clock FORD F250 SUPER DUTY 2014 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2014, Model line: F250 SUPER DUTY, Model: FORD F250 SUPER DUTY 2014Pages: 460, PDF Size: 6.55 MB

Page 239 of 460

Note:Electrical or electronic accessoriesor components added to the vehicle by thedealer or the owner may adversely affectbattery performance and durability.

Your vehicle is equipped with a Motorcraftmaintenance-free battery which normallydoes not require additional water duringits life of service.

For longer, trouble-free operation, keep thetop of the battery clean and dry. Also,make certain the battery cables are alwaystightly fastened to the battery terminals.

If you see any corrosion on the battery orterminals, remove the cables from theterminals and clean with a wire brush. Youcan neutralize the acid with a solution ofbaking soda and water.

It is recommended that the negativebattery cable terminal be disconnectedfrom the battery if you plan to store yourvehicle for an extended period of time.

Because your vehicle’s engine iselectronically controlled by a computer,some control conditions are maintainedby power from the battery. When thebattery is disconnected or a new batteryis installed, the engine must relearn its idleand fuel trim strategy for optimumdriveability and performance. Flexible fuelvehicles (FFV) must also relearn theethanol content of the fuel for optimumdriveability and performance. To begin thisprocess

1. With the vehicle at a complete stop,set the parking brake.

2. Put the gearshift in P, turn off allaccessories.

3. Start the engine. Run the engine untilit reaches normal operatingtemperature.

4.Allow the engine to idle for at least oneminute.

5. Turn the A/C on and allow the engineto idle for at least one minute.

6. Release the parking brake. With yourfoot on the brake pedal and with theA/C on, put the vehicle in D and allowthe engine to idle for at least oneminute.

•If you do not allow the engine torelearn its idle trim, the idle qualityof your vehicle may be adverselyaffected until the idle trim iseventually relearned.

7. Drive the vehicle to complete therelearning process

•The vehicle may need to be driven10 mi (16 km) or more to relearn theidle and fuel trim strategy alongwith the ethanol content for flexiblefuel vehicles.

•For flexible fuel vehicles, if you areoperating on E85, you mayexperience poor starts or aninability to start the engine anddriveability problems until the fueltrim and ethanol content have beenrelearned.

If the battery has been disconnected or anew battery has been installed, the clockand radio settings must be reset once thebattery is reconnected.

Always dispose of automotivebatteries in a responsible manner.Follow your local authorized standardsfor disposal. Call your local authorizedrecycling center to find out more aboutrecycling automotive batteries.

Battery Management System (IfEquipped)

The battery management system (BMS)monitors battery conditions and takesactions to extend battery life. If excessivebattery drain is detected, the system maytemporarily disable certain electricalfeatures to protect the battery. Thoseelectrical accessories affected include therear defrost, heated/cooled seats, climate

236

Super Duty (TFA)

