brake fluid FORD F650 2013 12.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2013, Model line: F650, Model: FORD F650 2013 12.GPages: 378, PDF Size: 3.82 MB

Page 145 of 378

The differential can be locked or unlocked when the vehicle is moving at

a constant speed of under 25 mph (40 km/h) and while the wheels are

not slipping. The differential must not be locked when the vehicle is

traveling down steep grades and traction is minimal.

The differential lock and differential lock light automatically disengage at

speeds above 25 mph (40 km/h). The differential lock remains off until

either the vehicle is restarted or the differential lock switch is turned off

then back on.

Turn the engine off and raise all drive wheels of the locker differential

axle in order to prevent the vehicle from moving when servicing the

wheels, tires or brakes. Axles equipped with a NoSPIN Detroit Locker

differential deliver power to both wheels even when only one wheel is on

the ground.

WARNING:Failure to raise all drive wheels with this type of

differential could cause the vehicle to move unexpectedly,

resulting in property damage, personal injury or death.

Care should be taken to avoid sudden accelerations when both drive

wheels are on a slippery surface.

WARNING:Sudden accelerations on slippery surfaces could

cause the wheels to spin, the vehicle to turn sideways on a

crowned road surface or in a turn, possibly resulting in loss of vehicle

control and personal injury.

Fluid Temperature

Axle operating temperatures normally do not exceed 100°F (38°C).

If the operating temperature exceeds 230°F (110°C), the rate of axle

lubrication oxidation increases and shortens the life of the lubricant and

seals, requiring axle lubrication changes to become more frequent to

preserve the axle. Extreme Pressure (EP) lubricants should not be run

consistently above 230°F (110°C).

Axle Conversions

WARNING:When operating a loaded vehicle, the driver must

keep all adjustable axles on the ground at all times, supporting

their share of the vehicle’s load. Failure to do so can overload other

axles, tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

144Transmission

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 149 of 378

Anti-lock Brake System (ABS)

This system helps you maintain steering control during emergency stops

by keeping the brakes from locking.

The ABS lamp momentarily illuminates when the ignition is

turned on. If the light does not illuminate during start-up,

remains on or flashes, the ABS may be disabled and may need

to be serviced.

If the ABS is disabled, normal braking is still effective. If the

brake warning lamp illuminates, have your brake system

serviced immediately.

If a PLC trailer is connected when the ignition is switched on,

the trailer ABS light also illuminates. If the light fails to

illuminate, remains on after the vehicle is started or continues

to flash, have the system serviced immediately.

FULL POWER BRAKE SYSTEM

WARNING:If the red BRAKE warning lamp in the instrument

cluster remains illuminated after engine start up, this indicates a

system failure in the Full Power Brake System. Stop the vehicle safely

as soon as possible and seek service immediately.

This system incorporates standard braking, an anti-lock braking system

(ABS) and optional Power Park Brake into one fully-integrated hydraulic

brake system. With the Full Power Brake System, braking energy is

stored, similar to an air brake system, resulting in faster response times

and shorter stopping distances. This is accomplished using motor and

pump assemblies that pressurize the system by pumping brake fluid into

accumulators. This is similar to the air compressor of an air brake system

pressurizing the air tanks. The system includes a master cylinder that

provides the normal pedal feel and transfers the pedal force, via brake

fluid, to the main components of the system.

Note:The motor and pumps run momentarily with the ignition switch in

the on or run position, or in the off position with the brake pedal

pressed.

Note:During normal driving, the pump and motors may be heard

replenishing the accumulators. This is a normal function of the system.

148Brakes

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 211 of 378

Some parts such as air brake chamber diaphragm, air compressor and air

cleaner should be inspected periodically and replaced if considered

unserviceable.

Air dryer:Climactic conditions affect performance of desiccant or

after-cooler type air dryers. Maintenance schedules must be established

for each specific operation.

The use of an air dryer on a vehicle does not eliminate the need to

periodically drain the air reservoirs.

Desiccant air dryer:Inspect for moisture in the air system by opening

reservoirs, draincocks or valves and checking for presence of water. The

presence of small amounts of water due to condensation is normal and

should not be considered as an indication that the dryer is not

functioning properly.

The desiccant cartridge should be replaced or rebuilt when it has been

determined that the desiccant is contaminated and does not have

adequate water absorption capacity. The desiccant change interval may

vary. It is generally recommended that the desiccant be replaced every

12 months (yearly). If experience has shown that extended or shortened

life has resulted for a particular installation, then the yearly interval can

be increased or decreased accordingly.

Draining the air brake reservoir:

Completely drain all the air brake

reservoirs daily by opening the

draincock at the ends of the tanks

(Where accessible. Pull-chains are

used when the drains are undercab

or otherwise inaccessible). Close the

draincock after draining. Air tanks

equipped with automatic moisture

ejector valves may also be drained

manually as required to maintain a

dry air system. Contact your dealer if you are unsure of the air reservoir

locations or the draining procedure.

