pipe FORD F250 SUPER DUTY 2017 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F250 SUPER DUTY, Model: FORD F250 SUPER DUTY 2017Pages: 642, PDF Size: 12.35 MB

Page 196 of 642

Use the following guidelines to avoidelectrostatic charge build-up when fillingan ungrounded fuel container:

•Place approved fuel container on theground.

•Do not fill a fuel container while it is inthe vehicle (including the cargo area).

•Keep the fuel pump nozzle in contactwith the fuel container while filling.

•Do not use a device that would holdthe fuel pump handle in the fill position.

Fuel Filler Cap

WARNINGS

The fuel system may be underpressure. If you hear a hissing soundnear the fuel filler door, do not refueluntil the sound stops. Otherwise, fuel mayspray out, which could cause seriouspersonal injury.

If you do not use the proper fuel fillercap, excessive pressure or vacuumin the fuel tank may damage the fuelsystem or cause the fuel cap to disengagein a collision, which may result in possiblepersonal injury.

Note:If you must replace the fuel filler cap,replace it with a fuel filler cap that isdesigned for your vehicle. The customerwarranty may be void for any damage to thefuel tank or fuel system if the correctgenuine Ford, Motorcraft or other certifiedfuel filler cap is not used.

Your fuel tank filler cap has an indexeddesign with a 1/4th turn on and off feature.When fueling your vehicle:

1. Put your vehicle in park (P).

2. Switch the engine off.

3. Carefully turn the filler capcounterclockwise until it spins off.

4. Pull to remove the cap from the fuelfiller pipe.

5.To install the cap, align the tabs on thecap with the notches on the filler pipe.

6. Turn the filler cap clockwise 1/4 of aturn clockwise until it clicks at leastonce.

If the Check Fuel Cap light or a Check FuelCap message appears in the instrumentcluster and stays on after you start theengine, you may not have installed the fuelfiller properly.

If the fuel cap light remains on, at the nextopportunity, safely pull off of the road,remove the fuel filler cap, align the capproperly and reinstall it. The check fuel caplight or Check fuel cap message may notreset immediately. It may take severaldriving cycles for the indicators to turn off.A driving cycle consists of an enginestart-up (after four or more hours with theengine off) followed by normal city andhighway driving.

REFUELING - DIESEL

WARNINGS

Read and follow all the instructionson the pump island.

Stay outside your vehicle and do notleave the fuel pump unattendedwhen refueling your vehicle.

Keep children away from the fuelpump. Never let children pump fuel.

Wait at least 10 seconds beforeremoving the fuel pump nozzle toallow any residual fuel to drain intothe fuel tank.

Do not remove the fuel pump nozzlefrom its fully inserted position whenrefueling.

193

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Fuel and Refueling

Page 197 of 642

WARNINGS

When refueling always shut theengine off and never allow sparks oropen flames near the fuel tank fillervalve. Never smoke or use a cell phonewhile refueling. Fuel vapor is extremelyhazardous under certain conditions. Avoidinhaling excess fumes.

Stop refueling after the fuel pumpnozzle automatically shuts off for thesecond time. Failure to follow thiswill fill the expansion space in the fuel tankand could lead to fuel overflowing.

The fuel system may be underpressure. If the fuel filler cap isventing vapor or if you hear a hissingsound, wait until it stops before completelyremoving the fuel filler cap. Otherwise, fuelmay spray out and injure you or others.

If you do not use the proper fuel fillercap, excessive pressure or vacuumin the fuel tank may damage the fuelsystem or cause the fuel cap to disengagein a collision, which may result in possiblepersonal injury.

Note:If you must replace the fuel filler cap,replace it with a fuel filler cap designed foryour vehicle. The vehicle Warranty may bevoid for any damage to the fuel tank or fuelsystem if the correct genuine Ford orMotorcraft® fuel filler cap is not used.

Fueling Tips

If air is allowed to enter the fuel system theengine automatically purges any trappedair. To purge the air sooner: prior to enginestart, prime the system by turning the keyto on for 30 seconds then to off. Repeatthis several times. The engine may runrough and produce white smoke while airis in the system. This is normal.

Use only clean, approved containers thatwill prevent the entry of dirt or waterwhenever you store diesel fuel.

Diesel fuel must not be stored in agalvanized container. The fuel will dissolvethe zinc in the galvanized container. Thezinc will then remain in the fuel. If you runthe contaminated fuel through the engine,the zinc will deposit in the fuel injectorscausing expensive-to-repair damage.

Diesel fuel dispensing nozzle fill rate

Your vehicle has a fuel fill pipe that is ableto accept fuel up to 20 gal (76 L) perminute from an 1.2 in (30 mm)fuel-dispensing nozzle. Pumping fuel atgreater flow rates may result in prematurenozzle shut-off or spit back.

Truck stops have pumps and nozzlesdesigned for larger, heavy-duty trucks.When refueling at truck stops: if the nozzleshuts off repeatedly when refueling, wait5–10 seconds; then use a slower rate offlow, do not depress the nozzle trigger asfar.

