service indicator FORD F650 2000 10.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: F650, Model: FORD F650 2000 10.GPages: 208, PDF Size: 1.08 MB

Page 12 of 208

Stop engine (if equipped)

This light is used in conjunction

with the electronic engine control.

Refer to the Engine Operator’s

Manual for specific information

regarding this feature.

If the engine shuts down, it can be

restarted and operated for 30

seconds at a time or until the

problem is corrected. Refer toEngine shutdown systemin theStarting

chapter.

Drivers of electronically controlled engines should know the

extent of warning engine shutdown system before operating the

vehicle. This information can be obtained from your dealer.

Turn signal

Illuminates when the left or right

turn signal or the hazard lights are

turned on. If one or both of the

indicators stay on continuously or

flash faster, check for a burned-out

turn signal bulb. Refer toExterior bulbsin theMaintenance and care

chapter.

High beams

Illuminates when the high beam

headlamps are turned on.

Anti-lock brake system (ABS)

Momentarily illuminates when the

ignition is turned to the ON position

and the engine is off. If the light

remains on after the vehicle is

started, continues to flash or fails to

illuminate, have the system serviced immediately. With the ABS light on,

STOP

ENGINE

ABS

Instrumentation

12

Page 14 of 208

Check trans (Allison automatic transmission)

The lamp will illuminate for several

seconds after the ignition is turned

to the ON position. Illumination of

this light indicates that a problem

has been detected and shifting may

be restricted. Depending upon the

severity of the problem, the

read-out digit on the shifter display

may be blank. Operation may

continue in order or reach service assistance. The ECU may not respond

to shift selector requests, since operating limitations are being placed on

the transmission, i.e. upshifts and downshifts may be restricted.

Direction changes will not occur.

Refer to theMaintenance and Carechapter.

Safety belt

Momentarily illuminates when the

ignition is turned to the ON position

to remind you to fasten your safety

belts. For more information, refer to

theSeating and safety restraints

chapter.

Service engine soon

TheService Engine Soonindicator

light illuminates when the ignition is

first turned to the ON position to

check the bulb. If it comes on after

the engine is started, one of the

engine’s control systems may be

malfunctioning. The light may illuminate without a driveability concern

being noted. The vehicle will usually be drivable and will not require

towing.

Temporary malfunctions may cause yourService Engine Soonlight to

illuminate. Examples are:

1. The vehicle has run out of fuel. (The engine may misfire or run

poorly.)

2. Poor fuel quality or water in the fuel.

CHECK

TRANS

SERVICE

ENGINE

SOON

Instrumentation

14

Page 89 of 208

![FORD F650 2000 10.G Owners Manual When air pressure is insufficient

(below 534 kPa [60 psi]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake app FORD F650 2000 10.G Owners Manual When air pressure is insufficient

(below 534 kPa [60 psi]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake app](/img/11/5066/w960_5066-88.png)

When air pressure is insufficient

(below 534 kPa [60 psi]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake applications depleting

the system air pressure. If this condition occurs, stop driving the vehicle

until the compressor has fully recharged the air system. Do not move the

vehicle in this condition because the brake system may be inoperative.

Select a gear ratio to help slow your vehicle before descending grades.

Supplement with brakes as required to safely slow the vehicle and avoid

overspeeding the engine.

Air chamber stroke indication

All Ford air chamber push rods have orange stroke indicator stripes that

alert the operator when the braking system requires adjustment or

repair. The orange stripe is painted on the air chamber push rod at the

slack adjuster readjustment stroke dimension.

Air brake inspection and adjustment should be performed by a qualified

service technician in accordance with the instructions in the Ford Truck

Service Manual.

Cam brakes—automatic slack adjusters

Standard air brakes (cam) are

equipped with automatic brake

adjusters. Automatic adjustment

occurs during forward and reverse

brake applications. Inspect brakes

for proper adjustment at the

intervals listed in the vehicle Service

Maintenance Guide.