WARNING:Failure to drain air brake reservoirs can result in a

reduction or loss of braking ability due to fluid accumulation in

the reservoir and/or possible freeze-up during cold weather.

210Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 212 of 378

Hydraulic Brakes

Establish a regular schedule for periodic cleaning, lubrication and

adjustment inspection based on vehicle use. Exact maintenance intervals

are difficult to predetermine since vehicles are used in a wide variety of

applications and conditions. If you are uncertain of the proper schedule

for your vehicle, contact your dealer.

Regular inspections should include:

•checking the brake lining (every service interval). Establish

inspection intervals that provide for lining replacement before damage

to the disc occurs. Excessive lining wear may expose the backing

plate to the disc causing scoring of the disc faces. This inspection

should be performed by a qualified technician and must be in

accordance with instructions provided by the service manual.

Hydraulic brake systems are power-assisted. Braking capabilities are

greatly reduced without engine assist.

•proper fluid level. The level should be at the bottom edge of the ring

on each reservoir fill port. Do not fill the master cylinder to the top of

the reservoir. If fluid level requires attention to maintain a proper

master cylinder level, this is an indication of either severe operation

(pad wear) or fluid leakage. A more frequent and thorough brake

inspection is required.

•brake lines, hoses and fittings. Repair or replace brake line tubes,

hoses or fittings as required. Inspect these components every

4000 miles (6000 kilometers):

•Lines for kinks, dents, corrosion or rupture.

•Hoses for abrasions, kinks, soft spots or rupture, collapse, cracks,

twists or loose frame supports. When replacing a hose, be sure

there is adequate clearance to the hose to avoid an abrasion to the

new hose.

•All connections for leaks.

Driveline Parking Brake

WARNING:Use wheel chocks and exercise caution when

inspecting under the vehicle. A vehicle roll-away could result in

property damage, personal injury or death.

Parking brake adjustment should only be performed by a qualified

technician, and in accordance with the instructions in the service

manual.

Maintenance211

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 224 of 378

TRANSMISSION FLUID CHECK

Allison Automatic Transmissions

See yourAllison Automatic Transmission Operator’s Manualfor

scheduled transmission fluid checks and change intervals. Your

transmission does not consume fluid. However, the fluid level should be

checked if the transmission is not working properly, i.e., if the

transmission slips or shifts slowly or if you notice some sign of fluid

leakage.

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 kilometers]). Verify that the

transmission fluid temperature gauge, located on the instrument cluster,

is within the normal range.

1. Drive the vehicle 20 miles (30 kilometers) or until it reaches normal

operating temperature.

2. Park the vehicle on a level surface and engage the parking brake.

3. With the engine running, parking brake engaged and your foot on the

brake pedal, move the gearshift lever through all of the gear ranges.

Allow sufficient time for each gear to engage.

4. Latch the gearshift lever in positionNorPand leave the engine

running.

5. Remove the dipstick, wiping it clean with a clean, dry, lint-free rag.

6. Install the dipstick making sure it is fully seated in the filler tube.

7. Remove the dipstick and inspect the fluid level. The fluid should be

in the designated area for normal operating temperature or ambient

temperature.

If you must add transmission fluid, see yourAllison Automatic

Transmission Operator’s Manualfor the correct fluid type.Use of a

non-approved automatic transmission fluid may cause internal

transmission component damage.

Fluid levels above the safe range may result in transmission failure. An

overfill condition of transmission fluid may cause shift or engagement

concerns or possible damage.

TorqShift® Automatic Transmission

See theScheduled Maintenancechapter for scheduled intervals for

fluid checks and changes. Your transmission does not consume fluid.

However, the fluid level should be checked if the transmission is not

working properly, i.e., if the transmission slips or shifts slowly or if you

notice some sign of fluid leakage.

Maintenance223

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 225 of 378

![FORD F650 2013 12.G User Guide Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 kilometers]). Verify that FORD F650 2013 12.G User Guide Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 kilometers]). Verify that](/img/11/5079/w960_5079-224.png)

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 kilometers]). Verify that the

transmission fluid temperature gauge, located on the instrument cluster,

is within the normal range.

1. Drive the vehicle 20 miles (30 kilometers) or until it reaches normal

operating temperature.

2. Park the vehicle on a level surface and engage the parking brake.

3. With the engine running, parking brake engaged and your foot on the

brake pedal, move the gearshift lever through all of the gear ranges.

Allow sufficient time for each gear to engage.

4. Latch the gearshift lever in positionPand leave the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry, lint-free rag.

6. Install the dipstick making sure it is fully seated in the filler tube.

7. Remove the dipstick and inspect the fluid level. The fluid should be

in the designated area for normal operating temperature or ambient

temperature.