Maintenance

Page 242 of 460

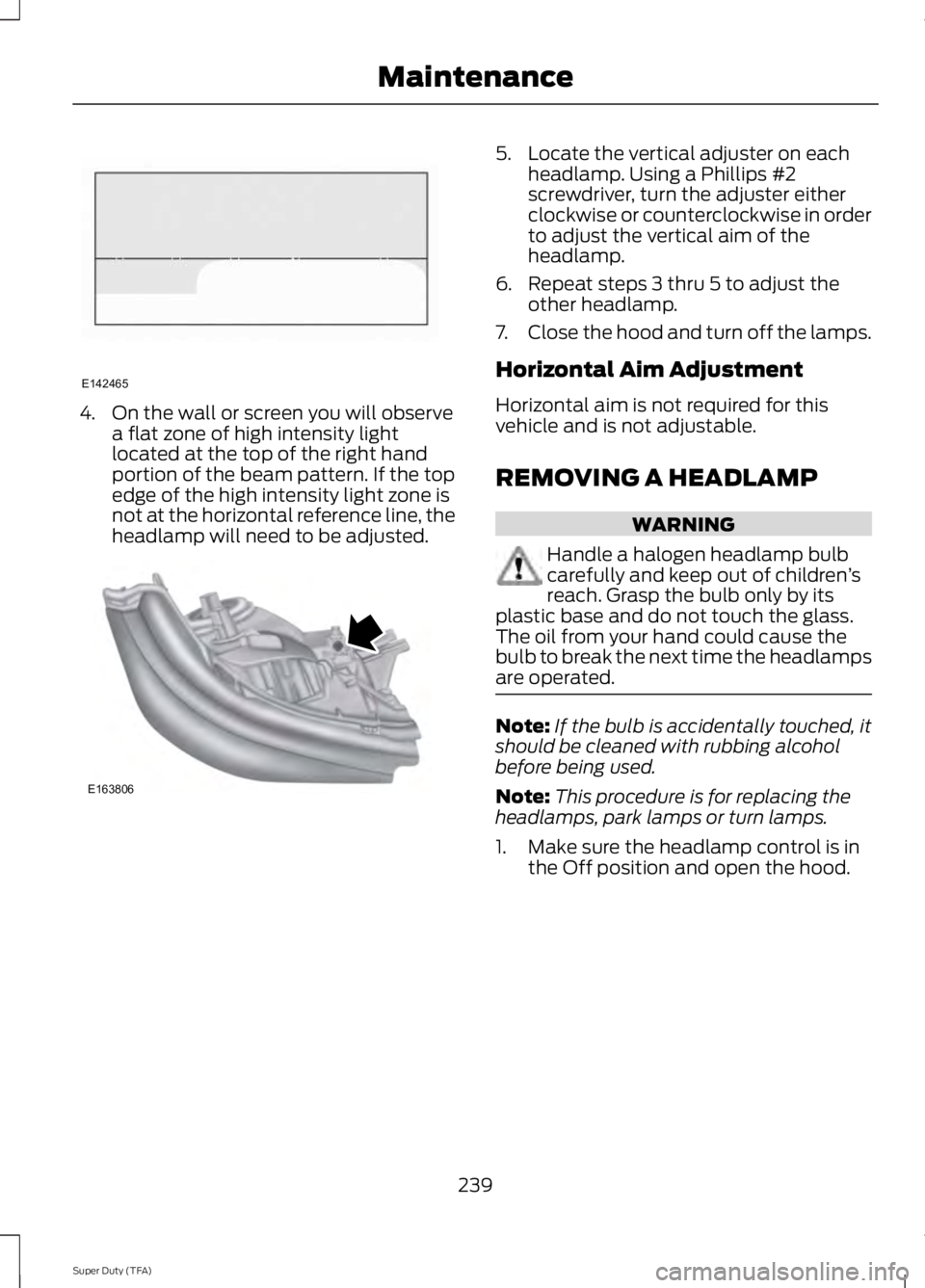

4. On the wall or screen you will observea flat zone of high intensity lightlocated at the top of the right handportion of the beam pattern. If the topedge of the high intensity light zone isnot at the horizontal reference line, theheadlamp will need to be adjusted.

5. Locate the vertical adjuster on eachheadlamp. Using a Phillips #2screwdriver, turn the adjuster eitherclockwise or counterclockwise in orderto adjust the vertical aim of theheadlamp.

6. Repeat steps 3 thru 5 to adjust theother headlamp.

7.Close the hood and turn off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for thisvehicle and is not adjustable.

REMOVING A HEADLAMP

WARNING

Handle a halogen headlamp bulbcarefully and keep out of children’sreach. Grasp the bulb only by itsplastic base and do not touch the glass.The oil from your hand could cause thebulb to break the next time the headlampsare operated.

Note:If the bulb is accidentally touched, itshould be cleaned with rubbing alcoholbefore being used.

Note:This procedure is for replacing theheadlamps, park lamps or turn lamps.

1. Make sure the headlamp control is inthe Off position and open the hood.

239

Super Duty (TFA)

MaintenanceE142465 E163806

Page 243 of 460

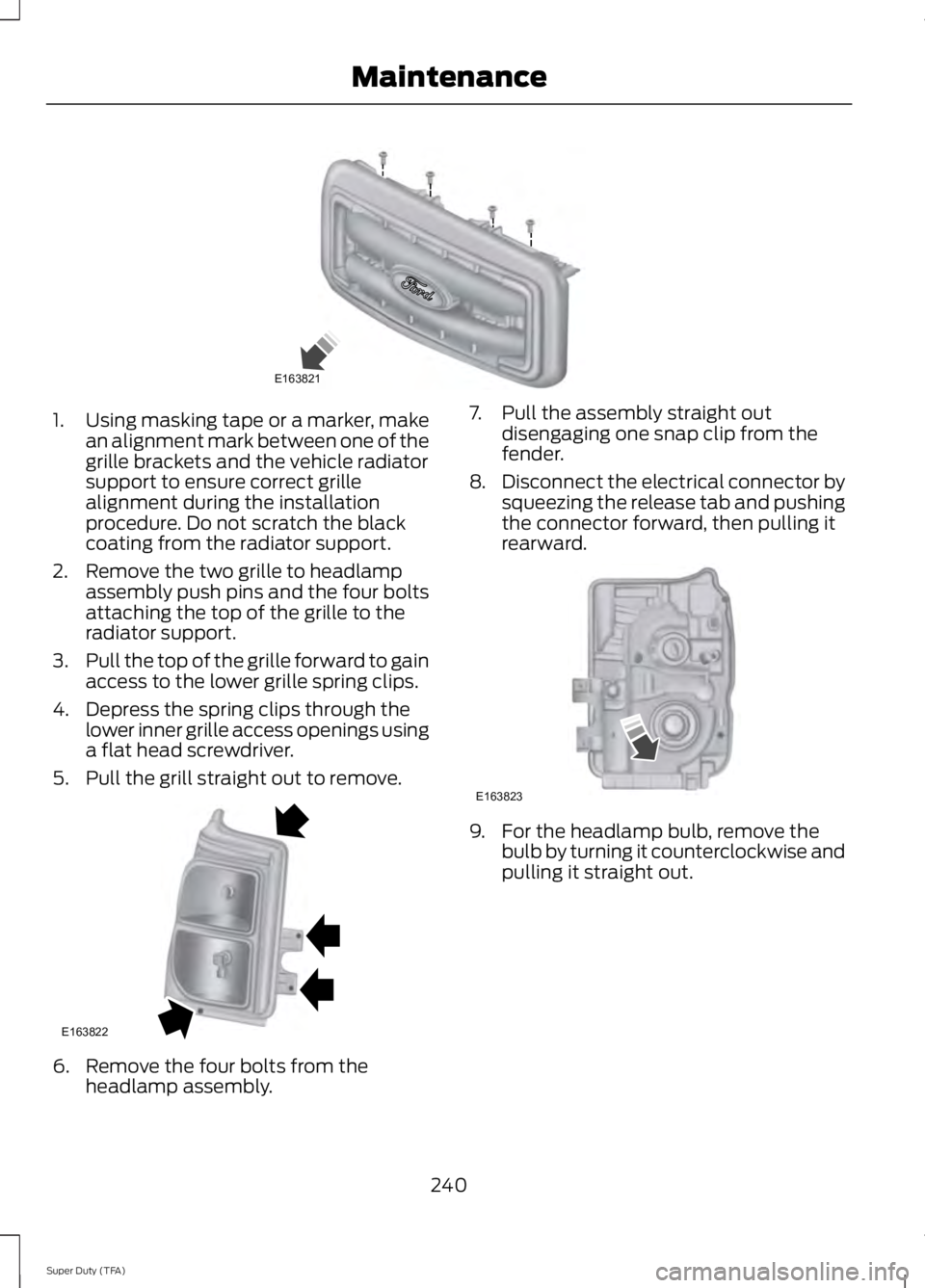

1.Using masking tape or a marker, makean alignment mark between one of thegrille brackets and the vehicle radiatorsupport to ensure correct grillealignment during the installationprocedure. Do not scratch the blackcoating from the radiator support.

