light FORD F650 2002 10.G Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2002, Model line: F650, Model: FORD F650 2002 10.GPages: 256, PDF Size: 1.75 MB

Page 99 of 256

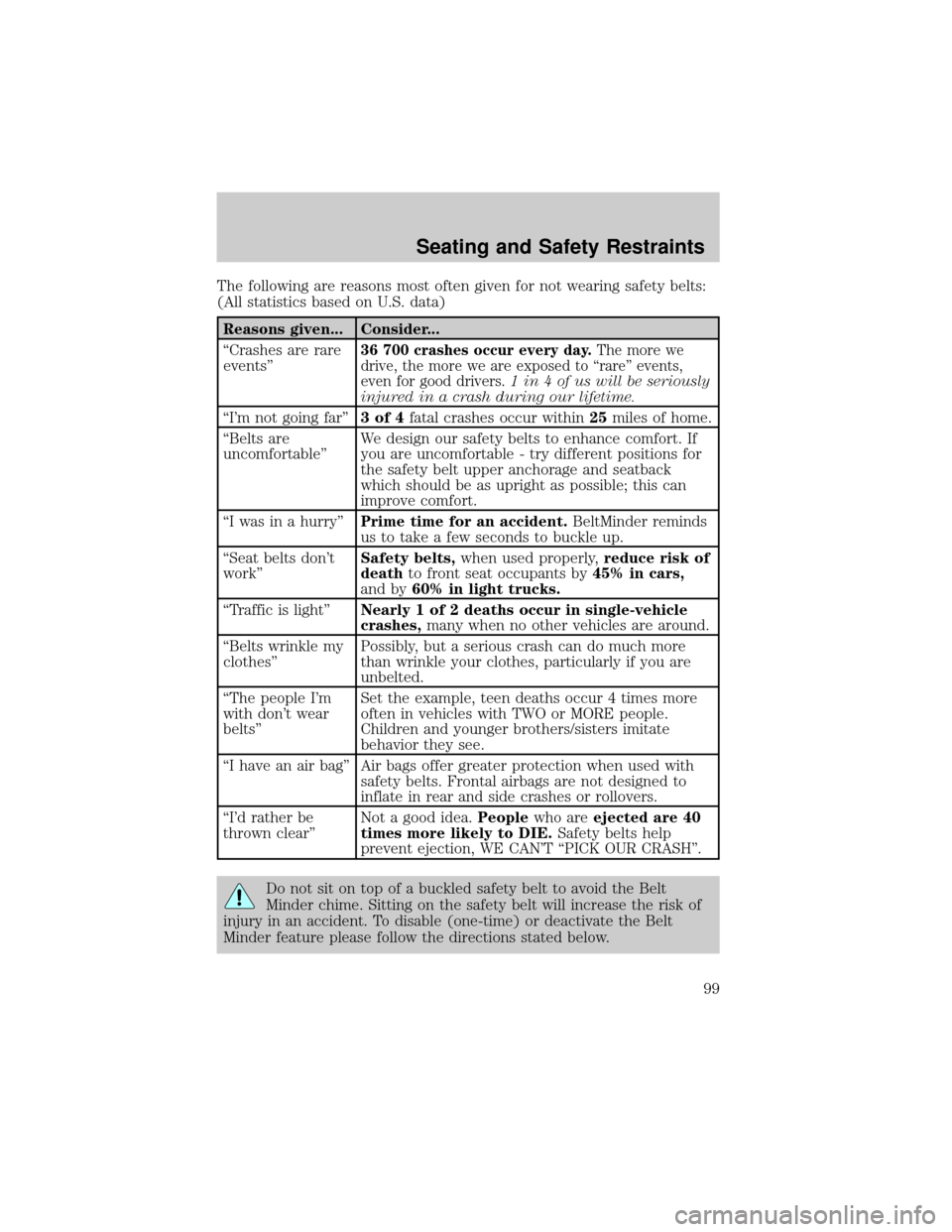

The following are reasons most often given for not wearing safety belts:

(All statistics based on U.S. data)

Reasons given... Consider...

ªCrashes are rare

eventsº

36 700 crashes occur every day.The more we

drive, the more we are exposed to ªrareº events,

even for good drivers.1 in 4 of us will be seriously

injured in a crash during our lifetime.

ªI'm not going farº3of4fatal crashes occur within25miles of home.

ªBelts are

uncomfortableºWe design our safety belts to enhance comfort. If

you are uncomfortable - try different positions for

the safety belt upper anchorage and seatback

which should be as upright as possible; this can

improve comfort.

