clock FORD F550 2012 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2012, Model line: F550, Model: FORD F550 2012Pages: 448, PDF Size: 6.01 MB

Page 242 of 448

3. Cycle the ignition to the on

position with the engine off.

4. Turn the hazard flashers on then

off three times. This must be

accomplished within 10 seconds.

If the reset mode has been entered successfully, the horn will sound

once, the TPMS indicator will flash and the message center (if

equipped) will display TRAIN LEFT FRONT TIRE . If this does not

occur, please try again starting at Step 2.

If after repeated attempts to enter the reset mode, the horn does not

sound, the TPMS indicator does not flash and the message center (if

equipped) does not display TRAIN LEFT FRONT TIRE , seek service

from your authorized dealer.

5. Train the TPMS sensors in the tires using the following TPMS reset

sequence starting with the left front tire in the following clockwise

order:

• Left front (Driver’s side front tire)

• Right front (Passenger’s side front tire)

• Right rear (Passenger’s side rear tire)

• Left rear (Driver’s side rear tire)

6. Remove the valve cap from the valve stem on the left front tire;

decrease the air pressure until the horn sounds.

Note: The single horn chirp confirms that the sensor identification code

has been learned by the module for this position. If a double horn is

heard, the reset procedure was unsuccessful, and must be repeated.Tires, Wheels and Loading

242

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 301 of 448

FOUR-WHEEL DRIVE (4WD) OPERATION (IF EQUIPPED)

WARNING: For important information regarding safe operation

of this type of vehicle, see Preparing to drive your vehicle in

this chapter.

When four–wheel drive (4WD) is engaged, power is supplied to all four

wheels through a transfer case. 4WD can be selected when additional

driving power is desired.

4WD operation is not recommended on dry pavement. Doing so could

result in difficult disengagement of the transfer case, increased tire wear

and decreased fuel economy.