Refueling

When fueling your vehicle do the following:

1.Fully open the fuel tank filler door untilit engages and remove the fuel tankfiller cap. The fuel tank filler cap hasan indexed design with a 1/4 turnon/off feature. Carefully turn the fillercap counterclockwise until it spins off.

194

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Fuel and Refueling

Page 198 of 642

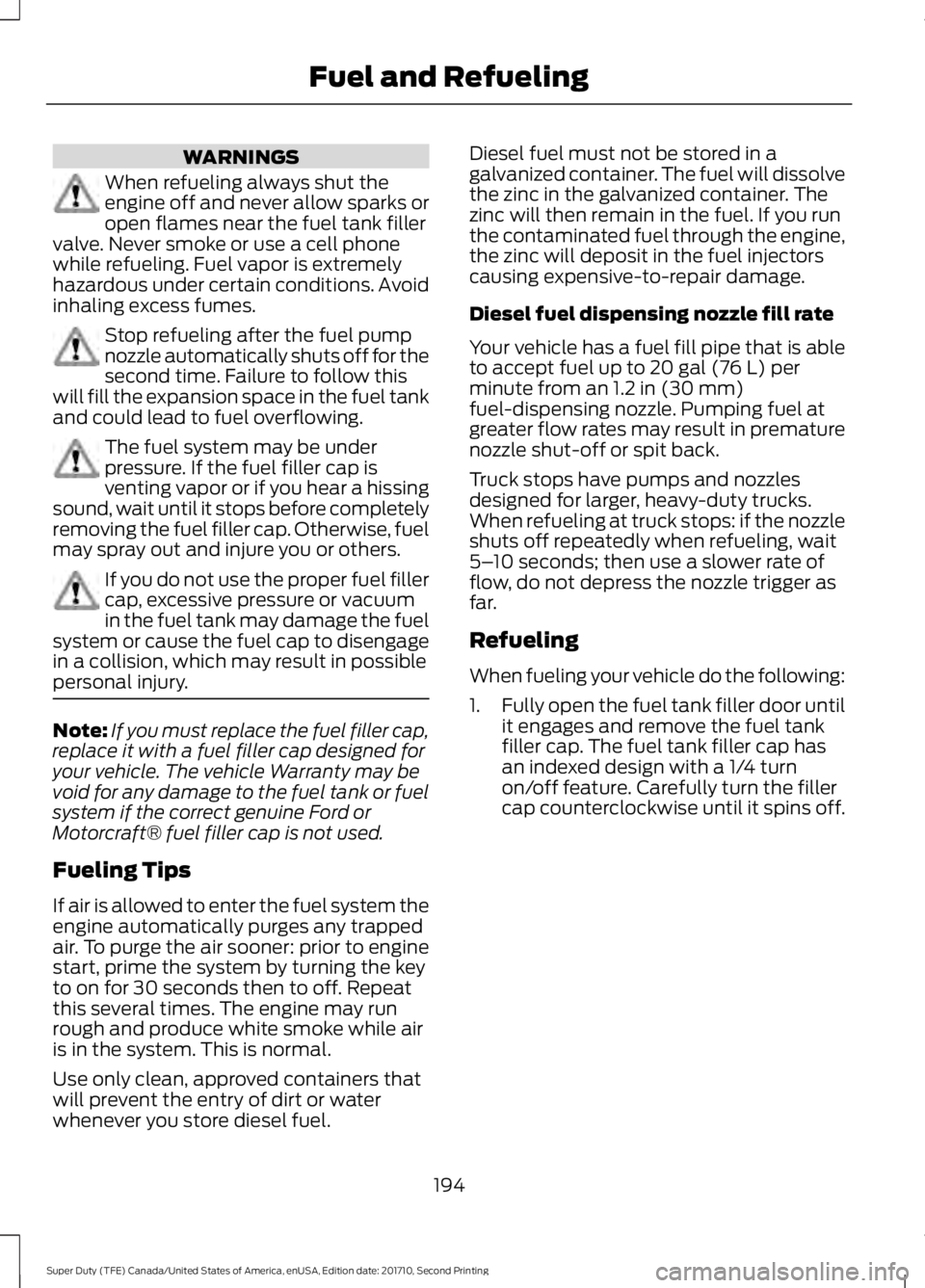

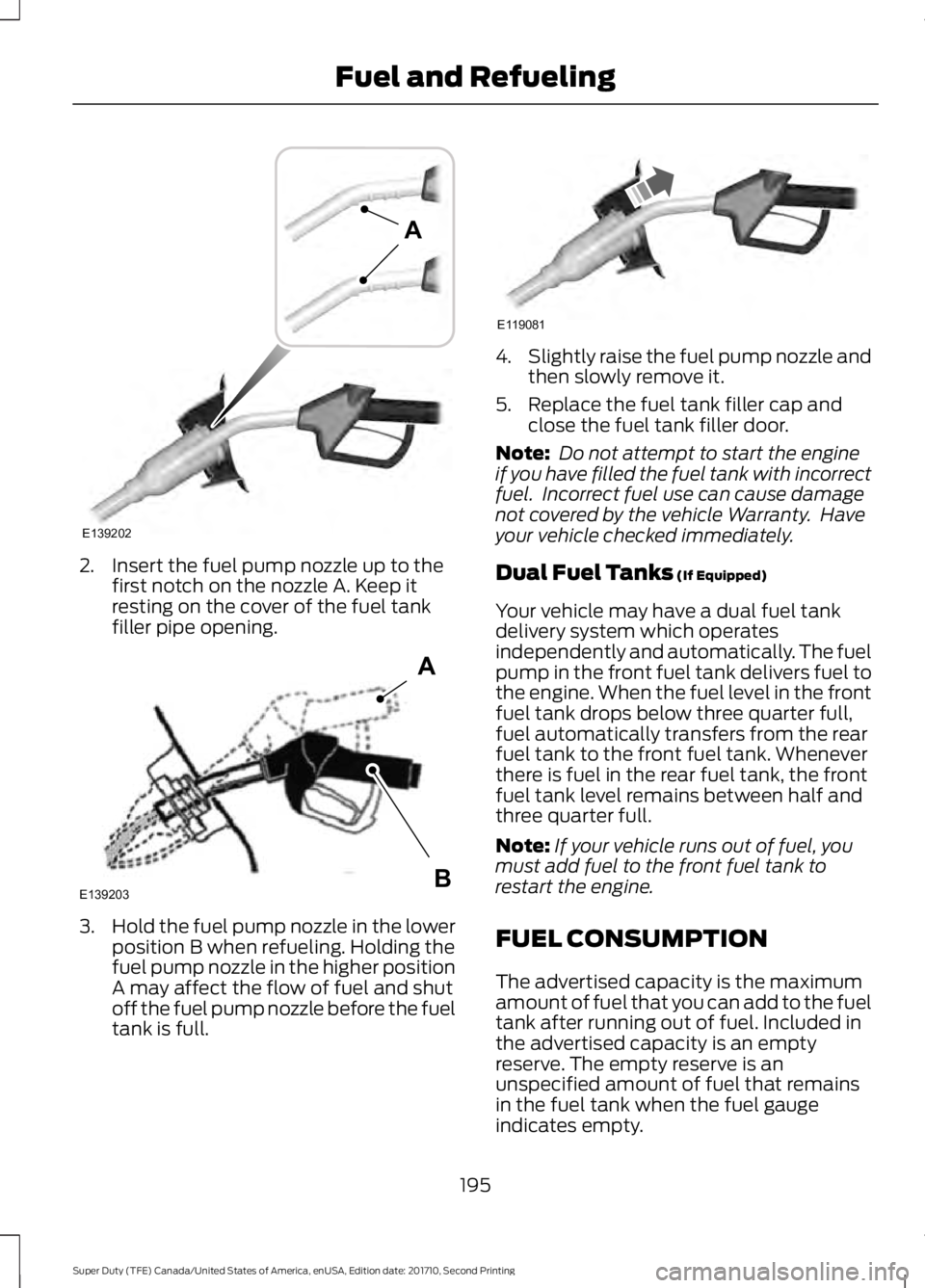

2. Insert the fuel pump nozzle up to thefirst notch on the nozzle A. Keep itresting on the cover of the fuel tankfiller pipe opening.

3.Hold the fuel pump nozzle in the lowerposition B when refueling. Holding thefuel pump nozzle in the higher positionA may affect the flow of fuel and shutoff the fuel pump nozzle before the fueltank is full.

4.Slightly raise the fuel pump nozzle andthen slowly remove it.

5. Replace the fuel tank filler cap andclose the fuel tank filler door.

Note: Do not attempt to start the engineif you have filled the fuel tank with incorrectfuel. Incorrect fuel use can cause damagenot covered by the vehicle Warranty. Haveyour vehicle checked immediately.

Dual Fuel Tanks (If Equipped)