ªI was in a hurryºPrime time for an accident.BeltMinder reminds

us to take a few seconds to buckle up.

ªSeat belts don't

workºSafety belts,when used properly,reduce risk of

deathto front seat occupants by45% in cars,

and by60% in light trucks.

ªTraffic is lightºNearly 1 of 2 deaths occur in single-vehicle

crashes,many when no other vehicles are around.

ªBelts wrinkle my

clothesºPossibly, but a serious crash can do much more

than wrinkle your clothes, particularly if you are

unbelted.

ªThe people I'm

with don't wear

beltsºSet the example, teen deaths occur 4 times more

often in vehicles with TWO or MORE people.

Children and younger brothers/sisters imitate

behavior they see.

ªI have an air bagº Air bags offer greater protection when used with

safety belts. Frontal airbags are not designed to

inflate in rear and side crashes or rollovers.

ªI'd rather be

thrown clearºNot a good idea.Peoplewho areejected are 40

times more likely to DIE.Safety belts help

prevent ejection, WE CAN'T ªPICK OUR CRASHº.

Do not sit on top of a buckled safety belt to avoid the Belt

Minder chime. Sitting on the safety belt will increase the risk of

injury in an accident. To disable (one-time) or deactivate the Belt

Minder feature please follow the directions stated below.

Seating and Safety Restraints

99

Page 100 of 256

One time disable

Any time the safety belt is buckled and then unbuckled during an

ignition ON cycle, BeltMinder will be disabled for that ignition cycle only.

Deactivating/activating the BeltMinder feature

Read steps1-9thoroughly before proceeding with the

deactivation/activation programming procedure.

The BeltMinder feature can be deactivated/activated by performing the

following procedure:

Before following the procedure, make sure that:

²The parking brake is set.

²The gearshift is in P (Park) (automatic transmission) or the neutral

position (manual transmission).

²The ignition switch is in the OFF position.

²All vehicle doors are closed.

²The driver's safety belt is unbuckled.

²The parklamps/headlamps are in OFF position (If vehicle is equipped

with Autolamps, this will not affect the procedure).

To reduce the risk of injury, do not deactivate/activate the Belt

Minder feature while driving the vehicle.

1. Turn the ignition switch to the RUN (or ON) position. (DO NOT

START THE ENGINE.)

2. Wait until the safety belt warning light turns off. (Approximately 1±2

minutes.)

²Steps 3±5 must be completed within 60 seconds or the procedure will

have to be repeated.

3. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled. This can be done before or during BeltMinder

warning activation.

4. Turn on the parklamps/headlamps, turn off the parklamps/headlamps.

5. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled.

²After step 5 the safety belt warning light will be turned on for three

seconds.

Seating and Safety Restraints

100

Page 101 of 256

6. Within seven seconds of the safety belt warning light turning off,

buckle then unbuckle the safety belt.

²This will disable BeltMinder if it is currently enabled, or enable

BeltMinder if it is currently disabled.

7. Confirmation of disabling BeltMinder is provided by the safety belt

warning light flashing four times per second for three seconds.

8. Confirmation of enabling BeltMinder is provided by:

²The safety belt warning light flashing four times per second for three

seconds.

²Followed by three seconds with the safety belt warning light off.

²Once again, the safety belt warning light will flash four times per

second for three seconds.

9. After receiving confirmation, the deactivation/activation procedure is

complete.

Safety belt extension assembly

If the safety belt is too short when fully extended, there is a 20 cm (8

inch) safety belt extension assembly that can be added (part number

611C22). This assembly can be obtained from your dealer at no cost.

Use only extensions manufactured by the same supplier as the safety

belt. Manufacturer identification is located at the end of the webbing on

the label. Also, use the safety belt extension only if the safety belt is too

short for you when fully extended. Do not use extensions to change the

fit of the shoulder belt across the torso.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, tears or cuts. Replace if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), shoulder belt guide on seatback (if