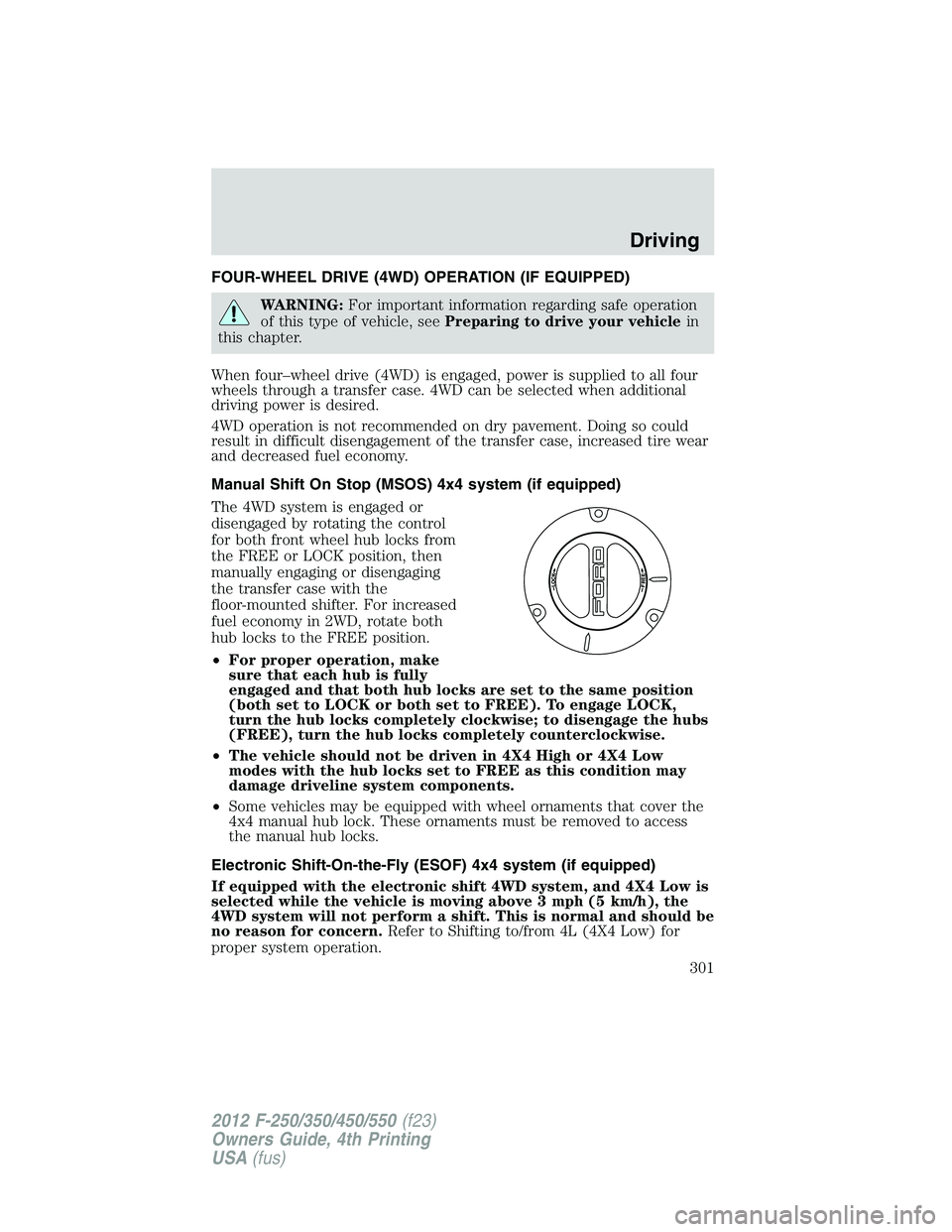

Manual Shift On Stop (MSOS) 4x4 system (if equipped)

The 4WD system is engaged or

disengaged by rotating the control

for both front wheel hub locks from

the FREE or LOCK position, then

manually engaging or disengaging

the transfer case with the

floor-mounted shifter. For increased

fuel economy in 2WD, rotate both

hub locks to the FREE position.

• For proper operation, make

sure that each hub is fully

engaged and that both hub locks are set to the same position

(both set to LOCK or both set to FREE). To engage LOCK,

turn the hub locks completely clockwise; to disengage the hubs

(FREE), turn the hub locks completely counterclockwise.

• The vehicle should not be driven in 4X4 High or 4X4 Low

modes with the hub locks set to FREE as this condition may

damage driveline system components.

• Some vehicles may be equipped with wheel ornaments that cover the

4x4 manual hub lock. These ornaments must be removed to access

the manual hub locks.

Electronic Shift-On-the-Fly (ESOF) 4x4 system (if equipped)

If equipped with the electronic shift 4WD system, and 4X4 Low is

selected while the vehicle is moving above 3 mph (5 km/h), the

4WD system will not perform a shift. This is normal and should be

no reason for concern. Refer to Shifting to/from 4L (4X4 Low) for

proper system operation. Driving

301

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 302 of 448

The ESOF 4WD system:

• provides 4x4 High engagement and disengagement while the vehicle is

moving.

• is operated by a rotary control located on the instrument panel that

allows you select 4x2, 4x4 High or 4x4 Low operation.

• uses auto-manual hub locks that can be engaged and disengaged

automatically based on the 4x4 mode selected.