2. Remove the two grille to headlampassembly push pins and the four boltsattaching the top of the grille to theradiator support.

3.Pull the top of the grille forward to gainaccess to the lower grille spring clips.

4. Depress the spring clips through thelower inner grille access openings usinga flat head screwdriver.

5. Pull the grill straight out to remove.

6. Remove the four bolts from theheadlamp assembly.

7. Pull the assembly straight outdisengaging one snap clip from thefender.

8.Disconnect the electrical connector bysqueezing the release tab and pushingthe connector forward, then pulling itrearward.

9. For the headlamp bulb, remove thebulb by turning it counterclockwise andpulling it straight out.

240

Super Duty (TFA)

MaintenanceE163821 E163822 E163823

Page 244 of 460

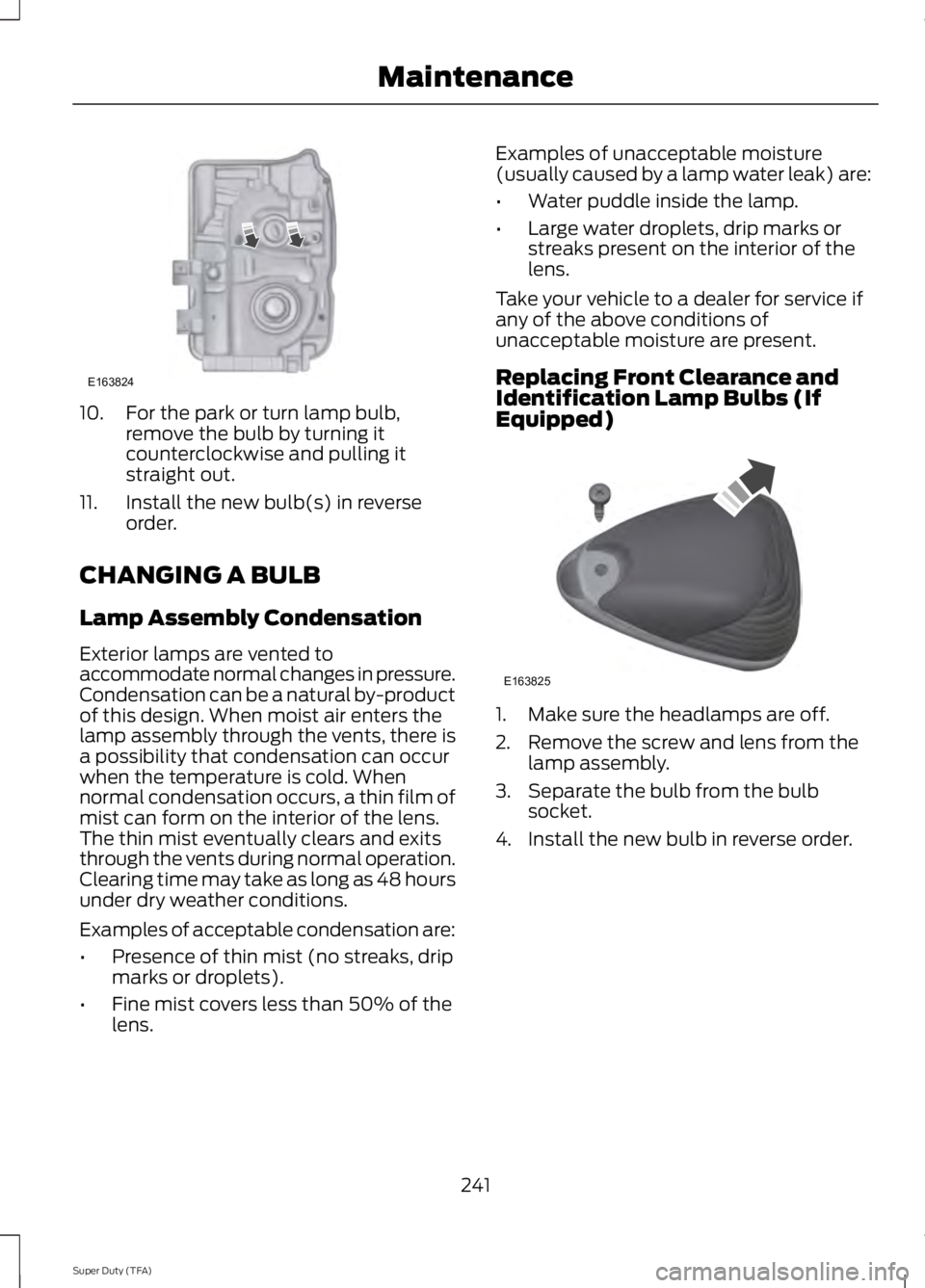

10. For the park or turn lamp bulb,remove the bulb by turning itcounterclockwise and pulling itstraight out.

11. Install the new bulb(s) in reverseorder.

CHANGING A BULB

Lamp Assembly Condensation

Exterior lamps are vented toaccommodate normal changes in pressure.Condensation can be a natural by-productof this design. When moist air enters thelamp assembly through the vents, there isa possibility that condensation can occurwhen the temperature is cold. Whennormal condensation occurs, a thin film ofmist can form on the interior of the lens.The thin mist eventually clears and exitsthrough the vents during normal operation.Clearing time may take as long as 48 hoursunder dry weather conditions.