equipped), child safety seat tether bracket assemblies (if equipped),

LATCH child seat tether anchors and lower anchors (if equipped), and

attaching hardware, should be inspected after a collision. Ford Motor

Company recommends that all safety belt assemblies used in vehicles

involved in a collision be replaced. However, if the collision was minor

and a qualified technician finds that the belts do not show damage and

Seating and Safety Restraints

101

Page 108 of 256

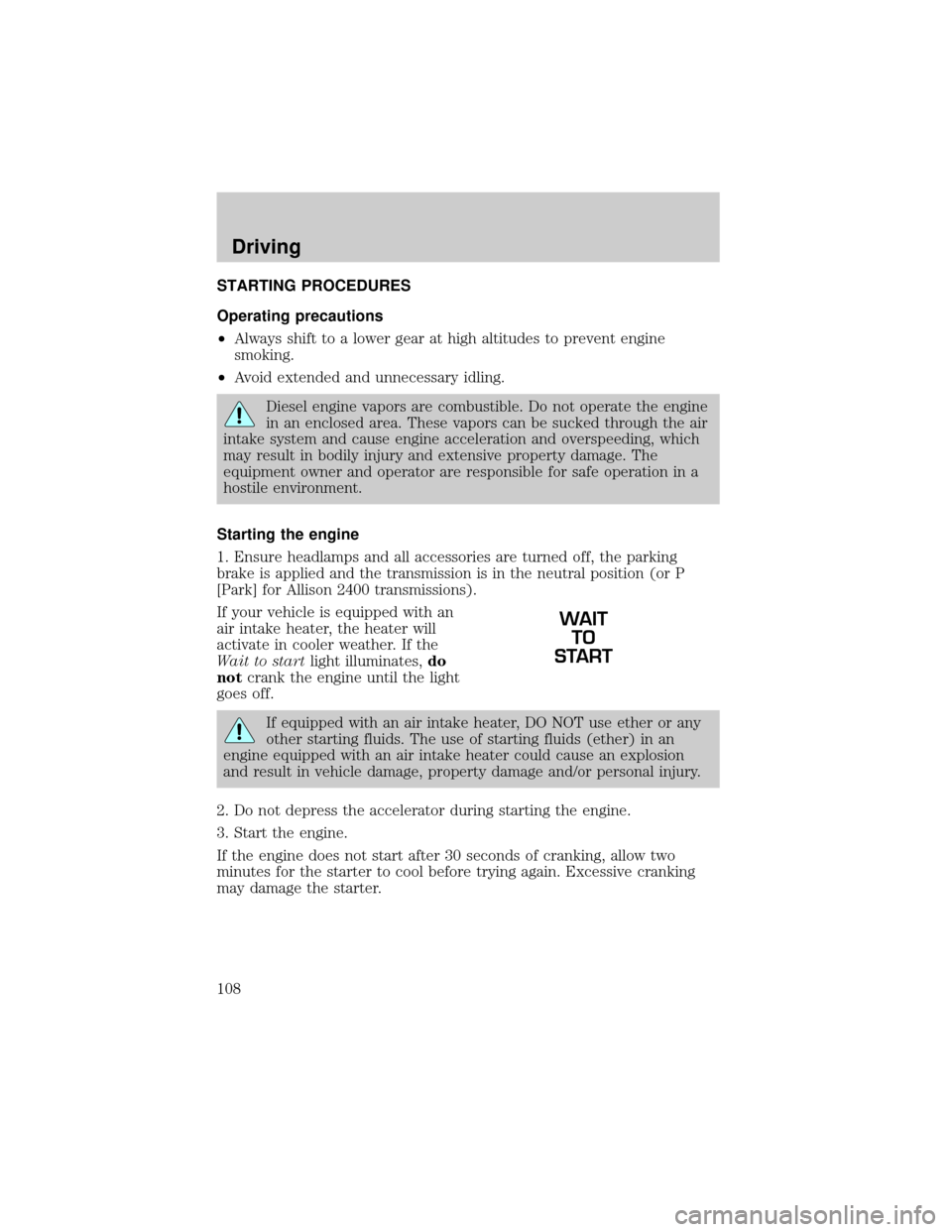

STARTING PROCEDURES

Operating precautions

²Always shift to a lower gear at high altitudes to prevent engine

smoking.

²Avoid extended and unnecessary idling.

Diesel engine vapors are combustible. Do not operate the engine

in an enclosed area. These vapors can be sucked through the air

intake system and cause engine acceleration and overspeeding, which

may result in bodily injury and extensive property damage. The

equipment owner and operator are responsible for safe operation in a

hostile environment.

Starting the engine

1. Ensure headlamps and all accessories are turned off, the parking

brake is applied and the transmission is in the neutral position (or P

[Park] for Allison 2400 transmissions).

If your vehicle is equipped with an

air intake heater, the heater will

activate in cooler weather. If the

Wait to startlight illuminates,do

notcrank the engine until the light

goes off.

If equipped with an air intake heater, DO NOT use ether or any

other starting fluids. The use of starting fluids (ether) in an

engine equipped with an air intake heater could cause an explosion

and result in vehicle damage, property damage and/or personal injury.

