart below. Headlamp bulbs must be

marked with an authorized “D.O.T.” for

North America and an “E” for Europe to

ensure lamp performance, light brightness

and pattern and safe visibility. The correct

bulbs will not damage the lamp assembly

or void the lamp assembly warranty and

will provide quality bulb illumination time. Trade name

Number of Bulbs

Function

H13/9008

2

Headlamps

W5W

2

Side marker lamp - front

3157NA

2

Park/Turn lamp- front

3157

2

Tail/stop/turn/side marker

(pickups only)

3157

2

Tail/stop/turn/side marker

(chassis cabs only)

921

2

Reverse (pickups only)

3157

2

Reverse (chassis cabs only)

194

—

License plate lamp

9145

—

Fog lamp

912

1

High-mount brake lamp

912

2

Cargo lamp

12V6W

2

Map lamp

252

Super Duty (TFA) Canada/United States of America, enUSA, First Printing MaintenanceE163830

Page 257 of 507

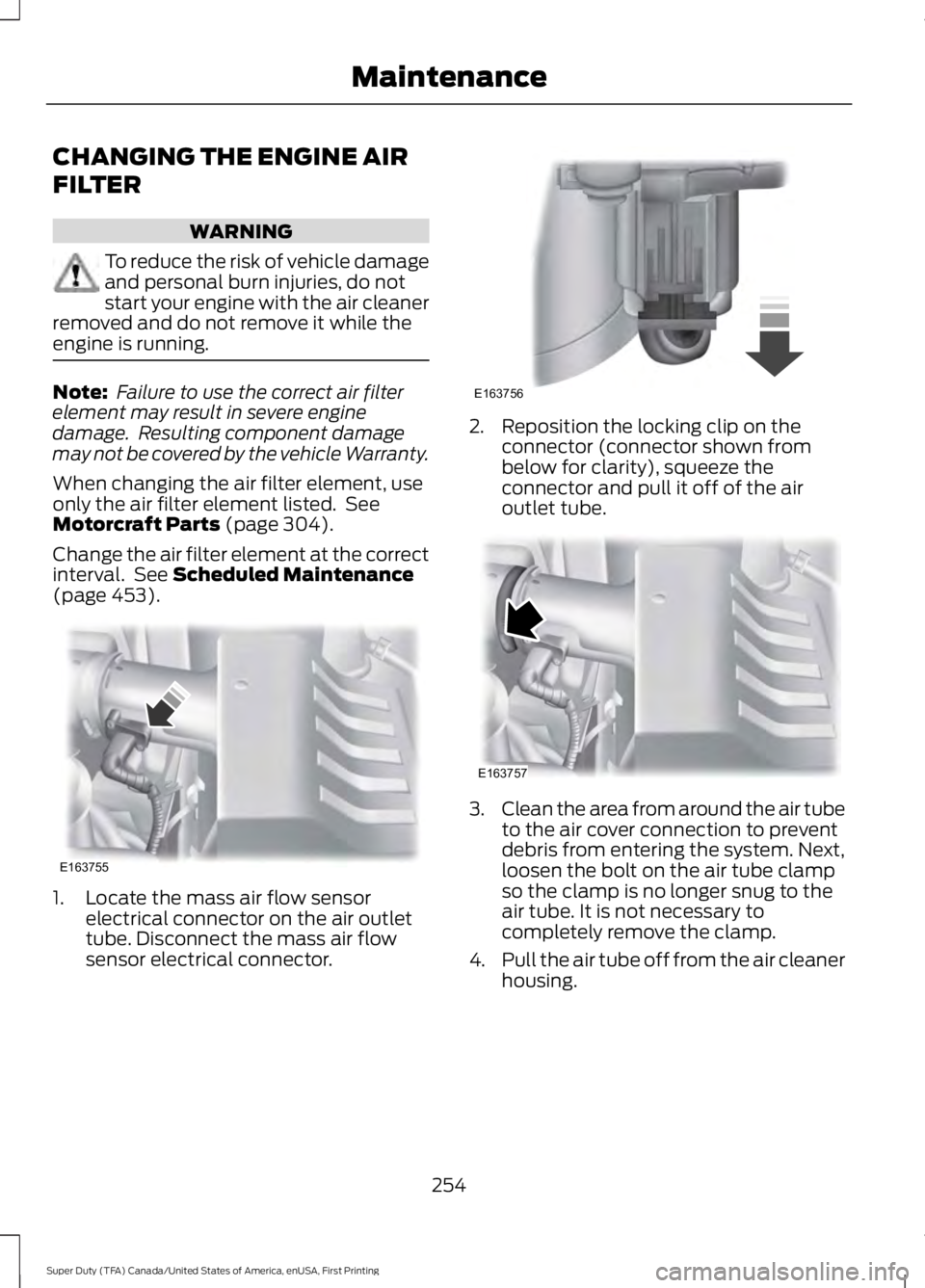

CHANGING THE ENGINE AIR

FILTER

WARNING

To reduce the risk of vehicle damage

and personal burn injuries, do not

start your engine with the air cleaner

removed and do not remove it while the

engine is running. Note:

Failure to use the correct air filter

element may result in severe engine

damage. Resulting component damage

may not be covered by the vehicle Warranty.

When changing the air filter element, use

only the air filter element listed. See

Motorcraft Parts (page 304).

Change the air filter element at the correct

interval. See

Scheduled Maintenance

(page 453). 1. Locate the mass air flow sensor

electrical connector on the air outlet

tube. Disconnect the mass air flow

sensor electrical connector. 2. Reposition the locking clip on the

connector (connector shown from

below for clarity), squeeze the

connector and pull it off of the air

outlet tube. 3.

Clean the area from around the air tube

to the air cover connection to prevent

debris from entering the system. Next,

loosen the bolt on the air tube clamp

so the clamp is no longer snug to the

air tube. It is not necessary to

completely remove the clamp.

4. Pull the air tube off from the air cleaner

housing.

254

Super Duty (TFA) Canada/United States of America, enUSA, First Printing MaintenanceE163755 E163756 E163757

