stop start FORD F250 2016 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: F250, Model: FORD F250 2016Pages: 507, PDF Size: 6.81 MB

Page 172 of 507

GENERAL INFORMATION

Note:

Occasional brake noise is normal. If

a metal-to-metal, continuous grinding or

continuous squeal sound is present, the

brake linings may be worn-out. Have the

system checked by an authorized dealer. If

your vehicle has continuous vibration or

shudder in the steering wheel while braking,

have it checked by an authorized dealer.

Note: Brake dust may accumulate on the

wheels, even under normal driving

conditions. Some dust is inevitable as the

brakes wear and does not contribute to

brake noise. See Cleaning the Alloy

Wheels (page 261). See

Warning Lamps and

Indicators (page 84).

Wet brakes result in reduced braking

efficiency. Gently press the brake pedal a

few times when driving from a car wash or

standing water to dry the brakes.

Brake Over Accelerator

In the event the accelerator pedal

becomes stuck or entrapped, apply steady

and firm pressure to the brake pedal to

slow the vehicle and reduce engine power.

If you experience this condition, apply the

brakes and bring your vehicle to a safe

stop. Move the transmission to park (P),

switch the engine off and apply the parking

brake. Inspect the accelerator pedal for

any interference. If none are found and the

condition persists, have your vehicle towed

to the nearest authorized dealer.

Brake Assist

Brake assist detects when you brake

rapidly by measuring the rate at which you

press the brake pedal. It provides

maximum braking efficiency as long as you

press the pedal, and can reduce stopping

distances in critical situations. Anti-lock Brake System

This system helps you maintain steering

control during emergency stops by keeping

the brakes from locking. This lamp momentarily

illuminates when you turn the

ignition on. If the light does not

illuminate during start up, remains on or

flashes, the system may be disabled. Have

the system checked by an authorized

dealer. If the anti-lock brake system is

disabled, normal braking is still effective. If the brake warning lamp

illuminates when you release the

parking brake, have the system

checked by an authorized dealer.

HINTS ON DRIVING WITH

ANTI-LOCK BRAKES

Note: When the system is operating, the

brake pedal will pulse and may travel

further. Maintain pressure on the brake

pedal. You may also hear a noise from the

system. This is normal.

The anti-lock braking system will not

eliminate the risks when:

• You drive too closely to the vehicle in

front of you.

• Your vehicle is hydroplaning.

• You take corners too fast.

• The road surface is poor.

169

Super Duty (TFA) Canada/United States of America, enUSA, First Printing BrakesE144522 E144522

Page 196 of 507

RV & Trailer Towing Guide Online

http://www.fleet.ford.com/towing-guides/

Website

TRAILER SWAY CONTROL (If

Equipped) WARNING

Turning off trailer sway control

increases the risk of loss of vehicle

control, serious injury or death. Ford

does not recommend disabling this feature

except in situations where speed reduction

may be detrimental (such as hill climbing),

the driver has significant trailer towing

experience, and can control trailer sway

and maintain safe operation. Note:

This feature does not prevent trailer

sway, but reduces it once it begins.

Note: This feature cannot stop all trailers

from swaying.

Note: In some cases, if vehicle speed is too

high, the system may activate multiple

times, gradually reducing vehicle speed.

This feature applies your vehicle brakes at

individual wheels and, if necessary, reduces

engine power. If the trailer begins to sway,

the stability control light flashes and the

message

TRAILER SWAY REDUCE

SPEED appears in the information display.

The first thing to do is slow your vehicle

down, then pull safely to the side of the

road and check for proper tongue load and

trailer load distribution. See

Load

Carrying (page 185). RECOMMENDED TOWING

WEIGHTS

Note:

Make sure to take into

consideration trailer frontal area.

Do not exceed 60 feet 2

(5.6

meters 2

) trailer frontal area for

conventional trailers. Do not

exceed 75 feet 2

(6.9 meters 2

) trailer

frontal area for 5th wheel and

gooseneck trailers.