2. Do not depress the accelerator during starting the engine.

3. Start the engine.

If the engine does not start after 30 seconds of cranking, allow two

minutes for the starter to cool before trying again. Excessive cranking

may damage the starter.

WAIT

TO

START

Driving

108

Page 109 of 256

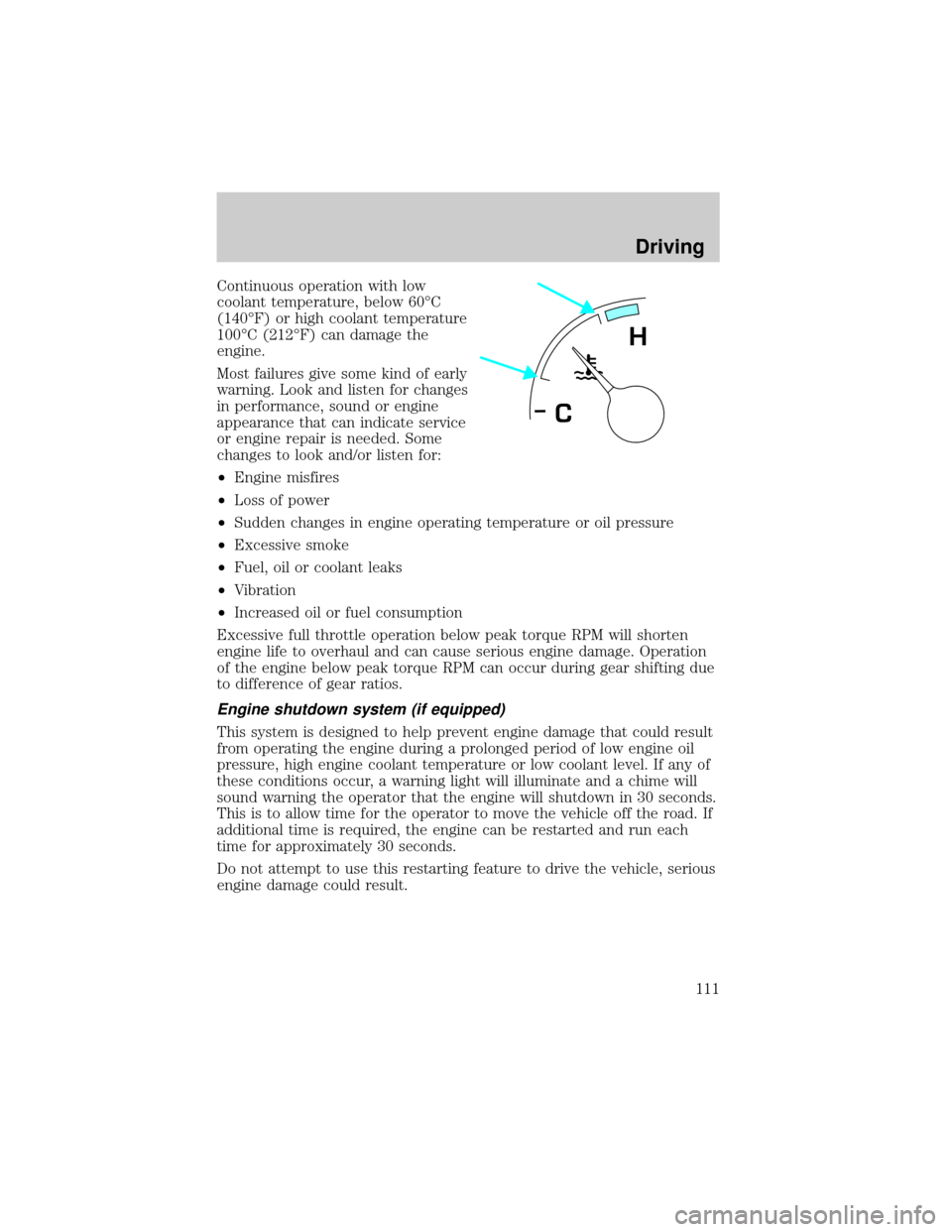

After the engine starts:

²On some engines, theWait to

startlight should illuminate after

the engine starts. Allow the

engine to idle about three

minutes or until the engine

coolant temperature gauge begins

to rise. Maintain idle speed until theWait to startlight cycles off to

indicate the air intake heater has shut off (approximately six

minutes). Operating the engine at higher speeds will reduce the

effectiveness of the air inlet heater.