Page 258 of 507

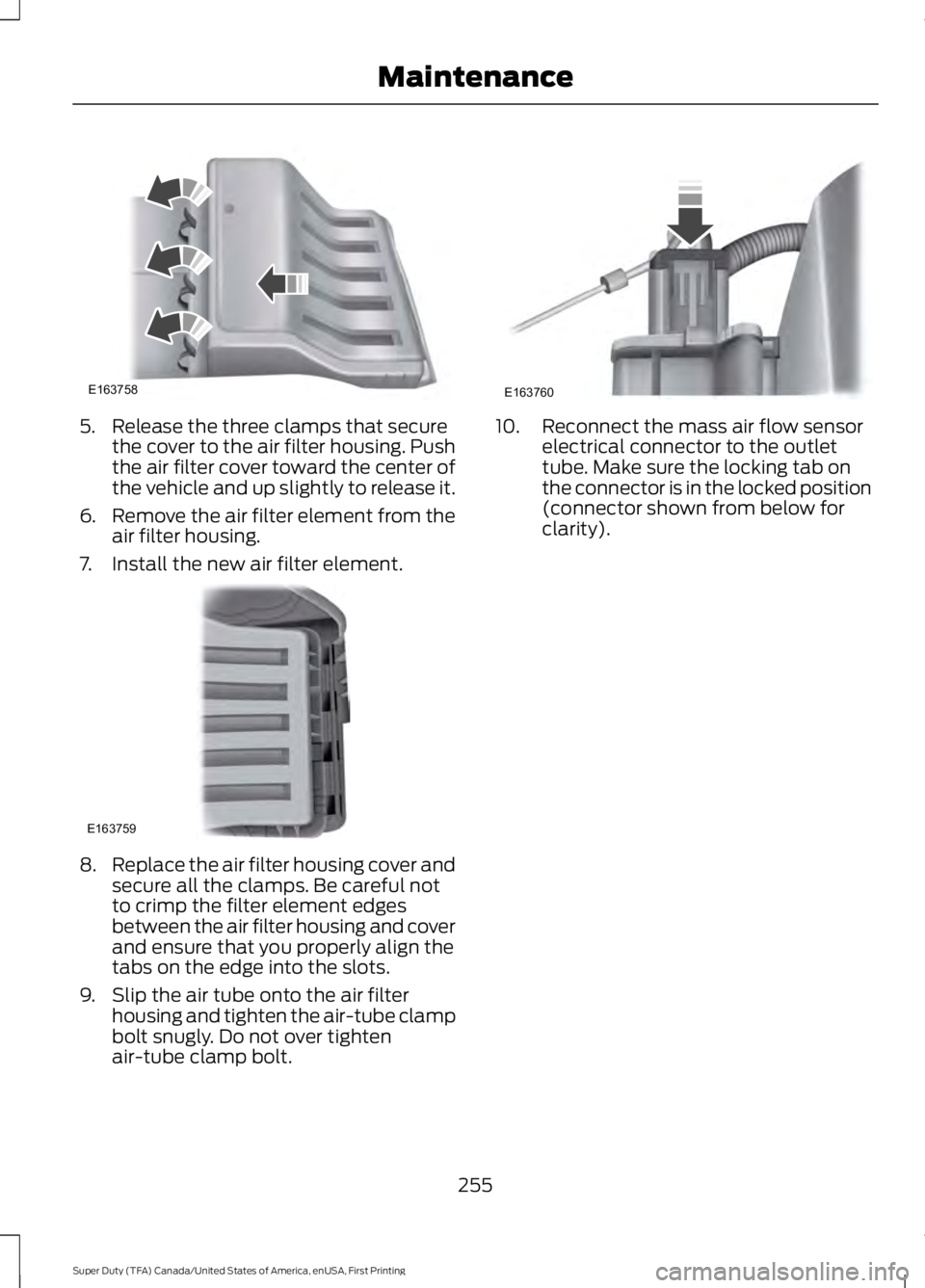

5. Release the three clamps that secure

the cover to the air filter housing. Push

the air filter cover toward the center of

the vehicle and up slightly to release it.

6. Remove the air filter element from the

air filter housing.

7. Install the new air filter element. 8.

Replace the air filter housing cover and

secure all the clamps. Be careful not

to crimp the filter element edges

between the air filter housing and cover

and ensure that you properly align the

tabs on the edge into the slots.

9. Slip the air tube onto the air filter housing and tighten the air-tube clamp

bolt snugly. Do not over tighten

air-tube clamp bolt. 10. Reconnect the mass air flow sensor

electrical connector to the outlet

tube. Make sure the locking tab on

the connector is in the locked position

(connector shown from below for

clarity).

255

Super Duty (TFA) Canada/United States of America, enUSA, First Printing MaintenanceE163758 E163759 E163760

Page 260 of 507

Note:

Never use abrasive materials, for

example steel wool or plastic pads as they

can scratch the chrome surface.

Note: Do not use chrome cleaner, metal

cleaner or polish on wheels or wheel covers.

Exterior Plastic Parts

For routine cleaning we recommend

Motorcraft Detail Wash. If tar or grease

spots are present, we recommend

Motorcraft Bug and Tar Remover.

Stripes or Graphics (If Equipped)

Do not use a commercial or high-pressure

sprayer on the surface or edge of stripes

and graphics. This can damage them and

cause the edges to peel away from the

vehicle surface.

Underbody

Flush the complete underside of your

vehicle frequently. Keep body and door

drain holes free of debris or foreign

material.

WAXING

Regular waxing is necessary to protect your

car's paint from the elements. We

recommend that you wash and wax the

painted surface once or twice a year.

When washing and waxing, park your

vehicle in a shaded area out of direct

sunlight. Always wash your vehicle before

applying wax.

• Use a quality wax that does not contain

abrasives.

• Follow the manufacturer ’s instructions

to apply and remove the wax.

• Apply a small amount of wax in a

back-and-forth motion, not in circles. •

Do not allow wax to come in contact

with any non-body (low-gloss black)

colored trim. The wax will discolor or

stain the parts over time.

•Roof racks.

• Bumpers.

• Grained door handles.

• Side moldings.

• Mirror housings.

• Windshield cowl area.

• Do not apply wax to glass areas.

• After waxing, your car's paint should

feel smooth, and be free of streaks and

smudges.

CLEANING THE ENGINE

Engines are more efficient when they are

clean because grease and dirt buildup keep

the engine warmer than normal.

