change time FORD F650 2006 11.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: F650, Model: FORD F650 2006 11.GPages: 272, PDF Size: 1.86 MB

Page 31 of 272

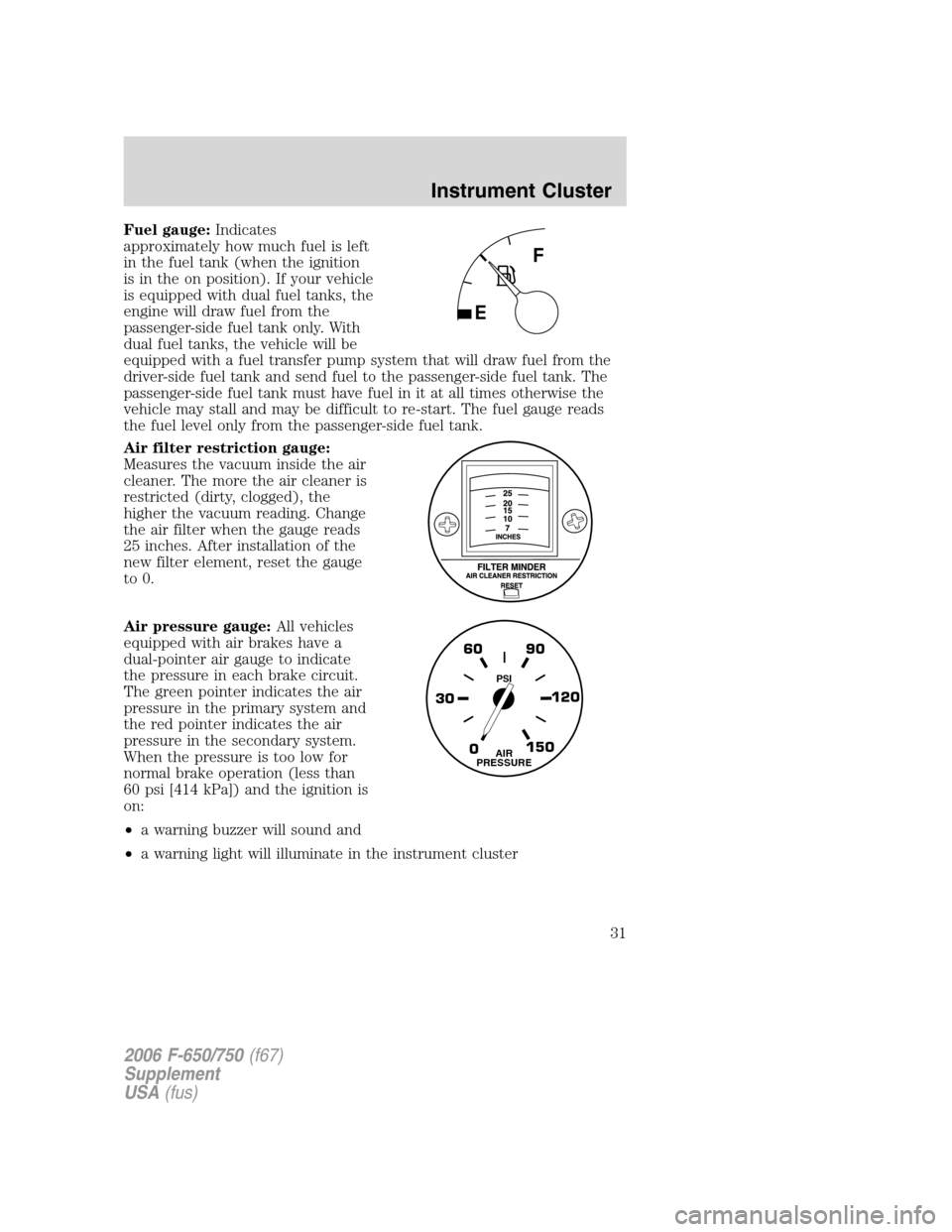

Fuel gauge:Indicates

approximately how much fuel is left

in the fuel tank (when the ignition

is in the on position). If your vehicle

is equipped with dual fuel tanks, the

engine will draw fuel from the

passenger-side fuel tank only. With

dual fuel tanks, the vehicle will be

equipped with a fuel transfer pump system that will draw fuel from the

driver-side fuel tank and send fuel to the passenger-side fuel tank. The

passenger-side fuel tank must have fuel in it at all times otherwise the

vehicle may stall and may be difficult to re-start. The fuel gauge reads

the fuel level only from the passenger-side fuel tank.