Note: Exceeding this limitation

may significantly reduce the

performance of your towing

vehicle. Selecting a trailer with a

low aerodynamic drag and rounded

front design helps optimize

performance and fuel economy.

Note: For high altitude operation,

reduce the gross combined weight

by 2% per 1000 feet (300 meters)

starting at the 1000 foot (300

meter) elevation point.

Note: Certain states require

electric trailer brakes for trailers

over a specified weight. Be sure to

check state regulations for this

specified weight. The maximum

trailer weights listed may be limited

to this specified weight, as your

vehicle's electrical system may not

include the wiring connector

needed to use electric trailer

brakes.

193

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Towing

Page 205 of 507

If the message only displays with a trailer

connected, the problem is with the trailer

wiring. Consult your trailer dealer for

assistance. This can be a short to ground

(such as a chaffed wire), short to voltage

(such as a pulled pin on trailer emergency

breakaway battery) or the trailer brakes

may be drawing too much current.

Points to Remember

Note:

Do not attempt removal of the trailer

brake controller without consulting the

Workshop Manual. Damage to the unit may

result.

• Adjust gain setting before using the

trailer brake controller.

• Adjust gain setting, using the procedure

above, whenever road, weather, trailer

or vehicle loading conditions change

from when the gain was initially set.

• Only use the manual control lever for

proper adjustment of the gain during

trailer setup. Misuse, such as

application during trailer sway, could

cause instability of trailer or tow

vehicle.

• Avoid towing in adverse weather

conditions. The trailer brake controller

does not provide anti-lock control of

the trailer wheels. Trailer wheels can

lock up on slippery surfaces, resulting

in reduced stability of trailer and tow

vehicle.

• The trailer brake controller is equipped

with a feature that reduces output at

vehicle speeds below 11 mph (18 km/h)

so trailer and vehicle braking is not jerky

or harsh. This feature is only active

when applying the brakes using your

vehicle's brake pedal, not the

controller. •

The controller interacts with the brake

control system and powertrain control

system of your vehicle to provide the

best performance on different road

conditions.

• Your vehicle's brake system and the

trailer brake system work

independently of each other. Changing

the gain setting on the controller does

not affect the operation of your

vehicle's brakes.

• When you switch the engine off, the

controller output is disabled and the

display and module shut down.

Trailer Lamps WARNING

Never connect any trailer lamp wiring

to the vehicle's tail lamp wiring; this

may damage the electrical system

resulting in fire. Contact your authorized

dealer as soon as possible for assistance

in proper trailer tow wiring installation.

Additional electrical equipment may be

required. Trailer lamps are required on most towed

vehicles. Make sure all running lights, brake

lights, turn signals and hazard lights are

working.

Before Towing a Trailer

Practice turning, stopping and backing up

to get the feel of your vehicle-trailer

combination before starting on a trip.

When turning, make wider turns so the

trailer wheels clear curbs and other

obstacles.

When Towing a Trailer

•

Do not drive faster than 70 mph (113

km/h) during the first 500 miles (800

kilometers).

• Do not make full-throttle starts.

202

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Towing

Page 217 of 507

In the event of a moderate to severe

collision, this vehicle is equipped with a

fuel pump shut-off feature that stops the

flow of fuel to the engine. Not every impact

will cause a shut-off.

Should your vehicle shut off after a

collision, you may restart your vehicle by

doing the following:

1. Turn the ignition off.

2. Turn the ignition to crank.

3. Turn the ignition off.

4.

Turn the ignition on again to re-enable

the fuel pump.

JUMP STARTING THE VEHICLE WARNINGS

Batteries normally produce explosive

gases which can cause personal

injury. Therefore, do not allow

flames, sparks or lighted substances to

come near the battery. When working near

the battery, always shield your face and

protect your eyes. Always provide correct

ventilation. Keep batteries out of reach of

children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or

clothing. Shield your eyes when working

near the battery to protect against possible

splashing of acid solution. In case of acid

contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Use only adequately sized cables

with insulated clamps.

Preparing Your Vehicle

Do not attempt to push-start your

automatic transmission vehicle. Note:

Attempting to push-start a vehicle

with an automatic transmission may cause

transmission damage.

