clock FORD F250 SUPER DUTY 2006 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: F250 SUPER DUTY, Model: FORD F250 SUPER DUTY 2006Pages: 312, PDF Size: 5.15 MB

Page 52 of 312

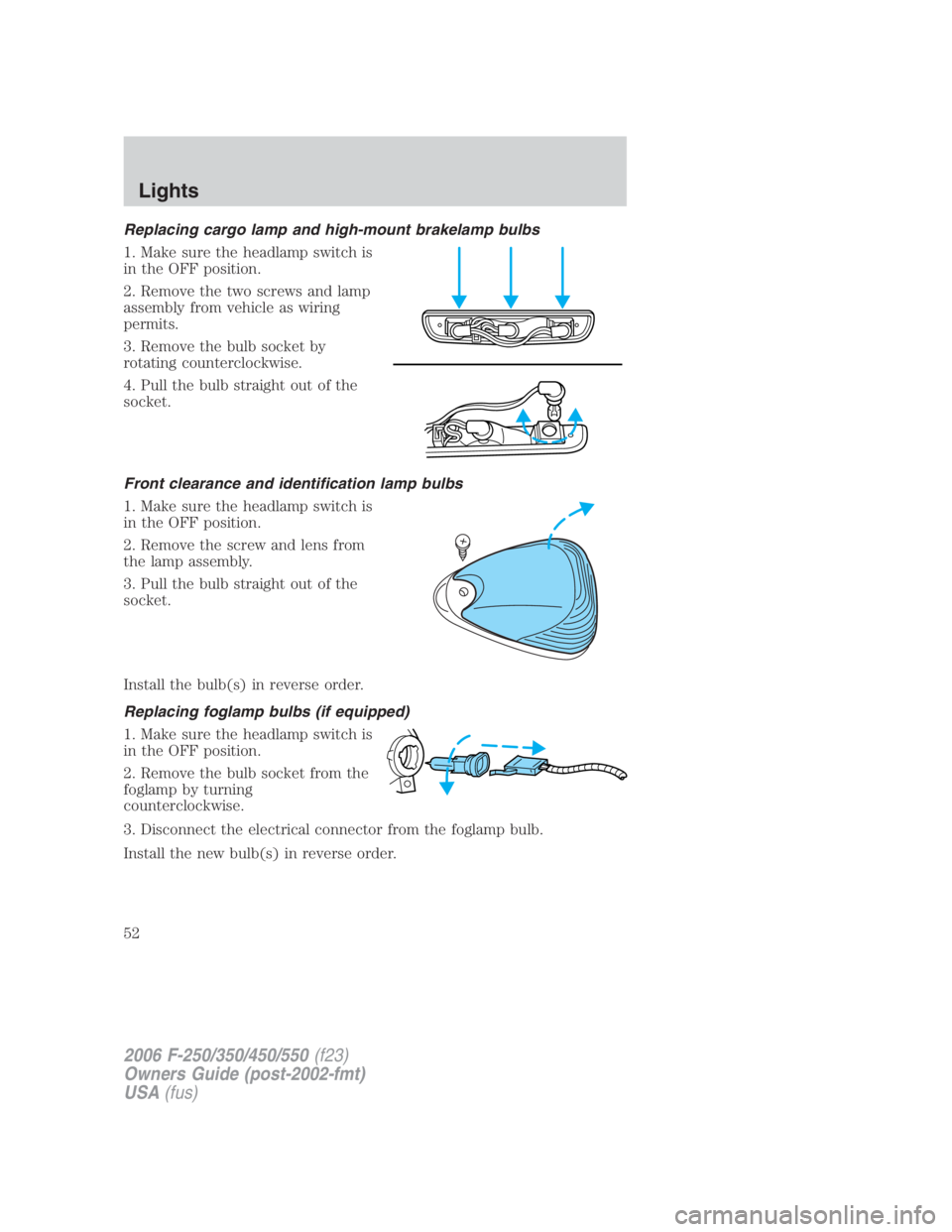

Replacing cargo lamp and high-mount brakelamp bulbs

1. Make sure the headlamp switch is

in the OFF position.

2. Remove the two screws and lamp

assembly from vehicle as wiring

permits.

3. Remove the bulb socket by

rotating counterclockwise.

4. Pull the bulb straight out of the

socket.

Front clearance and identification lamp bulbs

1. Make sure the headlamp switch is

in the OFF position.

2. Remove the screw and lens from

the lamp assembly.

3. Pull the bulb straight out of the

socket.

Install the bulb(s) in reverse order.

Replacing foglamp bulbs (if equipped)

1. Make sure the headlamp switch is

in the OFF position.

2. Remove the bulb socket from the

foglamp by turning

counterclockwise.

3. Disconnect the electrical connector from the foglamp bulb.

Install the new bulb(s) in reverse order.