Your vehicle may have a dual fuel tankdelivery system which operatesindependently and automatically. The fuelpump in the front fuel tank delivers fuel tothe engine. When the fuel level in the frontfuel tank drops below three quarter full,fuel automatically transfers from the rearfuel tank to the front fuel tank. Wheneverthere is fuel in the rear fuel tank, the frontfuel tank level remains between half andthree quarter full.

Note:If your vehicle runs out of fuel, youmust add fuel to the front fuel tank torestart the engine.

FUEL CONSUMPTION

The advertised capacity is the maximumamount of fuel that you can add to the fueltank after running out of fuel. Included inthe advertised capacity is an emptyreserve. The empty reserve is anunspecified amount of fuel that remainsin the fuel tank when the fuel gaugeindicates empty.

195

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Fuel and RefuelingE139202

A E139203

A

B E119081

Page 202 of 642

EMISSION CONTROL SYSTEM

- DIESEL

Oxidation Catalytic Converter andDiesel Particulate Filter System (If

Equipped)

WARNING

The normal operating temperatureof the exhaust system is very high.Never work around or attempt torepair any part of the exhaust system untilit has cooled. Use special care whenworking around the diesel oxidationcatalytic converter or the diesel particulatefilter. The diesel oxidation catalyticconverter and the diesel particulate filterheat up to very high temperatures afteronly a short period of engine operation andremain hot after you switch the engine off.

