service reset FORD F450 SUPER DUTY 2017 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F450 SUPER DUTY, Model: FORD F450 SUPER DUTY 2017Pages: 642, PDF Size: 12.35 MB

Page 7 of 642

Bed Ramps....................................................265

Towing

Towing a Trailer............................................268

Trailer Reversing Aids.................................269

Trailer Sway Control....................................277

Recommended Towing Weights............277

Essential Towing Checks...........................281

Towing the Vehicle on Four Wheels......289

Driving Hints

Breaking-In.....................................................292

Economical Driving.....................................292

Driving Through Water...............................293

Floor Mats.......................................................293

Snowplowing................................................294

Roadside Emergencies

Roadside Assistance..................................297

Hazard Flashers...........................................298

Fuel Shutoff - 6.2L/6.8L...........................298

Fuel Shutoff - 6.7L Diesel.........................298

Jump Starting the Vehicle........................299

Post-Crash Alert System..........................302

Transporting the Vehicle...........................302

Towing Points...............................................303

Customer Assistance

Getting the Services You Need..............305

In California (U.S. Only)............................306

The Better Business Bureau (BBB) AutoLine Program (U.S. Only)......................307

Utilizing the Mediation/ArbitrationProgram (Canada Only)......................308

Getting Assistance Outside the U.S. andCanada.......................................................308

Ordering Additional Owner'sLiterature....................................................309

Reporting Safety Defects (U.S.Only).............................................................310

Reporting Safety Defects (CanadaOnly).............................................................310

Fuses

Fuse Specification Chart............................312

Changing a Fuse..........................................320

Maintenance

General Information....................................322

Opening and Closing the Hood..............322

Under Hood Overview - 6.2L...................323

Under Hood Overview - 6.7L Diesel......324

Under Hood Overview - 6.8L..................326

Engine Oil Dipstick - 6.2L/6.8L...............327

Engine Oil Dipstick - 6.7L Diesel.............327

Engine Oil Check - 6.2L/6.8L...................327

Engine Oil Check - 6.7L Diesel................328

Changing the Engine Oil and OilFilter..............................................................329

Changing the Coalescer FilterElement......................................................330

Oil Change Indicator Reset.......................331

Engine Coolant Check - 6.2L/6.8L........332

Engine Coolant Check - 6.7L Diesel......336

Automatic Transmission FluidCheck...........................................................340

Transfer Case Fluid Check........................343

Brake Fluid Check........................................343

Power Steering Fluid Check....................344

Washer Fluid Check....................................344

Draining the Fuel Filter Water Trap - 6.7LDiesel...........................................................345

Fuel Filter - 6.2L/6.8L................................346

Changing the 12V Battery.........................346

Checking the Wiper Blades.....................348

Changing the Wiper Blades.....................348

Adjusting the Headlamps........................349

Changing a Bulb..........................................350

Bulb Specification Chart...........................353

Changing the Engine Air Filter - 6.2L/6.8L...............................................................356