Air filter restriction gauge:

Measures the vacuum inside the air

cleaner. The more the air cleaner is

restricted (dirty, clogged), the

higher the vacuum reading. Change

the air filter when the gauge reads

25 inches. After installation of the

new filter element, reset the gauge

to 0.

Air pressure gauge:All vehicles

equipped with air brakes have a

dual-pointer air gauge to indicate

the pressure in each brake circuit.

The green pointer indicates the air

pressure in the primary system and

the red pointer indicates the air

pressure in the secondary system.

When the pressure is too low for

normal brake operation (less than

60 psi [414 kPa]) and the ignition is

on:

•a warning buzzer will sound and

•a warning light will illuminate in the instrument cluster

0 30120 90 60

150AIR

PRESSURE

PSI

2006 F-650/750(f67)

Supplement

USA(fus)

Instrument Cluster

31

Page 49 of 272

•Tighten very loose tapes by inserting a finger or pencil into the hole

and turning the hub.

•Remove loose labels before inserting tapes.

•Allow tapes which have been subjected to extreme heat, humidity or

cold to reach a moderate temperature before playing.

•Clean the cassette player head with a cassette cleaning cartridge after

10–12 hours of play to maintain good sound/operation.

Don’t:

•Expose tapes to direct sunlight, extreme humidity, heat or cold.

•Leave tapes in the cassette player for a long time when not being

played.

CD/CD player care

Do:

•Handle discs by their edges only. Never touch the playing surface.

•Inspect discs before playing. Clean only with an approved CD cleaner

and wipe from the center out.

Don’t:

•Expose discs to direct sunlight or heat sources for extended periods

of time.

•Insert more than one disc into each slot of the CD changer magazine.

•Clean using a circular motion.

CD units are designed to play commercially pressed 4.75 inch (12

cm) audio compact discs only. Due to technical incompatibility,

certain recordable and re-recordable compact discs may not

function correctly when used in Ford CD players. Irregular

shaped CDs, CDs with a scratch protection film attached, and CDs

with homemade paper (adhesive) labels should not be inserted

into the CD player. The label may peel and cause the CD to

become jammed. It is recommended that homemade CDs be

identified with permanent felt tip marker rather than adhesive

labels. Ball point pens may damage CDs. Please contact your

dealer for further information.

Audio system warranty and service

Refer to theWarranty Guidefor audio system warranty information. If

service is necessary, see your dealer or qualified technician.

2006 F-650/750(f67)

Supplement

USA(fus)

Entertainment Systems

49

Page 82 of 272

4. Turn on the parklamps/headlamps, turn off the parklamps/headlamps.

5. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled.

•After step 5 the safety belt warning light will be turned on for three

seconds.

6. Within seven seconds of the safety belt warning light turning off,

buckle then unbuckle the safety belt.

•This will disable BeltMinder if it is currently enabled, or enable

BeltMinder if it is currently disabled.

7. Confirmation of disabling BeltMinder is provided by the safety belt

warning light flashing four times per second for three seconds.

8. Confirmation of enabling BeltMinder is provided by:

•The safety belt warning light flashing four times per second for three

seconds.

•Followed by three seconds with the safety belt warning light off.

•Once again, the safety belt warning light will flash four times per

second for three seconds.

9. After receiving confirmation, the deactivation/activation procedure is

complete.

Safety belt extension assembly

If the safety belt is too short when fully extended, there is an eight inch

(20 cm) safety belt extension assembly that can be added (part number

611C22). This assembly can be obtained from your dealer at no cost.

