ABS FORD F650 2013 12.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2013, Model line: F650, Model: FORD F650 2013 12.GPages: 378, PDF Size: 3.82 MB

Page 197 of 378

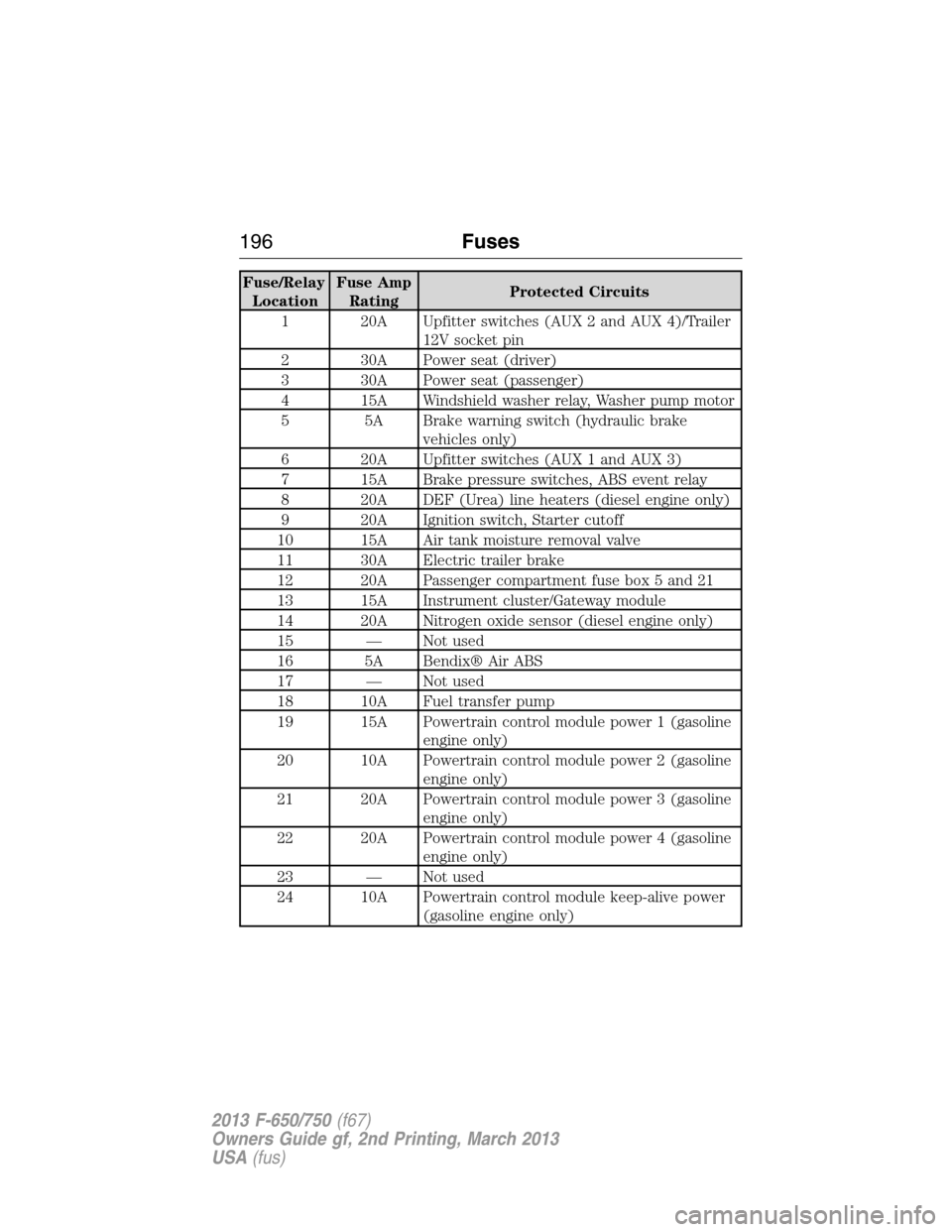

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

1 20A Upfitter switches (AUX 2 and AUX 4)/Trailer

12V socket pin

2 30A Power seat (driver)

3 30A Power seat (passenger)

4 15A Windshield washer relay, Washer pump motor

5 5A Brake warning switch (hydraulic brake

vehicles only)

6 20A Upfitter switches (AUX 1 and AUX 3)

7 15A Brake pressure switches, ABS event relay

8 20A DEF (Urea) line heaters (diesel engine only)

