warning FORD F650 2017 13.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F650, Model: FORD F650 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 152 of 382

This program is separate from the New

Vehicle Limited Warranty, but the coverage

is concurrent with the powertrain coverage

period of your vehicle.

Canadian customers who require roadside

assistance, call 1-800-665-2006.

Vehicles Sold in Canada: Using

Roadside Assistance

Complete the roadside assistance

identification card and place it in your

wallet for quick reference.

In Canada, this card is found in the

Warranty Guide in the glove compartment

of your vehicle.

Vehicles Sold in Canada: Roadside

Assistance Program Coverage

The service is available 24 hours a day,

seven days a week.

Canadian roadside coverage and benefits

may differ from the U.S. coverage.

For complete program coverage details

you may contact your dealer, you can call

us in Canada at 1-800-665-2006, or visit

our website at www.ford.ca.

HAZARD WARNING FLASHERS

Note:

The hazard warning flashers will

operate when the ignition is in any position

or if the key is not in the ignition. If used

when the engine is not running, the battery

will lose charge. As a result, there may be

insufficient power to restart your engine. In some models, the hazard

flasher control is located on the

instrument panel.

In other models, this feature is located on

the steering column, just behind the

steering wheel. Use your hazard warning flashers when

your vehicle is creating a safety hazard for

other motorists.

•

Press the flasher control and all front

and rear direction indicators flash.

• Press the flasher control again to turn

them off.

FUEL SHUTOFF WARNING

Failure to inspect and, if necessary,

repair fuel leaks after a collision may

increase the risk of fire and serious

injury. Ford Motor Company recommends

that the fuel system be inspected by an

authorized dealer after any collision. Note:

When you try to restart your vehicle

after a fuel shutoff, your vehicle makes sure

that various systems are safe to restart.

Once your vehicle determines that the

systems are safe, then your vehicle will

allow you to restart.

In the event of a moderate to severe

collision, your vehicle is equipped with a

fuel pump shut-off feature that stops the

flow of fuel to the engine. Not every impact

will cause a shutoff.

