set clock FORD F450 SUPER DUTY 2016 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: F450 SUPER DUTY, Model: FORD F450 SUPER DUTY 2016Pages: 507, PDF Size: 8.13 MB

Page 32 of 507

PRINCIPLE OF OPERATION

WARNINGS

Always drive and ride with theseatback upright and the lap beltsnug and low across the hips.

To reduce the risk of injury, makesure children sit where they can beproperly restrained.

Never let a passenger hold a child onhis or her lap while your vehicle ismoving. The passenger cannotprotect the child from injury in a crashwhich may result in serious injury or death.

All occupants of the vehicle,including the driver, should alwaysproperly wear their safety belts, evenwhen an airbag supplemental restraintsystem is provided. Failure to properly wearyour safety belt could seriously increasethe risk of injury or death.

It is extremely dangerous to ride in acargo area, inside or outside of avehicle. In a crash, people riding inthese areas are more likely to be seriouslyinjured or killed. Do not allow people to ridein any area of your vehicle that is notequipped with seats and safety belts. Besure everyone in your vehicle is in a seatand using a safety belt properly.

In a rollover crash, an unbeltedperson is significantly more likely todie than a person wearing a safetybelt.

Each seating position in your vehiclehas a specific safety belt assemblywhich is made up of one buckle andone tongue that are designed to be usedas a pair. 1) Use the shoulder belt on theoutside shoulder only. Never wear theshoulder belt under the arm. 2) Neverswing the safety belt around your neck overthe inside shoulder. 3) Never use a singlebelt for more than one person.

WARNINGS

When possible, all children 12 yearsold and under should be properlyrestrained in a rear seating position.Failure to follow this could seriouslyincrease the risk of injury or death.

Safety belts and seats can becomehot in a vehicle that has been closedup in sunny weather; they could burna small child. Check seat covers andbuckles before you place a child anywherenear them.

Front and rear seat occupants,including pregnant women, shouldwear safety belts for optimumprotection in an accident.

All seating positions in this vehicle havelap and shoulder safety belts. Alloccupants of the vehicle should alwaysproperly wear their safety belts, even whenan airbag supplemental restraint systemis provided.

The safety belt system consists of:

•Lap and shoulder safety belts.

•Shoulder safety belt with automaticlocking mode, (except driver safetybelt).

•Height adjuster at the front outboardseating positions.

•Safety belt pretensioner at the frontoutboard seating positions.

•Safety belt warning light and chime.

•Crash sensors and monitoring systemwith readiness indicator.

29

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Safety Belts

Page 74 of 507

GENERAL INFORMATION

Condensation in Lamp Assemblies

Exterior lamps have vents toaccommodate normal changes in airpressure.

Condensation can be a natural by-productof this design. When moist air enters thelamp assembly through the vents, there isa possibility that condensation can occurwhen the temperature is cold. Whennormal condensation occurs, a fine mistcan form on the interior of the lens. Thefine mist eventually clears and exitsthrough the vents during normal operation.

Clearing time may take as long as 48 hoursunder dry weather conditions.

Examples of acceptable condensation are:

•The presence of a fine mist (no streaks,drip marks or large droplets).

•A fine mist covers less than 50% of thelens.

Examples of unacceptable condensationare:

•A water puddle inside the lamp.

•Streaks, drip marks or large dropletspresent on the interior of the lens.

If you see any unacceptable condensation,have your vehicle checked by an authorizeddealer.