Your vehicle has a diesel particulate filter.The diesel particulate filter is an inline filterin the exhaust system that reduces carbonemissions by trapping exhaust particlesbefore they reach the tailpipe. The dieselparticulate filter looks similar to atraditional exhaust catalyst and is part ofthe exhaust system under your vehicle. Thefilter couples to a diesel oxidation catalystthat reduces the amount of harmfulexhaust emitted from the tailpipe. As sootgathers in the system, it begins to restrictthe filter. The system must periodicallyclean the soot that gathers inside the filter.This is carried out in two ways, passiveregeneration and active regeneration. Bothmethods occur automatically and requireno actions from the driver. During eitherone of these regeneration methods,although you may notice a change inexhaust tone. At certain times, theinformation display shows variousmessages related to the diesel particulatefilter. See Information Messages (page128).

Diesel Particulate Filter Maintenance

You must properly maintain your vehicle'sdiesel particulate filter in order for it tofunction properly.

Do not disregard maintenance messagesthat appear in the information display.Failure to follow the instructions of aninformation message may degrade vehicleperformance and could lead to enginedamage that may not be covered by thevehicle Warranty.

Failure to perform active or operatorcommanded regeneration when instructedcould result in a clogged diesel particulatefilter. If the diesel particulate filter fillsbeyond the regeneration threshold, yourvehicle disables the ability for active andoperator commanded regeneration. Thiscould result in irreversible damage to thediesel particulate filter requiringreplacement that may not be covered bythe vehicle Warranty.

Passive Regeneration

In passive regeneration, the exhaustsystem temperature and constituentsautomatically clean the filter by oxidizingthe soot. Cleaning automatically occursduring normal vehicle operating conditionsdue to driving patterns.

Active Regeneration

Once the diesel particulate filter is full ofexhaust particles, the engine controlmodule commands the exhaust system toclean the filter through active regeneration.Active regeneration requires the enginecomputer to raise the exhaust temperatureto eliminate the particles. During cleaning,the particles convert to harmless gasses.Once cleaned the diesel particulate filtercontinues trapping exhaust particles.

199

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Fuel and Refueling

Page 203 of 642

The regeneration process operates moreefficiently when you drive your vehicle ata constant speed above 30 mph(48 km/h) and at a steady engine speedfor approximately 20 minutes. Thefrequency and duration of regenerationfluctuates by how you drive your vehicle,outside air temperature and altitude. Formost driving, regeneration frequency variesfrom 100–500 mi (160–805 km) betweenoccurrences and each occurrence lasts9–35 minutes. You can usually reduce theduration of regeneration if you maintain aconstant speed above 30 mph (48 km/h).

When the engine control module detectsthat the diesel particulate filter is nearlyfull of particulates and you are notoperating your vehicle in a manner to alloweffective automatic regeneration,messages appear in the informationdisplay as a reminder for you to drive yourvehicle in order to clean the dieselparticulate filter. If you drive your vehiclein a manner to allow effective automaticregeneration, the information displayshows a cleaning exhaust filter message,which is the normal regeneration process.You can also choose operator commandedregeneration to clean the exhaust systemat this point. See Information Messages(page 128).

If you are not able to drive in a manner thatallows effective automatic activeregeneration or you choose to performregeneration of the diesel particulate filterwhile at idle, then operator commandedregeneration would need to be performed.

Operator Commanded Regeneration(If Equipped)

If your vehicle is operated with significantstationary operation, low speed drivecycles less than 25 mph (40 km/h), shortdrive cycles, a drive time is less than 10 -15 minutes or the vehicle does not fullywarm up, passive and active regenerationmay not sufficiently clean the diesel

particulate filter system. Operatorcommanded regeneration allows you tomanually start regeneration of the dieselparticulate filter at idle to clean the filter.If you are not sure whether your vehicle hasthis feature, contact an authorized dealer.

When to Carry Out Operator CommandedRegeneration

You can use the operator commandedregeneration feature when a messageappears in the information display and youare not able to drive in a manner thatallows effective automatic activeregeneration or if you choose to manuallystart the regeneration of the dieselparticulate filter manually while the vehicleis idle. See Information Messages (page128).

Operator Commanded RegenerationPrecautions and Safe Exhaust Position

WARNING

Failure to comply with the followinginstructions for OperatorCommanded Regeneration mayresult in fire, serious injury, death orproperty damage.

Make sure that the louvers located at thetip of the exhaust are clear of anyobstructions as they are used to introducefresh air into the tailpipe to cool theexhaust gases as they leave the exhaustsystem.

Before you start operator commandedregeneration, do the following:

•Shift into park (P) and apply theparking brake on stable, level ground.

•Park your vehicle outside of anystructure.

200

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Fuel and Refueling

Page 204 of 642

•Park your vehicle 10–15 ft (3–5 m)away from any obstructions and awayfrom materials that can easily combustor melt, for example paper, leaves,petroleum products, fuels, plastics andother dry organic material.

•Make sure there is a minimum of 1/8tank of fuel.

•Make sure all fluids are at proper levels.