9 20A Ignition switch, Starter cutoff

10 15A Air tank moisture removal valve

11 30A Electric trailer brake

12 20A Passenger compartment fuse box 5 and 21

13 15A Instrument cluster/Gateway module

14 20A Nitrogen oxide sensor (diesel engine only)

15 — Not used

16 5A Bendix® Air ABS

17 — Not used

18 10A Fuel transfer pump

19 15A Powertrain control module power 1 (gasoline

engine only)

20 10A Powertrain control module power 2 (gasoline

engine only)

21 20A Powertrain control module power 3 (gasoline

engine only)

22 20A Powertrain control module power 4 (gasoline

engine only)

23 — Not used

24 10A Powertrain control module keep-alive power

(gasoline engine only)

196Fuses

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 198 of 378

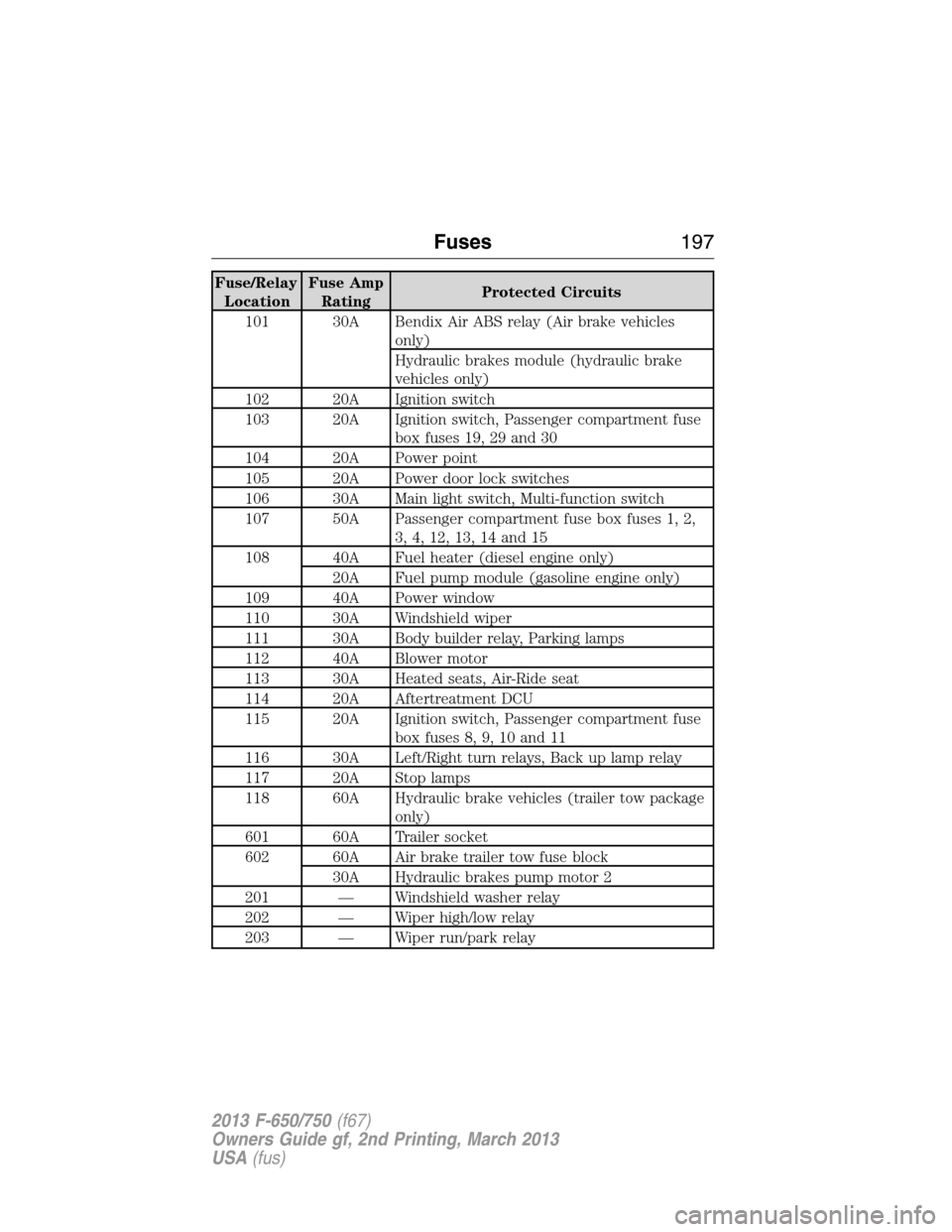

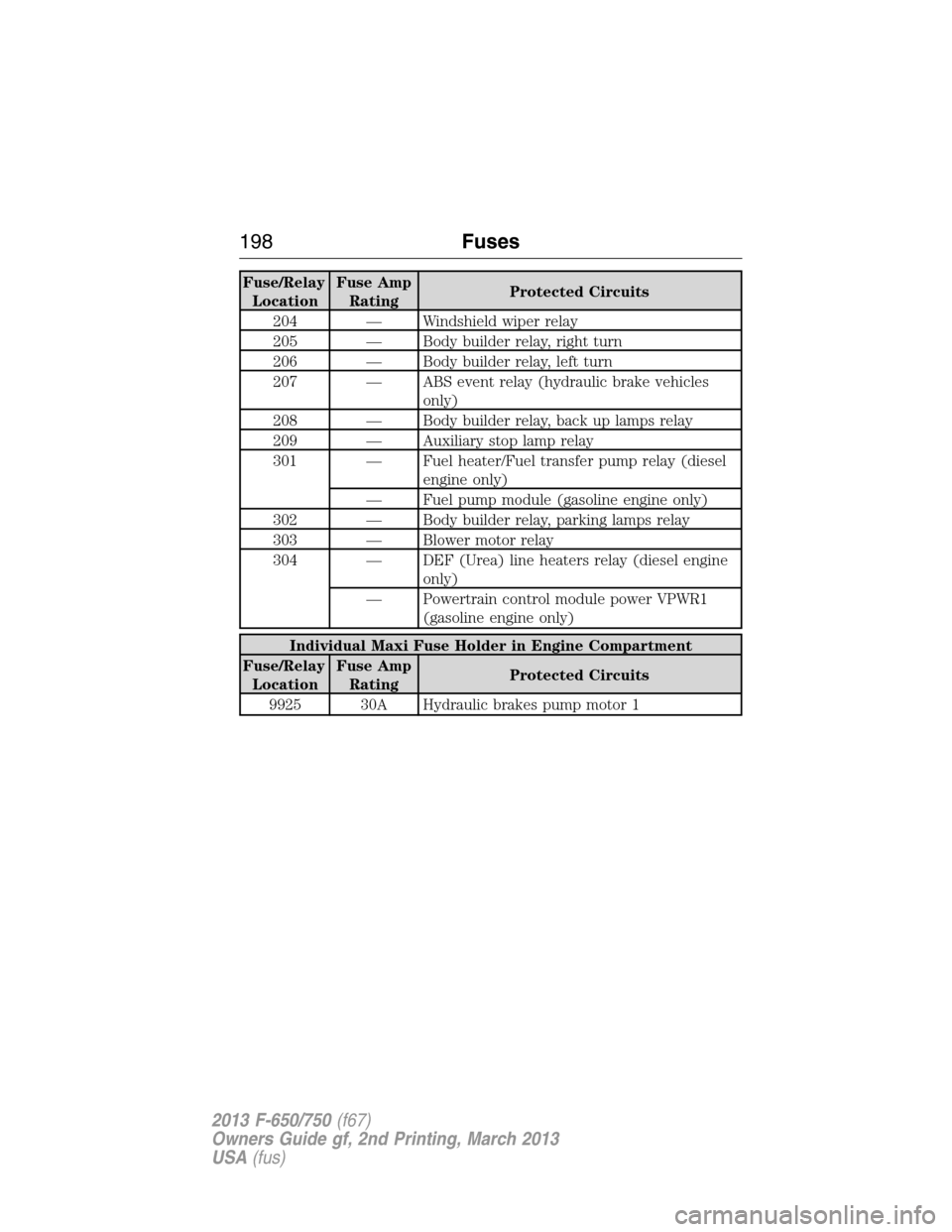

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

101 30A Bendix Air ABS relay (Air brake vehicles

only)

Hydraulic brakes module (hydraulic brake

vehicles only)

102 20A Ignition switch

103 20A Ignition switch, Passenger compartment fuse

box fuses 19, 29 and 30

104 20A Power point

105 20A Power door lock switches

106 30A Main light switch, Multi-function switch

107 50A Passenger compartment fuse box fuses 1, 2,

3, 4, 12, 13, 14 and 15

108 40A Fuel heater (diesel engine only)