²Do not increase engine speed

until the oil pressure gauge

indicates normal pressure.

²Ensure engine oil pressure is

indicated on the gauge within 15

seconds after starting.

²Idle the engine for three to five

minutes before operating with a

full load.

²Try to limit engine idle to 10

minutes. Excessive idling reduces fuel economy.

²When starting a cold engine, increase the engine speed (RPM) slowly

to make sure adequate lubrication is available to the bearings.

Restarting after running out of fuel

The fuel system may need to be purged of air, refer toRunning out of

fuelin theMaintenance and specificationschapter.

Cold weather starting

Perform the following to assure efficient starting in cold weather:

²Use the proper grade oil for your climate. Refer to your engine

operator's manual for proper grade oil.

²Test the battery more frequently to assure ample power for starting.

²All electrical connections should be tight and in good condition to

prevent losses through loose or corroded connections.

WAIT

TO

START

L

H

Driving

109

Page 111 of 256

Continuous operation with low

coolant temperature, below 60ÉC

(140ÉF) or high coolant temperature

100ÉC (212ÉF) can damage the

engine.

Most failures give some kind of early

warning. Look and listen for changes

in performance, sound or engine

appearance that can indicate service

or engine repair is needed. Some

changes to look and/or listen for:

²Engine misfires

²Loss of power

²Sudden changes in engine operating temperature or oil pressure

²Excessive smoke

²Fuel, oil or coolant leaks

²Vibration

²Increased oil or fuel consumption

Excessive full throttle operation below peak torque RPM will shorten

engine life to overhaul and can cause serious engine damage. Operation

of the engine below peak torque RPM can occur during gear shifting due

to difference of gear ratios.

Engine shutdown system (if equipped)

This system is designed to help prevent engine damage that could result

from operating the engine during a prolonged period of low engine oil

pressure, high engine coolant temperature or low coolant level. If any of

these conditions occur, a warning light will illuminate and a chime will

sound warning the operator that the engine will shutdown in 30 seconds.

This is to allow time for the operator to move the vehicle off the road. If

additional time is required, the engine can be restarted and run each

time for approximately 30 seconds.

Do not attempt to use this restarting feature to drive the vehicle, serious

engine damage could result.