When washing:

• Take care when using a power washer

to clean the engine. The high-pressure

fluid could penetrate the sealed parts

and cause damage.

• Do not spray a hot engine with cold

water to avoid cracking the engine

block or other engine components.

• Spray Motorcraft Engine Shampoo and

Degreaser on all parts that require

cleaning and pressure rinse clean. In

Canada, use Motorcraft Engine

Shampoo.

• Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage.

257

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Vehicle Care

Page 292 of 507

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least three

feet (one meter) away from another

Ford Motor Company vehicle

undergoing the system reset procedure

at the same time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system will time-out and the entire

procedure will have to be repeated on

all four wheels.

• A double horn will sound indicating the

need to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure before

attempting.

1. Drive the vehicle above 20 mph (32 km/h) for at least two minutes, then

park in a safe location where you can

easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If the reset mode

has been entered successfully, the horn

will sound once, the system indicator

will flash and a message is shown in

the information display. If this does not

occur, please try again starting at Step

2. If after repeated attempts to enter

the reset mode, the horn does not

sound, the system indicator does not

flash and no message is shown in the

information display, seek service from

your authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front

(driver's side front tire), Right front

(passenger's side front tire), Right rear

(passenger's side rear tire), Left rear

(driver's side rear tire).

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn chirp confirms

that the sensor identification code has

been learned by the module for this

position. If a double horn is heard, the

reset procedure was unsuccessful, and

you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained (driver's

side rear tire), the system indicator

stops flashing, and a message is shown

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

289

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 295 of 507

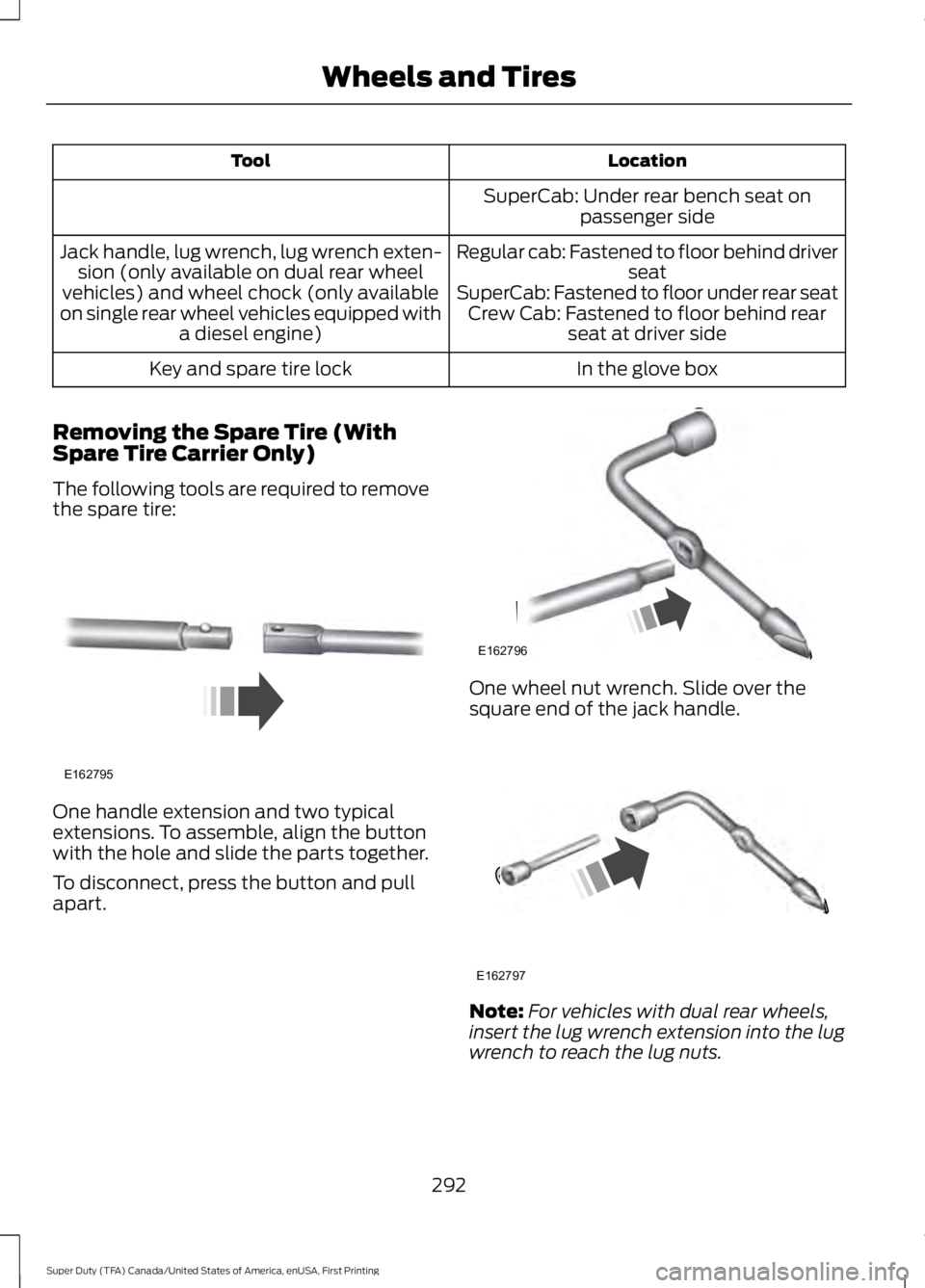

Location

Tool

SuperCab: Under rear bench seat onpassenger side

Regular cab: Fastened to floor behind driver seat

Jack handle, lug wrench, lug wrench exten-

sion (only available on dual rear wheel

vehicles) and wheel chock (only available

on single rear wheel vehicles equipped with a diesel engine) SuperCab: Fastened to floor under rear seat

Crew Cab: Fastened to floor behind rear seat at driver side

In the glove box

Key and spare tire lock

Removing the Spare Tire (With

Spare Tire Carrier Only)

The following tools are required to remove

the spare tire: One handle extension and two typical

extensions. To assemble, align the button

with the hole and slide the parts together.

To disconnect, press the button and pull

apart. One wheel nut wrench. Slide over the

square end of the jack handle.

Note:

For vehicles with dual rear wheels,

insert the lug wrench extension into the lug

wrench to reach the lug nuts.

292

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Wheels and TiresE162795 E162796 E162797