20A Fuel pump module (gasoline engine only)

109 40A Power window

110 30A Windshield wiper

111 30A Body builder relay, Parking lamps

112 40A Blower motor

113 30A Heated seats, Air-Ride seat

114 20A Aftertreatment DCU

115 20A Ignition switch, Passenger compartment fuse

box fuses 8, 9, 10 and 11

116 30A Left/Right turn relays, Back up lamp relay

117 20A Stop lamps

118 60A Hydraulic brake vehicles (trailer tow package

only)

601 60A Trailer socket

602 60A Air brake trailer tow fuse block

30A Hydraulic brakes pump motor 2

201 — Windshield washer relay

202 — Wiper high/low relay

203 — Wiper run/park relay

Fuses197

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 199 of 378

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

204 — Windshield wiper relay

205 — Body builder relay, right turn

206 — Body builder relay, left turn

207 — ABS event relay (hydraulic brake vehicles

only)

208 — Body builder relay, back up lamps relay

209 — Auxiliary stop lamp relay

301 — Fuel heater/Fuel transfer pump relay (diesel

engine only)

— Fuel pump module (gasoline engine only)

302 — Body builder relay, parking lamps relay

303 — Blower motor relay

304 — DEF (Urea) line heaters relay (diesel engine

only)

— Powertrain control module power VPWR1

(gasoline engine only)