Use only extensions manufactured by the same supplier as the safety

belt. Manufacturer identification is located at the end of the webbing on

the label. Also, use the safety belt extension only if the safety belt is too

short for you when fully extended.

Do not use extensions to change the fit of the shoulder belt

across the torso.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, tears or cuts. Replace if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

2006 F-650/750(f67)

Supplement

USA(fus)

Seating and Safety Restraints

82

Page 173 of 272

Air brakes - desiccant air dryer

Inspect for moisture in the air system by opening reservoirs, drain cocks

or valves and checking for presence of water. The presence of small

amounts of water due to condensation is normal and should not be

considered as an indication that the dryer is not functioning properly.

The desiccant cartridge should be replaced or rebuilt when it has been

determined that the desiccant is contaminated and does not have

adequate water absorption capacity. The desiccant change interval may

vary; it is generally recommended that the desiccant be replaced every

12 months (yearly). If experience has shown that extended or shortened

life has resulted for a particular installation, then the yearly interval can

be increased or decreased accordingly.

Hydraulic brakes - general inspection and adjustment

A regular schedule for periodic cleaning, lubrication, adjustment and

inspection should be established based on the type of vehicle operation.

It is difficult to predetermine an exact maintenance interval (time or

mileage), since vehicles will be used in a wide variety of applications and

conditions. If you are uncertain of the proper schedule and procedures

for your vehicle, contact your dealer.

Inspect the brake lining every maintenance interval. Establish inspection

intervals that provide for lining replacement before damage to the disc

occurs. Excessive lining wear may expose the backing plate to the disc

causing scoring of the disc faces.

This inspection should be performed by a qualified technician and must

be in accordance with instructions provided by the service manual.

Note:Hydraulic brake system are power assisted. Braking capabilities

will be greatly reduced without engine assist.

Hydraulic brakes - fluid level

Fluid level should be at the bottom edge of the ring on each reservoir fill

port. Do not fill the master cylinder to the top of the reservoir.

Note:If brake fluid requires attention to maintain a proper master

cylinder level, this is an indication of either severe operation (pad wear)

or fluid system leakage. A more frequent and thorough brake inspection

will be required.

Hydraulic brakes - fluid precautions

The HydroMax brake system consists of two completely separate

hydraulic systems operating with two different and incompatible fluids;

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

173

Page 179 of 272

•Change your engine oil and filter more frequently if your vehicle

operation includes extended periods of idling or low-speed operation,

driving for a long time in cold temperatures or short driving distances.

Diesel engines require specially formulated oil to resist contamination.

Proper quality oils also provide maximum efficiency of the crankcase

ventilation system which reduces air pollution.

For normal or severe service, use Motorcraft oil or an equivalent oil

conforming to Ford Specification WSS-M2C171–C or API Service

categories CI-4 or CI-4/SL. If CI-4 oil is not available, CH-4 is acceptable.

Diesel engine oils with improved fuel economy properties (energy

conserving) are currently available. If you use an energy conserving oil,

be sure it meets Ford specification WSS-M2C171–D or API service

category designation CI-4/SL and is of the proper viscosity grade for the

temperature range in which you expect to operate your vehicle. Some

energy conserving oils do not meet the requirements necessary for your

diesel engine.

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

179

Page 192 of 272

4. Lubricate clutch release wear pads at the two locations where they

contact the clutch release bearing using a brush or similar tool.

5. Install the inspection cover onto the clutch housing.

TRANSMISSION FLUID

Always dispose of used automotive fluids in a responsible manner.

Follow your community’s standards for disposing of these types of fluids.

Call your recycling center to find out about recycling automotive fluids.

Automatic transmission fluid

Refer to your Allison Automatic Transmission Operator’s Manual for

scheduled intervals for transmission fluid checks and changes. Your

transmission does not consume fluid. However, the fluid level should be

checked if the transmission is not working properly, i.e., if the

transmission slips or shifts slowly or if you notice some sign of fluid

leakage.