4

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Table of Contents

Page 12 of 642

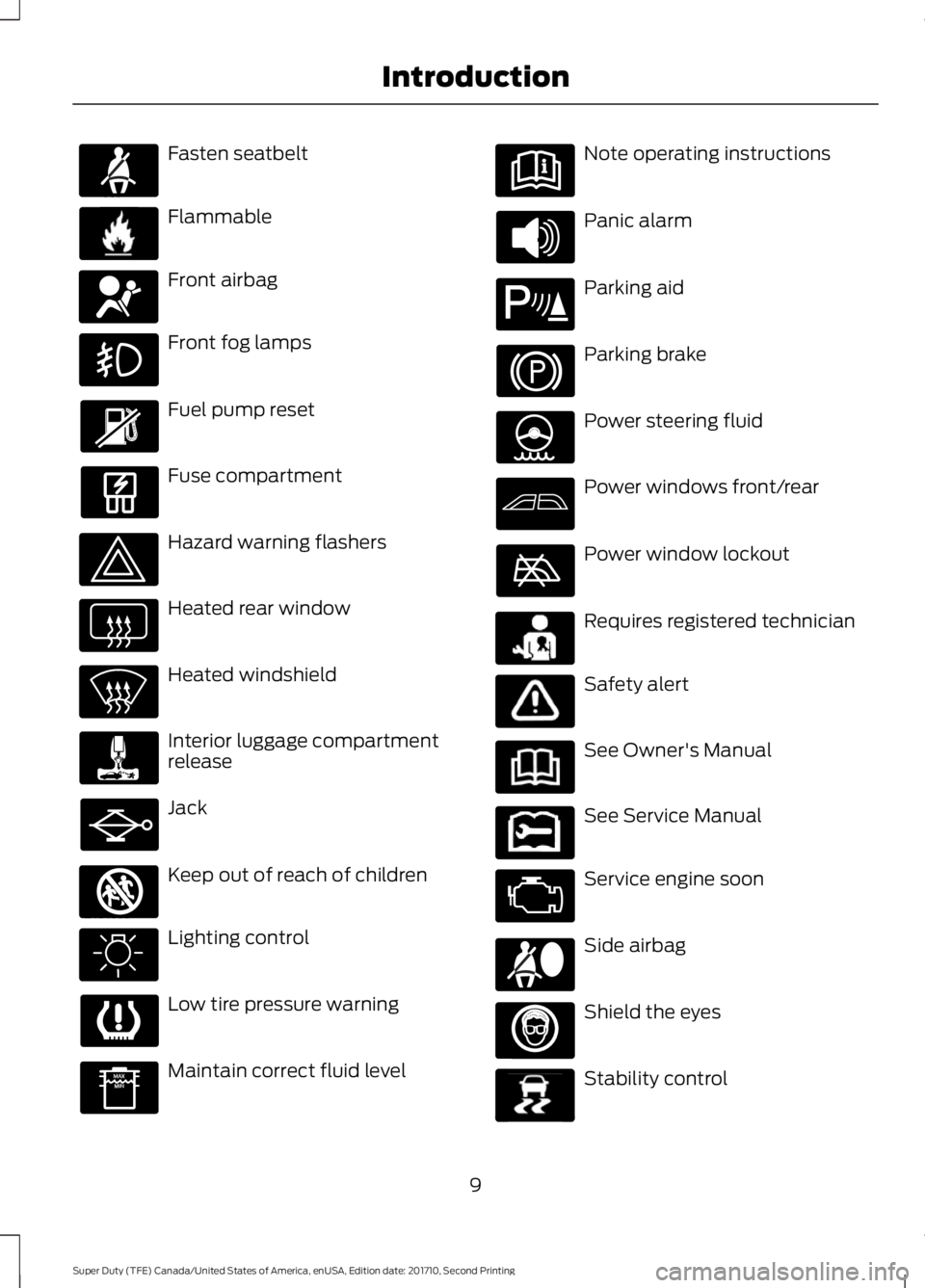

Fasten seatbelt

Flammable

Front airbag

Front fog lamps

Fuel pump reset

Fuse compartment

Hazard warning flashers

Heated rear window

Heated windshield

Interior luggage compartmentrelease

Jack

Keep out of reach of children

Lighting control

Low tire pressure warning

Maintain correct fluid level

Note operating instructions

Panic alarm

Parking aid

Parking brake

Power steering fluid

Power windows front/rear

Power window lockout

Requires registered technician

Safety alert

See Owner's Manual

See Service Manual

Service engine soon

Side airbag

Shield the eyes

Stability control

9

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

IntroductionE71880 E231160 E67017 E161353 E139213 E231159 E231158 E167012 E138639

Page 195 of 642

Typical Diesel Exhaust Fluid UsageWhen Using the Power Take Off (PTO)

Continuous PTO use—Minimal PTO use

0–7,800 mi (0–12,550 km)

Contaminated Diesel ExhaustFluid or Inoperative SelectiveCatalytic Reduction System

Selective catalytic reduction systems aresensitive to contamination of the dieselexhaust fluid. Maintaining the purity of thefluid is important to avoid systemmalfunctions. If you remove or drain thediesel exhaust fluid tank, do not use thesame fluid to refill the tank. The systemhas a sensor to monitor fluid quality.