Individual Maxi Fuse Holder in Engine Compartment

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

9925 30A Hydraulic brakes pump motor 1

198Fuses

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

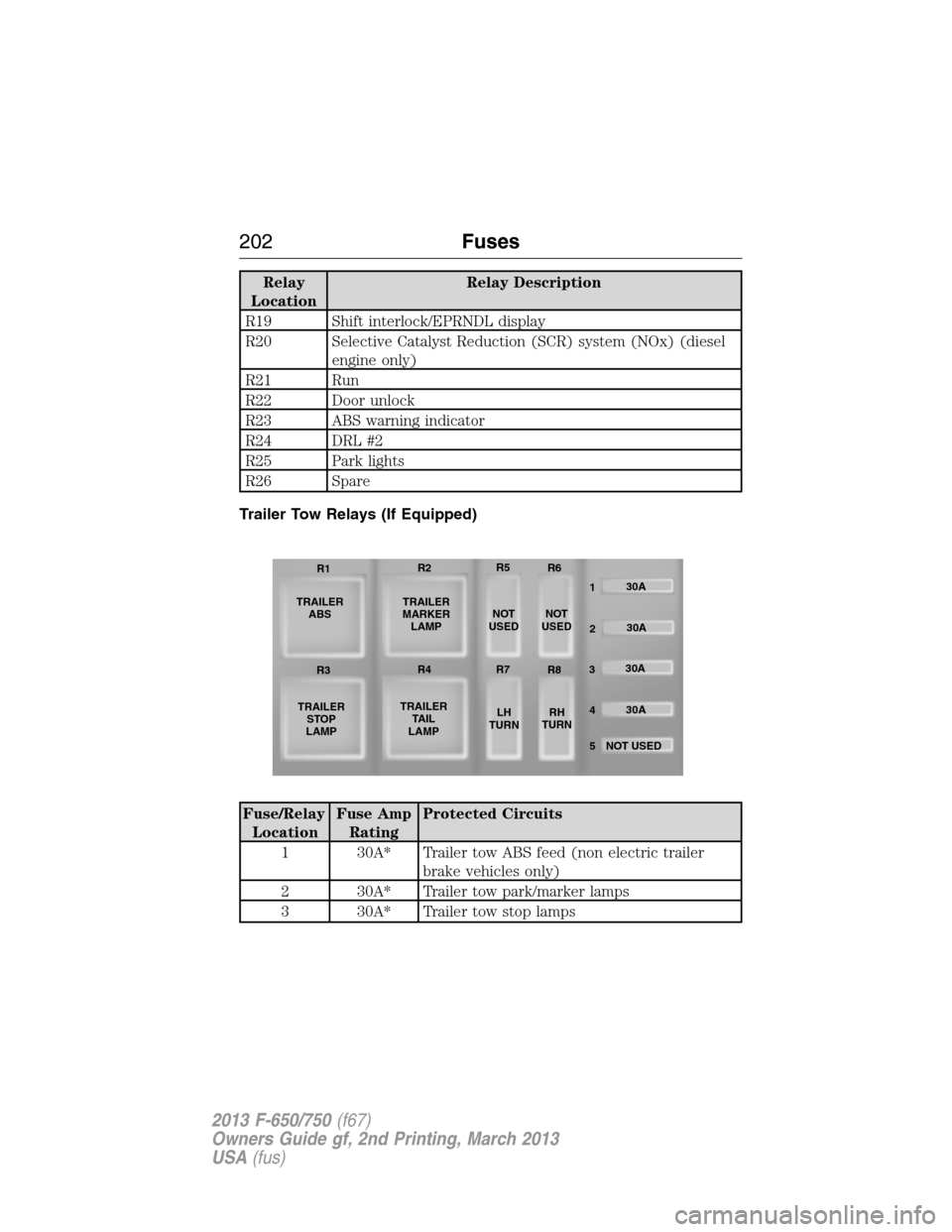

Page 203 of 378

Relay

LocationRelay Description

R19 Shift interlock/EPRNDL display

R20 Selective Catalyst Reduction (SCR) system (NOx) (diesel

engine only)

R21 Run

R22 Door unlock

R23 ABS warning indicator

R24 DRL #2

R25 Park lights

R26 Spare

Trailer Tow Relays (If Equipped)

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

1 30A* Trailer tow ABS feed (non electric trailer

brake vehicles only)

2 30A* Trailer tow park/marker lamps

3 30A* Trailer tow stop lamps

TRAILER

ABS

TRAILER

STOP

LAMPTRAILER

MARKER

LAMP

TRAILER

TA I L

LAMPNOT

USEDNOT

USED

LH

TURNRH

TURN30A

30A

30A

30A

NOT USED

5 4 32 1 R1R2R5

R6

R3R4R7

R8

202Fuses

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 204 of 378

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

4 30A* Trailer tow turn/stop lamps (combined)

Trailer tow turn lamps (separate)

5 — Not used

R1 — Trailer tow ABS relay (non electric trailer

brake vehicles only)

R2 — Trailer tow marker lamp relay

R3 — Trailer tow stop lamp relay

R4 — Trailer tow tail lamp relay

R5 — Not used

R6 — Not used

R7 — Trailer tow left turn lamp relay

R8 — Trailer tow right turn lamp relay

*Maxi fuse

Inline Fuses

Your vehicle may have several inline fuses located in, or on, the battery

cables located in the battery box (depending on application).

•All vehicles equipped with an Allison transmission have a 10 amp fuse

located in the clean power cables located in the battery box.

•All vehicles have a 30 amp fuse located in the clean power cables

located in the battery box.

•All vehicles equipped with an Eaton transmission have a 30 amp fuse

located in the clean power cables located in the battery box.

•All vehicles equipped with hydraulic brakes have a 40 amp fuse

located in the clean power cables located in the battery box. In

addition, another 30 amp fuse is located in a fuse holder just above

the power distribution center located in the vehicle’s engine

compartment.

Fuses203

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 206 of 378

WARNING:The use of inferior parts can adversely affect the

quality and reliability of your vehicle which, in turn, can result in

property damage, personal injury or death.

To avoid damage to the vehicle’s electrical components prior to electric

welding:

•disconnect both battery cables.

•attach the welder ground cable as close as possible to the part being

welded.

•it is recommended that the component be temporarily removed if

welding close to an electrical component.

Follow the checks and services in theScheduled Maintenancechapter.

Have your dealer or service center inspect your vehicle at least once a

year. Remember that regular maintenance and inspections usually

prevent serious problems from developing later.

If the owner or operator of the vehicle is a skilled technician and intends

on performing the vehicle maintenance and service, he is strongly urged

to purchase a service manual.

Electrical System

Periodically inspect electrical connectors on the outside of the cab and

on the engine and frame for corrosion and tightness. Exposed terminals,

such as the fuel sender, cranking motor, alternator and feed-through

studs, should be cleaned and re-coated with a lubricant sealing grease

such as Motorcraft® Silicone Brake Caliper Grease and Dielectic

Compound XG-3, or equivalent. This should include the ground cable

connector for batteries, engine and cab as well as the jump starting stud.

Accessory Feed Connections

Vehicle electrical systems are complex and often include powertrain

components, such as engine and transmission controls, instrument

panels, ABS, etc. While most systems operate on battery voltage

(12 volts), some systems can be as high as 90 volts or as low as five

volts. See theElectrical Circuit Diagram Manuals,available from your

vehicle’s manufacturer, to make sure that any additional body lights and

accessories are connected to circuits that are both appropriate and not

overloaded. No modification should be made to any vehicle control

system without first contacting your dealer.