Note: Use only a 12-volt supply to start your

vehicle.

Note: Do not disconnect the battery of the

disabled vehicle as this could damage the

vehicle electrical system.

Park the booster vehicle close to the hood

of the disabled vehicle, making sure the

two vehicles do not touch.

Connecting the Jumper Cables WARNINGS

Do not attach the cables to fuel lines,

engine rocker covers, the intake

manifold or electrical components

as grounding points. Stay clear of moving

parts. To avoid reverse polarity

connections, make sure that you correctly

identify the positive (+) and negative (-)

terminals on both the disabled and booster

vehicles before connecting the cables. Do not attach the end of the positive

cable to the studs or L-shaped eyelet

located above the positive (+)

terminal of your vehicle ’s battery. High

current may flow through and cause

damage to the fuses. Do not connect the end of the

second cable to the negative (-)

terminal of the battery to be jumped.

A spark may cause an explosion of the

gases that surround the battery. Note:

In the illustration, the bottom vehicle

represents the booster vehicle.

214

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Roadside Emergencies

Page 243 of 507

Engine Fluid Temperature

Management (If Equipped)

WARNINGS

To reduce the risk of collision and

injury, be prepared that the vehicle

speed may reduce and the vehicle

may not be able to accelerate with full

power until the fluid temperatures reduce. Never remove the coolant reservoir

cap while the engine is running or hot.

Your vehicle has been designed to pull a

trailer, but because of the added load, the

vehicle

’s engine may temporarily reach

higher temperatures during severe

operating conditions such as ascending a

long or steep grade while pulling a trailer

in hot ambient temperatures.

At this time, you may notice your engine

coolant temperature gauge needle move

toward the H and the POWER REDUCED

TO LOWER TEMP message may appear

in the information display.

You may notice a reduction in the vehicle ’s

speed caused by reduced engine power.

In order to manage the engine fluid

temperatures, your vehicle may enter this

mode if certain high-temperature and

high-load conditions take place. The

amount of speed reduction will depend on

the vehicle loading, towing, grade, ambient

temperature, and other factors. If this

occurs, there is no need to pull off the road.

The vehicle can continue to be driven while

this message is active.

The air conditioning may turn on and off

during severe operating conditions to

protect the engine from overheating. When

the engine coolant temperature decreases

to a more normal operating temperature,

the air conditioning will turn on once again. If the engine coolant temperature gauge

moves fully into the red (hot) area, or if the

coolant temperature warning or service

engine soon messages appear in your

information display:

1. Stop your vehicle as soon as safely

possible and shift the transmission into

park (P).

2. Leave the engine running until the coolant temperature gauge needle

moves away from the H range. After

several minutes, if this does not

happen, follow the remaining steps.

3. Switch the engine off and wait for it to

cool before checking the coolant level.

4. If the coolant level is normal, you may restart your engine and continue on.

5. If the coolant is low, add coolant, restart the engine and take your vehicle

to an authorized dealer. See Adding

engine coolant in this chapter for more

information. Refer to fail-safe cooling

for additional information.

AUTOMATIC TRANSMISSION

FLUID CHECK

Have an authorized dealer check and

change the transmission fluid and filter at

the correct service interval. See

Scheduled Maintenance (page 453).

Do not use supplemental transmission

fluid additives, treatments or cleaning

agents. The use of these materials may

affect transmission operation and result

in damage to internal transmission

components.

240

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Maintenance

Page 248 of 507

CHANGING THE 12V BATTERY

WARNINGS

This vehicle may be equipped with

more than one battery, removal of

cable from only one battery does not

disconnect the vehicle electrical system.

Be sure to disconnect cables from all

batteries when disconnecting power.