A warning lamp illuminates anda message appears in theinformation display if the systembecomes contaminated or inoperative.

Continued driving without replacing dieselexhaust fluid or having the selectivecatalytic reduction system repaired resultsin the following actions as required by theCalifornia Air Resources Board (CARB) andU.S. Environmental Protection Agency(EPA):

•Within a preset distance to empty,speed is limited upon vehicle restart.Prior to this occurring a messageappears in the information display.

•Further vehicle operation withoutreplacing contaminated diesel exhaustfluid causes the engine to enter anidle-only condition. This only occursupon vehicle refueling, vehicle idling inpark for 1 hour, or engine shutdown for10 minutes or more and is indicated bya message in the information displayindicating required actions to resumenormal operation.

Note:For vehicle speed limiting or idle-onlycondition, normal vehicle operation resumeswhen you repair the contaminated system.To service a contaminated or inoperativesystem, see an authorized dealer.

REFUELING - GASOLINE

WARNINGS

Fuel vapor burns violently and a fuelfire can cause severe injuries.

Read and follow all the instructionson the pump island.

Turn off your engine when you arerefueling.

Do not smoke if you are near fuel orrefueling your vehicle.

Keep sparks, flames and smokingmaterials away from fuel.

Stay outside your vehicle and do notleave the fuel pump unattendedwhen refueling your vehicle. This isagainst the law in some places.

Keep children away from the fuelpump; never let children pump fuel.

Do not use personal electronicdevices while refueling.

Wait at least 10 seconds beforeremoving the fuel pump nozzle toallow any residual fuel to drain intothe fuel tank.

Stop refueling after the fuel pumpnozzle automatically shuts off for thesecond time. Failure to follow thiswill fill the expansion space in the fuel tankand could lead to fuel overflowing.

Do not remove the fuel pump nozzlefrom its fully inserted position whenrefueling.