H

C

Driving

111

Page 114 of 256

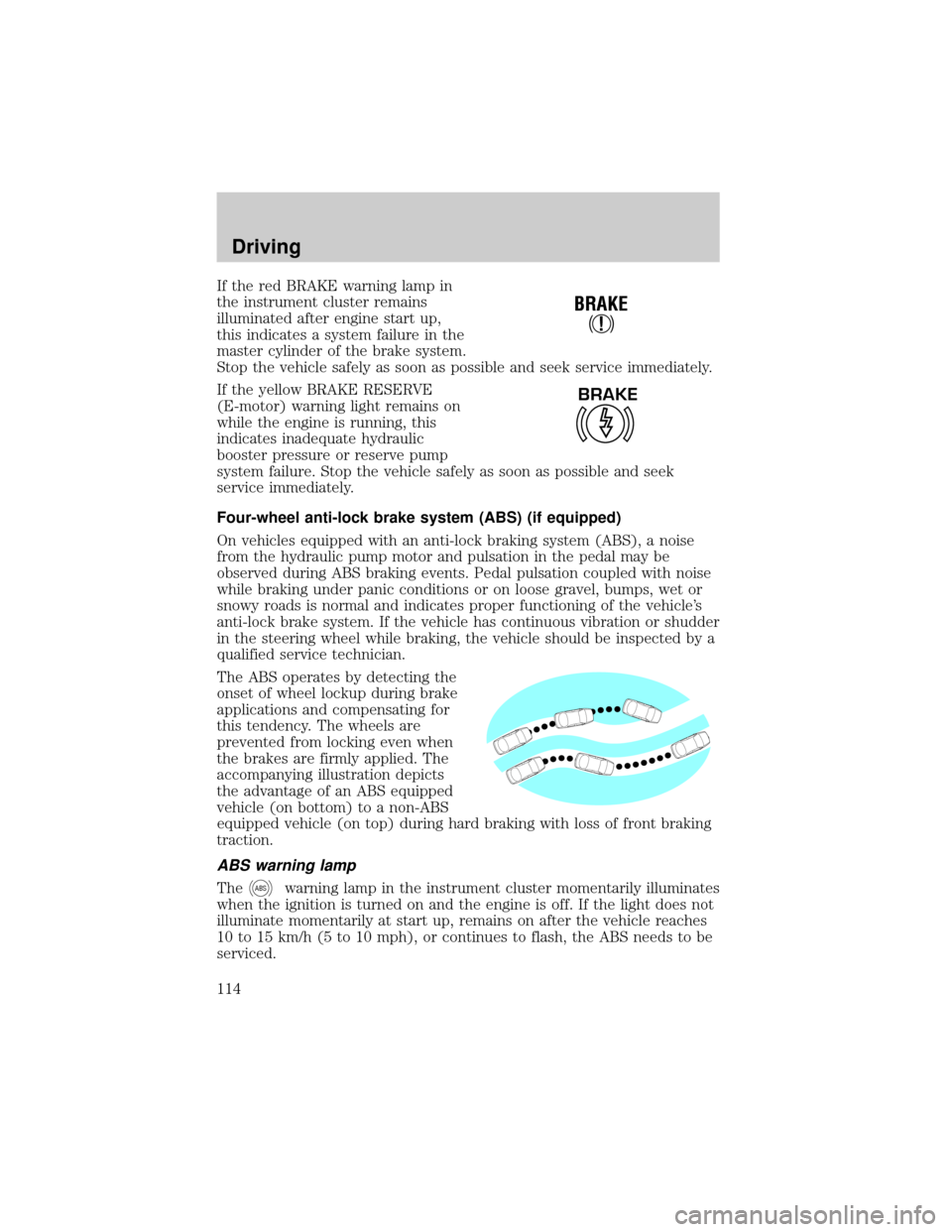

If the red BRAKE warning lamp in

the instrument cluster remains

illuminated after engine start up,

this indicates a system failure in the

master cylinder of the brake system.

Stop the vehicle safely as soon as possible and seek service immediately.

If the yellow BRAKE RESERVE

(E-motor) warning light remains on

while the engine is running, this

indicates inadequate hydraulic

booster pressure or reserve pump

system failure. Stop the vehicle safely as soon as possible and seek

service immediately.

Four-wheel anti-lock brake system (ABS) (if equipped)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. If the vehicle has continuous vibration or shudder

in the steering wheel while braking, the vehicle should be inspected by a

qualified service technician.

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensating for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

ABS warning lamp

TheABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned on and the engine is off. If the light does not

illuminate momentarily at start up, remains on after the vehicle reaches

10 to 15 km/h (5 to 10 mph), or continues to flash, the ABS needs to be

serviced.

!

BRAKE

BRAKE

Driving

114

Page 115 of 256

With the ABS light on, the anti-lock brake system is disabled and normal

braking is still effective unless the brake warning light also remains

illuminated. (If your parking brake warning lamp illuminates, have your

vehicle serviced immediately).

Using ABS

²In an emergency or when maximum efficiency from the ABS is

required, apply continuous full force on the brake. The ABS will be

activated immediately, thus allowing you to retain full steering control

of your vehicle and, providing there is sufficient space, will enable you

to avoid obstacles and bring the vehicle to a controlled stop.