Examples of acceptable condensation are:

•Presence of thin mist (no streaks, dripmarks or droplets).

•Fine mist covers less than 50% of thelens.

Examples of unacceptable moisture(usually caused by a lamp water leak) are:

•Water puddle inside the lamp.

•Large water droplets, drip marks orstreaks present on the interior of thelens.

Take your vehicle to a dealer for service ifany of the above conditions ofunacceptable moisture are present.

Replacing Front Clearance andIdentification Lamp Bulbs (IfEquipped)

1. Make sure the headlamps are off.

2. Remove the screw and lens from thelamp assembly.

3. Separate the bulb from the bulbsocket.

4. Install the new bulb in reverse order.

241

Super Duty (TFA)

MaintenanceE163824 E163825

Page 245 of 460

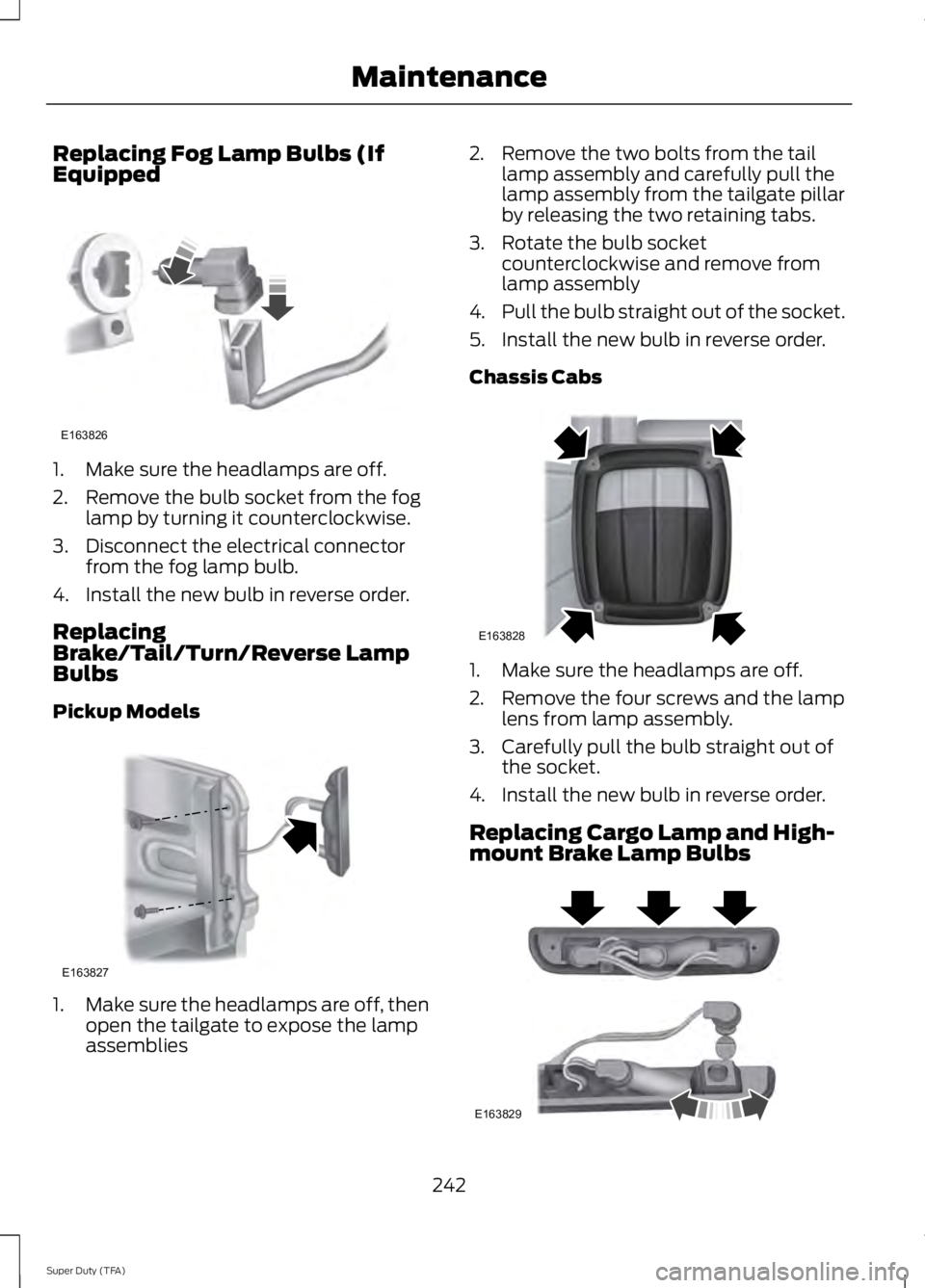

Replacing Fog Lamp Bulbs (IfEquipped

1. Make sure the headlamps are off.

2. Remove the bulb socket from the foglamp by turning it counterclockwise.

3. Disconnect the electrical connectorfrom the fog lamp bulb.

4. Install the new bulb in reverse order.

ReplacingBrake/Tail/Turn/Reverse LampBulbs

Pickup Models

1.Make sure the headlamps are off, thenopen the tailgate to expose the lampassemblies

2. Remove the two bolts from the taillamp assembly and carefully pull thelamp assembly from the tailgate pillarby releasing the two retaining tabs.

3. Rotate the bulb socketcounterclockwise and remove fromlamp assembly

4.Pull the bulb straight out of the socket.