!

BRAKE

Driving

89

Page 105 of 208

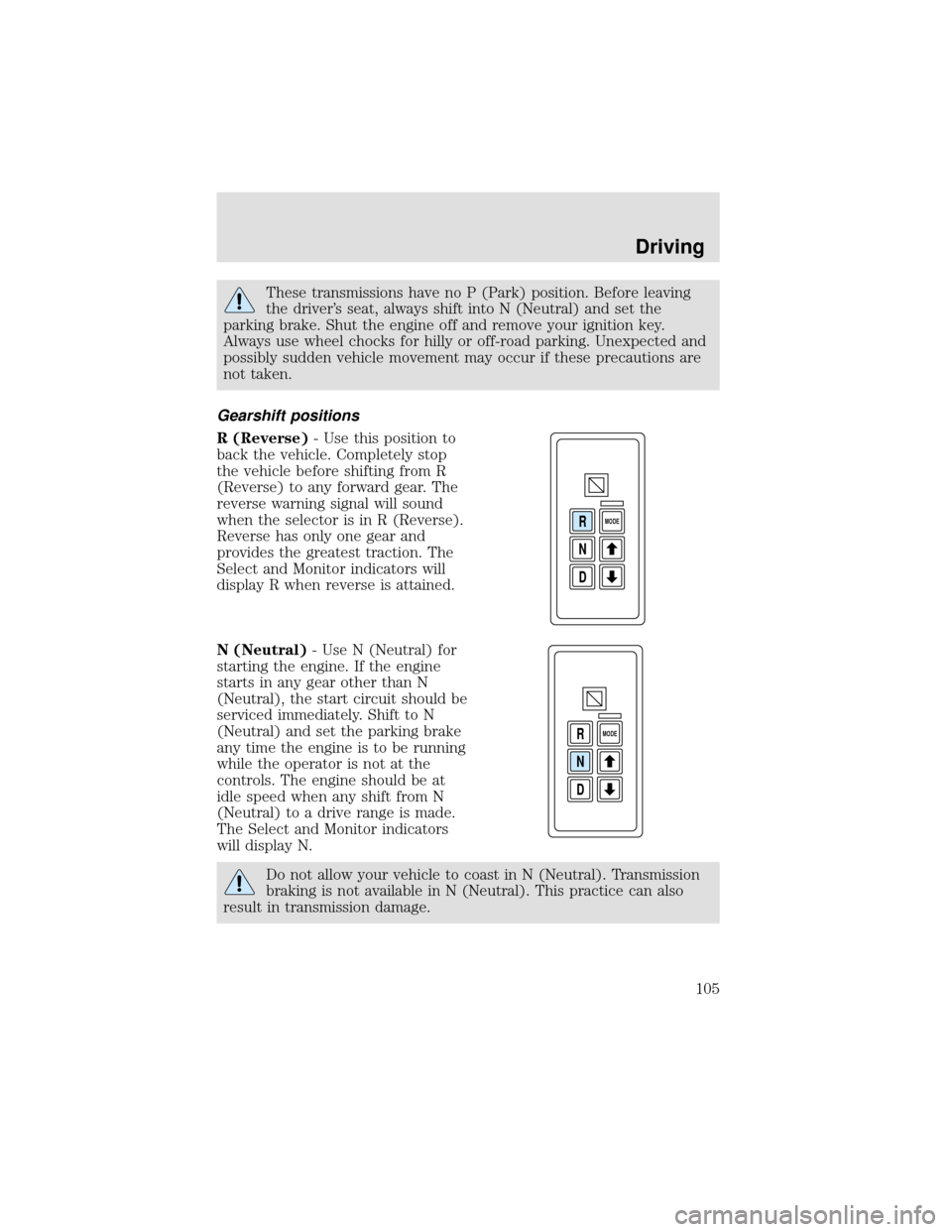

These transmissions have no P (Park) position. Before leaving

the driver’s seat, always shift into N (Neutral) and set the

parking brake. Shut the engine off and remove your ignition key.