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is warmed up

(approximately 20 miles [30 km]). If your vehicle has been operated for

an extended period at high speeds, in city traffic or during hot weather,

the vehicle should be turned off for about 30 minutes to allow fluid to

cool before checking.

1. Drive the vehicle 20 miles (30 km) or until it reaches normal operating

temperature.

2. Park the vehicle on a level surface and engage the parking brake.

3. With the parking brake engaged and your foot on the brake pedal,

start the engine and move the gearshift lever through all of the gear

ranges. Allow sufficient time for each gear to engage.

4. Place the gearshift lever in N (Neutral) or P (Park) and leave the

engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lint free rag.

6. Install the dipstick making sure it is fully seated in the filler tube.

7. Remove the dipstick and inspect the fluid level.

If you must add transmission fluid, make sure the correct type of fluid is

being used. The type of fluid used is indicated in your Allison Automatic

Transmission Operator’s Manual.

Fluid levels above the safe range may result in transmission failure; an

overfill condition of transmission fluid may cause shift and/or

engagement concerns and/or possible damage.

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

192

Page 200 of 272

•If your vehicle is equipped with a Caterpillar engine,the fuel

system must be primed before attempting to restart the engine. Refer

to the engine operator’s manual for instructions on priming the engine.

•Use caution not to overheat and damage the starterby cranking

the engine for an excessive period of time. You may need to crank the

engine for a longer time than normal. If the engine fails to start in 30

seconds, turn the ignition to the OFF position and wait for two

minutes before cranking the engine again.

•Any remaining trapped air will self-purge from the fuel system once

the engine starts running.

•The engine may run rough and produce white smoke while air is in

the fuel system. This is normal and should stop after a short period of

time.

FUEL CONSUMPTION IMPROVEMENT MEASURES

There are two important factors you can control to improve fuel

economy: the mechanical condition of your vehicle and how you drive it.

A properly maintained vehicle will deliver better performance than a

neglected vehicle. Always follow your maintenance schedule to keep your

vehicle in top operating condition.

Also, your driving habits have a significant influence on use of fuel. By

following these suggestions, you can stretch your fuel use:

•Avoid changes in speed as much as possible.

•Anticipate changing traffic conditions. Sudden stops and fast

acceleration waste fuel.

•Avoid extensive idling.

•Do not drive with your foot resting on the brake pedal.

Essentials of good fuel economy

Measuring techniques

Your best source of information about actual fuel economy is you, the

driver. You must gather information as accurately and consistently as

possible. Fuel expense, frequency of fill-ups or fuel gauge readings are

NOT accurate as a measure of fuel economy. We do not recommend

taking fuel economy measurements during the first 1,000 miles (1,600

km) of driving (engine break-in period). You will get a more accurate

measurement after 2,000–3,000 miles (3,000–5,000 km).

The advertised fuel capacity of the fuel tank(s) on your vehicle is equal

to the rated refill capacity of the fuel tank(s) as listed inFuel tanksin

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

200

Page 205 of 272

Verify drive axle air suspension height and height control valve

performance at engine lube oil change intervals.

Periodically:

•Check condition of spring leaves for evidence of fatigue, bending or

breakage.

•Check condition of suspension mounting brackets and bushings.

•Check that torque rod mounting fasteners are tight.

•Check to be sure the suspension alignment is maintained at all time.

•Check U-bolts after the chassis has been operating under load for

1,000 miles (1,600 km) or six months, whichever comes first, the

U-Bolt nuts must be re-torqued. The U-Bolt nuts thereafter must be

re-torqued every 36,000 miles (58,000 km). The U-Bolt and nut

threads and seats should be cleaned and lubricated to ensure a “like

new” condition when re-torquing.

Note:See theU-Bolt Nut Torquechart later in this section.

Supporting your vehicle for service

When performing service repairs on your vehicle, first prepare the

vehicle by doing the following:

1. Park the vehicle on a level concrete floor.

2. Set the parking brake and block the wheels to prevent the vehicle

from moving.