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus)Lights

52

Page 53 of 312

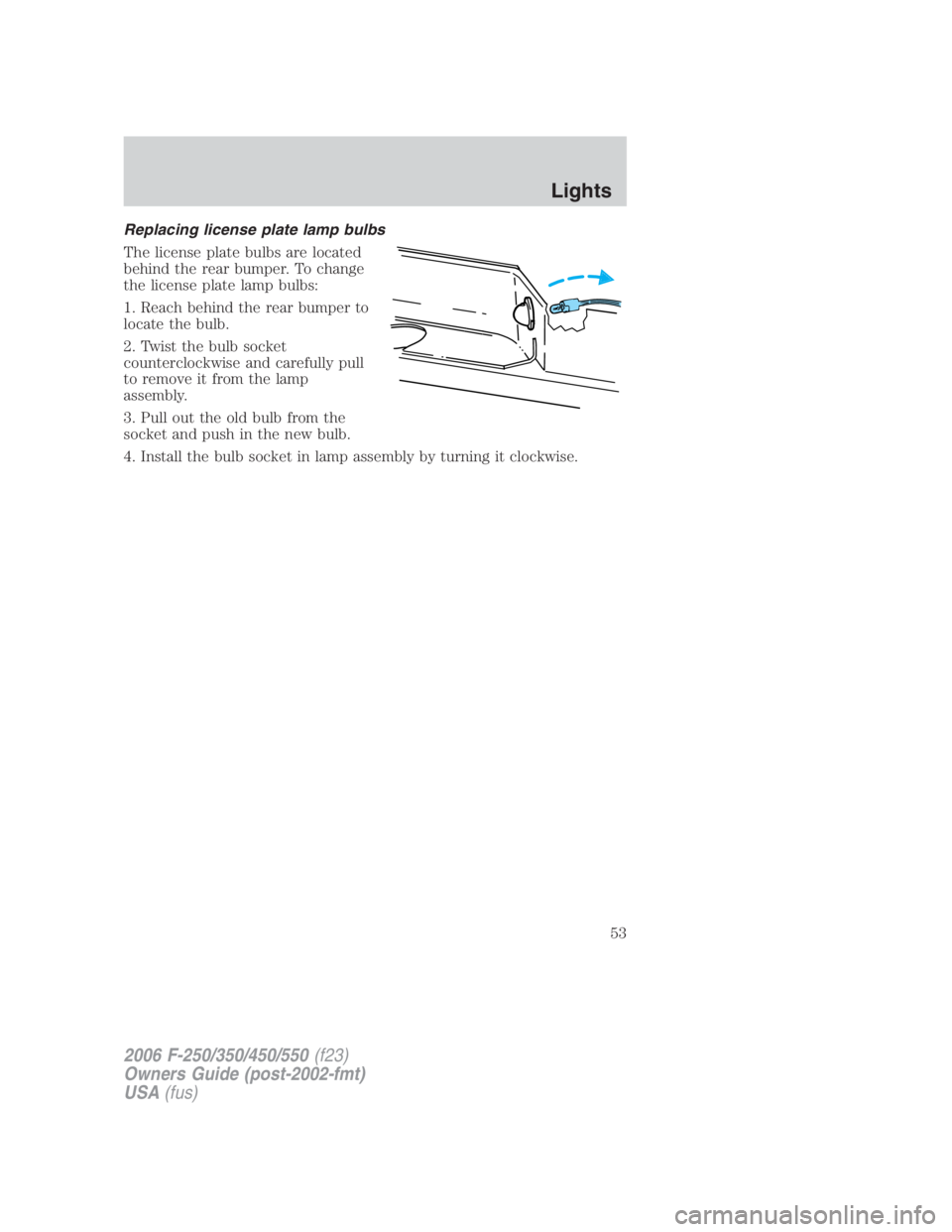

Replacing license plate lamp bulbs

The license plate bulbs are located

behind the rear bumper. To change

the license plate lamp bulbs:

1. Reach behind the rear bumper to

locate the bulb.

2. Twist the bulb socket

counterclockwise and carefully pull

to remove it from the lamp

assembly.

3. Pull out the old bulb from the

socket and push in the new bulb.