Always use wheel chocks for hilly or off-road parking. Unexpected and

possibly sudden vehicle movement may occur if these precautions are

not taken.

Gearshift positions

R (Reverse)- Use this position to

back the vehicle. Completely stop

the vehicle before shifting from R

(Reverse) to any forward gear. The

reverse warning signal will sound

when the selector is in R (Reverse).

Reverse has only one gear and

provides the greatest traction. The

Select and Monitor indicators will

display R when reverse is attained.

N (Neutral)- Use N (Neutral) for

starting the engine. If the engine

starts in any gear other than N

(Neutral), the start circuit should be

serviced immediately. Shift to N

(Neutral) and set the parking brake

any time the engine is to be running

while the operator is not at the

controls. The engine should be at

idle speed when any shift from N

(Neutral) to a drive range is made.

The Select and Monitor indicators

will display N.

Do not allow your vehicle to coast in N (Neutral). Transmission

braking is not available in N (Neutral). This practice can also

result in transmission damage.

D N R

MODE

D N R

MODE

Driving

105

Page 128 of 208

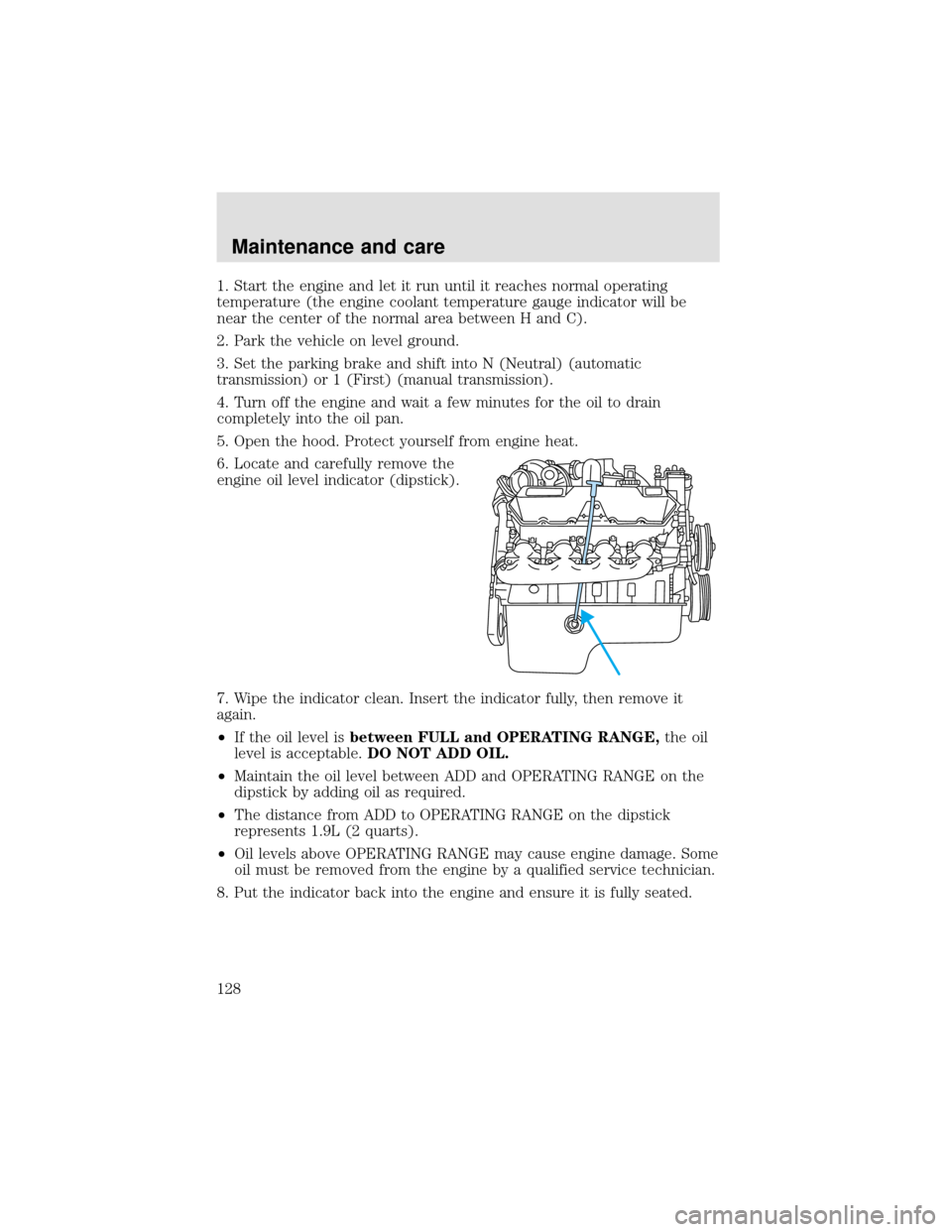

1. Start the engine and let it run until it reaches normal operating

temperature (the engine coolant temperature gauge indicator will be

near the center of the normal area between H and C).

2. Park the vehicle on level ground.

3. Set the parking brake and shift into N (Neutral) (automatic

transmission) or 1 (First) (manual transmission).

4. Turn off the engine and wait a few minutes for the oil to drain

completely into the oil pan.

5. Open the hood. Protect yourself from engine heat.

6. Locate and carefully remove the

engine oil level indicator (dipstick).

7. Wipe the indicator clean. Insert the indicator fully, then remove it

again.

•If the oil level isbetween FULL and OPERATING RANGE,the oil

level is acceptable.DO NOT ADD OIL.

•Maintain the oil level between ADD and OPERATING RANGE on the

dipstick by adding oil as required.

•The distance from ADD to OPERATING RANGE on the dipstick

represents 1.9L (2 quarts).

•Oil levels above OPERATING RANGE may cause engine damage. Some

oil must be removed from the engine by a qualified service technician.