Failure to do so may cause serious

personal injury or property damage. Batteries normally produce explosive

gases which can cause personal

injury. Therefore, do not allow

flames, sparks or lighted substances to

come near the battery. When working near

the battery, always shield your face and

protect your eyes. Always provide proper

ventilation. When lifting a plastic-cased battery,

excessive pressure on the end walls

could cause acid to flow through the

vent caps, resulting in personal injury and

damage to the vehicle or battery. Lift the

battery with a battery carrier or with your

hands on opposite corners. Keep batteries out of reach of

children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or

clothing. Shield your eyes when working

near the battery to protect against possible

splashing of acid solution. In case of acid

contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Note:

If your battery has a cover/shield,

make sure it is reinstalled after the battery

has been cleaned or replaced.

Note: Battery posts, terminals and related

accessories contain lead and lead

compounds. Wash hands after handling. Note:

Electrical or electronic accessories

or components added to the vehicle by the

dealer or the owner may adversely affect

battery performance and durability.

Your vehicle is equipped with a Motorcraft

maintenance-free battery which normally

does not require additional water during

its life of service.

For longer, trouble-free operation, keep the

top of the battery clean and dry. Also,

make certain the battery cables are always

tightly fastened to the battery terminals.

If you see any corrosion on the battery or

terminals, remove the cables from the

terminals and clean with a wire brush. You

can neutralize the acid with a solution of

baking soda and water.

It is recommended that the negative

battery cable terminal be disconnected

from the battery if you plan to store your

vehicle for an extended period of time.

Because your vehicle ’s engine is

electronically controlled by a computer,

some control conditions are maintained

by power from the battery. When the

battery is disconnected or a new battery

is installed, the engine must relearn its idle

and fuel trim strategy for optimum

driveability and performance. Flexible fuel

vehicles (FFV) must also relearn the

ethanol content of the fuel for optimum

driveability and performance. To begin this

process

1. With the vehicle at a complete stop, set the parking brake.

2. Put the gearshift in P, turn off all

accessories.

3. Start the engine. Run the engine until it reaches normal operating

temperature.

4. Allow the engine to idle for at least one

minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

245

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Maintenance

Page 285 of 507

*Avoid fast starts, stops and turns.

*Avoid potholes and objects on

the road.

*Do not run over curbs or hit the

tire against a curb when parking.

Highway Hazards

No matter how carefully you drive

there

’s always the possibility that

you may eventually have a flat tire

on the highway. Drive slowly to the

closest safe area out of traffic.

This may further damage the flat

tire, but your safety is more

important.

If you feel a sudden vibration or

ride disturbance while driving, or

you suspect your tire or vehicle

has been damaged, immediately

reduce your speed. Drive with

caution until you can safely pull

off the road. Stop and inspect the

tires for damage. If a tire is

under-inflated or damaged,

deflate it, remove wheel and

replace it with your spare tire and

wheel. If you cannot detect a

cause, have the vehicle towed to

the nearest repair facility or tire

dealer to have the vehicle

inspected. Tire and Wheel Alignment

A bad jolt from hitting a curb or

pothole can cause the front end

of your vehicle to become

misaligned or cause damage to

your tires. If your vehicle seems to

pull to one side when you’re

driving, the wheels may be out of

alignment. Have an authorized

dealer check the wheel alignment

periodically.

Wheel misalignment in the front

or the rear can cause uneven and

rapid treadwear of your tires and

should be corrected by an

authorized dealer. Front-wheel

drive vehicles and those with an

independent rear suspension may

require alignment of all four

wheels.

The tires should also be balanced

periodically. An unbalanced tire

and wheel assembly may result in

irregular tire wear.

Tire Rotation

WARNING

If the tire label shows

different tire pressures for the

front and rear tires and the vehicle

is equipped with a tire pressure

monitoring system, then the

settings for the system sensors

need to be updated. Always

perform the system reset

procedure after tire rotation. If the

system is not reset, it may not

provide a low tire pressure

warning when necessary. 282

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 288 of 507

Each tire, including the spare (if

provided), should be checked

monthly when cold and inflated

to the inflation pressure recommended by

the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. (If

your vehicle has tires of a different size

than the size indicated on the vehicle

placard or tire inflation pressure label, you

should determine the proper tire inflation

pressure for those tires.)