192

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Fuel and RefuelingE163176

Page 333 of 642

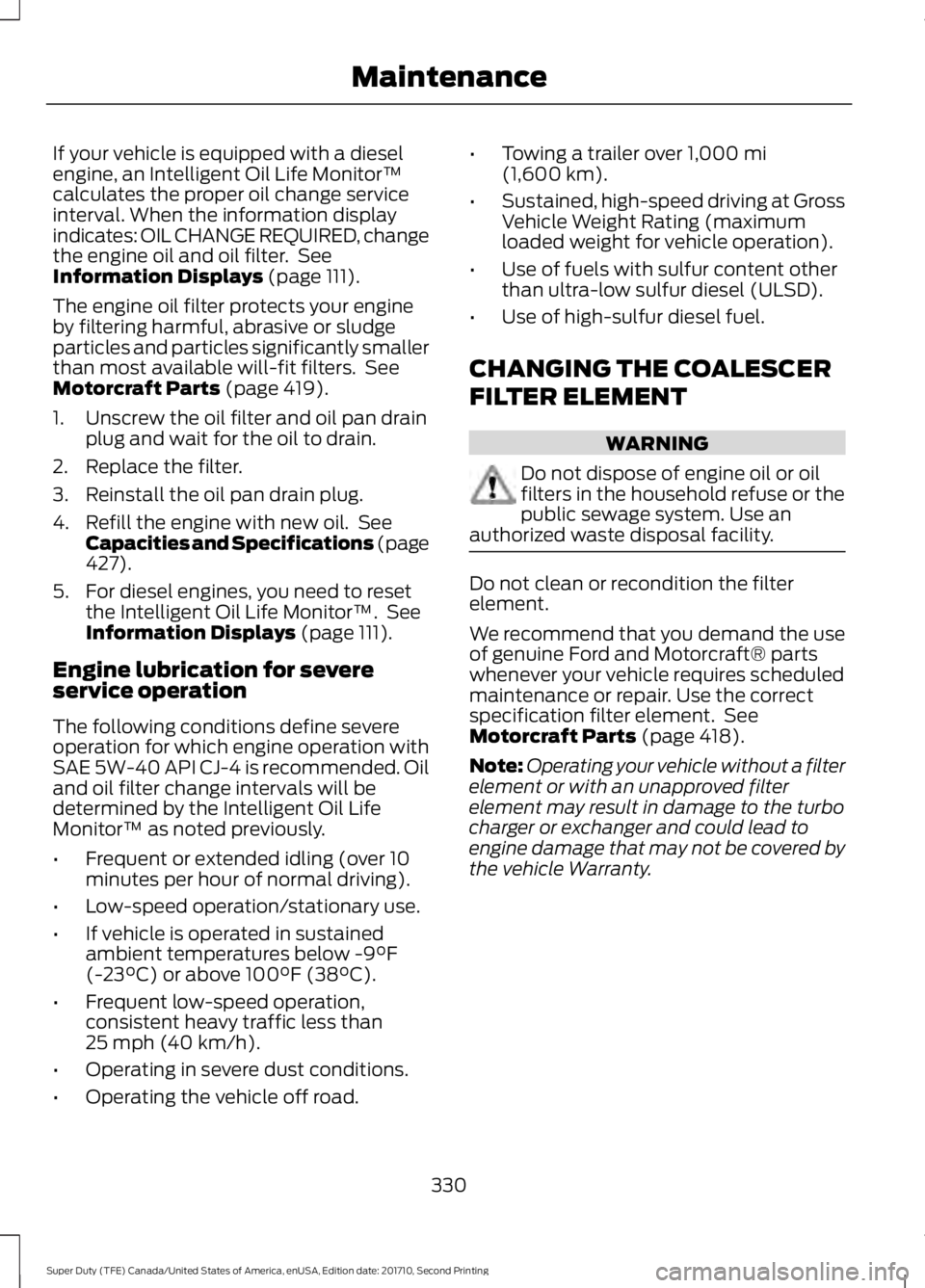

If your vehicle is equipped with a dieselengine, an Intelligent Oil Life Monitor™calculates the proper oil change serviceinterval. When the information displayindicates: OIL CHANGE REQUIRED, changethe engine oil and oil filter. SeeInformation Displays (page 111).

The engine oil filter protects your engineby filtering harmful, abrasive or sludgeparticles and particles significantly smallerthan most available will-fit filters. SeeMotorcraft Parts (page 419).

1. Unscrew the oil filter and oil pan drainplug and wait for the oil to drain.

2. Replace the filter.

3. Reinstall the oil pan drain plug.

4. Refill the engine with new oil. SeeCapacities and Specifications (page427).

5. For diesel engines, you need to resetthe Intelligent Oil Life Monitor™. SeeInformation Displays (page 111).

Engine lubrication for severeservice operation

The following conditions define severeoperation for which engine operation withSAE 5W-40 API CJ-4 is recommended. Oiland oil filter change intervals will bedetermined by the Intelligent Oil LifeMonitor™ as noted previously.

•Frequent or extended idling (over 10minutes per hour of normal driving).

•Low-speed operation/stationary use.

•If vehicle is operated in sustainedambient temperatures below -9°F(-23°C) or above 100°F (38°C).

•Frequent low-speed operation,consistent heavy traffic less than25 mph (40 km/h).

•Operating in severe dust conditions.

•Operating the vehicle off road.

•Towing a trailer over 1,000 mi(1,600 km).

•Sustained, high-speed driving at GrossVehicle Weight Rating (maximumloaded weight for vehicle operation).

•Use of fuels with sulfur content otherthan ultra-low sulfur diesel (ULSD).

•Use of high-sulfur diesel fuel.