4. Install the bulb socket in lamp assembly by turning it clockwise.

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus) Lights

53

Page 58 of 312

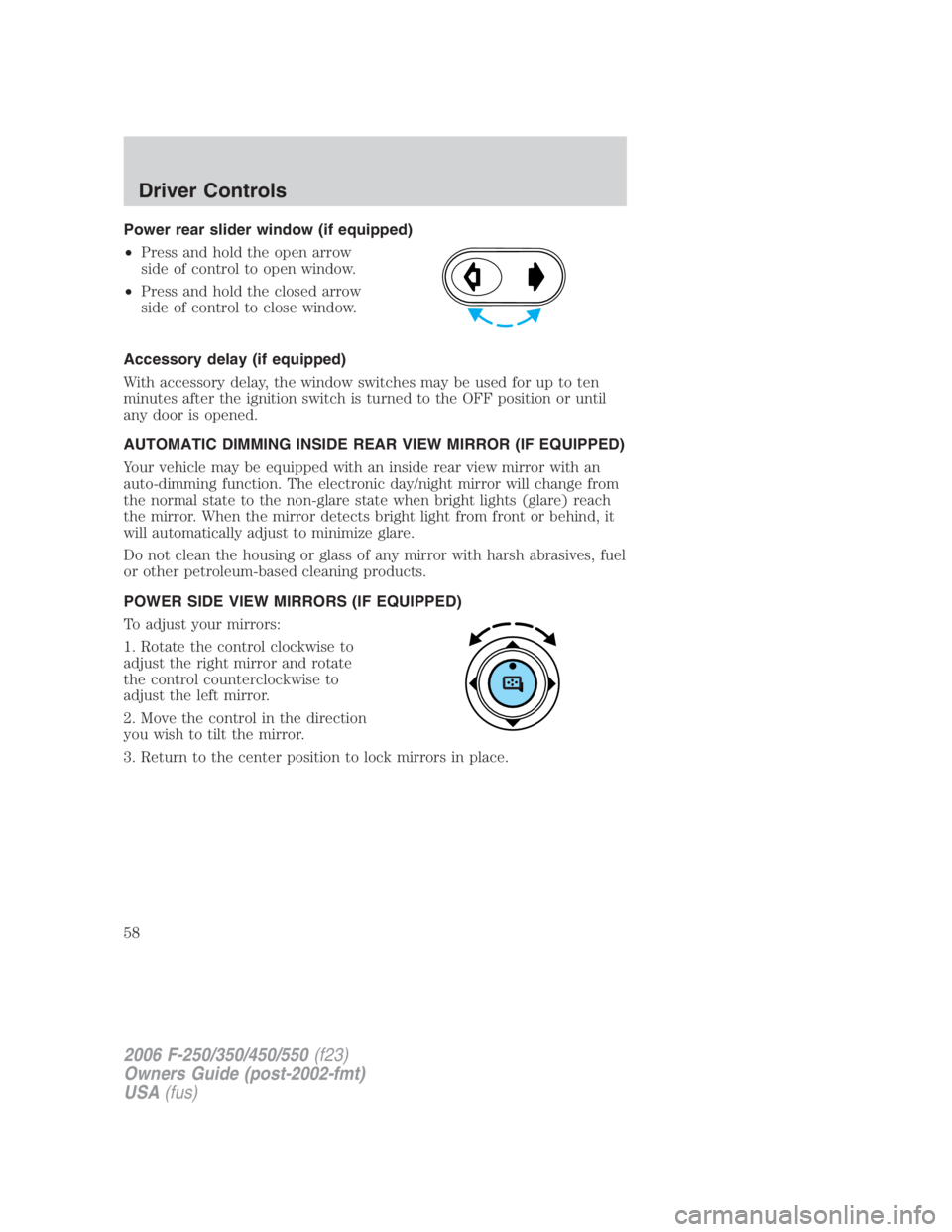

Power rear slider window (if equipped)

• Press and hold the open arrow

side of control to open window.

• Press and hold the closed arrow

side of control to close window.

Accessory delay (if equipped)

With accessory delay, the window switches may be used for up to ten

minutes after the ignition switch is turned to the OFF position or until

any door is opened.

AUTOMATIC DIMMING INSIDE REAR VIEW MIRROR (IF EQUIPPED)

Your vehicle may be equipped with an inside rear view mirror with an

auto-dimming function. The electronic day/night mirror will change from

the normal state to the non-glare state when bright lights (glare) reach

the mirror. When the mirror detects bright light from front or behind, it

will automatically adjust to minimize glare.

Do not clean the housing or glass of any mirror with harsh abrasives, fuel

or other petroleum-based cleaning products.

POWER SIDE VIEW MIRRORS (IF EQUIPPED)

To adjust your mirrors:

1. Rotate the control clockwise to

adjust the right mirror and rotate

the control counterclockwise to

adjust the left mirror.

2. Move the control in the direction

you wish to tilt the mirror.