How to Start Operator CommandedRegeneration

WARNING

Stay clear of the exhaust tailpipeduring regeneration. Hot exhaustgases can burn you badly.

Note:You cannot use the operatorcommanded regeneration until the dieselparticulate filter load percentage hasreached 100%. The diesel particulate filterload percentage fluctuates up and downwhen driving your vehicle due to active andpassive regenerations.

Note:During the use of operatorcommanded regeneration, you may observea light amount of white smoke. This isnormal.

You may not be able to useoperator commandedregeneration if the service enginesoon warning lamp appears in theinformation display

Information Display Procedure

Start with your vehicle engine and when ithas reached the normal operatingtemperature, press the information displaycontrol button on the steering wheel. SeeGeneral Information (page 111). If amessage advising that the exhaust filter isfull appears in the information display,press the OK button to set the display toY. Answer yes to this prompt and then

follow the next prompts regarding exhaustposition required to initiate operatorcommanded regeneration. Be sure tounderstand each prompt. If you are notsure what is being asked by each prompt,contact an authorized dealer. The displayconfirms the operation has started andwhen it has finished.

If the diesel particulate filter is near or atsaturation, a message requestingpermission to initiate filter cleaningappears in the information display. SeeInformation Messages (page 128).Answer yes to this prompt and then followthe next prompts regarding exhaustposition required to initiate operatorcommanded regeneration. Be sure tounderstand each prompt. If you are notsure what is being asked by each prompt,contact an authorized dealer. The displayconfirms the operation has started andwhen it has finished. You can also drive toclean the filter.

When the system is at the pointof oversaturation, the serviceengine warning lamp illuminatesand a message appears in the informationdisplay. You cannot initiate filter cleaning.You must have your vehicle checked assoon as possible.

Once operator commanded regenerationstarts, engine speed increases toapproximately 2000–2500 rpm and thecooling fan speed increases. You will heara change in audible sound due to enginespeed and cooling fan speed increases.

It is not necessary to open the hood on theengine compartment. Once operatorcommanded regeneration completes, theengine speed returns to normal idling. Theexhaust system remains very hot forseveral minutes even after regeneration iscomplete. Do not reposition the vehicleover materials that could burn until the

201

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Fuel and Refueling

Page 206 of 642

Resonator and Tailpipe AssemblyMaintenance

Aftermarket devices or modifications tothe exhaust system may reduce theeffectiveness of the exhaust system aswell as cause damage to the exhaustsystem or engine. This may also degradevehicle performance and could lead toengine damage that may not be coveredby the vehicle Warranty.

Emission Control System Laws

WARNING

Do not remove or alter the originalequipment floor covering orinsulation between it and the metalfloor of the vehicle. The floor covering andinsulation protect occupants of the vehiclefrom the engine and exhaust system heatand noise. On vehicles with no originalequipment floor covering insulation, do notcarry passengers in a manner that permitsprolonged skin contact with the metalfloor. Failure to follow these instructionsmay result in fire or personal injury.

In the United States, federal law andcertain state laws prohibit removing orrendering the emission control systeminoperative. Similar federal or provinciallaws may apply in Canada. We do notrecommend any vehicle modificationwithout determining applicable law.

Tampering with emissionscontrol system, including relatedsensors or the diesel exhaustfluid injection system can result in reducedengine power and the service engine soonwarning lamp illuminating in theinformation display.

Tampering with a Noise ControlSystem

Federal law prohibits the following acts orthe causing thereof:

•The removal or rendering inoperativeby any person other than for purposesof maintenance, repair or replacementof any device or element of designincorporated into any new vehicle forthe purpose of noise control prior to itssale or delivery to the ultimatepurchaser or while it is in use.

•The use of the vehicle after such deviceor element of design has been removedor rendered inoperative by any person.

Among those acts, which the United StatesEnvironmental Protection Agency maypresume to constitute tampering are theacts listed below:

•Removal of hood blanket, fender apronabsorbers, fender apron barriers,underbody noise shields or acousticallyabsorptive material.

•Tampering or rendering inoperative theengine speed governor, to allow enginespeed to exceed manufacturer’sspecifications.

The complexity of the diesel engine makesit so the owner is discouraged fromattempting to perform maintenance otherthan the services described in this Owner'sManual.

If you experience difficulty starting theengine, rough idling, excessive exhaustsmoke, a decrease in engine performanceor excess fuel consumption, perform thefollowing checks:

•A plugged or disconnected air inletsystem or engine air filter element.

•Water in the fuel filter and waterseparator.

•A clogged fuel filter.

•Contaminated fuel.