5. Install the new bulb in reverse order.

Chassis Cabs

1. Make sure the headlamps are off.

2. Remove the four screws and the lamplens from lamp assembly.

3. Carefully pull the bulb straight out ofthe socket.

4. Install the new bulb in reverse order.

Replacing Cargo Lamp and High-mount Brake Lamp Bulbs

242

Super Duty (TFA)

MaintenanceE163826 E163827 E163828 E163829

Page 246 of 460

1. Make sure the headlamps are off.

2. Remove the screws and lampassembly from the vehicle as wiringpermits.

3. Remove the bulb socket by rotating itcounterclockwise.

4.Pull the bulb straight out of the socket.

5. Install the new bulb in reverse order.

Replacing the License Plate LampBulb

Note:The license plate bulbs are locatedbehind the rear bumper.

1. Reach behind the rear bumper tolocate the bulb.

2.Twist the bulb socket counterclockwiseand carefully pull to remove it from thelamp assembly.

3. Pull out the old bulb from the socketand push in the new bulb.

4. Install the new bulb in reverse order.

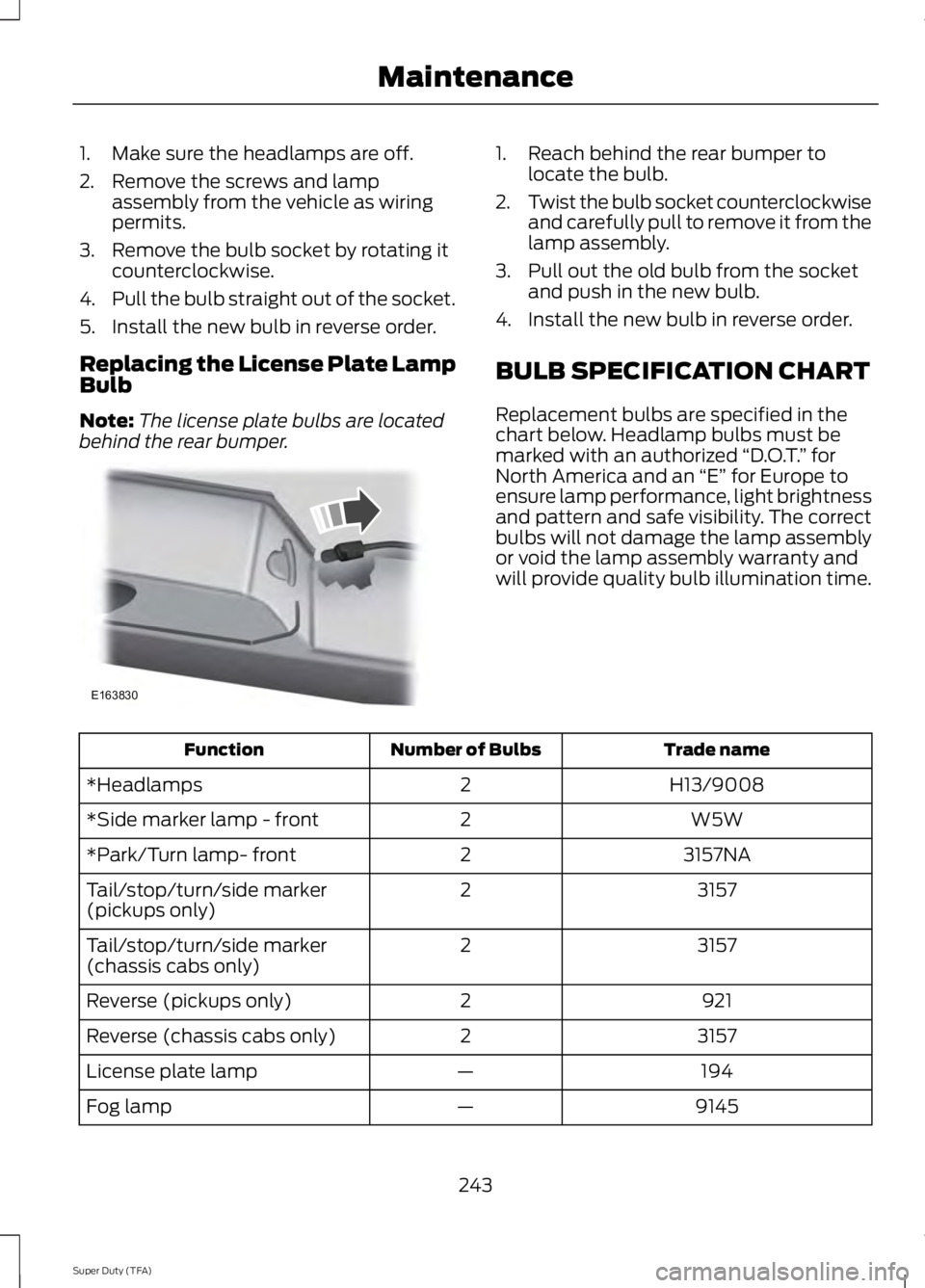

BULB SPECIFICATION CHART

Replacement bulbs are specified in thechart below. Headlamp bulbs must bemarked with an authorized “D.O.T.” forNorth America and an “E” for Europe toensure lamp performance, light brightnessand pattern and safe visibility. The correctbulbs will not damage the lamp assemblyor void the lamp assembly warranty andwill provide quality bulb illumination time.

Trade nameNumber of BulbsFunction

H13/90082*Headlamps

W5W2*Side marker lamp - front

3157NA2*Park/Turn lamp- front

31572Tail/stop/turn/side marker(pickups only)

31572Tail/stop/turn/side marker(chassis cabs only)

9212Reverse (pickups only)

31572Reverse (chassis cabs only)

194—License plate lamp

9145—Fog lamp

243

Super Duty (TFA)

MaintenanceE163830

Page 281 of 460

•To reduce the chances of interferencefrom another vehicle, perform thesystem reset procedure at least threefeet (one meter) away from anotherFord Motor Company vehicleundergoing the system reset procedureat the same time.