Maintenance205

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 211 of 378

Some parts such as air brake chamber diaphragm, air compressor and air

cleaner should be inspected periodically and replaced if considered

unserviceable.

Air dryer:Climactic conditions affect performance of desiccant or

after-cooler type air dryers. Maintenance schedules must be established

for each specific operation.

The use of an air dryer on a vehicle does not eliminate the need to

periodically drain the air reservoirs.

Desiccant air dryer:Inspect for moisture in the air system by opening

reservoirs, draincocks or valves and checking for presence of water. The

presence of small amounts of water due to condensation is normal and

should not be considered as an indication that the dryer is not

functioning properly.

The desiccant cartridge should be replaced or rebuilt when it has been

determined that the desiccant is contaminated and does not have

adequate water absorption capacity. The desiccant change interval may

vary. It is generally recommended that the desiccant be replaced every

12 months (yearly). If experience has shown that extended or shortened

life has resulted for a particular installation, then the yearly interval can

be increased or decreased accordingly.

Draining the air brake reservoir:

Completely drain all the air brake

reservoirs daily by opening the

draincock at the ends of the tanks

(Where accessible. Pull-chains are

used when the drains are undercab

or otherwise inaccessible). Close the

draincock after draining. Air tanks

equipped with automatic moisture

ejector valves may also be drained

manually as required to maintain a

dry air system. Contact your dealer if you are unsure of the air reservoir

locations or the draining procedure.

WARNING:Failure to drain air brake reservoirs can result in a

reduction or loss of braking ability due to fluid accumulation in

the reservoir and/or possible freeze-up during cold weather.

210Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 239 of 378

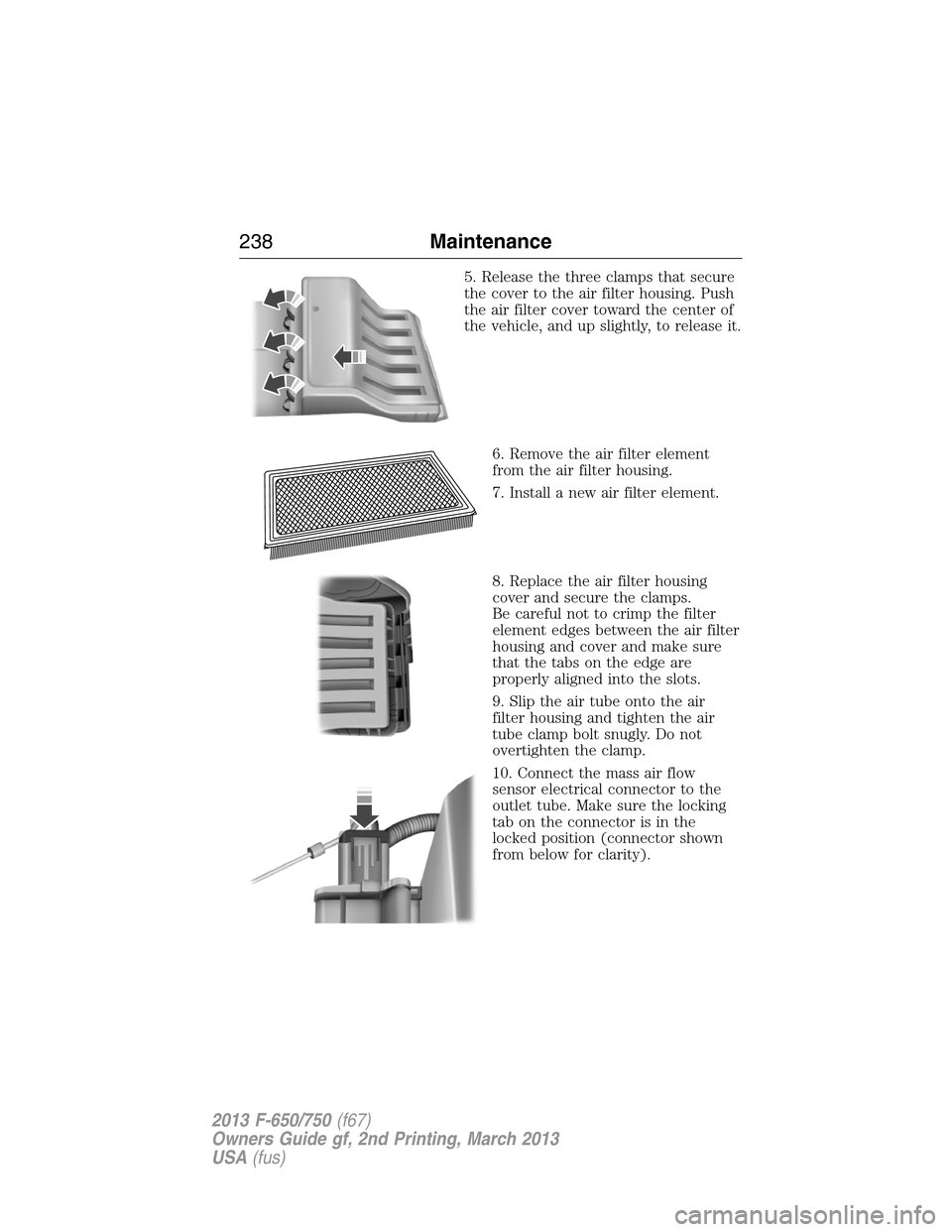

5. Release the three clamps that secure

the cover to the air filter housing. Push

the air filter cover toward the center of

the vehicle, and up slightly, to release it.

6. Remove the air filter element

from the air filter housing.

7. Install a new air filter element.

8. Replace the air filter housing

cover and secure the clamps.

Be careful not to crimp the filter

element edges between the air filter

housing and cover and make sure

that the tabs on the edge are

properly aligned into the slots.

9. Slip the air tube onto the air

filter housing and tighten the air

tube clamp bolt snugly. Do not

overtighten the clamp.

10. Connect the mass air flow

sensor electrical connector to the

outlet tube. Make sure the locking

tab on the connector is in the

locked position (connector shown

from below for clarity).

238Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 259 of 378

Rotating tires from one wheel position to another is a way often used to

even out many types of irregular wear or to avoid it altogether. Some of

the more effective tire rotation programs are:

•Steer tires that have developed some type of irregular wear pattern

can be rotated to drive axles if rib tires are being used on all wheel

positions. Applying steer tires to a drive position often cleans them

and they can be moved back to the steer axles or run out to re-tread

stage on the rear axle.

•Another rotation possibility for fleets with rib tires in all wheel

positions is to break in the new steer tires in the drive axle positions,

then move them to steer axles. This wears away tread rubber

relatively quickly in the early life of a tire when it is most likely to

develop an unusual wear pattern.

•Drive axle tires may be placed on the other end of the same axle so

that direction of rotation is reversed. This is often helpful if a heel

and toe or alternate lug wear pattern has developed.

Irregular wear can be minimized by:

•Using the right inflation pressure for the load being carried.

•Maintaining proper front wheel alignment, especially toe-in, to

specifications.

•Maintaining proper tire and wheel balance.

•Maintaining shock absorbers and suspension components.

Use of Tire Chains

See the chain manufacturer’s recommendation for correct tire chain

usage, installation and removal.

WHEELS

General Information

Note:Remember to replace the wheel air valves when the road tires are

replaced at the end of their useful lives.

Wheel bearings should be inspected, lubricated and adjusted at regular

intervals. This is especially important if operating in deep sand, mud or

water. See theCapacities and Specificationschapter.

Mount wheel balance weights on the dome-side of the wheel only. Failure

to do so may result in loss of wheel weight or damage to brakes or

wheels.