3. Return to the center position to lock mirrors in place.

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus)Driver Controls

58

Page 185 of 312

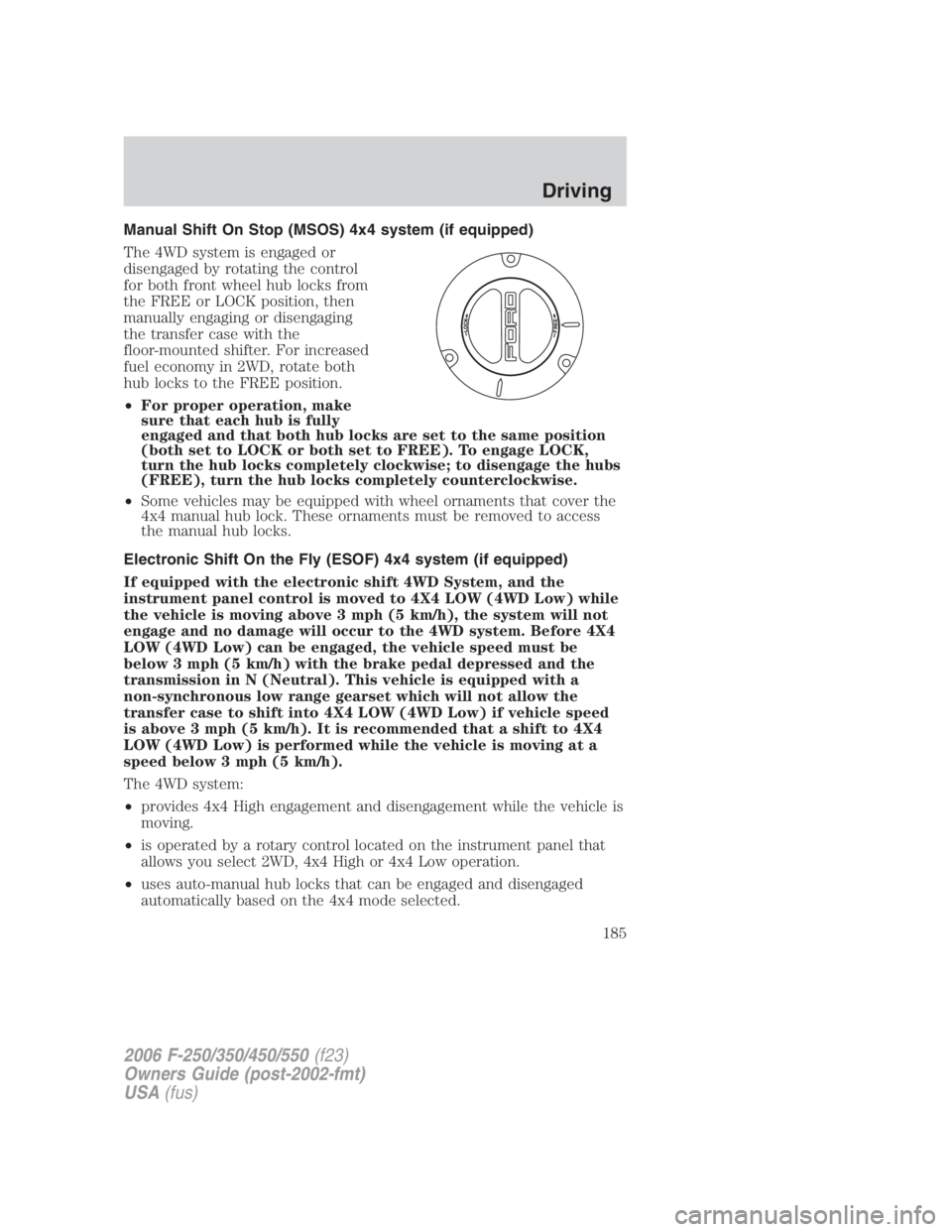

Manual Shift On Stop (MSOS) 4x4 system (if equipped)

The 4WD system is engaged or

disengaged by rotating the control

for both front wheel hub locks from

the FREE or LOCK position, then

manually engaging or disengaging

the transfer case with the

floor-mounted shifter. For increased

fuel economy in 2WD, rotate both

hub locks to the FREE position.

• For proper operation, make

sure that each hub is fully

engaged and that both hub locks are set to the same position

(both set to LOCK or both set to FREE). To engage LOCK,

turn the hub locks completely clockwise; to disengage the hubs

(FREE), turn the hub locks completely counterclockwise.

• Some vehicles may be equipped with wheel ornaments that cover the

4x4 manual hub lock. These ornaments must be removed to access

the manual hub locks.

Electronic Shift On the Fly (ESOF) 4x4 system (if equipped)

If equipped with the electronic shift 4WD System, and the

instrument panel control is moved to 4X4 LOW (4WD Low) while

the vehicle is moving above 3 mph (5 km/h), the system will not

engage and no damage will occur to the 4WD system. Before 4X4

LOW (4WD Low) can be engaged, the vehicle speed must be

below 3 mph (5 km/h) with the brake pedal depressed and the

transmission in N (Neutral). This vehicle is equipped with a

non-synchronous low range gearset which will not allow the

transfer case to shift into 4X4 LOW (4WD Low) if vehicle speed

is above 3 mph (5 km/h). It is recommended that a shift to 4X4

LOW (4WD Low) is performed while the vehicle is moving at a

speed below 3 mph (5 km/h).

The 4WD system:

• provides 4x4 High engagement and disengagement while the vehicle is

moving.

• is operated by a rotary control located on the instrument panel that

allows you select 2WD, 4x4 High or 4x4 Low operation.

• uses auto-manual hub locks that can be engaged and disengaged

automatically based on the 4x4 mode selected.