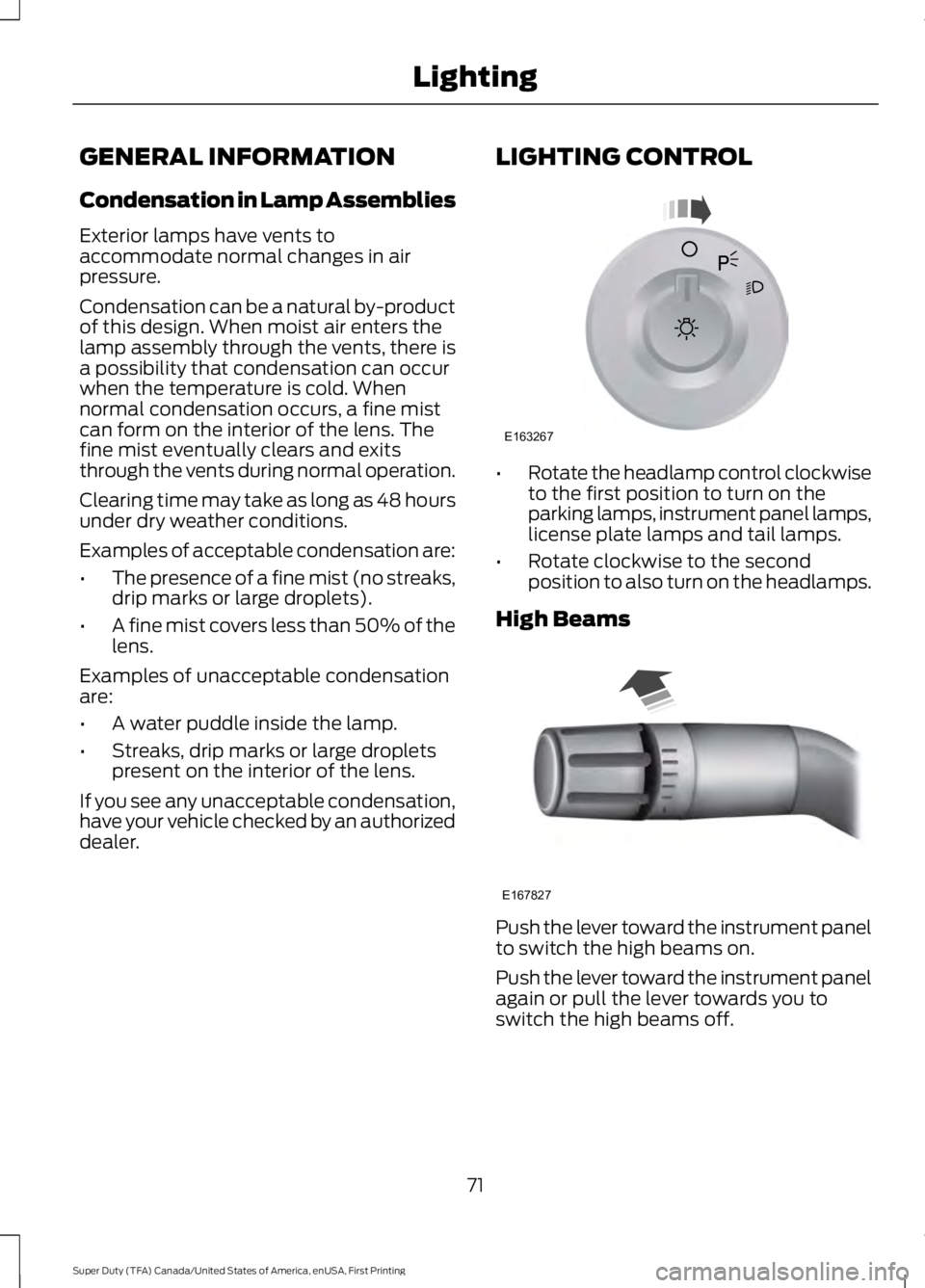

LIGHTING CONTROL

•Rotate the headlamp control clockwiseto the first position to turn on theparking lamps, instrument panel lamps,license plate lamps and tail lamps.

•Rotate clockwise to the secondposition to also turn on the headlamps.

High Beams

Push the lever toward the instrument panelto switch the high beams on.

Push the lever toward the instrument panelagain or pull the lever towards you toswitch the high beams off.

71

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

LightingE163267 E167827

Page 129 of 507

To operate the heated seats, touch theheated seat symbol on the touchscreen tocycle through the various heat settings andoff. More indicator lights indicate warmersettings.

Cooled Seats

The cooled seats will only function whenthe engine is running.

To operate the cooled seats, touch thecooled seat symbol on the touchscreen tocycle through the various cool settings andoff. More indicator lights indicate coolersettings.

If the engine falls below 350 RPM whilethe cooled seats are on, the feature willturn itself off. You will need to reactivateit.