149

F-650/750 (TBC) , enUSA, First Printing Roadside EmergenciesE142663 E161463

Page 153 of 382

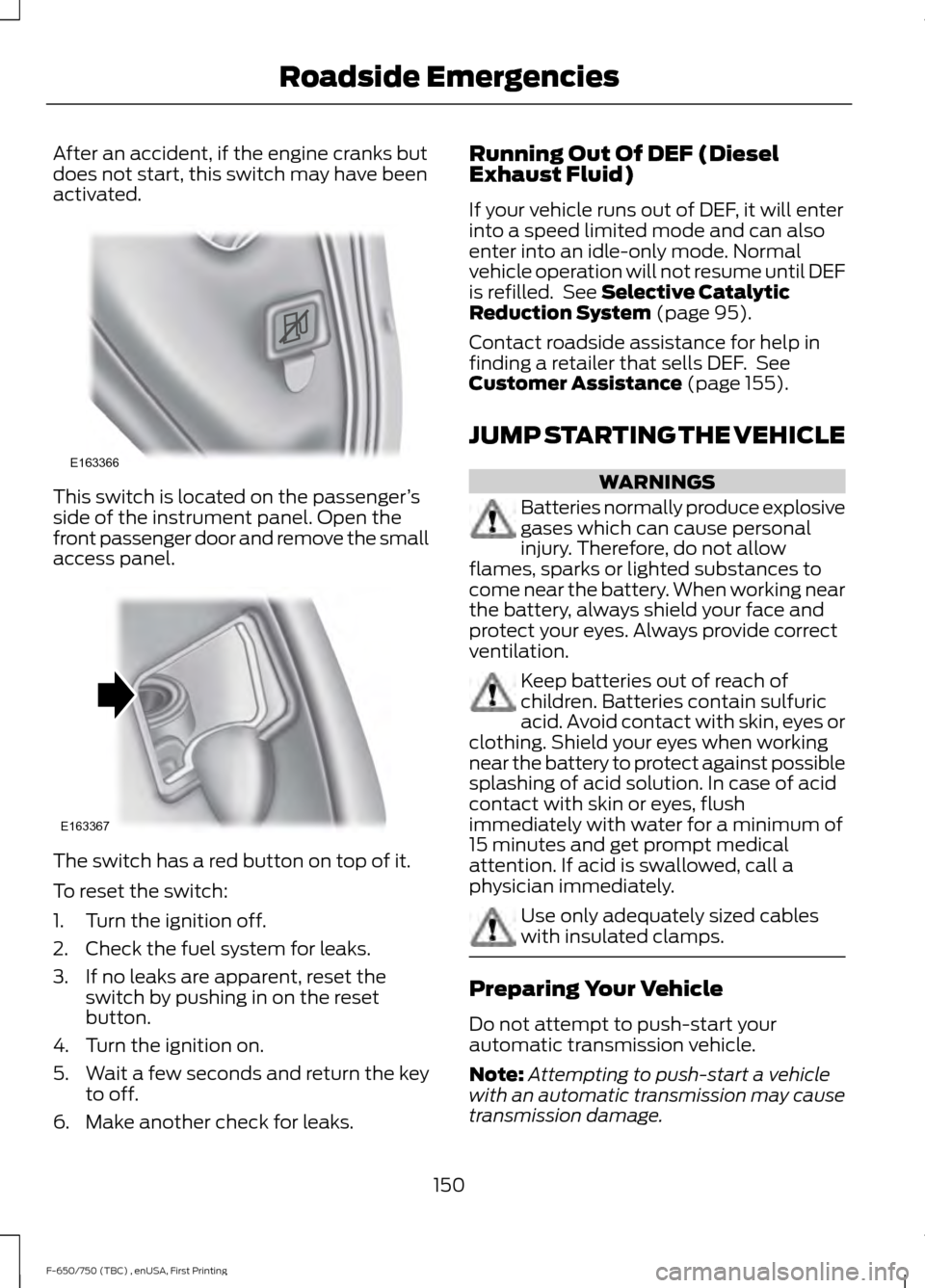

After an accident, if the engine cranks but

does not start, this switch may have been

activated.

This switch is located on the passenger

’s

side of the instrument panel. Open the

front passenger door and remove the small

access panel. The switch has a red button on top of it.

To reset the switch:

1. Turn the ignition off.

2. Check the fuel system for leaks.

3. If no leaks are apparent, reset the

switch by pushing in on the reset

button.

4. Turn the ignition on.

5. Wait a few seconds and return the key

to off.

6. Make another check for leaks. Running Out Of DEF (Diesel

Exhaust Fluid)

If your vehicle runs out of DEF, it will enter

into a speed limited mode and can also

enter into an idle-only mode. Normal

vehicle operation will not resume until DEF

is refilled. See Selective Catalytic

Reduction System (page 95).

Contact roadside assistance for help in

finding a retailer that sells DEF. See

Customer Assistance

(page 155).

JUMP STARTING THE VEHICLE WARNINGS

Batteries normally produce explosive

gases which can cause personal

injury. Therefore, do not allow

flames, sparks or lighted substances to

come near the battery. When working near

the battery, always shield your face and

protect your eyes. Always provide correct

ventilation. Keep batteries out of reach of

children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or

clothing. Shield your eyes when working

near the battery to protect against possible

splashing of acid solution. In case of acid

contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Use only adequately sized cables

with insulated clamps.

Preparing Your Vehicle

Do not attempt to push-start your

automatic transmission vehicle.

Note:

Attempting to push-start a vehicle

with an automatic transmission may cause

transmission damage.