As an added safety feature, your vehicle

has been equipped with a Tire Pressure

Monitoring System (TPMS) that

illuminates a low tire pressure telltale

when one or more of your tires is

significantly under-inflated. Accordingly,

when the low tire pressure telltale

illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly under-inflated tire causes the

tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency

and tire tread life, and may affect the

vehicle ’s handling and stopping ability.

Please note that the TPMS is not a

substitute for proper tire maintenance, and

it is the driver ’s responsibility to maintain

correct tire pressure, even if under-inflation

has not reached the level to trigger

illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with

a TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is

combined with the low tire pressure

telltale. When the system detects a

malfunction, the telltale will flash for

approximately one minute and then remain

continuously illuminated. This sequence

will continue upon subsequent vehicle

start-ups as long as the malfunction exists. When the malfunction indicator is

illuminated, the system may not be able

to detect or signal low tire pressure as

intended. TPMS malfunctions may occur

for a variety of reasons, including the

installation of replacement or alternate

tires or wheels on the vehicle that prevent

the TPMS from functioning properly.

Always check the TPMS malfunction

telltale after replacing one or more tires or

wheels on your vehicle to ensure that the

replacement or alternate tires and wheels

allow the TPMS to continue to function

properly.

The tire pressure monitoring system

complies with part 15 of the FCC rules and

with RSS-210 of Industry Canada.

Operation is subject to the following two

conditions: (1) This device may not cause

harmful interference, and (2) This device

must accept any interference received,

including interference that may cause

undesired operation.

This device complies with part 15 of the

FCC Rules and with Licence exempt RSS

Standards of Industry Canada. Operation

is subject to the following two conditions:

•

This device may not cause harmful

interference.

• This device must accept any

interference received, including

interference that may cause undesired

operation.

285

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 292 of 507

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least three

feet (one meter) away from another

Ford Motor Company vehicle

undergoing the system reset procedure

at the same time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system will time-out and the entire

procedure will have to be repeated on

all four wheels.

• A double horn will sound indicating the

need to repeat the procedure.