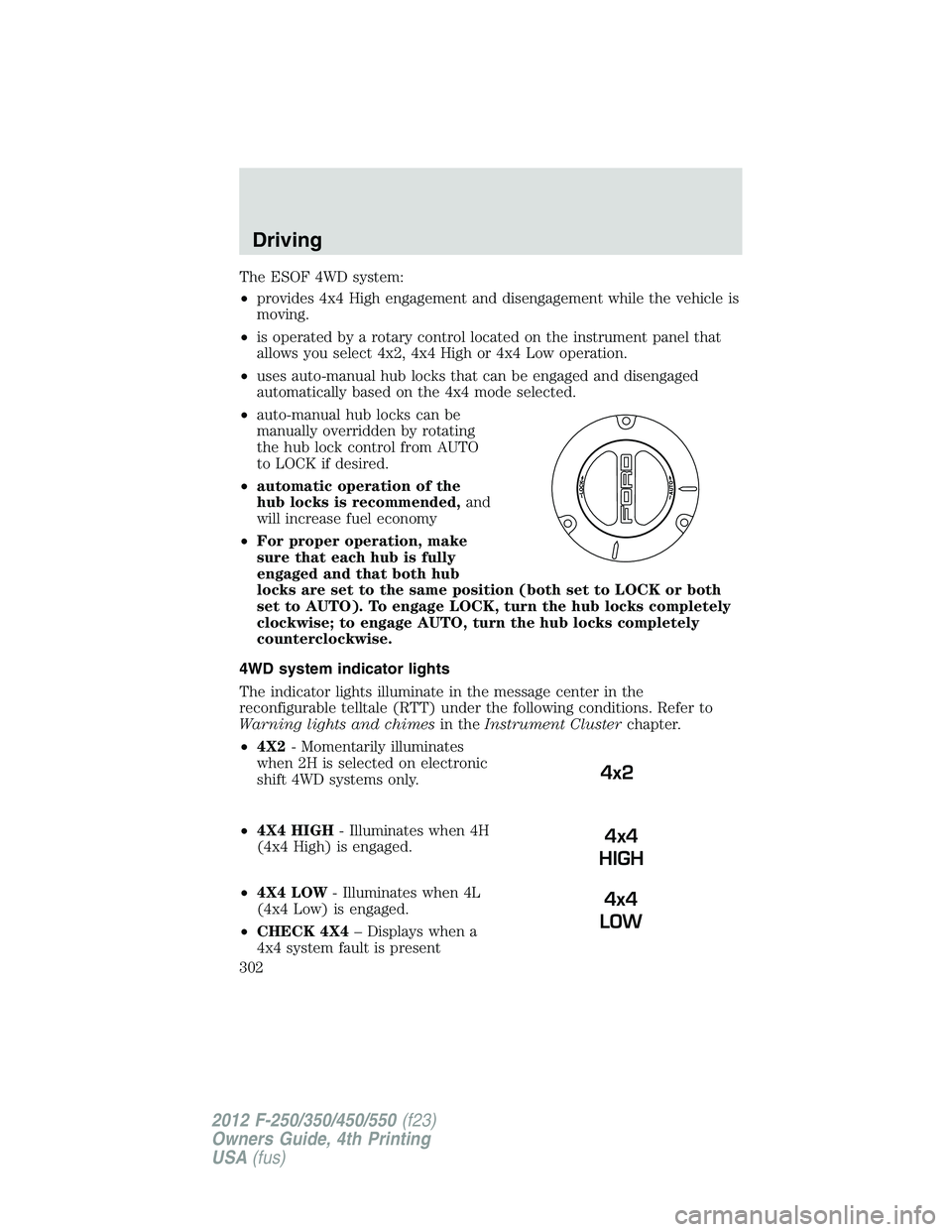

• auto-manual hub locks can be

manually overridden by rotating

the hub lock control from AUTO

to LOCK if desired.

• automatic operation of the

hub locks is recommended, and

will increase fuel economy

• For proper operation, make

sure that each hub is fully

engaged and that both hub

locks are set to the same position (both set to LOCK or both

set to AUTO). To engage LOCK, turn the hub locks completely

clockwise; to engage AUTO, turn the hub locks completely

counterclockwise.

4WD system indicator lights

The indicator lights illuminate in the message center in the

reconfigurable telltale (RTT) under the following conditions. Refer to

Warning lights and chimes in the Instrument Cluster chapter.

• 4X2 - Momentarily illuminates

when 2H is selected on electronic

shift 4WD systems only.

• 4X4 HIGH - Illuminates when 4H

(4x4 High) is engaged.

• 4X4 LOW - Illuminates when 4L

(4x4 Low) is engaged.