150

F-650/750 (TBC) , enUSA, First Printing Roadside EmergenciesE163366 E163367

Page 154 of 382

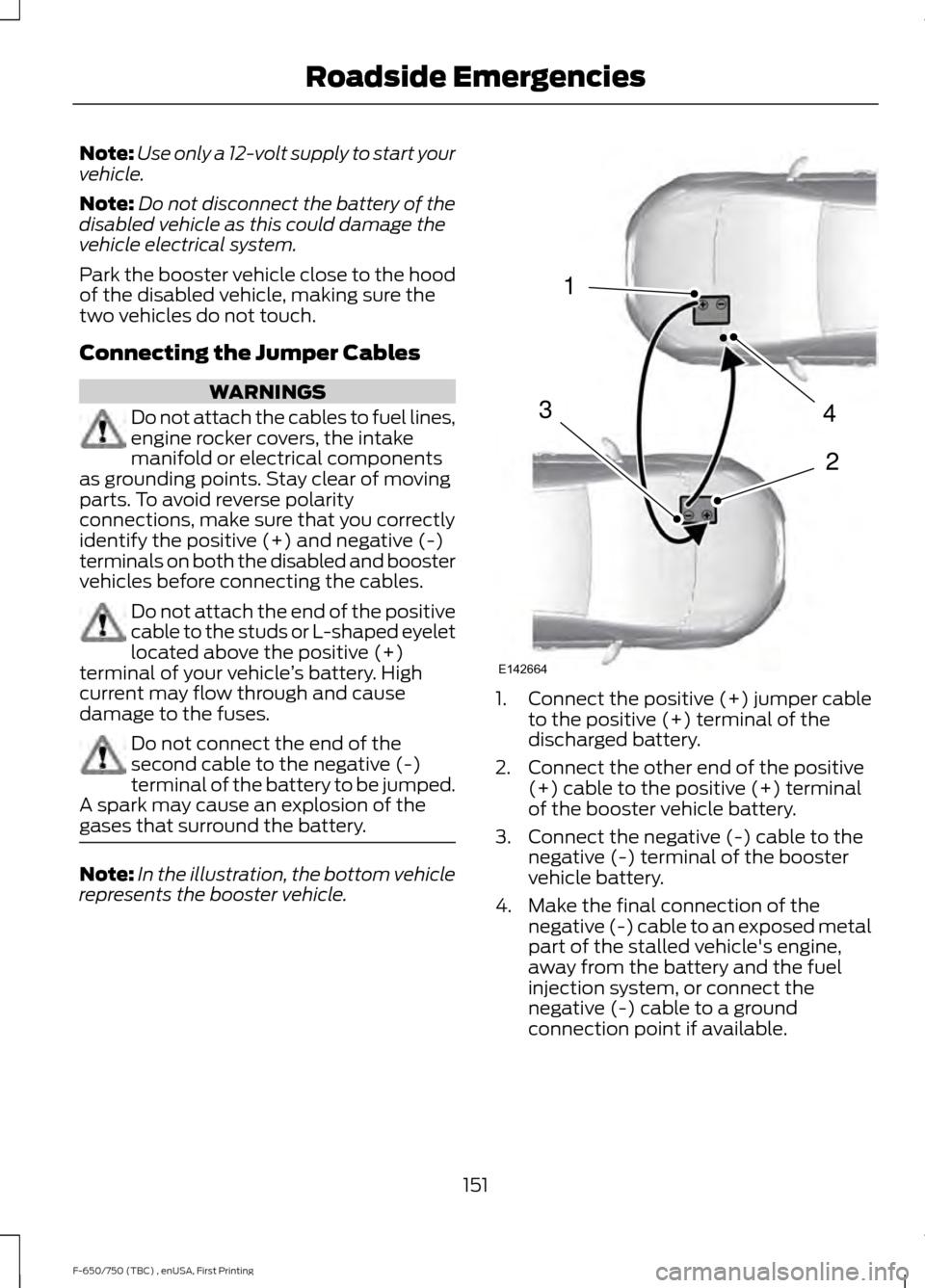

Note:

Use only a 12-volt supply to start your

vehicle.

Note: Do not disconnect the battery of the

disabled vehicle as this could damage the

vehicle electrical system.

Park the booster vehicle close to the hood

of the disabled vehicle, making sure the

two vehicles do not touch.