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus) Driving

185

Page 186 of 312

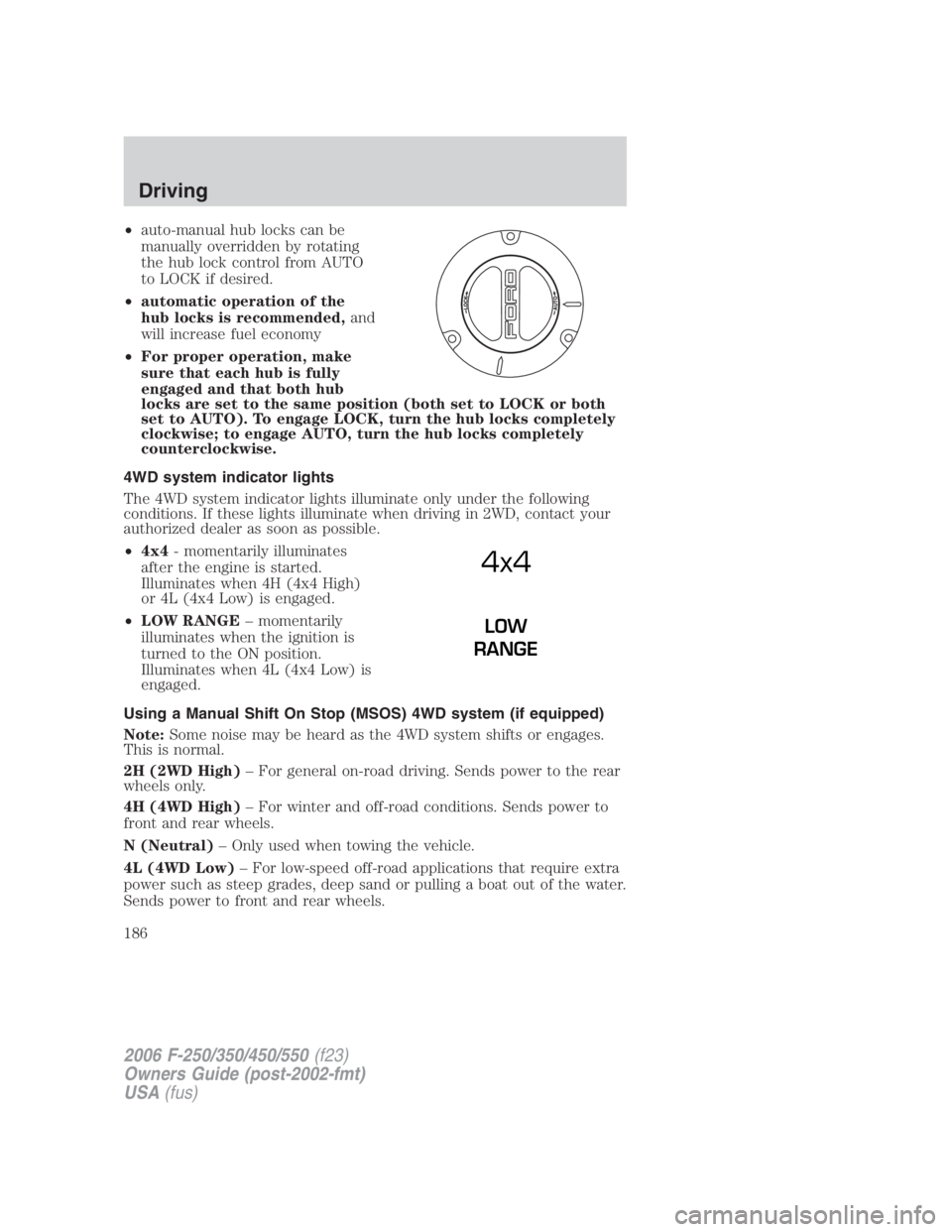

• auto-manual hub locks can be

manually overridden by rotating

the hub lock control from AUTO

to LOCK if desired.

• automatic operation of the

hub locks is recommended, and

will increase fuel economy

• For proper operation, make

sure that each hub is fully

engaged and that both hub

locks are set to the same position (both set to LOCK or both

set to AUTO). To engage LOCK, turn the hub locks completely

clockwise; to engage AUTO, turn the hub locks completely

counterclockwise.

4WD system indicator lights

The 4WD system indicator lights illuminate only under the following

conditions. If these lights illuminate when driving in 2WD, contact your

authorized dealer as soon as possible.

• 4x4 - momentarily illuminates

after the engine is started.

Illuminates when 4H (4x4 High)

or 4L (4x4 Low) is engaged.

• LOW RANGE – momentarily

illuminates when the ignition is

turned to the ON position.

Illuminates when 4L (4x4 Low) is

engaged.

Using a Manual Shift On Stop (MSOS) 4WD system (if equipped)

Note: Some noise may be heard as the 4WD system shifts or engages.

This is normal.

2H (2WD High) – For general on-road driving. Sends power to the rear

wheels only.

4H (4WD High) – For winter and off-road conditions. Sends power to

front and rear wheels.

N (Neutral) – Only used when towing the vehicle.

4L (4WD Low) – For low-speed off-road applications that require extra

power such as steep grades, deep sand or pulling a boat out of the water.

Sends power to front and rear wheels. 4x4 LOW

RANGE

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus)Driving

186

Page 218 of 312

3. Fully insert the jack handle

through the bumper hole and into

the guide tube. The key and lock

will engage with a slight push and

counterclockwise turn. Some

resistance will be felt when turning

the jack handle assembly.

4. Turn the handle counterclockwise

and lower the spare tire until you

can slide the tire rearward and the

cable is slack.