203

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Fuel and Refueling

Page 353 of 642

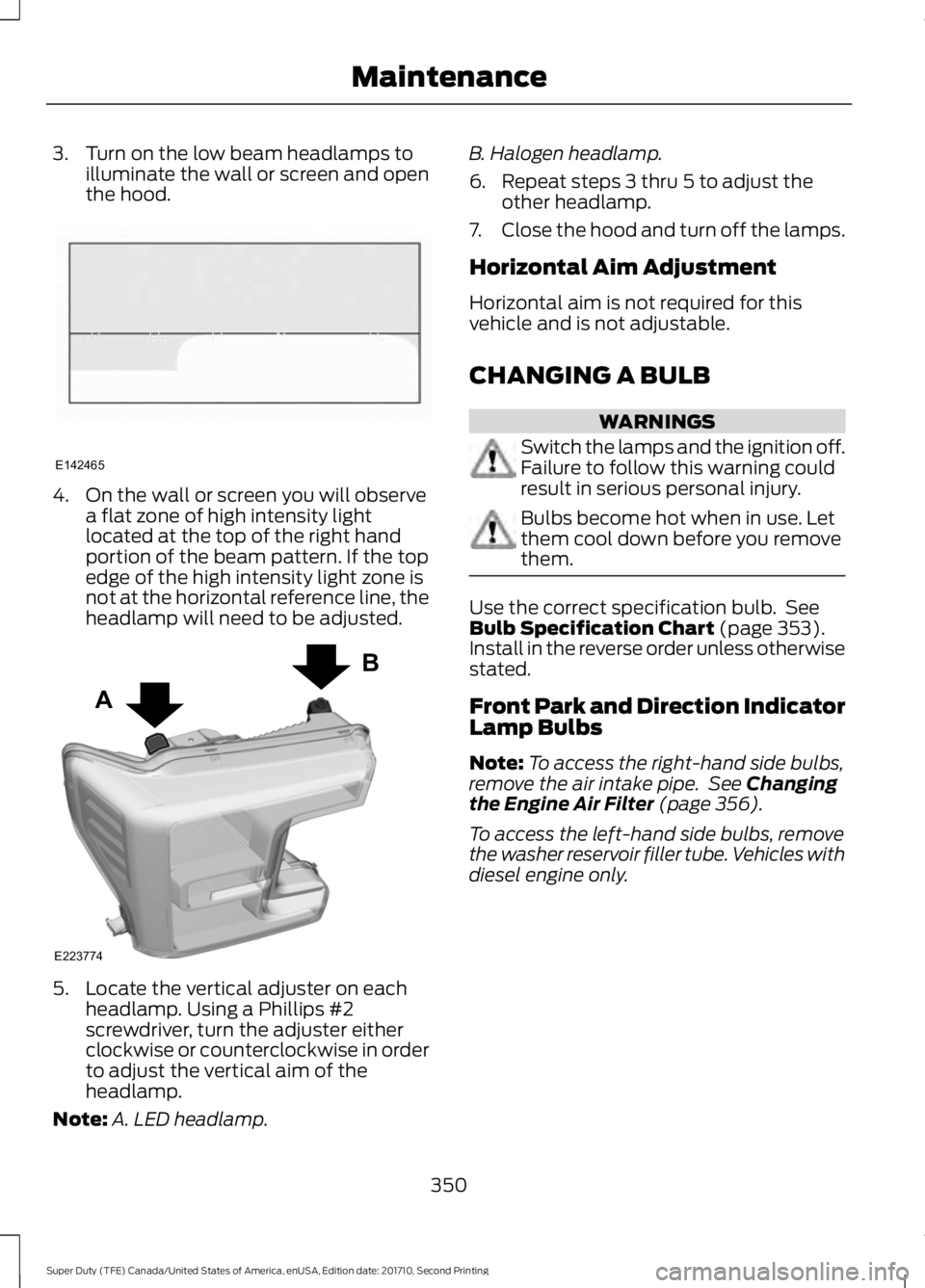

3. Turn on the low beam headlamps toilluminate the wall or screen and openthe hood.

4. On the wall or screen you will observea flat zone of high intensity lightlocated at the top of the right handportion of the beam pattern. If the topedge of the high intensity light zone isnot at the horizontal reference line, theheadlamp will need to be adjusted.

5. Locate the vertical adjuster on eachheadlamp. Using a Phillips #2screwdriver, turn the adjuster eitherclockwise or counterclockwise in orderto adjust the vertical aim of theheadlamp.

Note:A. LED headlamp.

B. Halogen headlamp.

6. Repeat steps 3 thru 5 to adjust theother headlamp.

7.Close the hood and turn off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for thisvehicle and is not adjustable.

CHANGING A BULB

WARNINGS

Switch the lamps and the ignition off.Failure to follow this warning couldresult in serious personal injury.

Bulbs become hot when in use. Letthem cool down before you removethem.

Use the correct specification bulb. SeeBulb Specification Chart (page 353).Install in the reverse order unless otherwisestated.

Front Park and Direction IndicatorLamp Bulbs

Note:To access the right-hand side bulbs,remove the air intake pipe. See Changingthe Engine Air Filter (page 356).

To access the left-hand side bulbs, removethe washer reservoir filler tube. Vehicles withdiesel engine only.