3. Select a jack with a rated capacity sufficient to lift and hold up the

vehicle.

4. Raise the vehicle with the jack applied to the axle(s). DO NOT use the

bumper as a lifting point.

5. Support the vehicle with floor stands under the axle(s). If the axle or

the suspension are being serviced, support the vehicle with floor stands

under the frame side-members, preferably between the axles.

Do not use a jack when working under a vehicle. It may give

way, causing the vehicle to fall and result in property damage,

personal injury or death. Always use floor stands to support the

vehicle.

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

205

Page 239 of 272

Information Decal. The following services are to be performed at

scheduled intervals because they are considered essential to the life and

performance of your vehicle. Ford recommends that you perform

maintenance on all designated items to achieve best vehicle operation.

Maintenance intervals are provided for three types of general vehicle

environments: On-Highway, City and Severe Service. In all applications,

the actual interval is determined by monitoring kilometers (miles) and

time and when the engine is due for an oil change. When the engine oil

change is required prior to the truck lubrication interval, it is

recommended that the lubrication be performed at the same time in

order to reduce your vehicle’s time out of service.

•On-Highway:60,000 miles (96,000 km) or more annually.

•City:60,000 miles (96,000 km) or less annually.

•Severe Service:20,000 miles (32,000 km) or less annually on/off

road in dirty conditions.

Scheduled maintenance beyond 100,000 miles (160,000 km) should be

continued as before 100,000 miles (160,000 km).

AIR BRAKE ADJUSTMENT

Failure to maintain proper air brake adjustment can result in

reduction or loss of braking ability.

Air brake inspection and adjustment should be performed by a qualified

service technician in accordance with the instructions in the Ford Truck

Service Manual.

Cam brakes - automatic slack adjusters

Inspect standard air brakes equipped with automatic slack adjusters for

proper brake adjustment every four months or 20,000 miles (32,000 km)

whichever occurs first.

However, more frequent inspection is required if your vehicle’s brakes

are subjected to heavy use or adverse operating conditions such as:

•Frequent brake applications while fully loaded.

•Operation on hilly or mountainous terrain.

•Frequent operation on dirt, gravel or mud.

Some aftermarket brake linings also require more frequent inspections.

2006 F-650/750(f67)

Supplement

USA(fus)

Scheduled Maintenance Guide

239

Page 269 of 272

Headlamps ...................................53

aiming ........................................54

daytime running lights .............53

high beam .................................53

warning chime ..........................23

Heating ..................................50–51

heater only system ...................50

manual heating and air

conditioning system .................51

Hood ..........................................175

I

Ignition .........................................91

chime .........................................23

Infant seats (see Safety seats) ..86

Instrument panel

cleaning ...................................165

lighting up panel and

interior .......................................54

J

Jump-starting your vehicle ......151

K

Keys

key in ignition chime ...............23

positions of the ignition ...........91

L

Lamps

bulb replacement

specifications chart ..................55

cargo lamps ...............................54

daytime running light ...............53

headlamps .................................53

high beams ................................53instrument panel, dimming .....54

interior lamps ...........................55

replacing bulbs ...................55–57

Lane change indicator

(see Turn signal) ........................54

Lights, warning and indicator ....23

air suspension ...........................23

anti-lock brakes (ABS) ....23, 117

brake ..........................................23

charging system ........................23

safety belt .................................23

service engine soon ..................23

traction control off ...................23

turn signal indicator .................23

Lubricant specifications ...........218

M

Manual transmission .................125

lubricant specifications ..........218

Mirrors .........................................61

fold away ...................................63

heated ........................................62

side view mirrors (power) .......61

O

Odometer .....................................28

P

Paint chips, repairing ...............163

Parking brake ....................100, 106

warning light .............................23

Power door locks ........................67

Power mirrors .............................61

Power point .................................59

Power steering ..........................189

fluid, checking and adding ....189

2006 F-650/750(f67)

Supplement

USA(fus)

Index

269