Connecting the Jumper Cables WARNINGS

Do not attach the cables to fuel lines,

engine rocker covers, the intake

manifold or electrical components

as grounding points. Stay clear of moving

parts. To avoid reverse polarity

connections, make sure that you correctly

identify the positive (+) and negative (-)

terminals on both the disabled and booster

vehicles before connecting the cables. Do not attach the end of the positive

cable to the studs or L-shaped eyelet

located above the positive (+)

terminal of your vehicle ’s battery. High

current may flow through and cause

damage to the fuses. Do not connect the end of the

second cable to the negative (-)

terminal of the battery to be jumped.

A spark may cause an explosion of the

gases that surround the battery. Note:

In the illustration, the bottom vehicle

represents the booster vehicle. 1.

Connect the positive (+) jumper cable

to the positive (+) terminal of the

discharged battery.

2. Connect the other end of the positive (+) cable to the positive (+) terminal

of the booster vehicle battery.

3. Connect the negative (-) cable to the negative (-) terminal of the booster

vehicle battery.

4. Make the final connection of the negative (-) cable to an exposed metal

part of the stalled vehicle's engine,

away from the battery and the fuel

injection system, or connect the

negative (-) cable to a ground

connection point if available.

151

F-650/750 (TBC) , enUSA, First Printing Roadside Emergencies4

2

1

3

E142664

Page 156 of 382

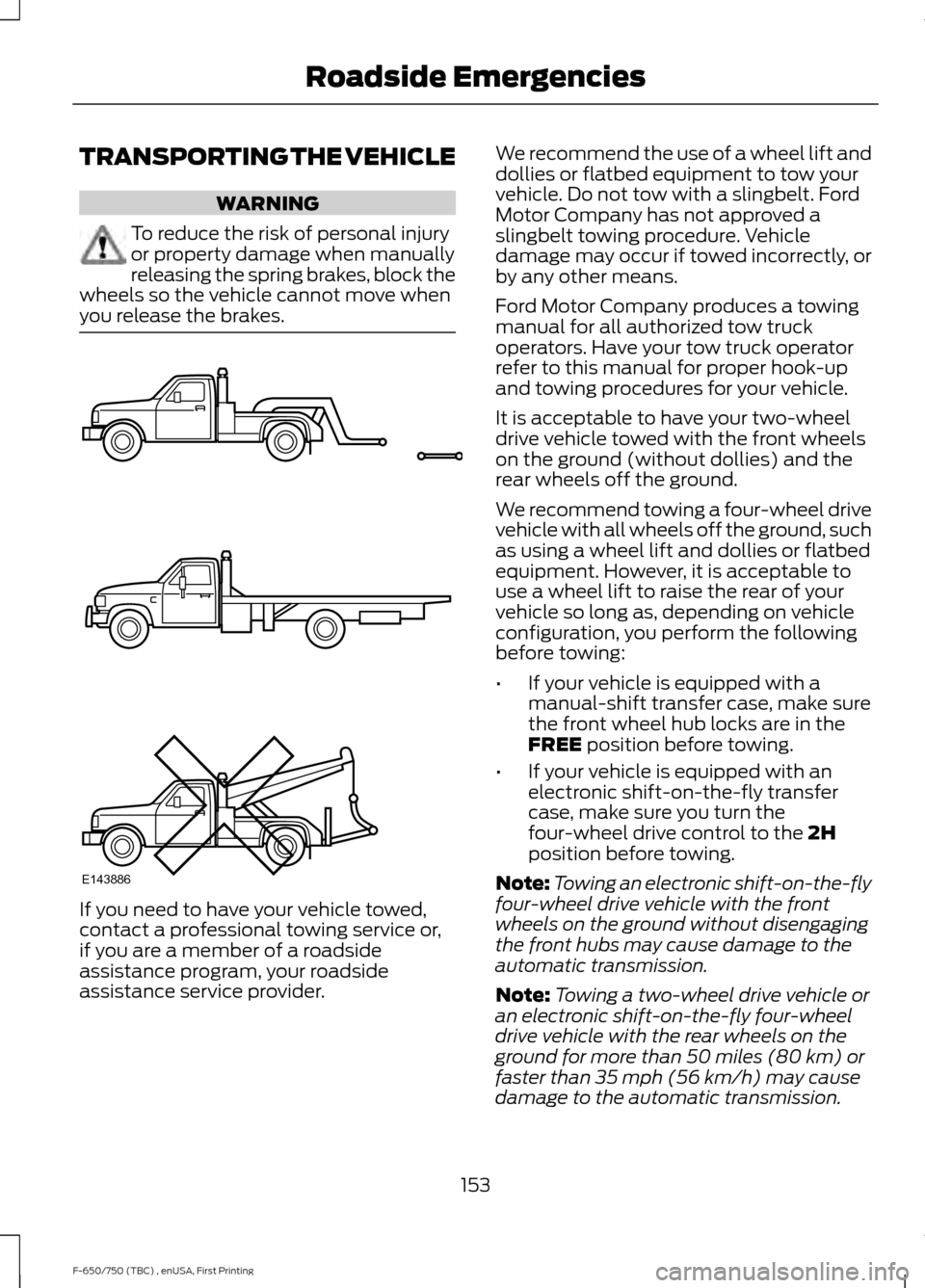

TRANSPORTING THE VEHICLE

WARNING

To reduce the risk of personal injury

or property damage when manually

releasing the spring brakes, block the

wheels so the vehicle cannot move when

you release the brakes. If you need to have your vehicle towed,