²The Anti-Lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

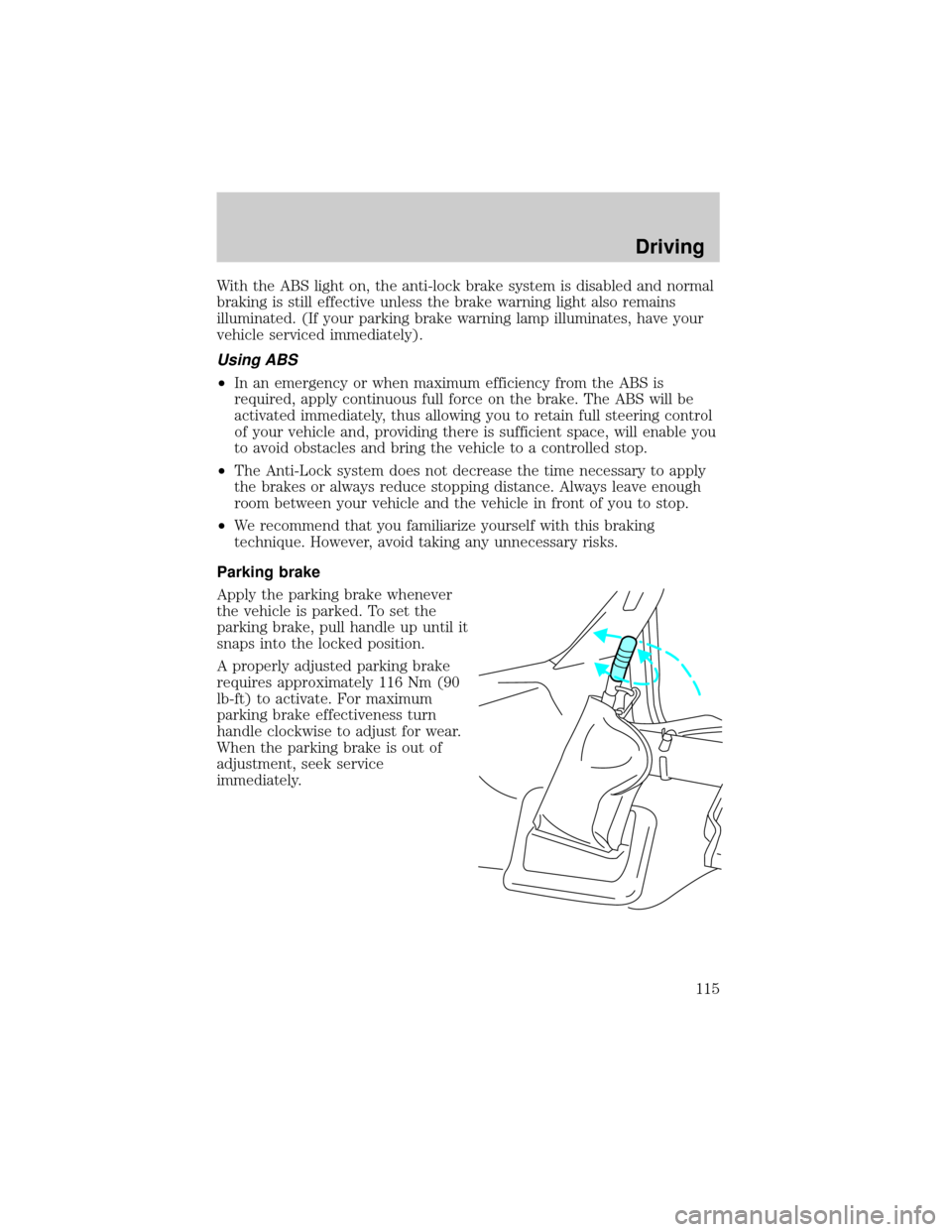

Parking brake

Apply the parking brake whenever

the vehicle is parked. To set the

parking brake, pull handle up until it

snaps into the locked position.

A properly adjusted parking brake

requires approximately 116 Nm (90

lb-ft) to activate. For maximum

parking brake effectiveness turn

handle clockwise to adjust for wear.

When the parking brake is out of

adjustment, seek service

immediately.