Page 296 of 507

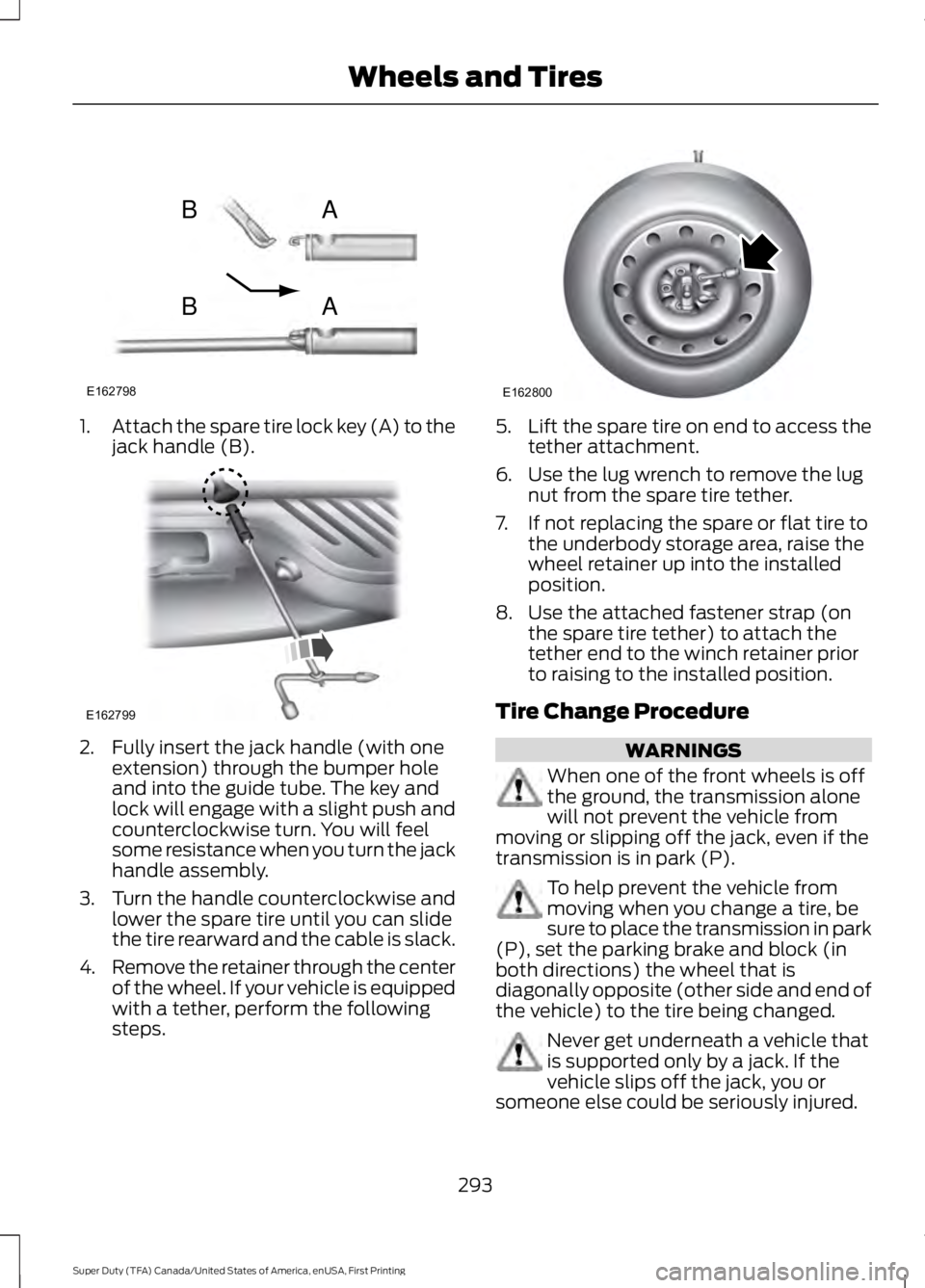

1.

Attach the spare tire lock key (A) to the

jack handle (B). 2. Fully insert the jack handle (with one

extension) through the bumper hole

and into the guide tube. The key and

lock will engage with a slight push and

counterclockwise turn. You will feel

some resistance when you turn the jack

handle assembly.

3. Turn the handle counterclockwise and

lower the spare tire until you can slide

the tire rearward and the cable is slack.

4. Remove the retainer through the center

of the wheel. If your vehicle is equipped

with a tether, perform the following

steps. 5.

Lift the spare tire on end to access the

tether attachment.

6. Use the lug wrench to remove the lug nut from the spare tire tether.

7. If not replacing the spare or flat tire to the underbody storage area, raise the

wheel retainer up into the installed

position.

8. Use the attached fastener strap (on the spare tire tether) to attach the

tether end to the winch retainer prior

to raising to the installed position.

Tire Change Procedure WARNINGS

When one of the front wheels is off

the ground, the transmission alone

will not prevent the vehicle from

moving or slipping off the jack, even if the

transmission is in park (P). To help prevent the vehicle from

moving when you change a tire, be

sure to place the transmission in park

(P), set the parking brake and block (in

both directions) the wheel that is

diagonally opposite (other side and end of

the vehicle) to the tire being changed. Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured.

293

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Wheels and TiresE162798

AB

AB E162799 E162800

Page 297 of 507

WARNINGS

Do not attempt to change a tire on

the side of the vehicle close to

moving traffic. Pull far enough off the

road to avoid the danger of being hit when

operating the jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one

provided as original equipment with your

vehicle, make sure the jack capacity is

adequate for the vehicle weight, including

any vehicle cargo or modifications. Note:

Passengers should not remain in the

vehicle when the vehicle is being jacked.

Park on a level surface, set the parking

brake and activate the hazard flashers. 1.

Turn the engine off and block the wheel

that is diagonally opposite of the flat

tire using the wheel chock. Note: Lock

the manual hub on the wheel if the

vehicle is a 4x4.

2. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

3. Use the tip of the lug wrench to remove

any wheel trim. 4. Loosen each wheel lug nut ½ turn

counterclockwise, but do not remove

them until the wheel is raised off the

ground.