contact a professional towing service or,

if you are a member of a roadside

assistance program, your roadside

assistance service provider. We recommend the use of a wheel lift and

dollies or flatbed equipment to tow your

vehicle. Do not tow with a slingbelt. Ford

Motor Company has not approved a

slingbelt towing procedure. Vehicle

damage may occur if towed incorrectly, or

by any other means.

Ford Motor Company produces a towing

manual for all authorized tow truck

operators. Have your tow truck operator

refer to this manual for proper hook-up

and towing procedures for your vehicle.

It is acceptable to have your two-wheel

drive vehicle towed with the front wheels

on the ground (without dollies) and the

rear wheels off the ground.

We recommend towing a four-wheel drive

vehicle with all wheels off the ground, such

as using a wheel lift and dollies or flatbed

equipment. However, it is acceptable to

use a wheel lift to raise the rear of your

vehicle so long as, depending on vehicle

configuration, you perform the following

before towing:

•

If your vehicle is equipped with a

manual-shift transfer case, make sure

the front wheel hub locks are in the

FREE position before towing.

• If your vehicle is equipped with an

electronic shift-on-the-fly transfer

case, make sure you turn the

four-wheel drive control to the

2H

position before towing.

Note: Towing an electronic shift-on-the-fly

four-wheel drive vehicle with the front

wheels on the ground without disengaging

the front hubs may cause damage to the

automatic transmission.

Note: Towing a two-wheel drive vehicle or

an electronic shift-on-the-fly four-wheel

drive vehicle with the rear wheels on the

ground for more than 50 miles (80 km) or

faster than 35 mph (56 km/h) may cause

damage to the automatic transmission.