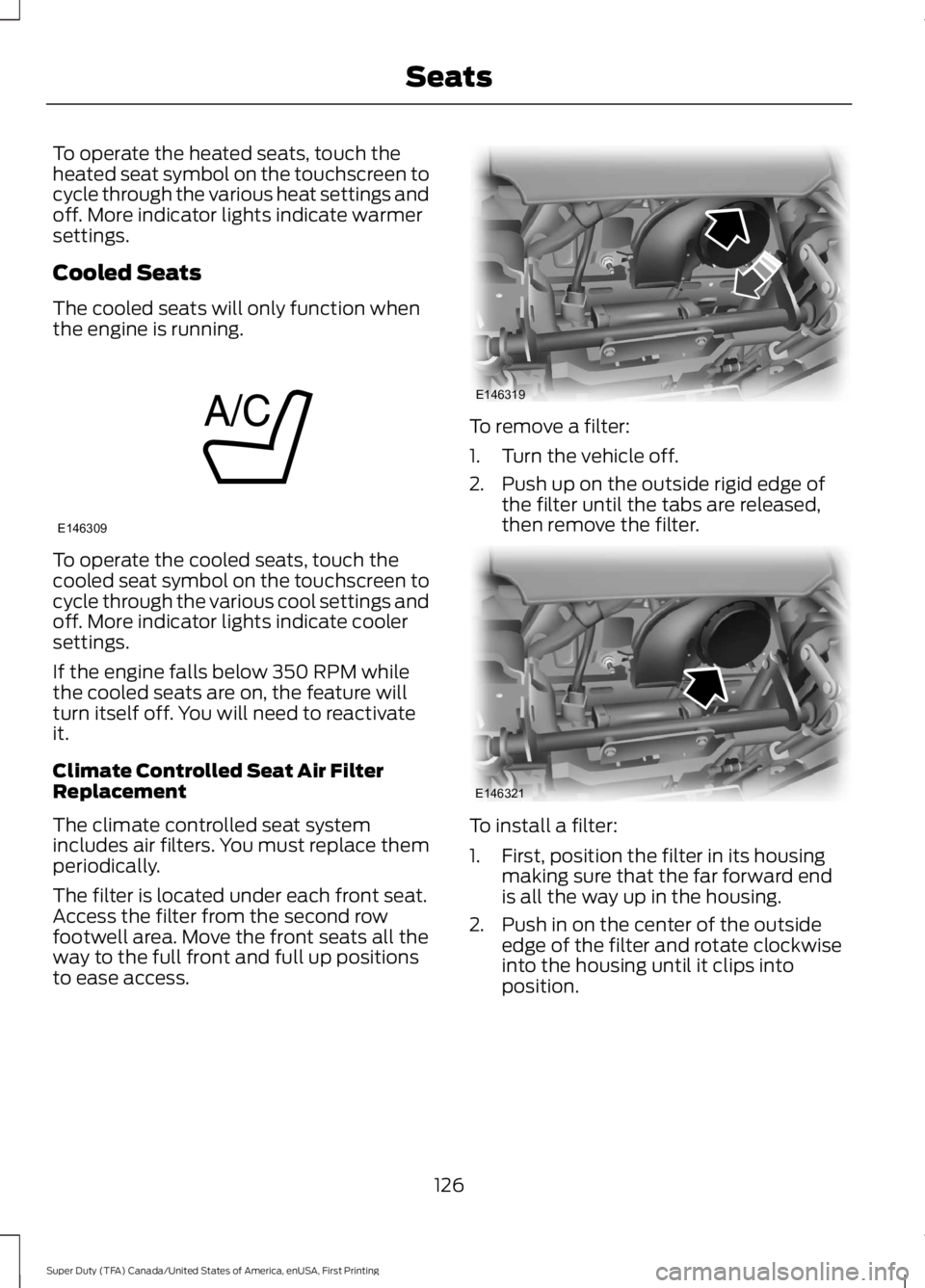

Climate Controlled Seat Air FilterReplacement

The climate controlled seat systemincludes air filters. You must replace themperiodically.

The filter is located under each front seat.Access the filter from the second rowfootwell area. Move the front seats all theway to the full front and full up positionsto ease access.

To remove a filter:

1. Turn the vehicle off.

2. Push up on the outside rigid edge ofthe filter until the tabs are released,then remove the filter.

To install a filter:

1. First, position the filter in its housingmaking sure that the far forward endis all the way up in the housing.

2. Push in on the center of the outsideedge of the filter and rotate clockwiseinto the housing until it clips intoposition.

126

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

SeatsE146309 E146319 E146321

Page 150 of 507

Fuel Filler Cap

WARNINGS

The fuel system may be underpressure. If you hear a hissing soundnear the fuel filler door, do not refueluntil the sound stops. Otherwise, fuel mayspray out, which could cause seriouspersonal injury.

If you do not use the proper fuel fillercap, excessive pressure or vacuumin the fuel tank may damage the fuelsystem or cause the fuel cap to disengagein a collision, which may result in possiblepersonal injury.

Note:If you must replace the fuel filler cap,replace it with a fuel filler cap that isdesigned for your vehicle. The customerwarranty may be void for any damage to thefuel tank or fuel system if the correctgenuine Ford, Motorcraft or other certifiedfuel filler cap is not used.

Your fuel tank filler cap has an indexeddesign with a 1/4th turn on and off feature.When fueling your vehicle:

1. Put your vehicle in park (P).

2. Switch the engine off.

3. Carefully turn the filler capcounterclockwise until it spins off.

4. Pull to remove the cap from the fuelfiller pipe.

5.To install the cap, align the tabs on thecap with the notches on the filler pipe.

6. Turn the filler cap clockwise 1/4 of aturn clockwise until it clicks at leastonce.

If the Check Fuel Cap light or a Check FuelCap message appears in the instrumentcluster and stays on after you start theengine, you may not have installed the fuelfiller properly.