CHANGING THE COALESCER

FILTER ELEMENT

WARNING

Do not dispose of engine oil or oilfilters in the household refuse or thepublic sewage system. Use anauthorized waste disposal facility.

Do not clean or recondition the filterelement.

We recommend that you demand the useof genuine Ford and Motorcraft® partswhenever your vehicle requires scheduledmaintenance or repair. Use the correctspecification filter element. SeeMotorcraft Parts (page 418).

Note:Operating your vehicle without a filterelement or with an unapproved filterelement may result in damage to the turbocharger or exchanger and could lead toengine damage that may not be covered bythe vehicle Warranty.

330

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Maintenance

Page 334 of 642

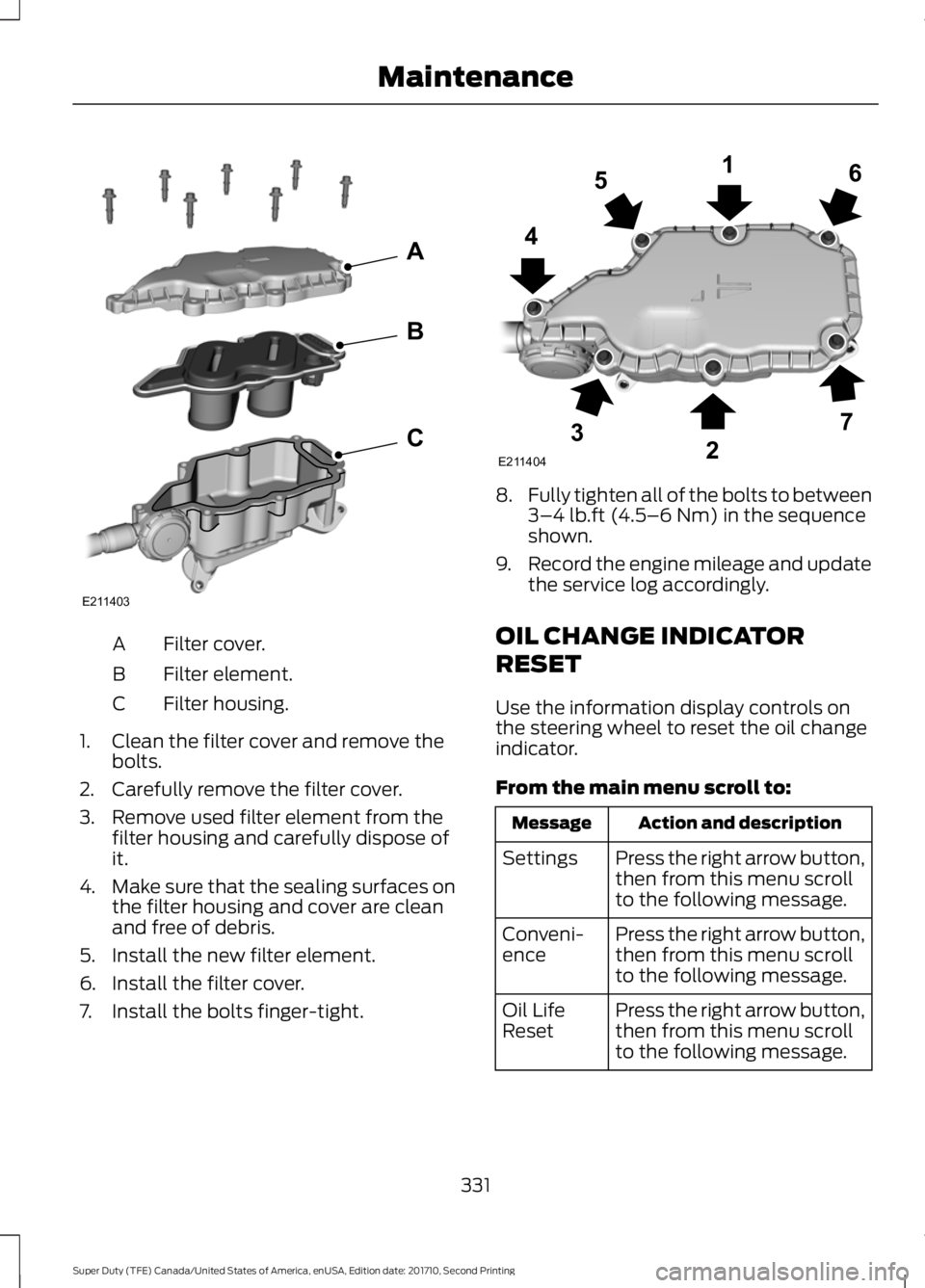

Filter cover.A

Filter element.B

Filter housing.C

1. Clean the filter cover and remove thebolts.

2. Carefully remove the filter cover.

3. Remove used filter element from thefilter housing and carefully dispose ofit.

4.Make sure that the sealing surfaces onthe filter housing and cover are cleanand free of debris.

5. Install the new filter element.

6. Install the filter cover.

7. Install the bolts finger-tight.

8.Fully tighten all of the bolts to between3–4 lb.ft (4.5–6 Nm) in the sequenceshown.

9.Record the engine mileage and updatethe service log accordingly.

OIL CHANGE INDICATOR

RESET

Use the information display controls onthe steering wheel to reset the oil changeindicator.

From the main menu scroll to:

Action and descriptionMessage

Press the right arrow button,then from this menu scrollto the following message.

Settings

Press the right arrow button,then from this menu scrollto the following message.

Conveni-ence

Press the right arrow button,then from this menu scrollto the following message.

Oil LifeReset

331

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

MaintenanceE211403

A

B

C E211404

165

4

32

7

Page 362 of 642

Operating your vehicle in heavy snowfallor extreme rain conditions may allowexcessive amounts of snow or water intothe air intake system. This could restrict airflow and cause the engine to lose poweror shut down.