8. Put the indicator back into the engine and ensure it is fully seated.

Maintenance and care

128

Page 141 of 208

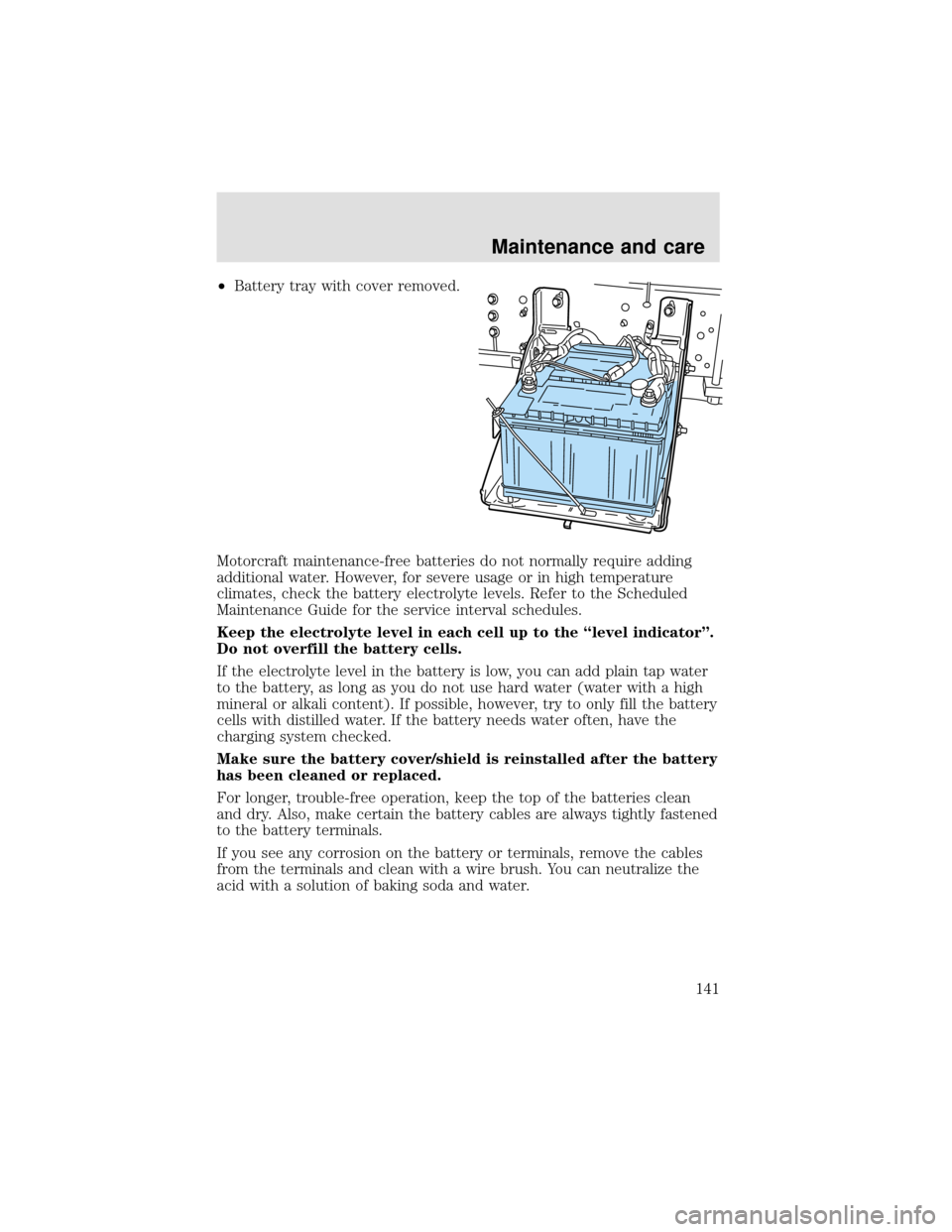

•Battery tray with cover removed.

Motorcraft maintenance-free batteries do not normally require adding

additional water. However, for severe usage or in high temperature

climates, check the battery electrolyte levels. Refer to the Scheduled

Maintenance Guide for the service interval schedules.

Keep the electrolyte level in each cell up to the “level indicator”.

Do not overfill the battery cells.

If the electrolyte level in the battery is low, you can add plain tap water

to the battery, as long as you do not use hard water (water with a high

mineral or alkali content). If possible, however, try to only fill the battery

cells with distilled water. If the battery needs water often, have the

charging system checked.

Make sure the battery cover/shield is reinstalled after the battery

has been cleaned or replaced.

For longer, trouble-free operation, keep the top of the batteries clean

and dry. Also, make certain the battery cables are always tightly fastened

to the battery terminals.

If you see any corrosion on the battery or terminals, remove the cables

from the terminals and clean with a wire brush. You can neutralize the

acid with a solution of baking soda and water.

Maintenance and care

141

Page 142 of 208

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

When lifting a plastic-cased battery, excessive pressure on the

end walls could cause acid to flow through the vent caps,

resulting in personal injury and/or damage to the vehicle or battery.

Lift the battery with a battery carrier or with your hands on opposite

corners.