If the fuel cap light remains on, at the nextopportunity, safely pull off of the road,remove the fuel filler cap, align the capproperly and reinstall it. The check fuel caplight or Check fuel cap message may notreset immediately. It may take severaldriving cycles for the indicators to turn off.A driving cycle consists of an enginestart-up (after four or more hours with theengine off) followed by normal city andhighway driving.

FUEL CONSUMPTION

Empty reserve is the amount of fuelremaining in the tank after the fuel gaugeindicates empty. The amount of usablefuel in the empty reserve varies and shouldnot be relied upon to increase driving range.

•The usable capacity of the fuel tank isthe amount of fuel that can be addedinto the tank after the gauge indicatesempty

•The advertised capacity is the total fueltank size. See Capacities andSpecifications (page 303). It is thecombined usable capacity plus theempty reserve.

•Due to the empty reserve, you may notbe able to refuel the full amount of theadvertised capacity of the fuel tankeven when the fuel gauge reads empty.

Filling the Tank

For consistent results when filling the fueltank:

•Turn the ignition off before fueling; aninaccurate reading results if the engineis left running.

•Use the same fill rate(low-medium-high) each time the tankis filled.

•Allow no more than two automaticclick-offs when filling.

147

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Fuel and Refueling

Page 161 of 507

USING FOUR-WHEEL DRIVE

WARNING

For important information regardingsafe operation of this type of vehicle,See General Information (page264).

Note:Do not use 4X4 mode on dry, hardsurfaced roads. Doing so will produceexcessive noise, increase tire wear and maydamage drive components. 4X4 mode isonly intended for consistently slippery orloose surfaces.

Note:If 4X4 low is selected while thevehicle is moving above 3 mph (5 km/h),the 4WD system will not perform a shift.This is normal and should be no reason forconcern. Refer to Shifting to/from 4L (4X4Low) for proper operation.