Low Fluid Level

Do not drive the vehicle if there is

no indication of fluid on the dipstick

and the ambient temperature is

above 50°F (10°C).

Correct Fluid Level

The fluid should be checked at

normal operating temperature

196°F-216°F (91°C-102°C) on a

level surface. The normal operating

temperature can be reached after approximately 20 miles (30 kilometers)

of driving.

224Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 227 of 378

Checking Fluid Level

1. Park the vehicle on level ground.

2. Set the parking brake, shift into first gear and turn the engine off.

3. Clean any dirt from around the filler plug.

4. Remove the filler plug and inspect the fluid level. The fluid level

should be at the bottom of the filler plug opening.

5. Add fluid, if necessary, through the filler plug opening.

6. Clean and install the filler plug securely.

Changing Fluid

Drain and refill your transmission fluid while it is warm.

1. Park the vehicle on level ground.

2. Set the parking brake, shift into first gear and turn the engine off.

3. Clean any dirt from around the filler and drain plugs.

4. Remove the filler and drain plugs and drain the fluid into a suitable

container. Dispose of all used automotive fluids in a responsible

manner following your local authorized standards.

5. Clean and install the drain plug securely.

6. Add fluid through the filler plug opening.

7. Clean and install the filler plug securely.

DRIVESHAFT

Check the universal joints for any evidence of wear or looseness at the

regular lubrication interval. Stop the vehicle immediately, should

driveshaft vibrations occur, to avoid possible hazardous consequences or

damage to other components.

REAR AXLE FLUID

Your rear axle may be filled with an optional synthetic lubricant which

allows the use of extended service intervals. A tag on the filler plug

identifies the use of the synthetic lubricant.

Only use a lubricant that meets manufacturer specifications. See the

Capacities and Specificationschapter.Use of a non-approved rear

axle lubricant may cause internal axle component damage.

226Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 228 of 378

Checking the Fluid Level

See theScheduled Maintenancechapter for rear axle lubricant level

check intervals.

1. Park the vehicle on level ground.

2. Set the parking brake and shift into positionNorP(automatic

transmission), or first gear (manual transmission). Turn the engine

off.

3. Clean any dirt from around the rear axle filler plug.

4. Remove the filler plug and inspect the lubricant level. It should be at

the bottom of the filler plug opening.

5. Add lubricant, if necessary, through the filler plug opening.

6. Clean and install the filler plug securely.

Changing the Fluid

See theScheduled Maintenancechapter for rear axle lubricant change

intervals.

1. Drain the rear axle while the lubricant is warm.

2. Park the vehicle on level ground.

3. Set the parking brake and shift into positionNorP(automatic

transmission), or first gear (manual transmission). Turn the engine

off.

4. Clean any dirt from around the rear axle filler and drain plugs.

5. Remove the filler and drain plugs. Drain the lubricant into a suitable

container. Dispose of all used automotive fluids in a responsible

manner following your local authorized standards.

6. Clean and install the drain plug securely.

7. Add lubricant through the filler plug opening.

8. Clean and install the filler plug securely.

Maintenance227

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 230 of 378

BRAKE FLUID CHECK

WARNING:Brake fluid is toxic. If brake fluid contacts the eyes,

flush eyes with running water for 15 minutes. Seek medical

attention if irritation persists. If taken internally, drink water and induce

vomiting. Seek medical attention immediately.

WARNING:If you use a brake fluid that is not DOT 3, you will

cause permanent damage to your brakes.

WARNING:Do not let the reservoir for the master cylinder run

dry. This may cause the brakes to fail.

Check and refill the Full Power brake fluid reservoir using the following

procedure. See theScheduled Maintenancechapter for the service

interval.

1. Clean the reservoir caps before removal to prevent dirt or water from

entering the reservoir.

2. Visually inspect the fluid level. It should be at the bottom of the fill

ports.

3. Add brake fluid, if necessary, from a clean, unopened container until

the level reaches the bottom of the fill ports. Do not fill above this

line.

Only use a DOT 3 brake fluid certified to meet manufacturer

specifications. See theCapacities and Specificationschapter.

CLUTCH FLUID AND LINKAGE

Clutch Fluid

WARNING:Carefully read cautionary information on product

label. For MEDICAL EMERGENCY INFORMATION, contact a

physician or Poison Control Center immediately; on Ford-Motorcraft®

products call: 1-800-959-3673 (FORD). Failure to follow these

instructions may result in personal injury.

Use only a DOT 3 brake fluid designed to meet manufacturer

specifications. See theCapacities and Specificationschapter.

During normal operation, the fluid level in the clutch reservoir should

remain constant. If the fluid level drops, fill to the step in the reservoir.