After installing a new air filter element, youmust reset the gauge by pressing the resetbutton.

After operating your vehicle during in heavysnowfall or extreme rain, do the following:

•Snow: At the earliest opportunity, openthe hood and clear any snow and icefrom the air filter housing inlet andreset the air filter restriction gauge.

•Extreme rain: The air filter elementdries out after approximately 15–30minutes of driving at highway speeds.At the earliest opportunity, open thehood and reset the air filter restrictiongauge.

Note:Do not remove the foam filter.

CHANGING THE ENGINE-

MOUNTED AND DIESEL FUEL

CONDITIONER MODULE FUEL

FILTERS - 6.7L DIESEL

WARNING

Do not dispose of fuel in thehousehold refuse or the publicsewage system. Use an authorizedwaste disposal facility.

Your vehicle has two fuel filters. The firstfilter mounts on top of the engine on theleft-hand side. The second filter is insidethe diesel fuel conditioner module. Themodule is mounted between the outboardside of the fuel tank and the frame rail.

Note:The module is at the front of the fueltank or at the front of the aft-axle fuel tankon some models.

Regular fuel filter changes are animportant part of engine maintenance;failing to keep with the scheduledmaintenance could lead to engineperformance issues and fuel injectionsystem damage. See ScheduledMaintenance (page 573).

Use only recommended service partsconforming to specifications. SeeMotorcraft Parts (page 418).

Note:Using fuel that has high levels ofimpurities may require more frequent filterreplacements than the service intervalspecifies.

Diesel Fuel Conditioner ModuleFilter

Filter Location

Use the tables below to find the locationof your filter.

359

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Maintenance

Page 402 of 642

•To reduce the chances of interferencefrom another vehicle, perform thesystem reset procedure at least threefeet (one meter) away from anotherFord Motor Company vehicleundergoing the system reset procedureat the same time.

•Do not wait more than two minutesbetween resetting each tire sensor orthe system will time-out and the entireprocedure will have to be repeated onall four wheels.

•A double horn will sound indicating theneed to repeat the procedure.