350

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

MaintenanceE142465 A

B

E223774

Page 354 of 642

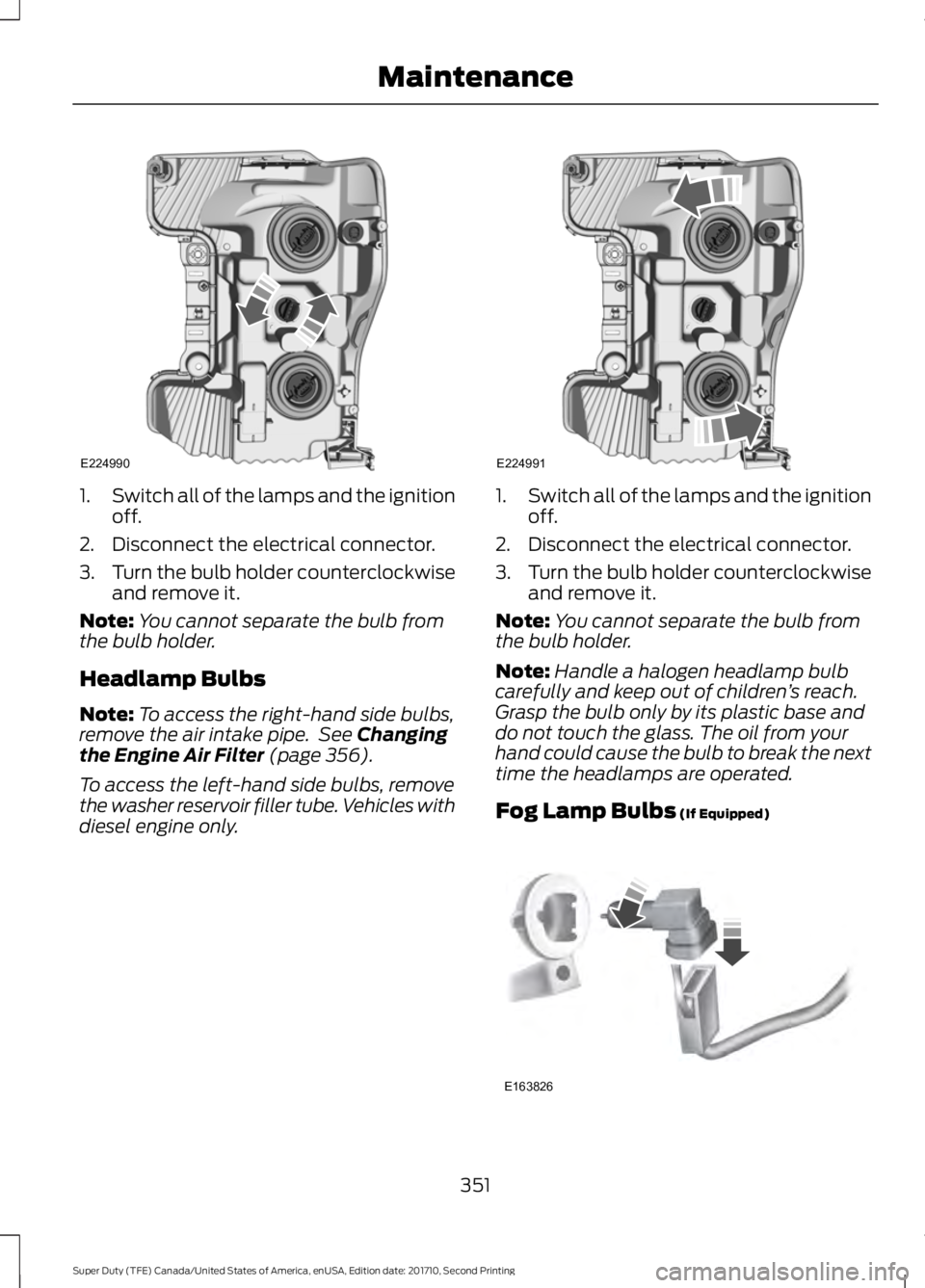

1.Switch all of the lamps and the ignitionoff.

2. Disconnect the electrical connector.

3.Turn the bulb holder counterclockwiseand remove it.

Note:You cannot separate the bulb fromthe bulb holder.

Headlamp Bulbs

Note:To access the right-hand side bulbs,remove the air intake pipe. See Changingthe Engine Air Filter (page 356).

To access the left-hand side bulbs, removethe washer reservoir filler tube. Vehicles withdiesel engine only.

1.Switch all of the lamps and the ignitionoff.

2. Disconnect the electrical connector.

3.Turn the bulb holder counterclockwiseand remove it.

Note:You cannot separate the bulb fromthe bulb holder.

Note:Handle a halogen headlamp bulbcarefully and keep out of children’s reach.Grasp the bulb only by its plastic base anddo not touch the glass. The oil from yourhand could cause the bulb to break the nexttime the headlamps are operated.

Fog Lamp Bulbs (If Equipped)

351

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

MaintenanceE224990 E224991 E163826

Page 370 of 642

•Never wash or rinse any ignition coil,spark plug wire or spark plug well, orthe area in and around these locations.

•Cover the battery, power distributionbox, and air filter assembly to preventwater damage when cleaning theengine.