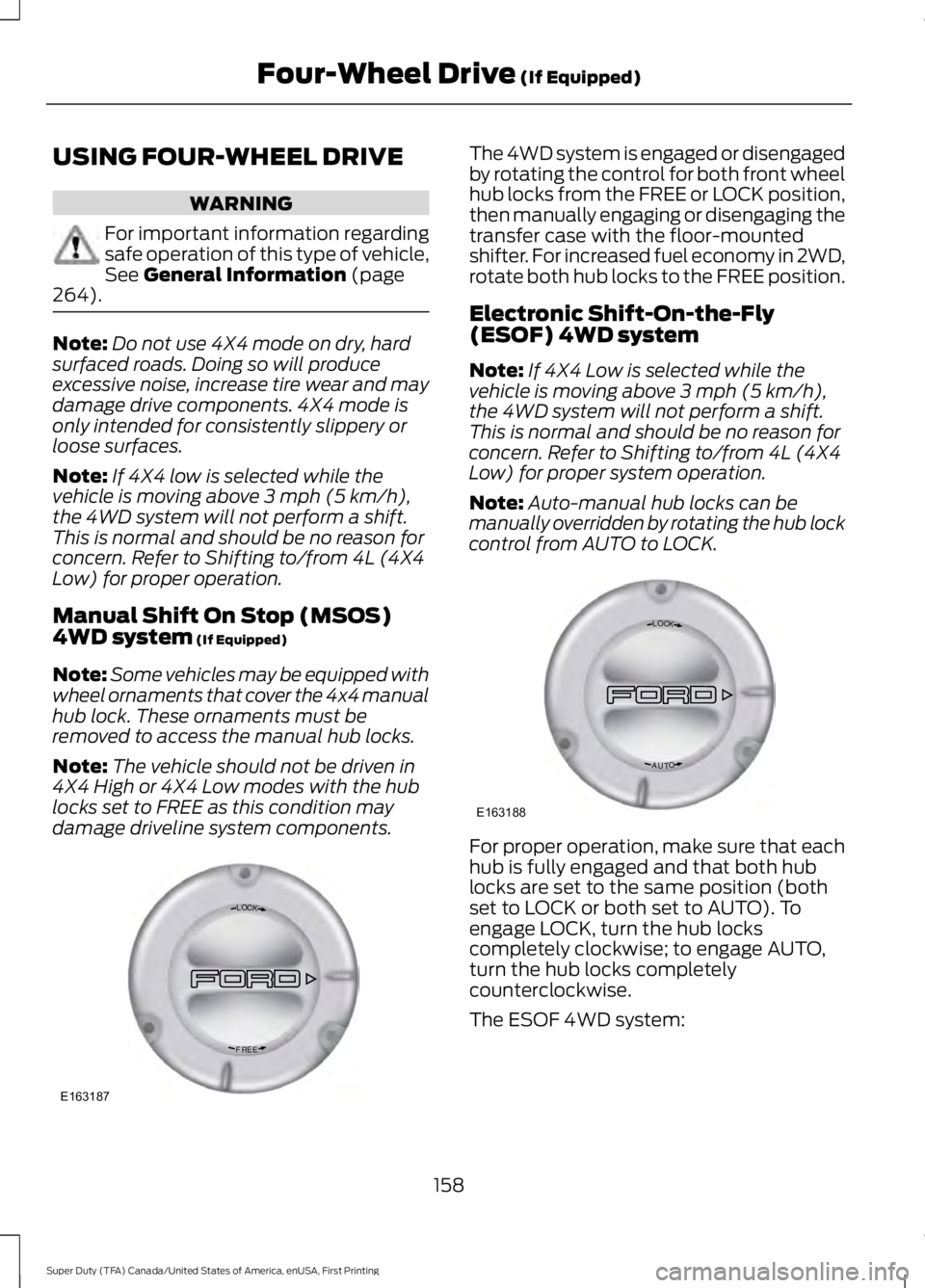

Manual Shift On Stop (MSOS)4WD system (If Equipped)

Note:Some vehicles may be equipped withwheel ornaments that cover the 4x4 manualhub lock. These ornaments must beremoved to access the manual hub locks.

Note:The vehicle should not be driven in4X4 High or 4X4 Low modes with the hublocks set to FREE as this condition maydamage driveline system components.

The 4WD system is engaged or disengagedby rotating the control for both front wheelhub locks from the FREE or LOCK position,then manually engaging or disengaging thetransfer case with the floor-mountedshifter. For increased fuel economy in 2WD,rotate both hub locks to the FREE position.

Electronic Shift-On-the-Fly(ESOF) 4WD system

Note:If 4X4 Low is selected while thevehicle is moving above 3 mph (5 km/h),the 4WD system will not perform a shift.This is normal and should be no reason forconcern. Refer to Shifting to/from 4L (4X4Low) for proper system operation.

Note:Auto-manual hub locks can bemanually overridden by rotating the hub lockcontrol from AUTO to LOCK.

For proper operation, make sure that eachhub is fully engaged and that both hublocks are set to the same position (bothset to LOCK or both set to AUTO). Toengage LOCK, turn the hub lockscompletely clockwise; to engage AUTO,turn the hub locks completelycounterclockwise.

The ESOF 4WD system:

158

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Four-Wheel Drive (If Equipped)LOC K

EERF

E163187 LOC K

OTUA

E163188

Page 239 of 507

Only use oils certified for gasoline enginesby the American Petroleum Institute (API).An oil with this trademark symbolconforms to the current engine andemission system protection standards andfuel economy requirements of theInternational Lubricants SpecificationAdvisory Council (ILSAC), comprised ofU.S. and Japanese automobilemanufacturers.

1. Check the engine oil level.

2. If the engine oil level is not within thenormal range, add engine oil thatmeets Ford specifications. SeeCapacities and Specifications for moreinformation.

3. Remove the engine oil filler cap anduse a funnel to pour the engine oil intothe opening.

4.Recheck the engine oil level. Make surethe oil level is not above the normaloperating range on the engine oil leveldipstick.

5. Install the engine oil level dipstick andensure it is fully seated.

6. Fully install the engine oil filler cap byturning the filler cap clockwise untilthree clicks are heard or until the capis fully seated.

OIL CHANGE INDICATOR

RESET

Resetting the Oil Life MonitoringSystem

Only reset the oil life monitoring systemafter changing the engine oil and oil filter.

1.Switch the ignition on. Do not start theengine. For vehicles with push-buttonstart, press and hold the start buttonfor two seconds without pressing thebrake pedal. Do not start the engine.

2.Press the accelerator and brake pedalsat the same time.

3.Keep the accelerator and brake pedalsfully pressed.

4. After three seconds, a messageconfirming that the reset is in progresswill be displayed.

5. After 25 seconds, a messageconfirming that the reset is completewill be displayed.

6. Release the accelerator and brakepedals.

7.The message confirming that the resetis complete will no longer be displayed.

8.Switch the ignition off. For vehicles withpush-button start, press the startbutton to switch the ignition off.

ENGINE COOLANT CHECK

WARNINGS

Do not add engine coolant when theengine is hot. Steam and scaldingliquids released from a hot coolingsystem can burn you badly. Also, you canbe burned if you spill coolant on hot engineparts.

236

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE142732

Page 249 of 507

6. Release the parking brake. With yourfoot on the brake pedal and with theA/C on, put the vehicle in D and allowthe engine to idle for at least oneminute.

•If you do not allow the engine torelearn its idle trim, the idle qualityof your vehicle may be adverselyaffected until the idle trim iseventually relearned.