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

AIR FILTER

When to service

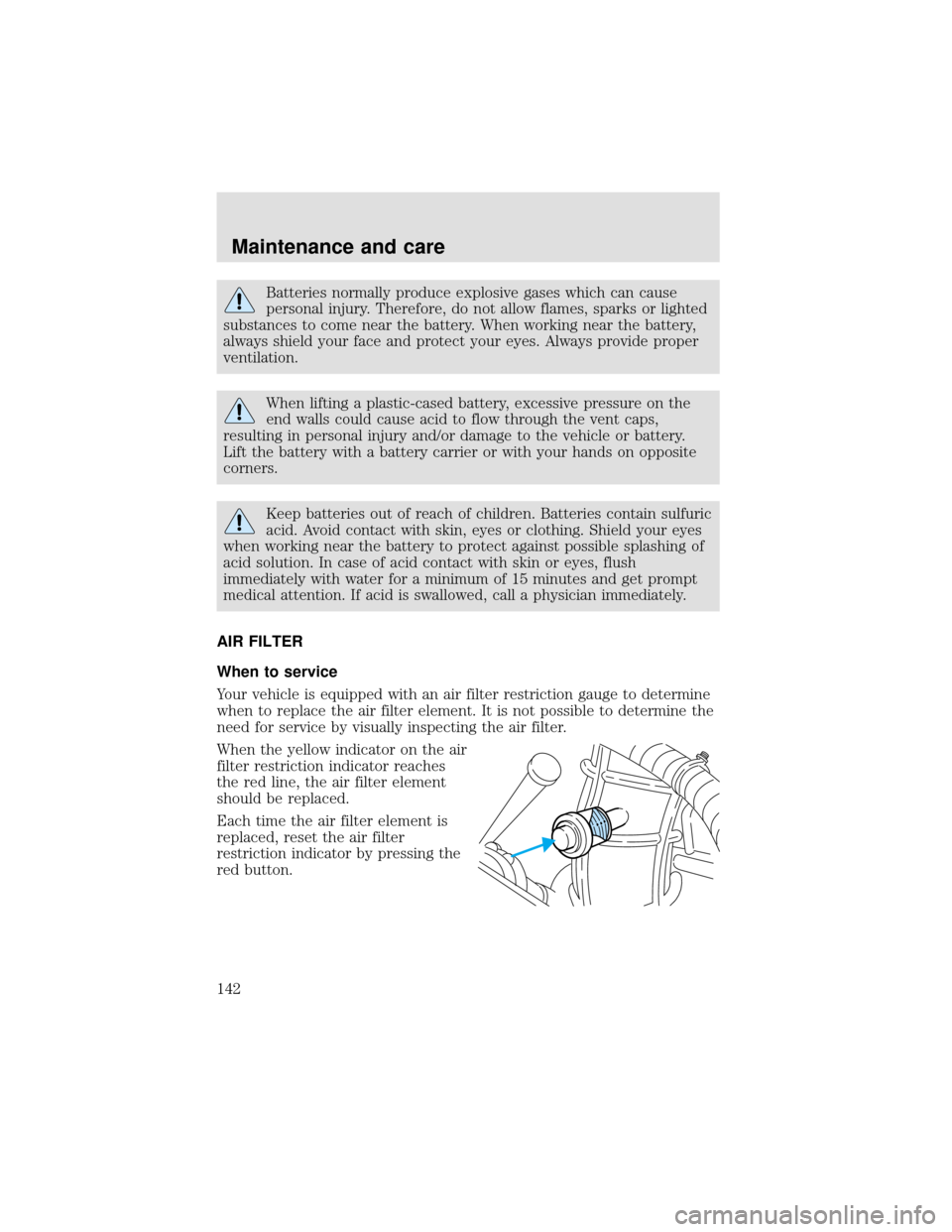

Your vehicle is equipped with an air filter restriction gauge to determine

when to replace the air filter element. It is not possible to determine the

need for service by visually inspecting the air filter.

When the yellow indicator on the air

filter restriction indicator reaches

the red line, the air filter element

should be replaced.

Each time the air filter element is

replaced, reset the air filter

restriction indicator by pressing the

red button.

Maintenance and care

142

Page 146 of 208

10. Reset the air filter restriction indicator.

11. Inspect the air induction system for loose fitting, damaged or missing

components and repair as necessary.