CLEANING THE EXHAUST -

6.7L DIESEL

WARNINGS

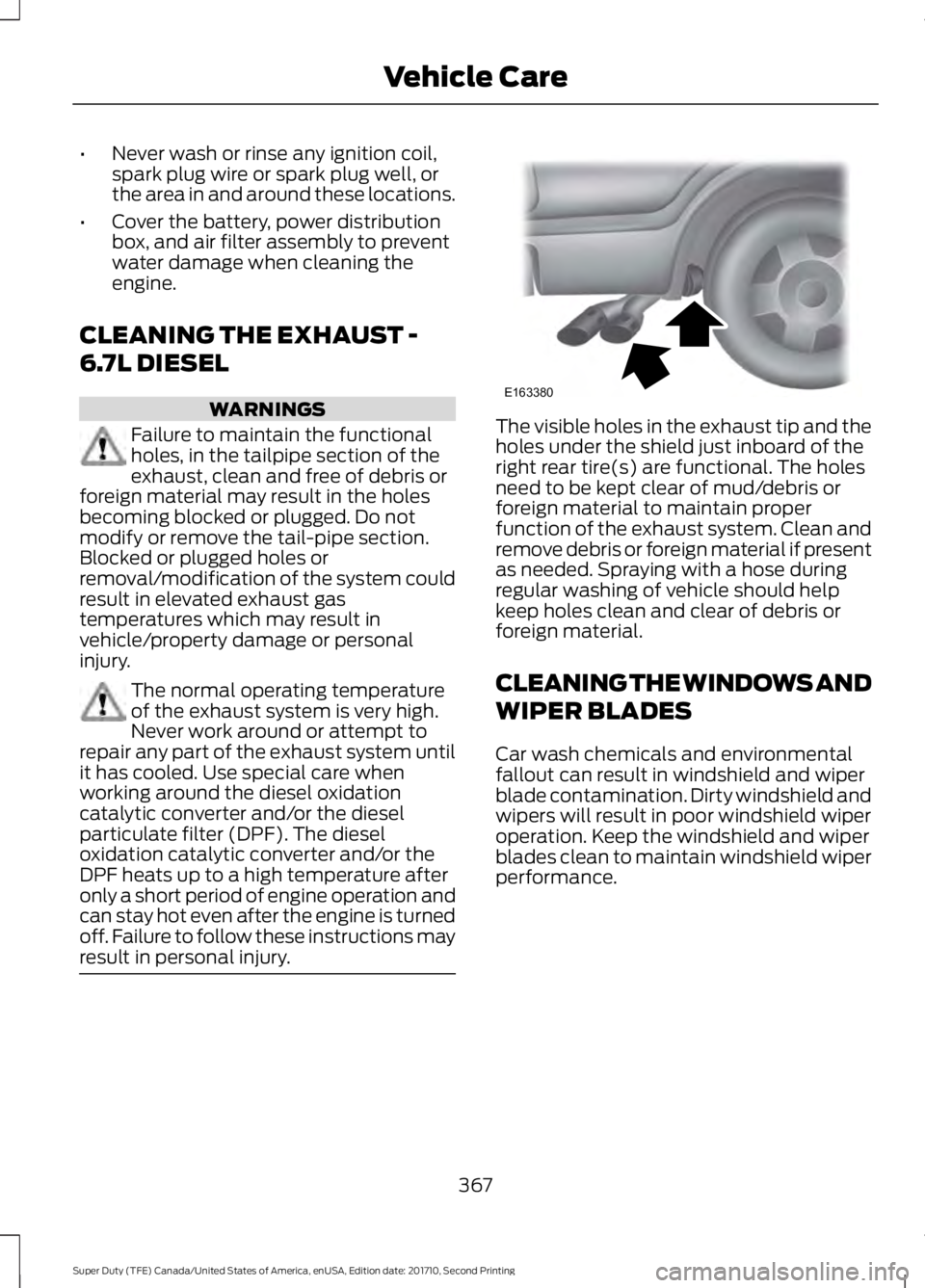

Failure to maintain the functionalholes, in the tailpipe section of theexhaust, clean and free of debris orforeign material may result in the holesbecoming blocked or plugged. Do notmodify or remove the tail-pipe section.Blocked or plugged holes orremoval/modification of the system couldresult in elevated exhaust gastemperatures which may result invehicle/property damage or personalinjury.

The normal operating temperatureof the exhaust system is very high.Never work around or attempt torepair any part of the exhaust system untilit has cooled. Use special care whenworking around the diesel oxidationcatalytic converter and/or the dieselparticulate filter (DPF). The dieseloxidation catalytic converter and/or theDPF heats up to a high temperature afteronly a short period of engine operation andcan stay hot even after the engine is turnedoff. Failure to follow these instructions mayresult in personal injury.

The visible holes in the exhaust tip and theholes under the shield just inboard of theright rear tire(s) are functional. The holesneed to be kept clear of mud/debris orforeign material to maintain properfunction of the exhaust system. Clean andremove debris or foreign material if presentas needed. Spraying with a hose duringregular washing of vehicle should helpkeep holes clean and clear of debris orforeign material.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmentalfallout can result in windshield and wiperblade contamination. Dirty windshield andwipers will result in poor windshield wiperoperation. Keep the windshield and wiperblades clean to maintain windshield wiperperformance.

367

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Vehicle CareE163380