Maintenance229

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 231 of 378

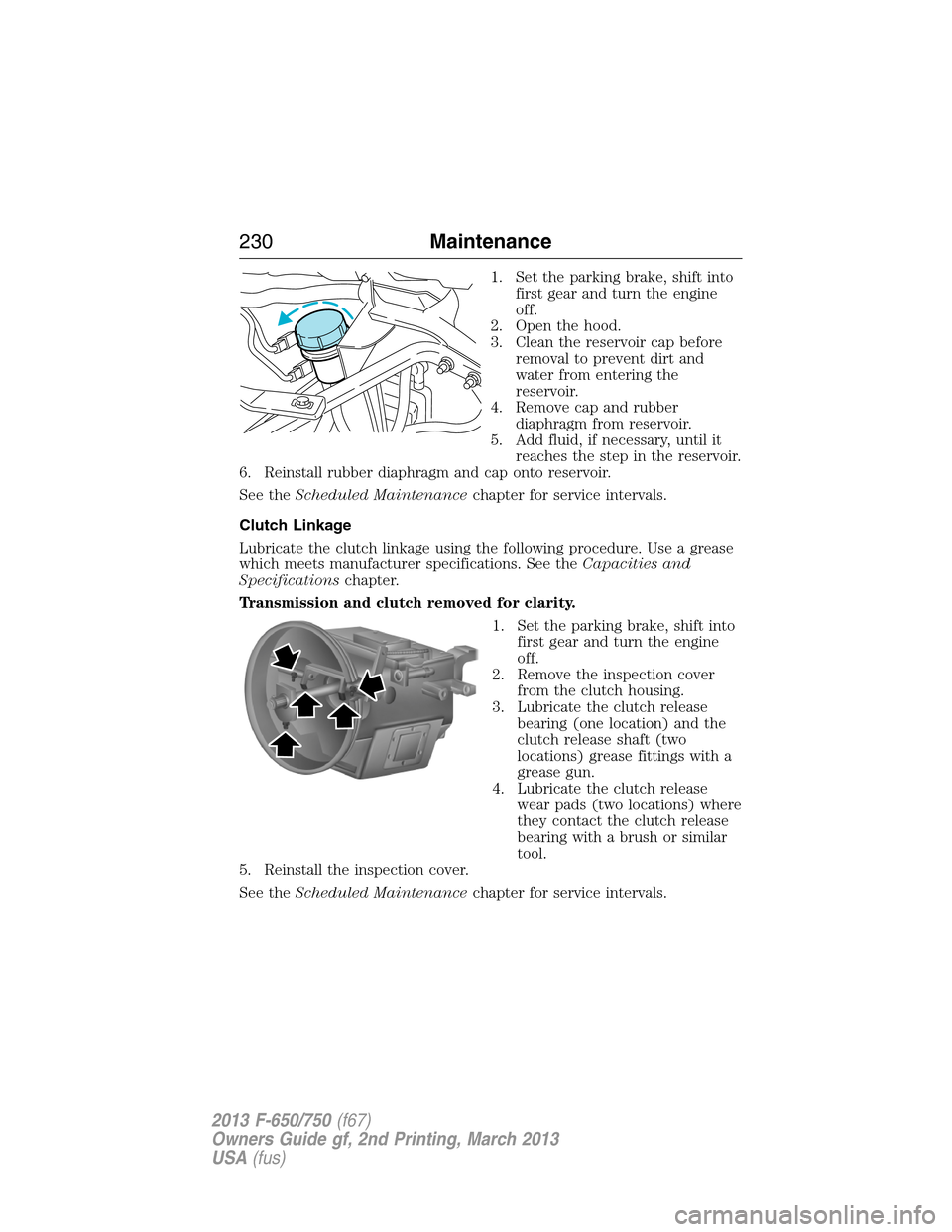

1. Set the parking brake, shift into

first gear and turn the engine

off.

2. Open the hood.

3. Clean the reservoir cap before

removal to prevent dirt and

water from entering the

reservoir.

4. Remove cap and rubber

diaphragm from reservoir.

5. Add fluid, if necessary, until it

reaches the step in the reservoir.

6. Reinstall rubber diaphragm and cap onto reservoir.

See theScheduled Maintenancechapter for service intervals.

Clutch Linkage

Lubricate the clutch linkage using the following procedure. Use a grease

which meets manufacturer specifications. See theCapacities and

Specificationschapter.

Transmission and clutch removed for clarity.

1. Set the parking brake, shift into

first gear and turn the engine

off.

2. Remove the inspection cover

from the clutch housing.

3. Lubricate the clutch release

bearing (one location) and the

clutch release shaft (two

locations) grease fittings with a

grease gun.

4. Lubricate the clutch release

wear pads (two locations) where

they contact the clutch release

bearing with a brush or similar

tool.

5. Reinstall the inspection cover.

See theScheduled Maintenancechapter for service intervals.

230Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)