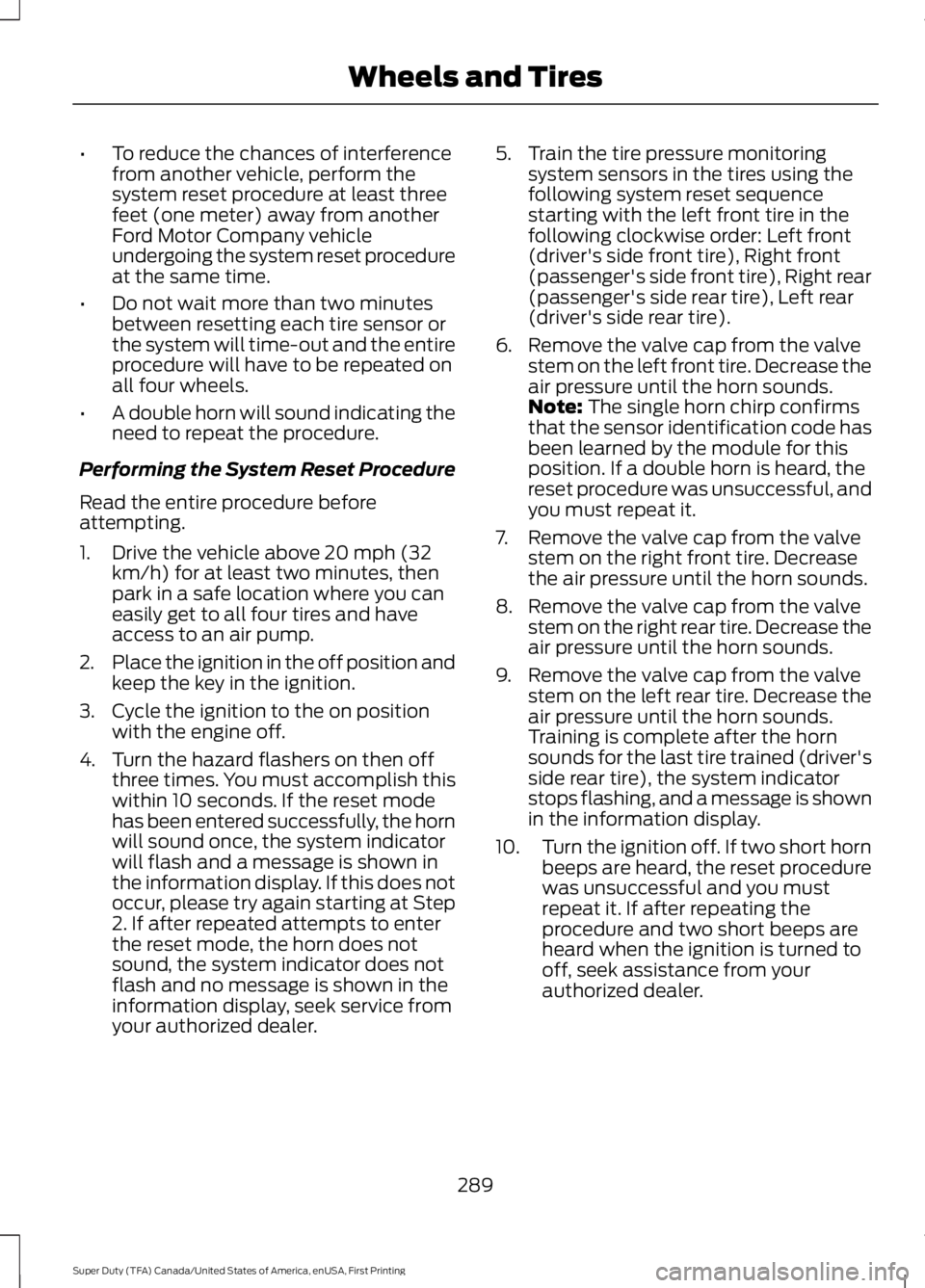

Performing the System Reset Procedure

Read the entire procedure before

attempting.

1. Drive the vehicle above 20 mph (32 km/h) for at least two minutes, then

park in a safe location where you can

easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If the reset mode

has been entered successfully, the horn

will sound once, the system indicator

will flash and a message is shown in

the information display. If this does not

occur, please try again starting at Step

2. If after repeated attempts to enter

the reset mode, the horn does not

sound, the system indicator does not

flash and no message is shown in the

information display, seek service from

your authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front

(driver's side front tire), Right front

(passenger's side front tire), Right rear

(passenger's side rear tire), Left rear

(driver's side rear tire).