5. Remove the retainer through the center of the wheel.

Tire change procedure

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

• Automatic transmission: Place

gearshift lever in P (Park).

• Manual transmission: Place

gearshift lever in R (Reverse).

• Electronic Shift-On-the-Fly

(ESOF) 4WD: Place transfer case

in any position.

• Manual shift transfer case 4WD:

Place transfer case in 2H, 4H or

4L.

To help prevent the vehicle

from moving when you

change a tire, be sure the parking

brake is set, then block (in both

directions) the wheel that is

diagonally opposite (other side

and end of the vehicle) to the tire

being changed.

2. Turn engine off and block the diagonally opposite wheel (block not

provided).

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus)Roadside Emergencies

218

Page 219 of 312

3. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

4. Use the tip of the lug wrench to remove any wheel trim.

5. Loosen each wheel lug nut one-half turn counterclockwise but do not

remove them until the wheel is raised off the ground.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park) (automatic transmission)

or R (Reverse) (manual transmission). To prevent the vehicle from

moving when you change the tire, be sure that the parking brake is set

and the diagonally opposite wheel is blocked.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

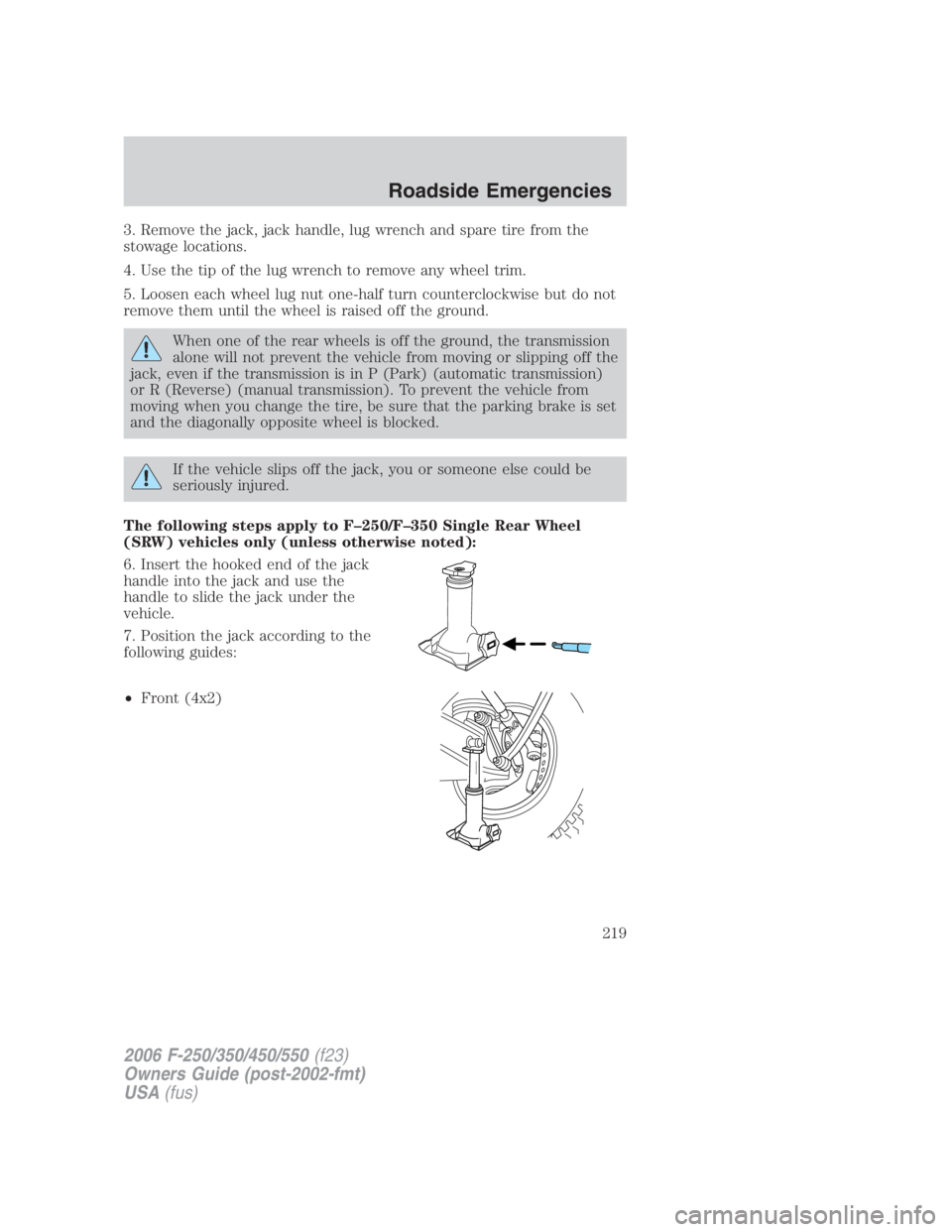

The following steps apply to F–250/F–350 Single Rear Wheel

(SRW) vehicles only (unless otherwise noted):

6. Insert the hooked end of the jack

handle into the jack and use the

handle to slide the jack under the

vehicle.