7. Drive the vehicle to complete therelearning process

•The vehicle may need to be driven10 mi (16 km) or more to relearn theidle and fuel trim strategy alongwith the ethanol content for flexiblefuel vehicles.

•For flexible fuel vehicles, if you areoperating on E85, you mayexperience poor starts or aninability to start the engine anddriveability problems until the fueltrim and ethanol content have beenrelearned.

If the battery has been disconnected or anew battery has been installed, the clockand radio settings must be reset once thebattery is reconnected.

Always dispose of automotivebatteries in a responsible manner.Follow your local authorized standardsfor disposal. Call your local authorizedrecycling center to find out more aboutrecycling automotive batteries.

Battery Management System (IfEquipped)

The battery management system (BMS)monitors battery conditions and takesactions to extend battery life. If excessivebattery drain is detected, the system maytemporarily disable certain electricalfeatures to protect the battery. Thoseelectrical accessories affected include therear defrost, heated/cooled seats, climate

control fan, heated steering wheel, audioand navigation system. A message may beshown in the information displays to alertthe driver that battery protection actionsare active. These messages are only fornotification that an action is taking place,and not intended to indicate an electricalproblem or that the battery requiresreplacement.

Electrical accessory installation

To ensure proper operation of the BMS,any electrical devices that are added tothe vehicle should not have their groundconnection made directly at the negativebattery post. A connection at the negativebattery post can cause inaccuratemeasurements of the battery conditionand potential incorrect system operation.

Note:Electrical or electronic accessoriesadded to the vehicle by the dealer or theowner may adversely affect batteryperformance and durability, and may alsoaffect the performance of other electricalsystems in the vehicle.

When a battery replacement is required,the battery should only be replaced witha Ford recommended replacement batterywhich matches the electrical requirementsof the vehicle. After battery replacement,or in some cases after charging the batterywith the external charger, the BMS requireseight hours of vehicle sleep time (key offwith doors closed) to relearn the newbattery state of charge. Prior to relearningthe state of charge, the BMS may disableelectrical features (to protect the battery)earlier than normal.

246

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Maintenance

Page 292 of 507

•To reduce the chances of interferencefrom another vehicle, perform thesystem reset procedure at least threefeet (one meter) away from anotherFord Motor Company vehicleundergoing the system reset procedureat the same time.

•Do not wait more than two minutesbetween resetting each tire sensor orthe system will time-out and the entireprocedure will have to be repeated onall four wheels.

•A double horn will sound indicating theneed to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure beforeattempting.

1. Drive the vehicle above 20 mph (32km/h) for at least two minutes, thenpark in a safe location where you caneasily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3. Cycle the ignition to the on positionwith the engine off.

4. Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If the reset modehas been entered successfully, the hornwill sound once, the system indicatorwill flash and a message is shown inthe information display. If this does notoccur, please try again starting at Step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message is shown in theinformation display, seek service fromyour authorized dealer.

5. Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing clockwise order: Left front(driver's side front tire), Right front(passenger's side front tire), Right rear(passenger's side rear tire), Left rear(driver's side rear tire).

6. Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.Note: The single horn chirp confirmsthat the sensor identification code hasbeen learned by the module for thisposition. If a double horn is heard, thereset procedure was unsuccessful, andyou must repeat it.

7. Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8. Remove the valve cap from the valvestem on the right rear tire. Decrease theair pressure until the horn sounds.

9. Remove the valve cap from the valvestem on the left rear tire. Decrease theair pressure until the horn sounds.Training is complete after the hornsounds for the last tire trained (driver'sside rear tire), the system indicatorstops flashing, and a message is shownin the information display.