•Do not wait more than two minutesbetween resetting each tire sensor orthe system will time-out and the entireprocedure will have to be repeated onall four wheels.

•A double horn will sound indicating theneed to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure beforeattempting.

1. Drive the vehicle above 20 mph (32km/h) for at least two minutes, thenpark in a safe location where you caneasily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3. Cycle the ignition to the on positionwith the engine off.

4. Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If the reset modehas been entered successfully, the hornwill sound once, the system indicatorwill flash and a message is shown inthe information display. If this does notoccur, please try again starting at Step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message is shown in theinformation display, seek service fromyour authorized dealer.

5. Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing clockwise order: Left front(driver's side front tire), Right front(passenger's side front tire), Right rear(passenger's side rear tire), Left rear(driver's side rear tire)

6. Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.Note: The single horn chirp confirmsthat the sensor identification code hasbeen learned by the module for thisposition. If a double horn is heard, thereset procedure was unsuccessful, andyou must repeat it.

7. Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8. Remove the valve cap from the valvestem on the right rear tire. Decrease theair pressure until the horn sounds.

9. Remove the valve cap from the valvestem on the left rear tire. Decrease theair pressure until the horn sounds.Training is complete after the hornsounds for the last tire trained (driver'sside rear tire), the system indicatorstops flashing, and a message is shownin the information display.

10.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

278

Super Duty (TFA)

Wheels and Tires

Page 285 of 460

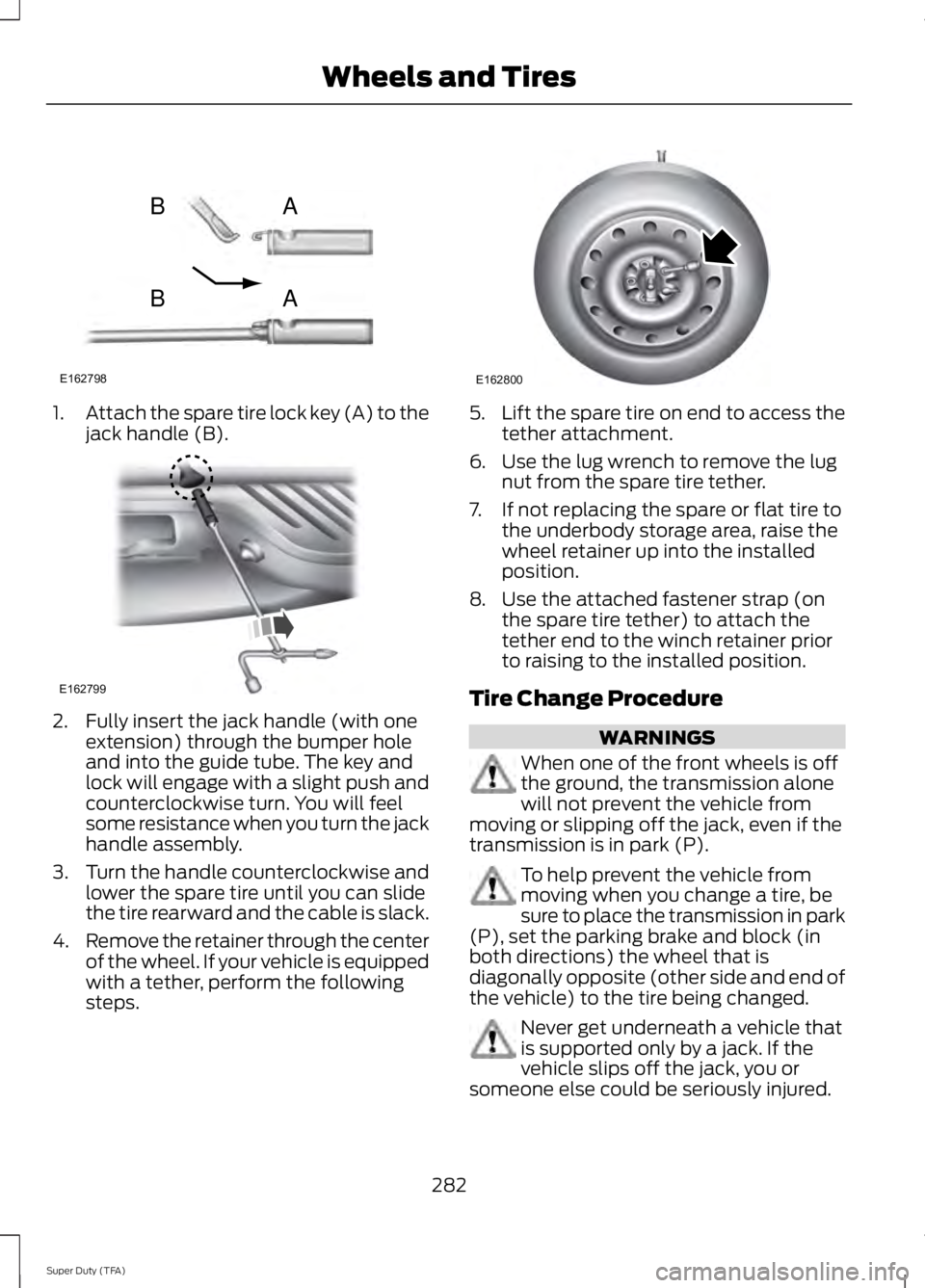

1.Attach the spare tire lock key (A) to thejack handle (B).

2. Fully insert the jack handle (with oneextension) through the bumper holeand into the guide tube. The key andlock will engage with a slight push andcounterclockwise turn. You will feelsome resistance when you turn the jackhandle assembly.

3.Turn the handle counterclockwise andlower the spare tire until you can slidethe tire rearward and the cable is slack.