• CHECK 4X4 – Displays when a

4x4 system fault is present 4x2

4x4

HIGH

4x4

LOWDriving

302

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 336 of 448

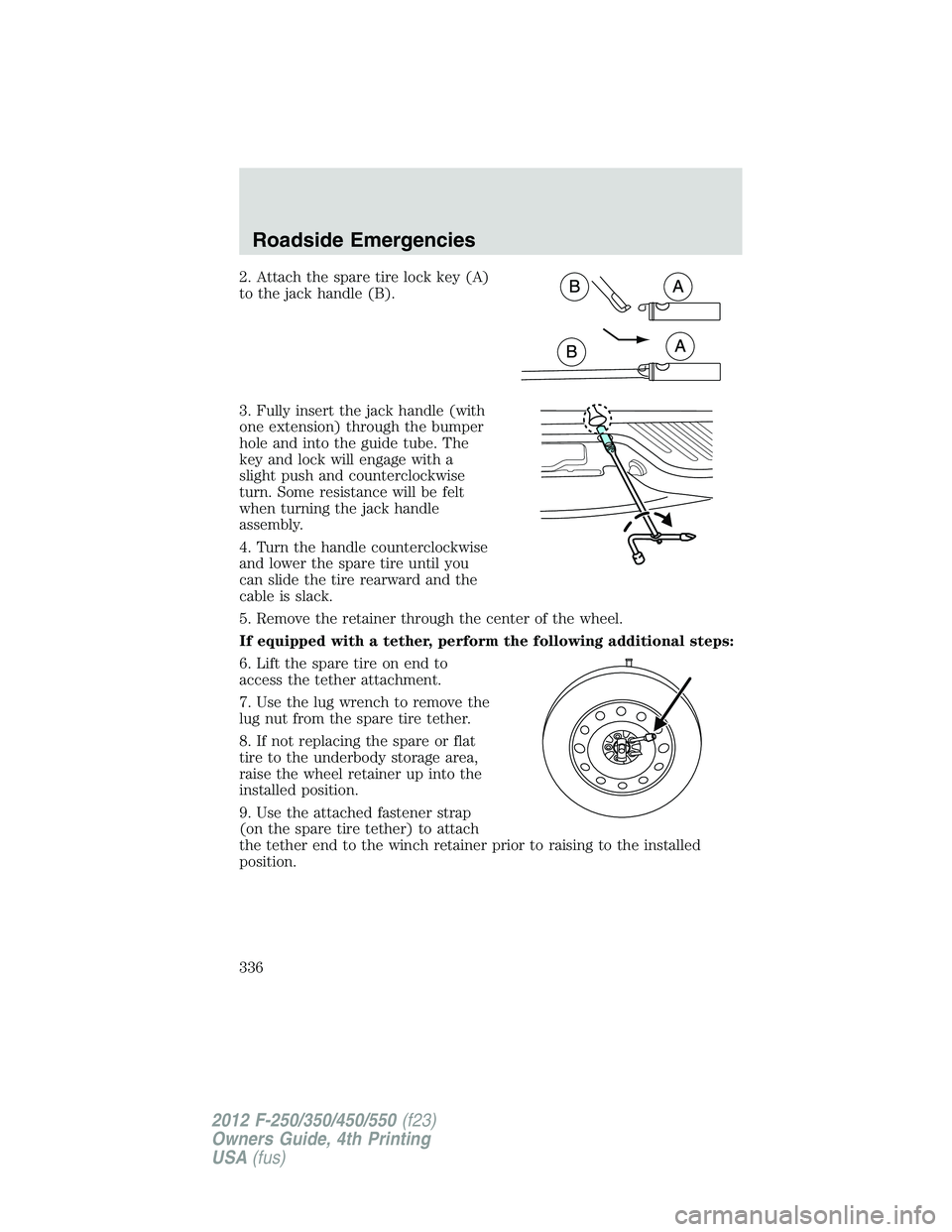

2. Attach the spare tire lock key (A)

to the jack handle (B).

3. Fully insert the jack handle (with

one extension) through the bumper

hole and into the guide tube. The

key and lock will engage with a

slight push and counterclockwise

turn. Some resistance will be felt

when turning the jack handle

assembly.

4. Turn the handle counterclockwise

and lower the spare tire until you

can slide the tire rearward and the

cable is slack.

5. Remove the retainer through the center of the wheel.

If equipped with a tether, perform the following additional steps:

6. Lift the spare tire on end to

access the tether attachment.

7. Use the lug wrench to remove the

lug nut from the spare tire tether.

8. If not replacing the spare or flat

tire to the underbody storage area,

raise the wheel retainer up into the

installed position.

9. Use the attached fastener strap

(on the spare tire tether) to attach

the tether end to the winch retainer prior to raising to the installed

position.Roadside Emergencies

336

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 337 of 448

Tire change procedure

WARNING: When one of the rear wheels is off the ground, the

transmission alone will not prevent the vehicle from moving or

slipping off the jack, even if the transmission is in P (Park).

WARNING: To prevent the vehicle from moving when you

change a tire, be sure the parking brake is set, then block (in

both directions) the wheel that is diagonally opposite (other side and

end of the vehicle) to the tire being changed.

WARNING: If the vehicle slips off the jack, you or someone else

could be seriously injured.

WARNING: Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the road to

avoid the danger of being hit when operating the jack or changing the

wheel.

Note: Passengers should not remain in the vehicle when the vehicle is

being jacked.