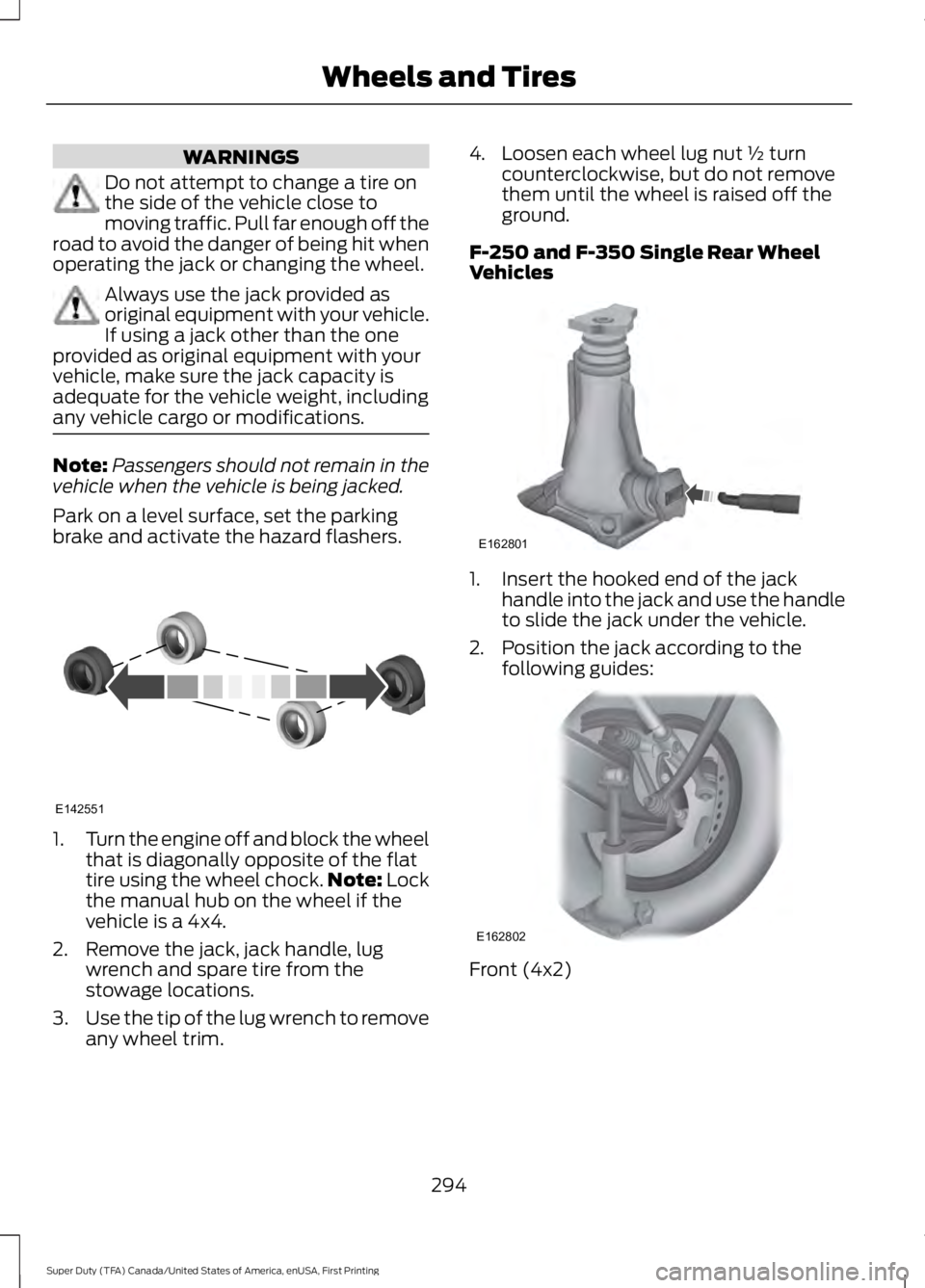

F-250 and F-350 Single Rear Wheel

Vehicles 1. Insert the hooked end of the jack

handle into the jack and use the handle

to slide the jack under the vehicle.

2. Position the jack according to the following guides: Front (4x2)

294

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Wheels and TiresE142551 E162801 E162802