10.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

289

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 296 of 507

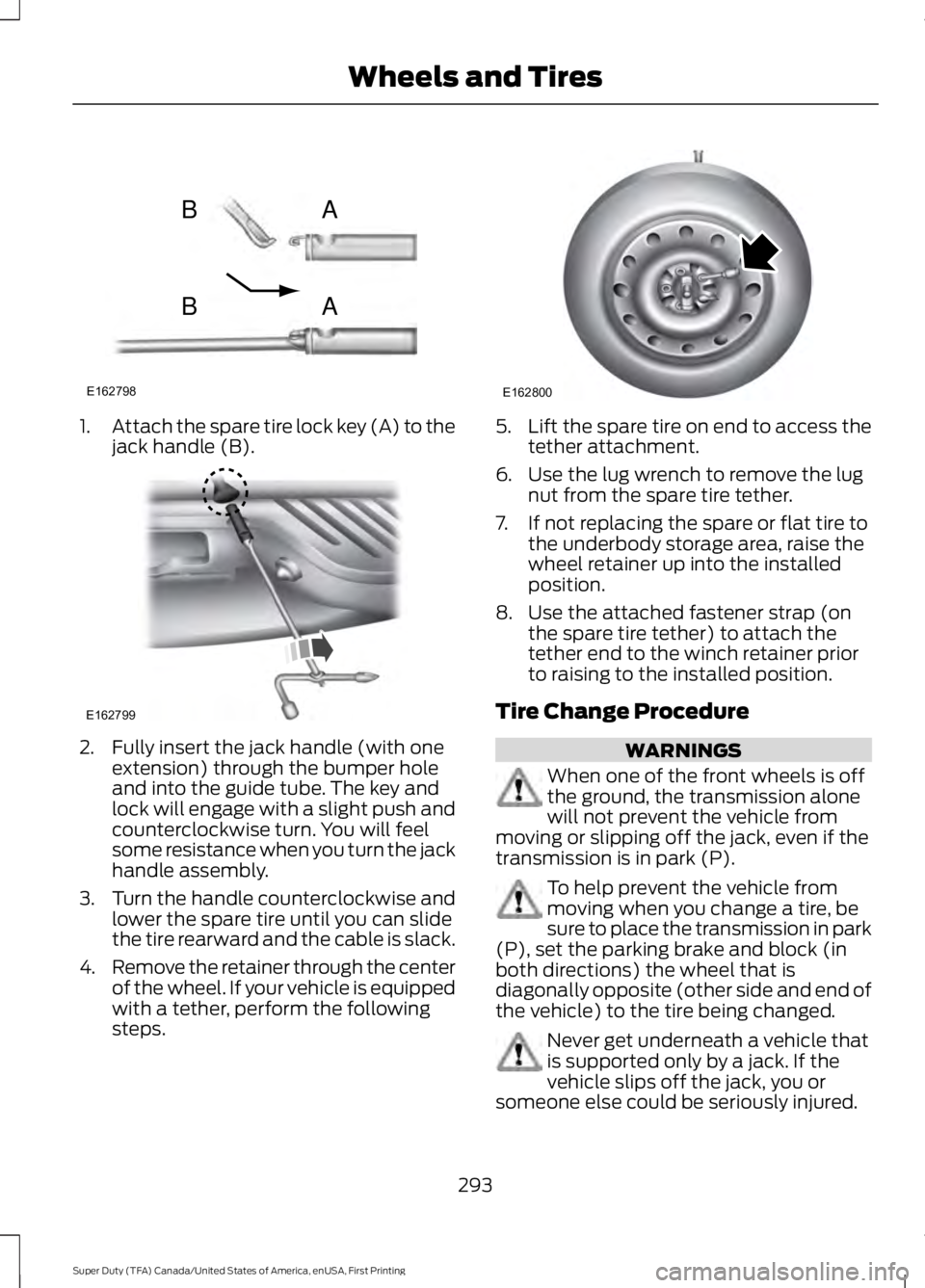

1.Attach the spare tire lock key (A) to thejack handle (B).

2. Fully insert the jack handle (with oneextension) through the bumper holeand into the guide tube. The key andlock will engage with a slight push andcounterclockwise turn. You will feelsome resistance when you turn the jackhandle assembly.

3.Turn the handle counterclockwise andlower the spare tire until you can slidethe tire rearward and the cable is slack.

4.Remove the retainer through the centerof the wheel. If your vehicle is equippedwith a tether, perform the followingsteps.

5.Lift the spare tire on end to access thetether attachment.

6. Use the lug wrench to remove the lugnut from the spare tire tether.

7. If not replacing the spare or flat tire tothe underbody storage area, raise thewheel retainer up into the installedposition.

8. Use the attached fastener strap (onthe spare tire tether) to attach thetether end to the winch retainer priorto raising to the installed position.

Tire Change Procedure

WARNINGS

When one of the front wheels is offthe ground, the transmission alonewill not prevent the vehicle frommoving or slipping off the jack, even if thetransmission is in park (P).

To help prevent the vehicle frommoving when you change a tire, besure to place the transmission in park(P), set the parking brake and block (inboth directions) the wheel that isdiagonally opposite (other side and end ofthe vehicle) to the tire being changed.

Never get underneath a vehicle thatis supported only by a jack. If thevehicle slips off the jack, you orsomeone else could be seriously injured.

293

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and TiresE162798

AB

AB E162799 E162800

Page 297 of 507

WARNINGS

Do not attempt to change a tire onthe side of the vehicle close tomoving traffic. Pull far enough off theroad to avoid the danger of being hit whenoperating the jack or changing the wheel.

Always use the jack provided asoriginal equipment with your vehicle.If using a jack other than the oneprovided as original equipment with yourvehicle, make sure the jack capacity isadequate for the vehicle weight, includingany vehicle cargo or modifications.

Note:Passengers should not remain in thevehicle when the vehicle is being jacked.