7. Position the jack according to the

following guides:

• Front (4x2)

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus) Roadside Emergencies

219

Page 221 of 312

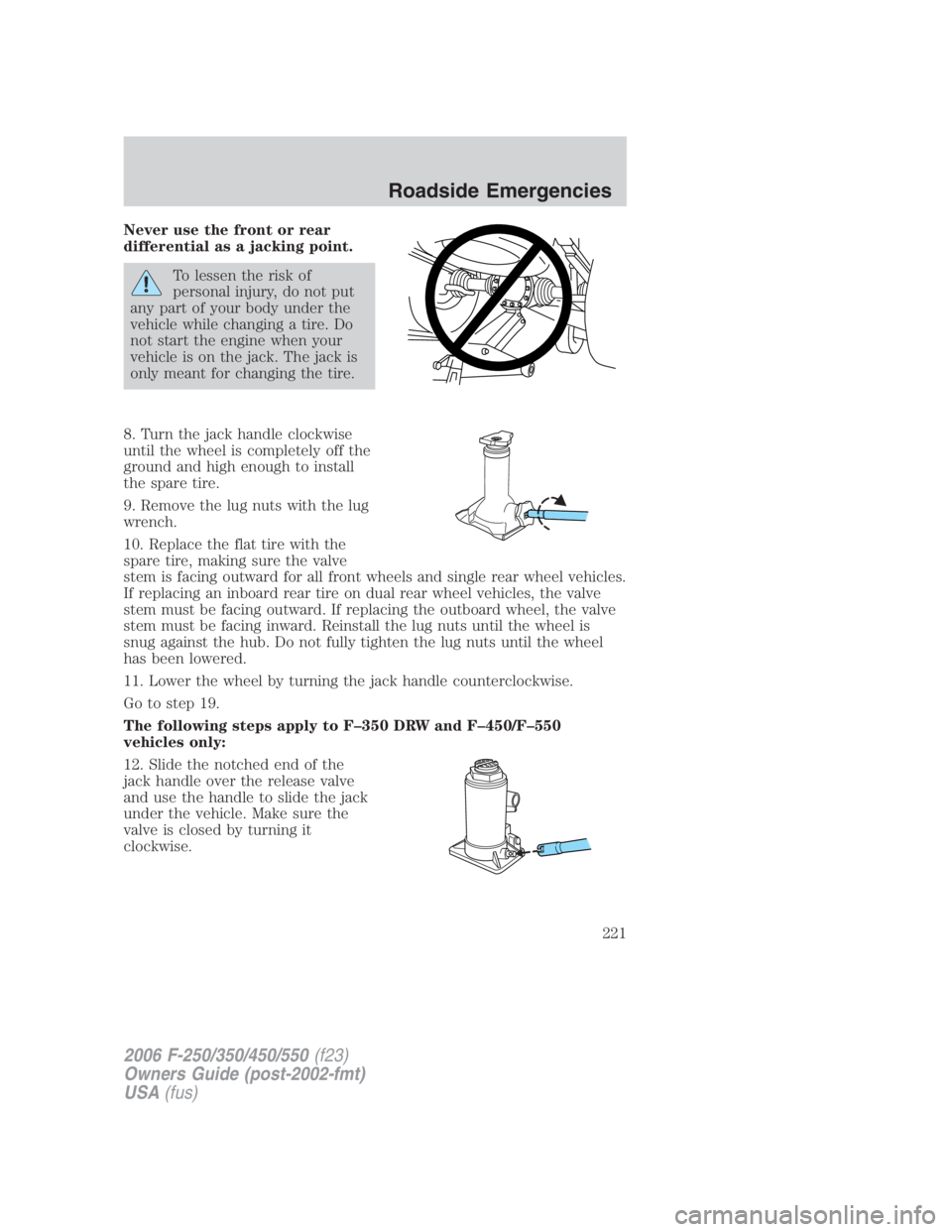

Never use the front or rear

differential as a jacking point.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

8. Turn the jack handle clockwise

until the wheel is completely off the

ground and high enough to install

the spare tire.

9. Remove the lug nuts with the lug

wrench.

10. Replace the flat tire with the

spare tire, making sure the valve

stem is facing outward for all front wheels and single rear wheel vehicles.

If replacing an inboard rear tire on dual rear wheel vehicles, the valve

stem must be facing outward. If replacing the outboard wheel, the valve

stem must be facing inward. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

11. Lower the wheel by turning the jack handle counterclockwise.

Go to step 19.

The following steps apply to F–350 DRW and F–450/F–550

vehicles only:

12. Slide the notched end of the

jack handle over the release valve

and use the handle to slide the jack

under the vehicle. Make sure the

valve is closed by turning it

clockwise.