WINDSHIELD WIPER BLADES

Check the wiper blades at least twice a year or when they seem less

effective. Substances such as tree sap and some hot wax treatments used

by commercial car washes reduce the effectiveness of wiper blades.

Checking the wiper blades

If the wiper blades do not wipe properly, clean both the windshield and

wiper blades using undiluted windshield wiper solution or a mild

detergent. Rinse thoroughly with clean water. To avoid damaging the

blades, do not use fuel, kerosene, paint thinner or other solvents.

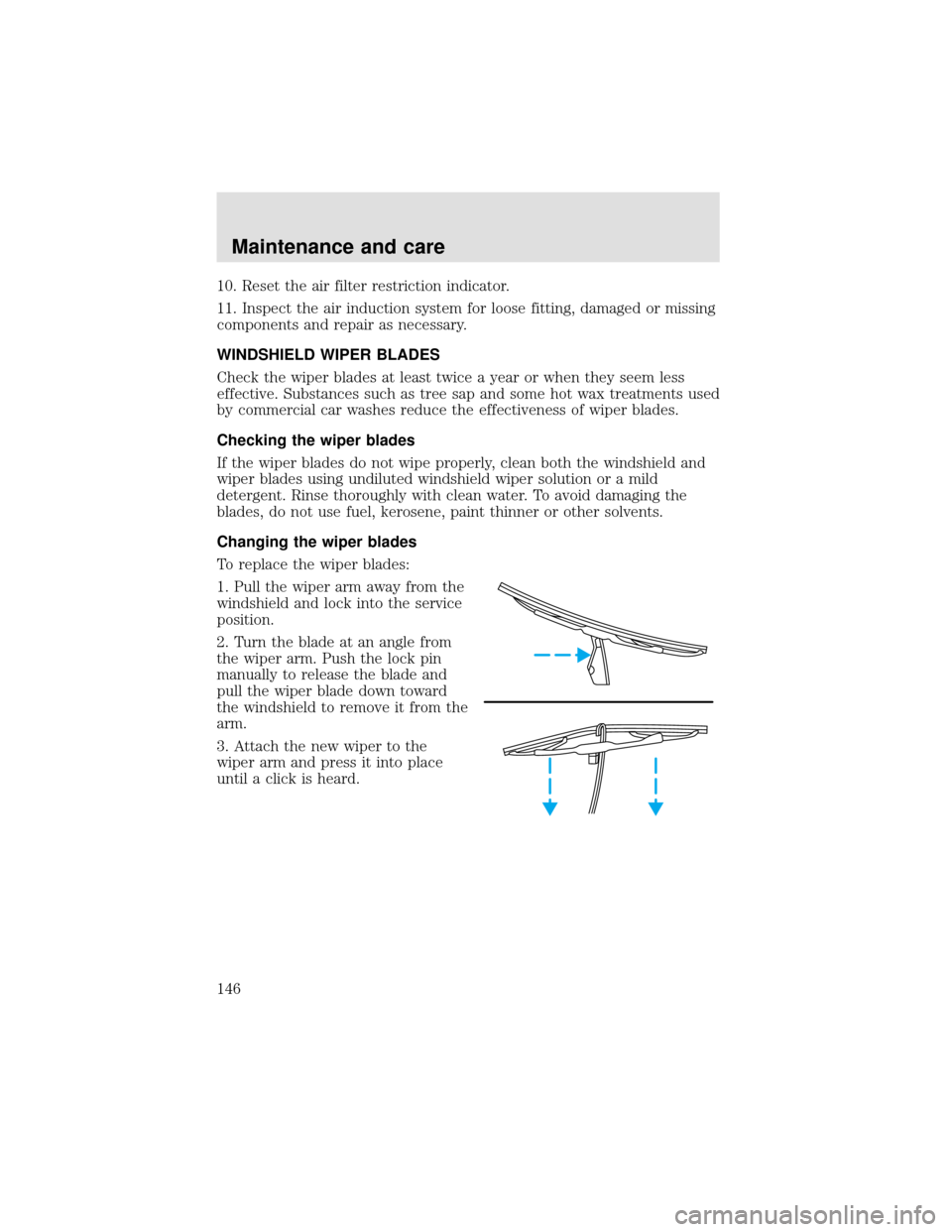

Changing the wiper blades

To replace the wiper blades:

1. Pull the wiper arm away from the

windshield and lock into the service

position.