258Wheels and Tires

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 287 of 378

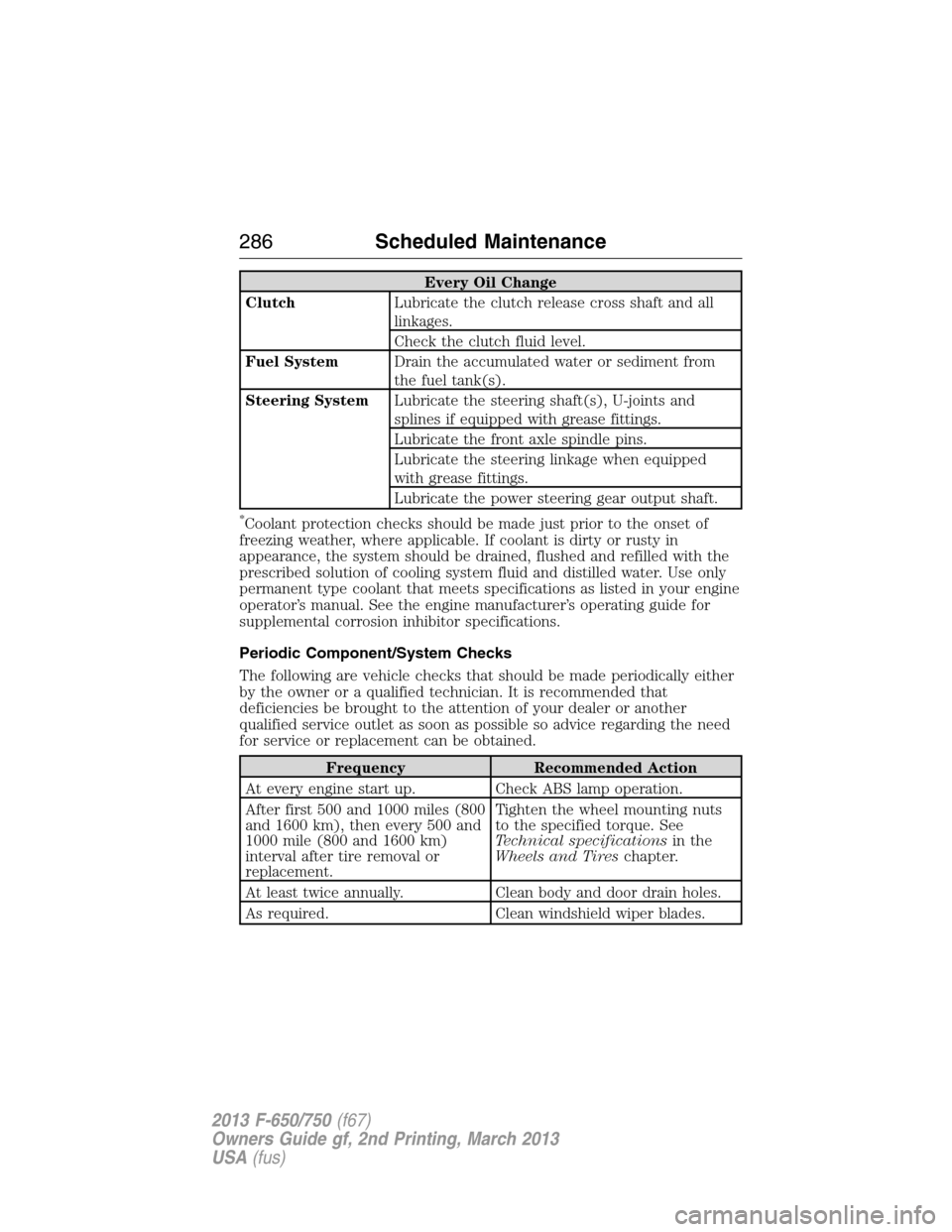

Every Oil Change

ClutchLubricate the clutch release cross shaft and all

linkages.

Check the clutch fluid level.

Fuel SystemDrain the accumulated water or sediment from

the fuel tank(s).

Steering SystemLubricate the steering shaft(s), U-joints and

splines if equipped with grease fittings.

Lubricate the front axle spindle pins.

Lubricate the steering linkage when equipped

with grease fittings.

Lubricate the power steering gear output shaft.

*Coolant protection checks should be made just prior to the onset of

freezing weather, where applicable. If coolant is dirty or rusty in

appearance, the system should be drained, flushed and refilled with the

prescribed solution of cooling system fluid and distilled water. Use only

permanent type coolant that meets specifications as listed in your engine

operator’s manual. See the engine manufacturer’s operating guide for

supplemental corrosion inhibitor specifications.

Periodic Component/System Checks

The following are vehicle checks that should be made periodically either

by the owner or a qualified technician. It is recommended that

deficiencies be brought to the attention of your dealer or another

qualified service outlet as soon as possible so advice regarding the need

for service or replacement can be obtained.

Frequency Recommended Action

At every engine start up. Check ABS lamp operation.

After first 500 and 1000 miles (800

and 1600 km), then every 500 and

1000 mile (800 and 1600 km)

interval after tire removal or

replacement.Tighten the wheel mounting nuts

to the specified torque. See

Technical specificationsin the

Wheels and Tireschapter.

At least twice annually. Clean body and door drain holes.

As required. Clean windshield wiper blades.

286Scheduled Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)