Driving

115

Page 120 of 256

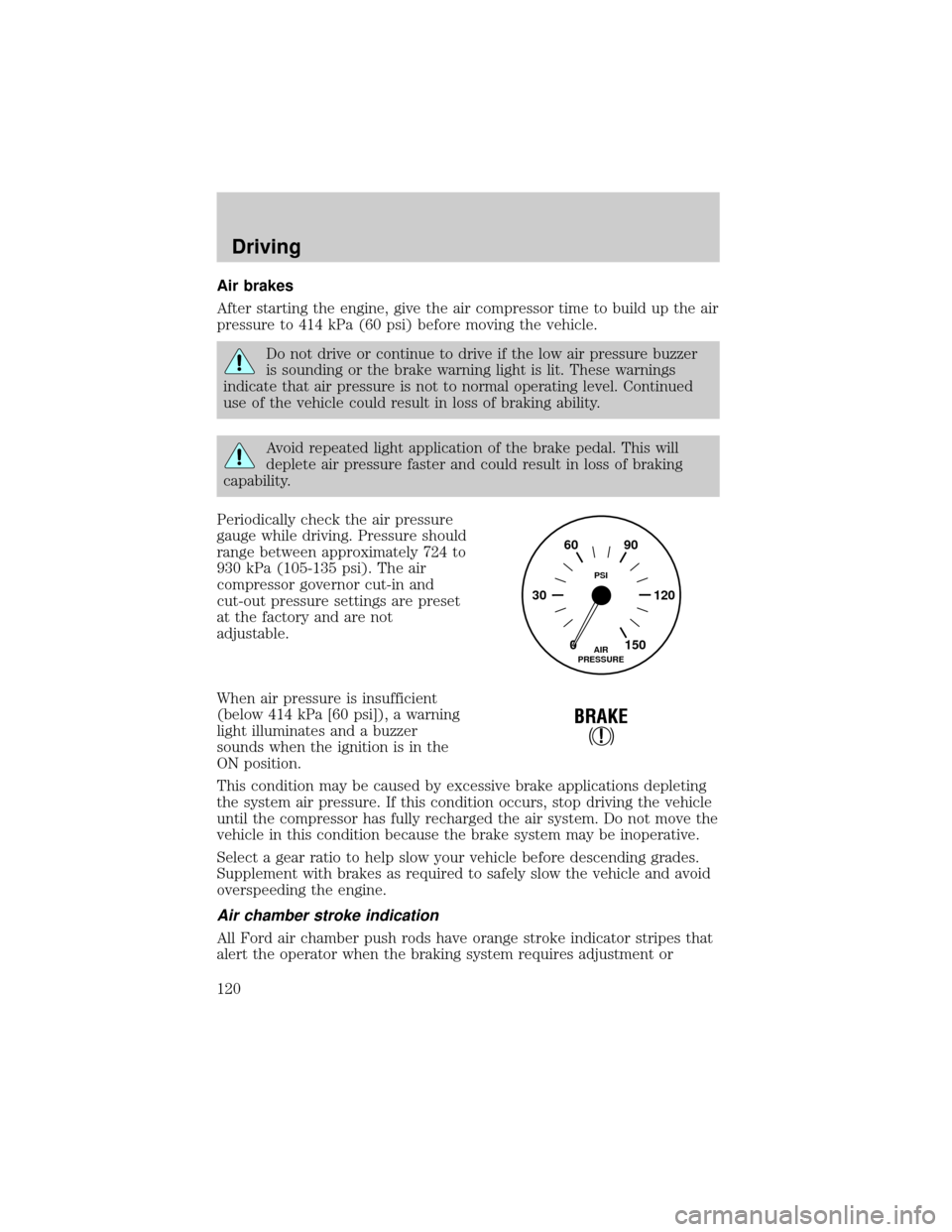

Air brakes

After starting the engine, give the air compressor time to build up the air

pressure to 414 kPa (60 psi) before moving the vehicle.

Do not drive or continue to drive if the low air pressure buzzer

is sounding or the brake warning light is lit. These warnings

indicate that air pressure is not to normal operating level. Continued

use of the vehicle could result in loss of braking ability.

Avoid repeated light application of the brake pedal. This will

deplete air pressure faster and could result in loss of braking

capability.

Periodically check the air pressure

gauge while driving. Pressure should

range between approximately 724 to

930 kPa (105-135 psi). The air

compressor governor cut-in and

cut-out pressure settings are preset

at the factory and are not

adjustable.

When air pressure is insufficient

(below 414 kPa [60 psi]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake applications depleting

the system air pressure. If this condition occurs, stop driving the vehicle

until the compressor has fully recharged the air system. Do not move the

vehicle in this condition because the brake system may be inoperative.

Select a gear ratio to help slow your vehicle before descending grades.

Supplement with brakes as required to safely slow the vehicle and avoid

overspeeding the engine.

Air chamber stroke indication

All Ford air chamber push rods have orange stroke indicator stripes that

alert the operator when the braking system requires adjustment or

0 30 12090 60

150AIR

PRESSUREPSI

!

BRAKE

Driving

120

Page 129 of 256

Exhaust brake operating characteristics

When you remove your feet from both the accelerator and clutch pedals

and the exhaust brake switch is in the ON position, the exhaust brake is

activated. The following conditions should exist if the brake is operating

properly:

²A slight change in the sound of the engine when the exhaust brake is

activated.

²Exhaust smoke appears normal.

²Engine temperature remains in the normal operating range.

²Road speed usually decreases when the exhaust brake is applied

during a descent, except when the vehicle is carrying a heavy load or

the grade is extremely steep. In these instances, you may need to

apply the service brakes occasionally.

²During a descent, the tachometer usually shows a drop in RPM

depending on the grade and the vehicle load.

²Do not expect a retarding effect similar to sudden hard application of

the service brakes. The exhaust brake retards the vehicle with a

smooth braking effect.

²Depending on the grade and vehicle load, you may or may not feel the

retarding force acting against your body when the brake is applied.

The brake's retarding force is actually preventing the vehicle from

going much faster.

Make sure the exhaust brake is turned off before shutting off the engine.

Installing an exhaust or auxiliary brake should never allow the

engine to exceed maximum governed speeds under any

conditions.

Air brake reservoir draining

Failure to drain air brake reservoirs can result in a reduction or

loss of braking ability due to fluid accumulation in the reservoir

and/or possible freeze-up during cold weather.

Driving

129