Performing the System Reset Procedure(Single Rear Wheel)

Read the entire procedure beforeattempting.

1. Drive the vehicle above 20 mph(32 km/h) for at least two minutes,then park in a safe location where youcan easily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3. Cycle the ignition to the on positionwith the engine off.

4. Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If the reset modehas been entered successfully, the hornwill sound once, the system indicatorwill flash and a message is shown inthe information display. If this does notoccur, please try again starting at Step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message is shown in theinformation display, seek service fromyour authorized dealer.

5. Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing clockwise order: Left front(driver's side front tire), Right front(passenger's side front tire), Right rear(passenger's side rear tire), Left rear(driver's side rear tire).

6. Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.

Note:The single horn chirp confirms thatthe sensor identification code has beenlearned by the module for this position. If adouble horn is heard, the reset procedurewas unsuccessful, and you must repeat it.

7. Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8. Remove the valve cap from the valvestem on the right rear tire. Decrease theair pressure until the horn sounds.

9. Remove the valve cap from the valvestem on the left rear tire. Decrease theair pressure until the horn sounds.Training is complete after the hornsounds for the last tire trained (driver'sside rear tire), the system indicatorstops flashing, and a message is shownin the information display.

10.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

399

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and Tires

Page 403 of 642

11.Set all four tires to the recommendedair pressure as indicated on theSafety Compliance CertificationLabel (affixed to either the door hingepillar, door-latch post, or the dooredge that meets the door-latch post,next to the driver's seating position)or Tire Label located on the B-Pillaror the edge of the driver's door.

Performing the System Reset Procedure(Dual Rear Wheel)

For further information seeUnderstanding Your Tire PressureMonitoring System and refer to DualRear Wheel, earlier in this section.

Read the entire procedure beforeattempting.

1. Drive the vehicle above 20 mph(32 km/h) for at least two minutes,then park in a safe location where youcan easily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3. Cycle the ignition to the on positionwith the engine off.

4. Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If the reset modehas been entered successfully, the hornwill sound once, the system indicatorwill flash and a message is shown inthe information display. If this does notoccur, please try again starting at Step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message is shown in theinformation display, seek service fromyour authorized dealer.

5. Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing order: Left front (driver's sidefront tire), Right front (passenger's sidefront tire), Right outer rear (passenger'sside rear outer tire), Right inner rear(passenger's side rear inner tire), Leftouter rear (driver's side rear outer tire),Left inner rear (driver's side rear innertire).

6. Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.

Note:The single horn chirp confirms thatthe sensor identification code has beenlearned by the module for this position. If adouble horn is heard, the reset procedurewas unsuccessful, and you must repeat it.

7. Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8. Remove the valve cap from the valvestem on the right outer rear tire.Decrease the air pressure until the hornsounds.

9. Remove the valve cap from the valvestem on the right inner rear tire.Decrease the air pressure until the hornsounds.

10.Remove the valve cap from the valvestem on the left outer rear tire.Decrease the air pressure until thehorn sounds.

11.Remove the valve cap from the valvestem on the left inner rear tire.Decrease the air pressure until thehorn sounds. Training is completeafter the horn sounds for the last tiretrained, the system indicator stopsflashing, and a message is shown inthe information display.

400

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and Tires

Page 404 of 642

12.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

13.Set all four tires to the recommendedair pressure as indicated on theSafety Compliance CertificationLabel (affixed to either the door hingepillar, door-latch post, or the dooredge that meets the door-latch post,next to the driver's seating position)or Tire Label located on the B-Pillaror the edge of the driver's door.

Trailer Tire Pressure MonitoringSystem (If Equipped)

Note:Additional equipment may berequired for your vehicle to support trailertire pressure monitoring. See your authorizeddealer for more information.

Note:The trailer tire pressure monitoringsystem is not a substitute for proper tiremaintenance. It is your responsibility tomaintain correct tire pressures at all times.

Note:If a trailer tire is repaired, replaced orbroken down for service, the screw and valveon the trailer tire pressure sensor should bereplaced. See your authorized dealer fordetails.