Park on a level surface, set the parkingbrake and activate the hazard flashers.

1.Turn the engine off and block the wheelthat is diagonally opposite of the flattire using the wheel chock.Note: Lockthe manual hub on the wheel if thevehicle is a 4x4.

2. Remove the jack, jack handle, lugwrench and spare tire from thestowage locations.

3.Use the tip of the lug wrench to removeany wheel trim.

4. Loosen each wheel lug nut ½ turncounterclockwise, but do not removethem until the wheel is raised off theground.

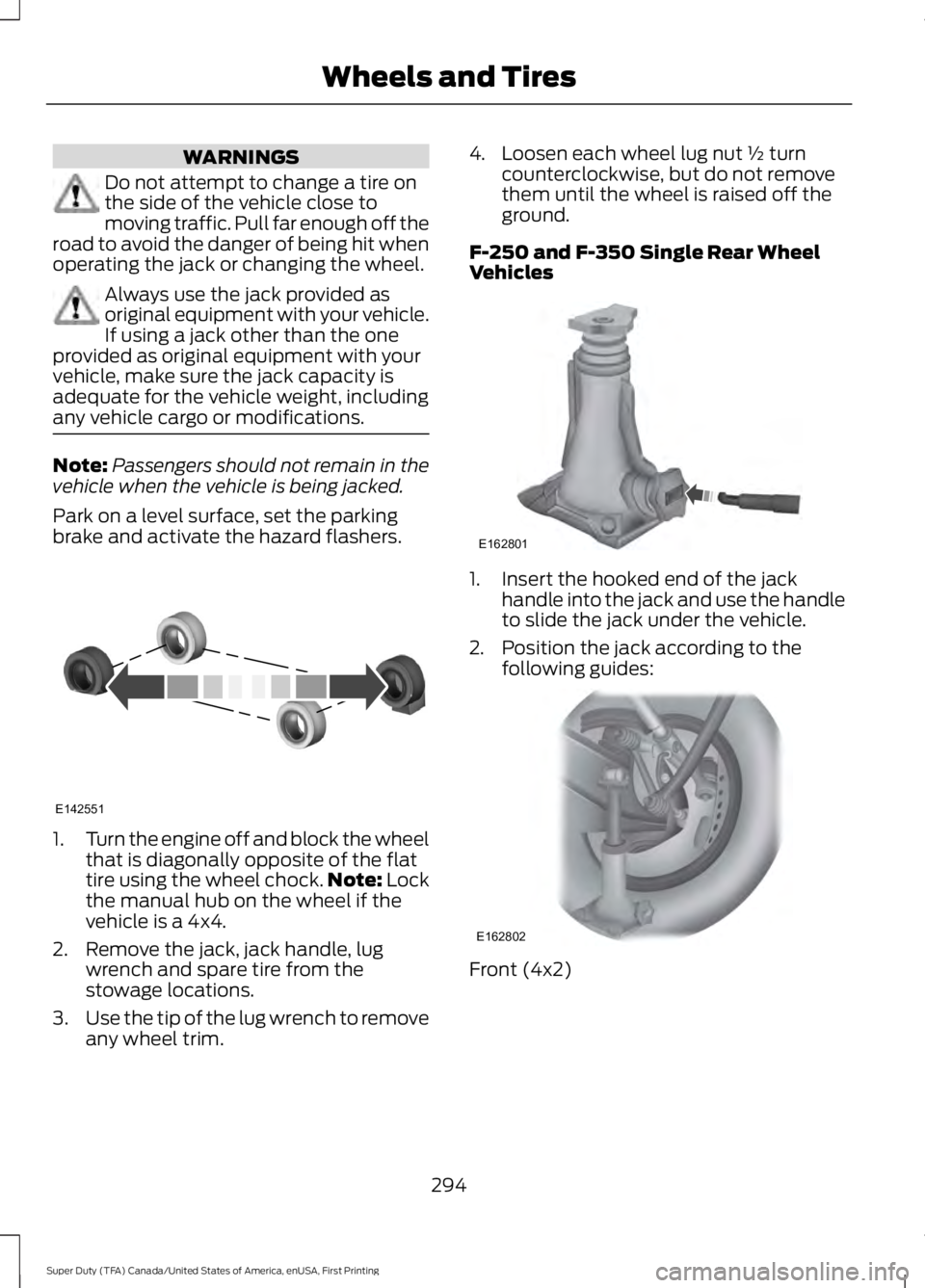

F-250 and F-350 Single Rear WheelVehicles

1. Insert the hooked end of the jackhandle into the jack and use the handleto slide the jack under the vehicle.

2. Position the jack according to thefollowing guides:

Front (4x2)

294

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and TiresE142551 E162801 E162802