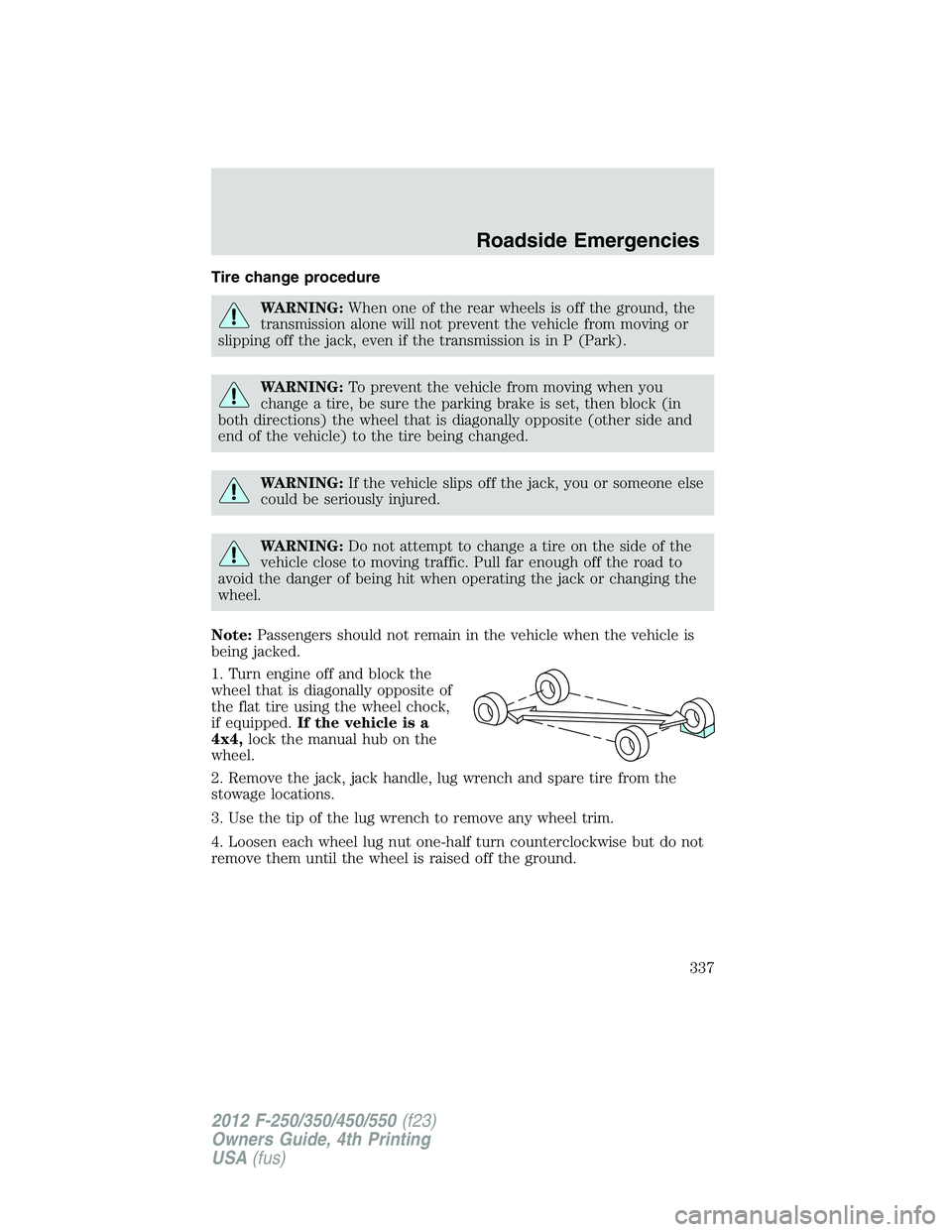

1. Turn engine off and block the

wheel that is diagonally opposite of

the flat tire using the wheel chock,

if equipped. If the vehicle is a

4x4, lock the manual hub on the

wheel.

2. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

3. Use the tip of the lug wrench to remove any wheel trim.

4. Loosen each wheel lug nut one-half turn counterclockwise but do not

remove them until the wheel is raised off the ground. Roadside Emergencies

337

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 340 of 448

7. Turn the jack handle clockwise

until the wheel is completely off the

ground and high enough to install

the spare tire.

8. Remove the lug nuts with the lug

wrench.

9. Replace the flat tire with the

spare tire, making sure the valve

stem is facing outward for all front wheels and single rear wheel vehicles.

If replacing an inboard rear tire on dual rear wheel vehicles, the valve

stem must be facing outward. If replacing the outboard wheel, the valve

stem must be facing inward. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

10. Lower the wheel by turning the jack handle counterclockwise.

Go to Step 19.

The following steps apply to F–350 Dual Rear Wheel (DRW) and

F–450/F–550 vehicles only:

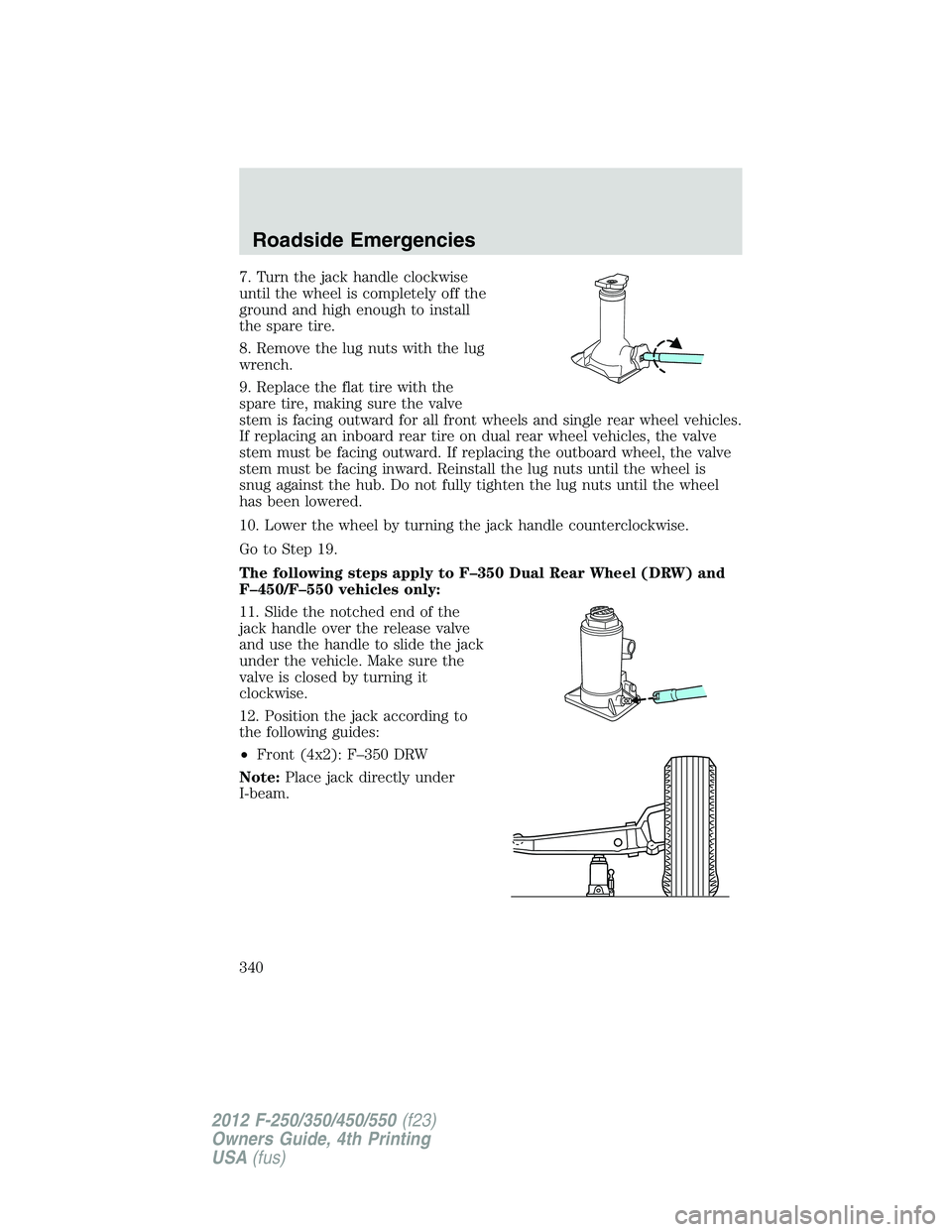

11. Slide the notched end of the

jack handle over the release valve

and use the handle to slide the jack

under the vehicle. Make sure the

valve is closed by turning it

clockwise.

12. Position the jack according to

the following guides:

• Front (4x2): F–350 DRW

Note: Place jack directly under

I-beam.Roadside Emergencies

340

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 342 of 448

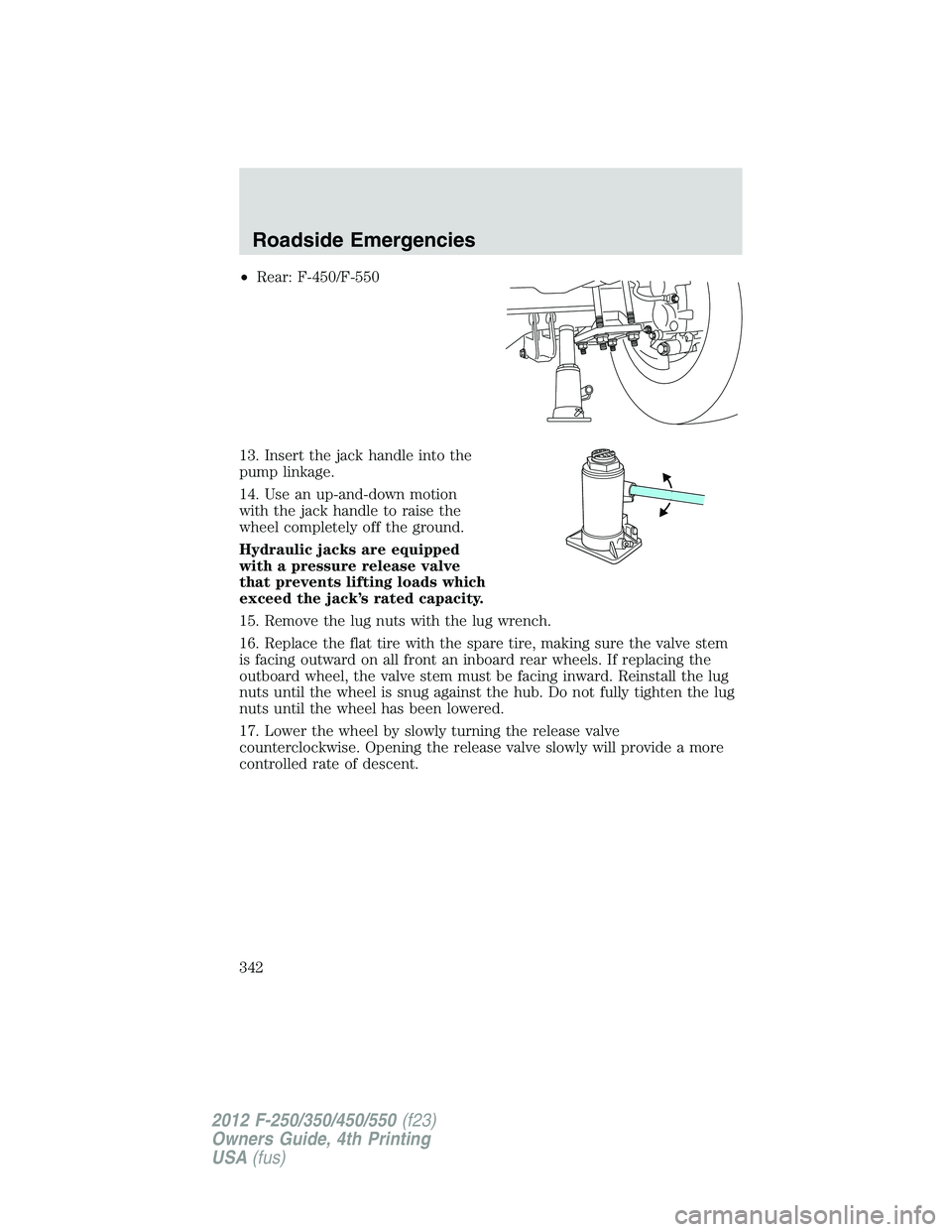

• Rear: F-450/F-550

13. Insert the jack handle into the

pump linkage.

14. Use an up-and-down motion

with the jack handle to raise the

wheel completely off the ground.

Hydraulic jacks are equipped

with a pressure release valve

that prevents lifting loads which

exceed the jack’s rated capacity.

15. Remove the lug nuts with the lug wrench.

16. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward on all front an inboard rear wheels. If replacing the

outboard wheel, the valve stem must be facing inward. Reinstall the lug

nuts until the wheel is snug against the hub. Do not fully tighten the lug

nuts until the wheel has been lowered.

17. Lower the wheel by slowly turning the release valve

counterclockwise. Opening the release valve slowly will provide a more

controlled rate of descent.Roadside Emergencies

342

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 346 of 448

Stowing the flat/spare tire

Note: Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

If you are stowing a tire that requires reattaching it to the

vehicle with a tether, perform these steps first, then proceed with

the steps following.

1. Place the tire on end with the

valve stem facing toward the front

of the vehicle.

2. Place the tether into the bolt

holes in the wheel and attach the

lug nut using the lug winch.

3. Lay the tire on the ground with the valve stem facing up.

4. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

5. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your authorized

dealer for assistance at your earliest convenience.

6. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

7. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, per scheduled maintenance information),

or at any time that the spare tire is disturbed through service of other

components.

8. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.Roadside Emergencies

346

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 376 of 448

• Oil levels above the upper hole may cause engine damage. Some oil

must be removed from the engine by a service technician.

7. Put the dipstick back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer to Checking the engine

oil in this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

normal operating range on the engine oil level dipstick.

4. Install the dipstick and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until three clicks are heard or until the cap is fully seated.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level dipstick and/or the engine oil filler cap removed.