2. Turn the blade at an angle from

the wiper arm. Push the lock pin

manually to release the blade and

pull the wiper blade down toward

the windshield to remove it from the

arm.

3. Attach the new wiper to the

wiper arm and press it into place

until a click is heard.

Maintenance and care

146

Page 176 of 208

OWNER MAINTENANCE

You can do much of the maintenance your vehicle requires yourself, if

you have the time and a reasonable amount of mechanical ability. If you

prefer to have this work done professionally, your authorized dealer

stands ready to help you.

All mechanical components and attachments are important in that they

could affect the performance of vital components and systems. If

replacement becomes necessary, they must be replaced with parts having

the same part number or with equivalent parts. Torque values of the

attaching parts must be used as specified during any reassembly

procedure to assure proper retention.

EMISSIONS CONTROL SYSTEM

To assure the emissions control systems operate effectively, you should

have the services listed in the maintenance schedule performed at the

specified time and km/mileage intervals. You should avoid running out of

fuel or turning off the ignition while the vehicle is in motion, especially

at high speeds.

Because of high engine compartment and exhaust system

temperatures resulting from emissions equipment, do not park,

idle or operate your vehicle in dry grass or other dry ground cover

where the possibility of ground fire exists.

Do not make unauthorized modifications to the engine or vehicle.

Modifications causing increased amounts of unburned fuel to reach the

exhaust system can significantly increase the temperature of the engine

compartment and/or the exhaust system.

Avoid driving your vehicle if it does not operate properly. If the engine

diesels (more than five seconds of engine run-on after shut-off), misfires,

surges, stalls or backfires, see your dealer. Be alert for fluid leakage,

odor, smoke, loss of oil pressure, or charge indicator or over temperature

warning.

Do NOT use diesel fuel blended with waste oil in engines equipped with

a CATALYTIC CONVERTER-MUFFLER. Waste lube oil blending in fuel

will plug the CATALYTIC CONVERTER-MUFFLER, resulting in a

significant loss of engine power.

General maintenance information

176

Page 179 of 208

SCHEDULED MAINTENANCE SERVICES

Maintenance service adjustments must conform to specifications

contained in this manual, and those shown on the Important Engine

Information Decal. The following services are to be performed at

scheduled intervals because they are considered essential to the life and

performance of your vehicle. Ford recommends that you perform

maintenance on all designated items to achieve best vehicle operation.

Scheduled maintenance beyond 160 930 km (100 000 miles) should be

continued as before 160 930 km (100 000 miles).

SPECIAL OPERATING CONDITIONS

If your driving habitsfrequentlyinclude one or more the following

conditions:

•Short trips oflessthan 16 km (ten miles) when outside temperatures

remain below freezing.

•Operating duringhot weatherin stop-and-go“rush hour”traffic.

•Operating in severe dust conditions.

•Extensive idling, or low speed operation such as door-to-door delivery

service.

•High speed operation with a fully loaded vehicle (max. GVW).

•Snowplowing.

Perform the following:

•Change engine oil and oil filter every three months, 8 000 km (5 000

miles) or 125 hours of engine service.

•If operating in severe dust conditions, replace the air cleaner filter

more often than regular intervals as determined by the air filter

restriction indicator. Make sure that the air filter restriction indicator

is in good working order.

•Lube the manual transmission and the rear axle every 48 279 km

(30 000 miles) or 6 months, whichever comes first.

•See the Allison, Cummins and Caterpillar Operator’s Manual.

General maintenance information

179