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn chirp confirms

that the sensor identification code has

been learned by the module for this

position. If a double horn is heard, the

reset procedure was unsuccessful, and

you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained (driver's

side rear tire), the system indicator

stops flashing, and a message is shown

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

289

Super Duty (TFA) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 374 of 507

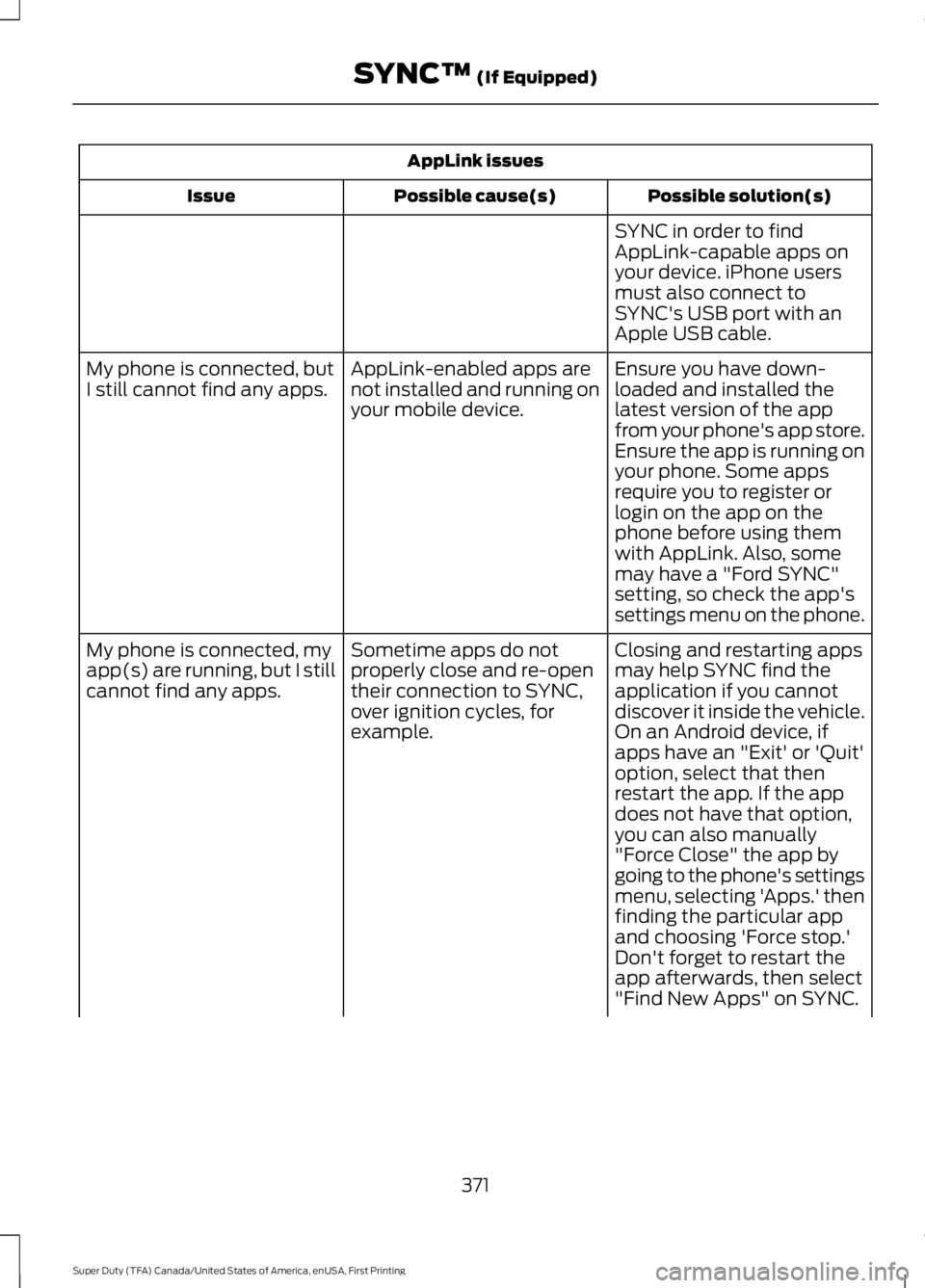

AppLink issues

Possible solution(s)

Possible cause(s)

Issue

SYNC in order to find

AppLink-capable apps on

your device. iPhone users

must also connect to

SYNC's USB port with an

Apple USB cable.

Ensure you have down-

loaded and installed the

latest version of the app

from your phone's app store.

Ensure the app is running on

your phone. Some apps

AppLink-enabled apps are

not installed and running on

your mobile device.

My phone is connected, but

I still cannot find any apps.

require you to register or

login on the app on the

phone before using them

with AppLink. Also, some

may have a "Ford SYNC"

setting, so check the app's

settings menu on the phone.

Closing and restarting apps

may help SYNC find the

application if you cannot

discover it inside the vehicle.

On an Android device, if

apps have an "Exit' or 'Quit'

Sometime apps do not

properly close and re-open

their connection to SYNC,

over ignition cycles, for

example.

My phone is connected, my

app(s) are running, but I still

cannot find any apps.

option, select that then

restart the app. If the app

does not have that option,

you can also manually

"Force Close" the app by

going to the phone's settings

menu, selecting 'Apps.' then

finding the particular app

and choosing 'Force stop.'

Don't forget to restart the

app afterwards, then select

"Find New Apps" on SYNC.

371

Super Duty (TFA) Canada/United States of America, enUSA, First Printing SYNC™ (If Equipped)