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus) Roadside Emergencies

221

Page 223 of 312

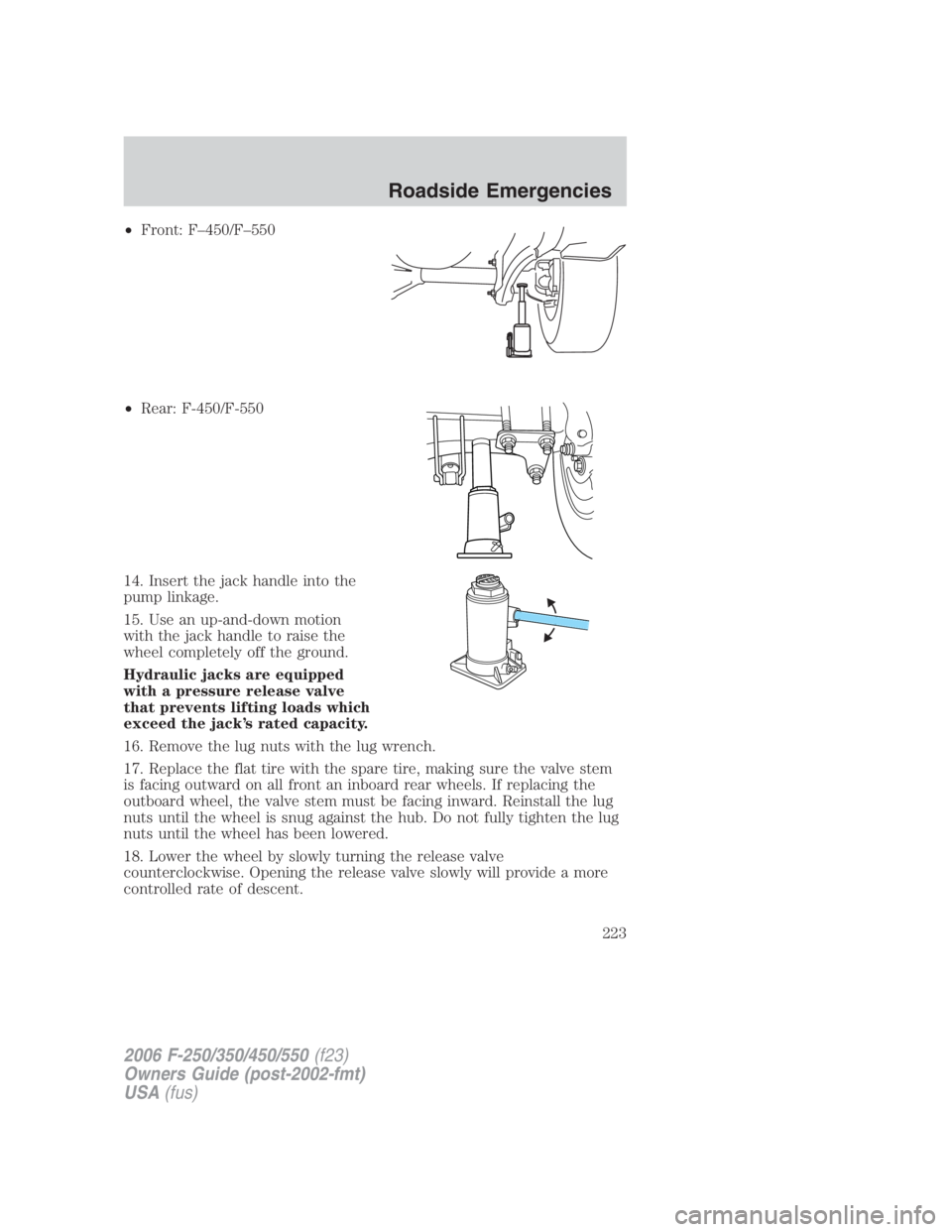

• Front: F–450/F–550

• Rear: F-450/F-550

14. Insert the jack handle into the

pump linkage.

15. Use an up-and-down motion

with the jack handle to raise the

wheel completely off the ground.

Hydraulic jacks are equipped

with a pressure release valve

that prevents lifting loads which

exceed the jack’s rated capacity.

16. Remove the lug nuts with the lug wrench.

17. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward on all front an inboard rear wheels. If replacing the

outboard wheel, the valve stem must be facing inward. Reinstall the lug

nuts until the wheel is snug against the hub. Do not fully tighten the lug

nuts until the wheel has been lowered.

18. Lower the wheel by slowly turning the release valve

counterclockwise. Opening the release valve slowly will provide a more

controlled rate of descent.

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus) Roadside Emergencies

223

Page 225 of 312

Stowing the flat/spare tire

Note: Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located with the jack

hardware.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your authorized

dealer for assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, per scheduled maintenance information),

or at any time that the spare tire is disturbed through service of other

components.

6. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.

WHEEL LUG NUT TORQUE SPECIFICATIONS

On vehicles equipped with single rear wheels, retighten the lug nuts to

the specified torque at 500 miles (800 km) after any wheel disturbance

(tire rotation, changing a flat tire, wheel removal, etc.).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts

to the specified torque at 100 miles (160 km), and again at 500 miles

(800 km) of new vehicle operation and after any wheel disturbance (tire

rotation, changing a flat tire, wheel removal, etc.).

2006 F-250/350/450/550 (f23)

Owners Guide (post-2002-fmt)

USA (fus) Roadside Emergencies

225