4.Remove the retainer through the centerof the wheel. If your vehicle is equippedwith a tether, perform the followingsteps.

5.Lift the spare tire on end to access thetether attachment.

6. Use the lug wrench to remove the lugnut from the spare tire tether.

7. If not replacing the spare or flat tire tothe underbody storage area, raise thewheel retainer up into the installedposition.

8. Use the attached fastener strap (onthe spare tire tether) to attach thetether end to the winch retainer priorto raising to the installed position.

Tire Change Procedure

WARNINGS

When one of the front wheels is offthe ground, the transmission alonewill not prevent the vehicle frommoving or slipping off the jack, even if thetransmission is in park (P).

To help prevent the vehicle frommoving when you change a tire, besure to place the transmission in park(P), set the parking brake and block (inboth directions) the wheel that isdiagonally opposite (other side and end ofthe vehicle) to the tire being changed.

Never get underneath a vehicle thatis supported only by a jack. If thevehicle slips off the jack, you orsomeone else could be seriously injured.

282

Super Duty (TFA)

Wheels and TiresE162798

AB

AB E162799 E162800

Page 286 of 460

WARNINGS

Do not attempt to change a tire onthe side of the vehicle close tomoving traffic. Pull far enough off theroad to avoid the danger of being hit whenoperating the jack or changing the wheel.

Always use the jack provided asoriginal equipment with your vehicle.If using a jack other than the oneprovided as original equipment with yourvehicle, make sure the jack capacity isadequate for the vehicle weight, includingany vehicle cargo or modifications.

Note:Passengers should not remain in thevehicle when the vehicle is being jacked.

Park on a level surface, set the parkingbrake and activate the hazard flashers.

1.Turn the engine off and block the wheelthat is diagonally opposite of the flattire using the wheel chock.Note: Lockthe manual hub on the wheel if thevehicle is a 4x4.

2. Remove the jack, jack handle, lugwrench and spare tire from thestowage locations.

3.Use the tip of the lug wrench to removeany wheel trim.

4. Loosen each wheel lug nut ½ turncounterclockwise, but do not removethem until the wheel is raised off theground.

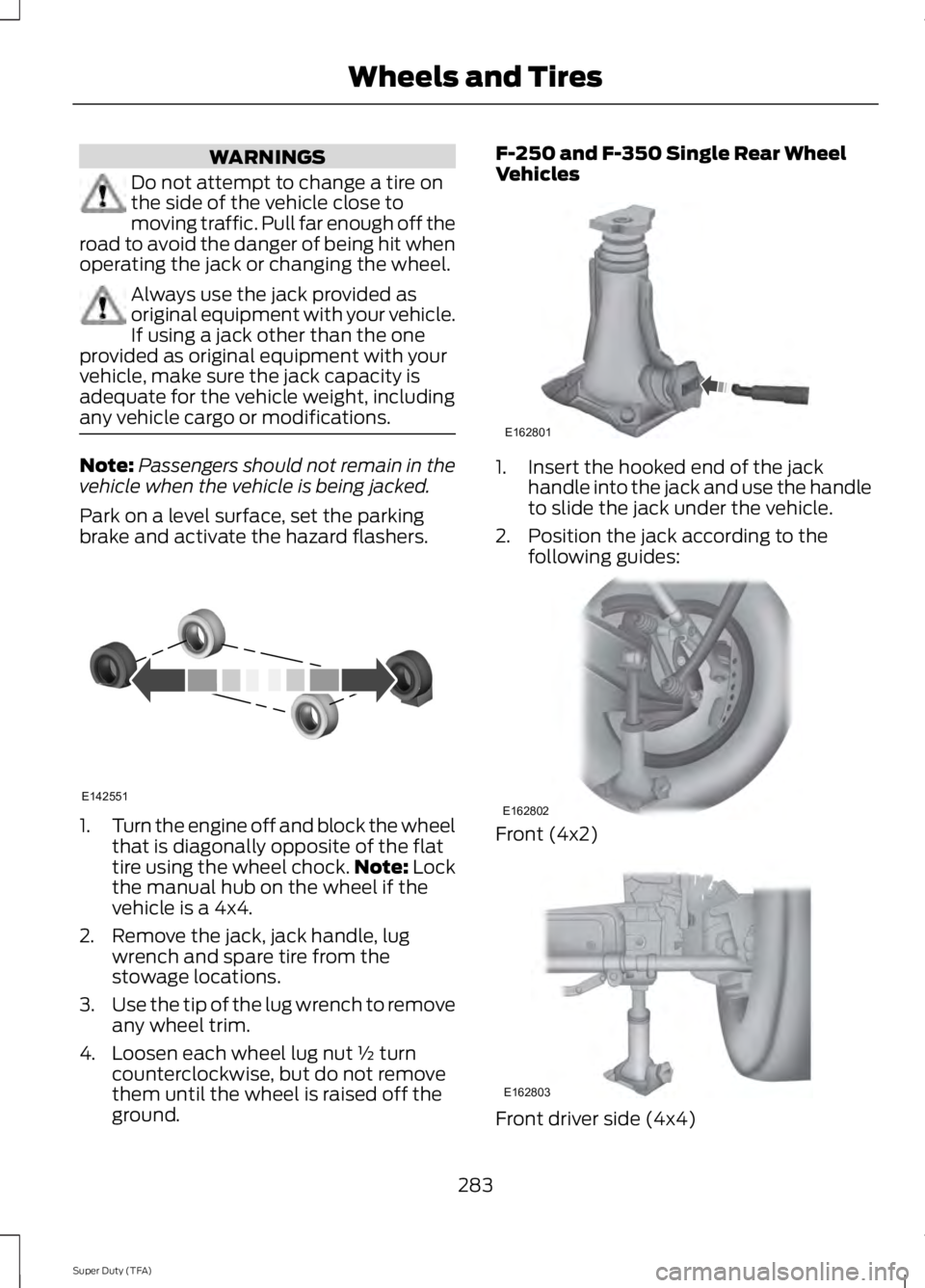

F-250 and F-350 Single Rear WheelVehicles

1. Insert the hooked end of the jackhandle into the jack and use the handleto slide the jack under the vehicle.

2. Position the jack according to thefollowing guides:

Front (4x2)