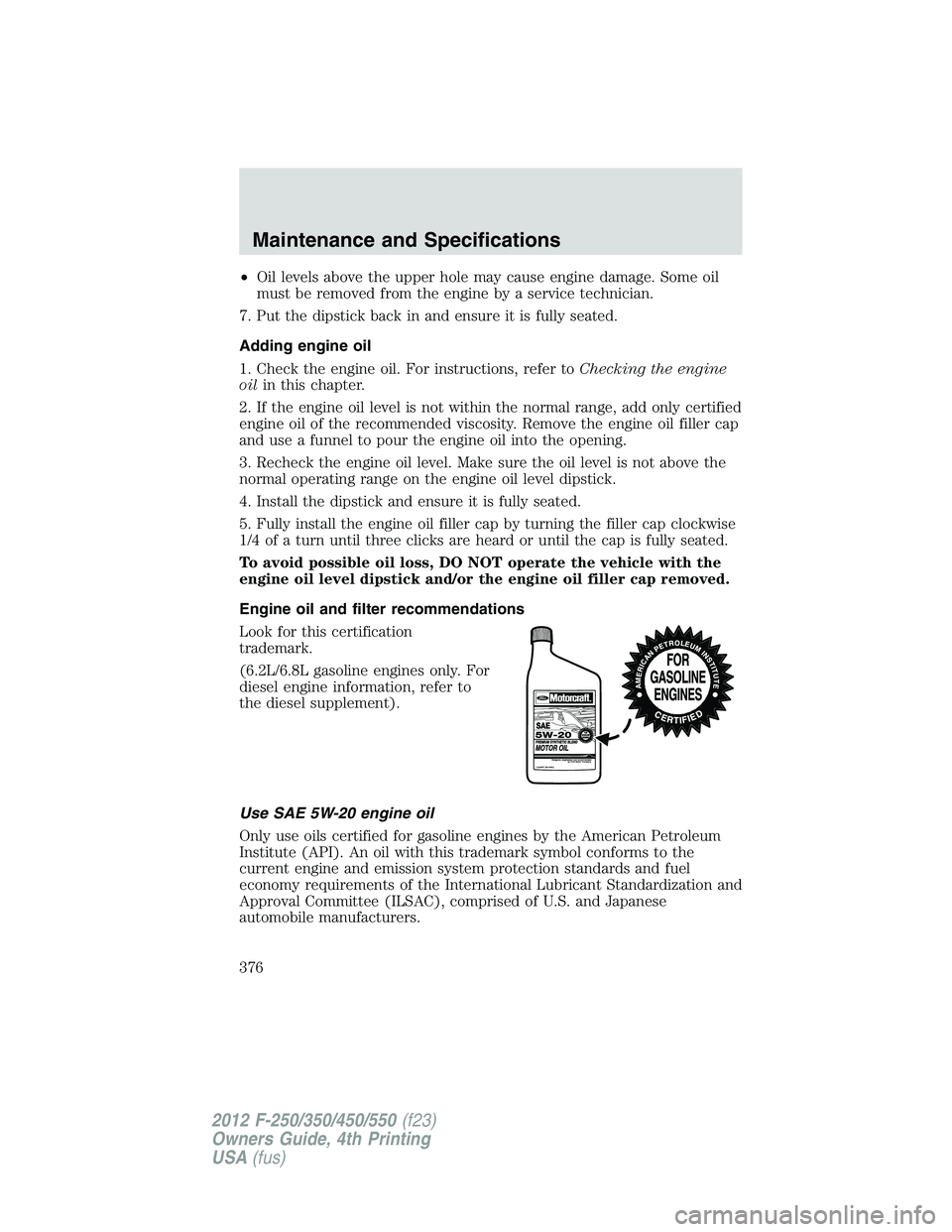

Engine oil and filter recommendations

Look for this certification

trademark.

(6.2L/6.8L gasoline engines only. For

diesel engine information, refer to

the diesel supplement).

Use SAE 5W-20 engine oil

Only use oils certified for gasoline engines by the American Petroleum

Institute (API). An oil with this trademark symbol conforms to the

current engine and emission system protection standards and fuel

economy requirements of the International Lubricant Standardization and

Approval Committee (ILSAC), comprised of U.S. and Japanese

automobile manufacturers.Maintenance and Specifications

376

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)

Page 379 of 448

Because your vehicle’s engine is electronically controlled by a computer,

some control conditions are maintained by power from the battery. When

the battery is disconnected or a new battery is installed, the engine must

relearn its idle and fuel trim strategy for optimum driveability and

performance. To begin this process:

1. With the vehicle at a complete stop, set the parking brake.

2. Put the gearshift in P (Park), turn off all accessories and start the engine.

3. Run the engine until it reaches normal operating temperature.

4. Allow the engine to idle for at least one minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

6. Drive the vehicle to complete the relearning process.

• The vehicle may need to be driven 10 miles (16 km) or more to

relearn the idle and fuel trim strategy.

• If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock and radio settings must be reset once the battery is reconnected.

• Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking the engine coolant

Note: If your vehicle is equipped with a diesel engine, refer to the

Maintenance and Specifications section of your Diesel Supplement.

Check the concentration and level of the engine coolant at the intervals

listed in the Scheduled Maintenance Information.

The coolant concentration should be maintained at 50%.

L E A D

RETURN

RECYCLEMaintenance and Specifications

379

2012 F-250/350/450/550 (f23)

Owners Guide, 4th Printing

USA (fus)