The trailer tire pressure monitoring systemis an added safety feature that allows youto view your trailer tire pressures throughthe information display. See GeneralInformation (page 111). Tire pressuresensors are mounted into each tire on yourtrailer. The sensors send a message to yourvehicle indicating the current trailer tirepressure.

If the trailer tire pressure monitoringsystem detects that a tire is low, a warningmessage appears in the informationdisplay. The trailer tire pressure statusscreen in the information display highlightsthe tire with a low pressure.

The main function of the trailer tirepressure monitoring system is to warn youwhen your trailer tires need air. It can alsowarn you in the event the system is nolonger capable of functioning as intended.See Information Messages (page 128).

When a Temporary Spare or New Tireis Installed

If you have replaced a trailer tire with a newor spare tire, a warning message appearsand pressure readings are no longerdisplayed for that tire.

To restore the full function of the trailertire pressure monitoring system:

•Have the damaged wheel and tireassembly repaired and remounted toyour trailer.

•Install the trailer tire pressuremonitoring sensor into the new wheeland tire assembly.

•Perform the trailer tire pressuremonitoring system reset procedure.

Trailer Tire Pressure MonitoringSystem Reset Procedure

Note:You need to perform the tire pressuremonitoring system reset procedure aftereach tire rotation, or when a new trailer tirepressure sensor is installed into a trailer tire.

401

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and TiresE235807

Page 405 of 642

The trailer tire pressure monitoring systemcan be reset through the menu in theinformation display. See GeneralInformation (page 111). Performing thetrailer setup process also resets the trailertire pressure monitoring system.

CHANGING A ROAD WHEEL

WARNINGS

The use of tire sealant may damageyour tire pressure monitoring systemand should only be used in roadsideemergencies. If you must use a sealant, theFord Tire Mobility Kit sealant should beused. The tire pressure monitoring systemsensor and valve stem on the wheel mustbe replaced by an authorized dealer afteruse of the sealant.

If the tire pressure monitor sensorbecomes damaged, it will no longerfunction. See Tire PressureMonitoring System (page 394).

Note:If your vehicle is equipped with thetire pressure monitoring system, theindicator light will illuminate when the sparetire is in use. To restore the full function ofthe monitoring system, all road wheelsequipped with tire pressure monitoringsensors must be mounted on the vehicle.

If you get a flat tire while driving, do notapply the brake heavily. Instead, graduallydecrease your speed. Hold the steeringwheel firmly and slowly move to a safeplace on the side of the road.

If your vehicle is equipped with the tirepressure monitoring system, have a flatserviced by an authorized dealer in orderto prevent damage to the system sensors.See Tire Pressure Monitoring System(page 394). Replace the spare tire with aroad tire as soon as possible. Duringrepairing or replacing of the flat tire, havethe authorized dealer inspect the systemsensor for damage.

Dissimilar Spare Wheel and TireAssembly Information

WARNING

Failure to follow these guidelinescould result in an increased risk ofloss of vehicle control, injury or death.

If you have a dissimilar spare wheel andtire, then it is intended for temporary useonly. This means that if you need to use it,you should replace it as soon as possiblewith a road wheel and tire assembly thatis the same size and type as the road tiresand wheels that were originally providedby Ford. If the dissimilar spare tire or wheelis damaged, it should be replaced ratherthan repaired.

A dissimilar spare wheel and tire assemblyis defined as a spare wheel and tireassembly that is different in brand, size orappearance from the road tires and wheelsand can be one of three types:

1.T-type mini-spare: This spare tirebegins with the letter T for tire size andmay have Temporary Use Only molded inthe sidewall.

2.Full-size dissimilar spare with labelon wheel: This spare tire has a label onthe wheel that states: THIS WHEEL ANDTIRE ASSEMBLY FOR TEMPORARY USEONLY

When driving with one of the dissimilarspare tires listed above, do not:

402

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and Tires