Front driver side (4x4)

283

Super Duty (TFA)

Wheels and TiresE142551 E162801 E162802 E162803

Page 287 of 460

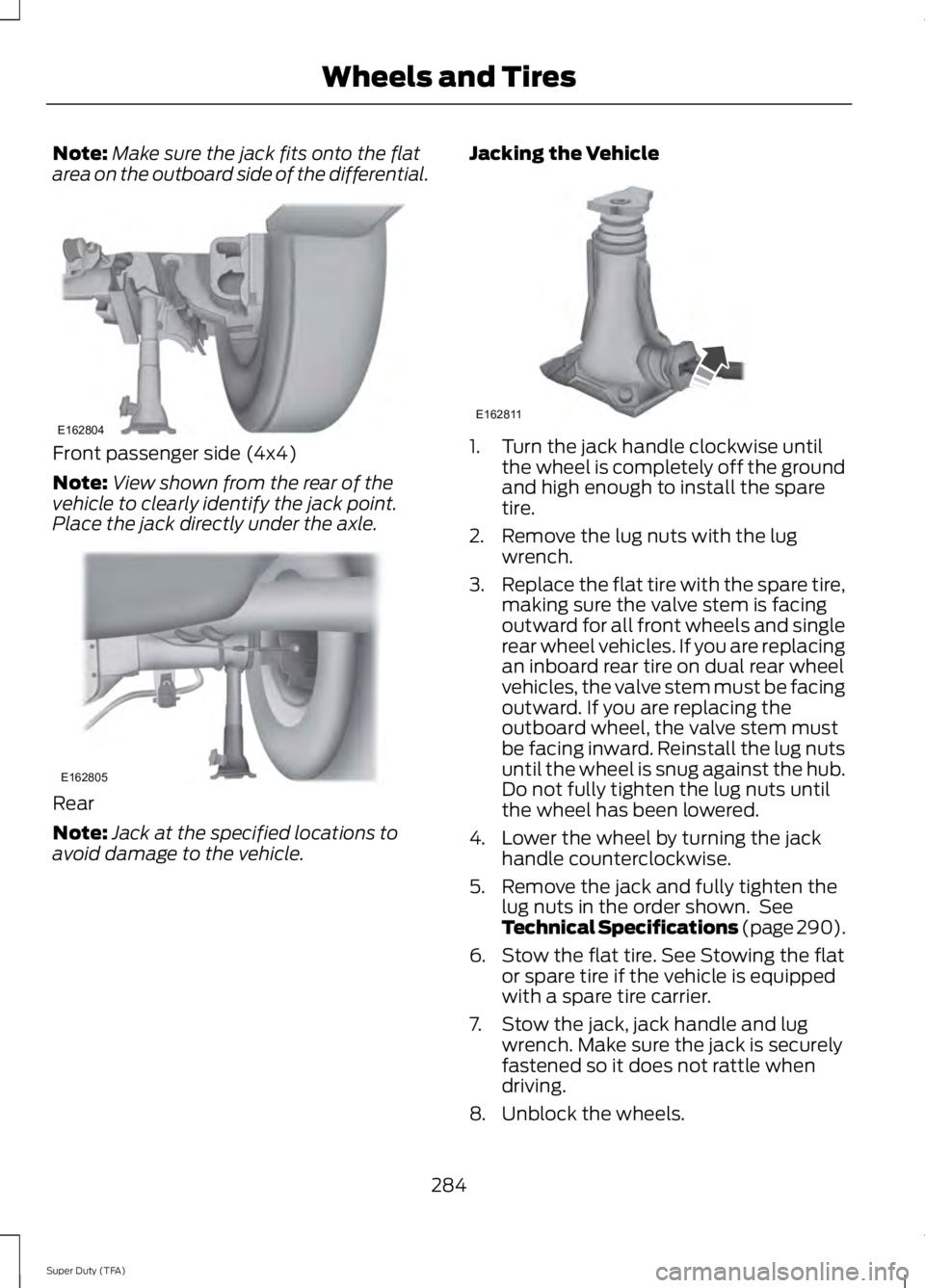

Note:Make sure the jack fits onto the flatarea on the outboard side of the differential.

Front passenger side (4x4)

Note:View shown from the rear of thevehicle to clearly identify the jack point.Place the jack directly under the axle.

Rear

Note:Jack at the specified locations toavoid damage to the vehicle.

Jacking the Vehicle

1. Turn the jack handle clockwise untilthe wheel is completely off the groundand high enough to install the sparetire.

2. Remove the lug nuts with the lugwrench.

3.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward for all front wheels and singlerear wheel vehicles. If you are replacingan inboard rear tire on dual rear wheelvehicles, the valve stem must be facingoutward. If you are replacing theoutboard wheel, the valve stem mustbe facing inward. Reinstall the lug nutsuntil the wheel is snug against the hub.Do not fully tighten the lug nuts untilthe wheel has been lowered.

4. Lower the wheel by turning the jackhandle counterclockwise.

5. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 290).

6. Stow the flat tire. See Stowing the flator spare tire if the vehicle is equippedwith a spare tire carrier.

7. Stow the jack, jack handle and lugwrench. Make sure the jack is securelyfastened so it does not rattle whendriving.

8. Unblock the wheels.

284

Super Duty (TFA)

Wheels and TiresE162804 E162805 E162811