153

F-650/750 (TBC) , enUSA, First Printing Roadside EmergenciesE143886

Page 164 of 382

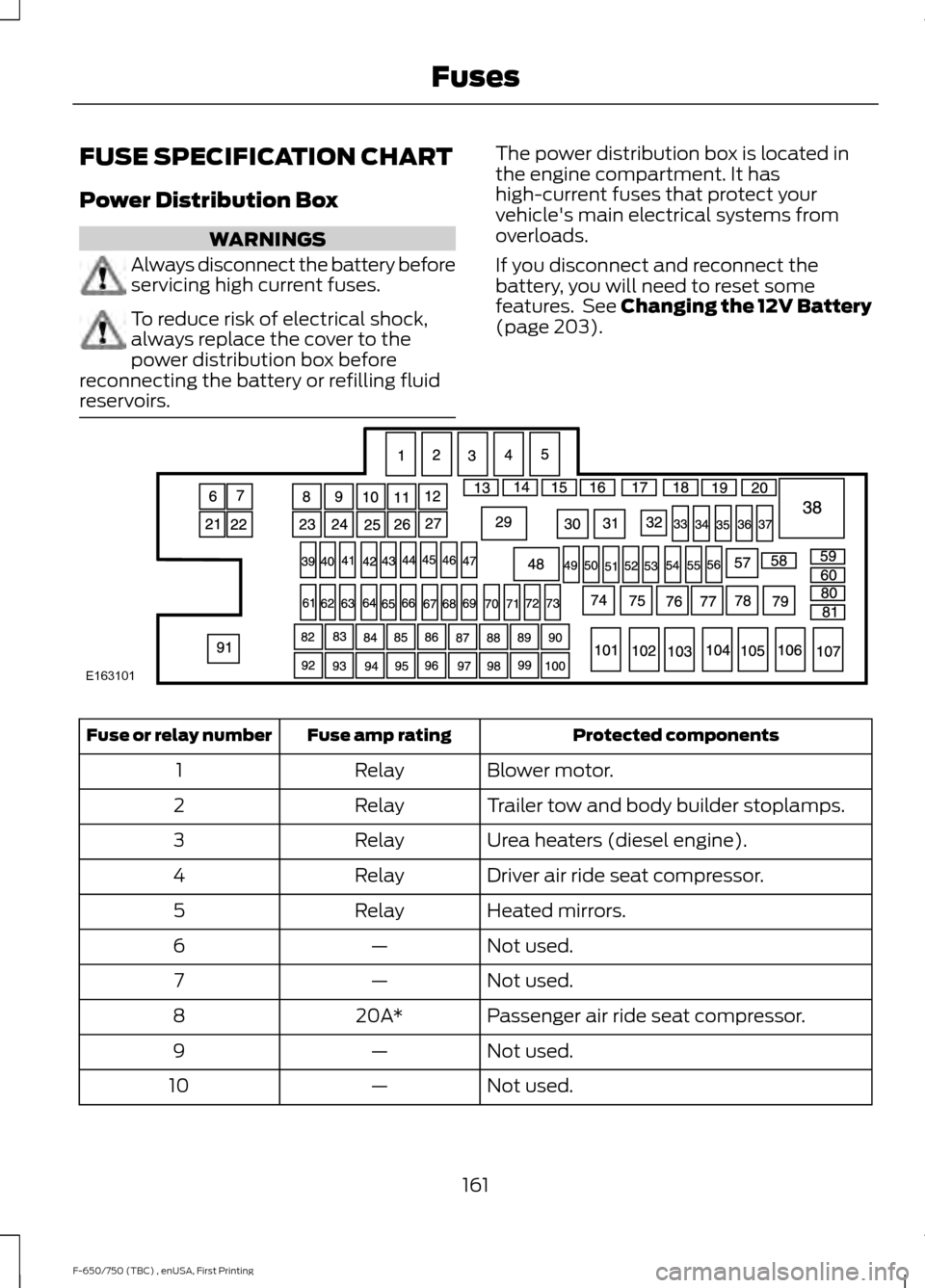

FUSE SPECIFICATION CHART

Power Distribution Box

WARNINGS

Always disconnect the battery before

servicing high current fuses.

To reduce risk of electrical shock,

always replace the cover to the

power distribution box before

reconnecting the battery or refilling fluid

reservoirs. The power distribution box is located in

the engine compartment. It has

high-current fuses that protect your

vehicle's main electrical systems from

overloads.

If you disconnect and reconnect the

battery, you will need to reset some

features. See Changing the 12V Battery

(page 203).

Protected components

Fuse amp rating

Fuse or relay number

Blower motor.

Relay

1

Trailer tow and body builder stoplamps.

Relay

2

Urea heaters (diesel engine).

Relay

3

Driver air ride seat compressor.

Relay

4

Heated mirrors.

Relay

5

Not used.

—

6

Not used.

—

7

Passenger air ride seat compressor.

20A*

8

Not used.

—

9

Not used.

—

10

161

F-650/750 (TBC) , enUSA, First Printing FusesE163101

Page 172 of 382

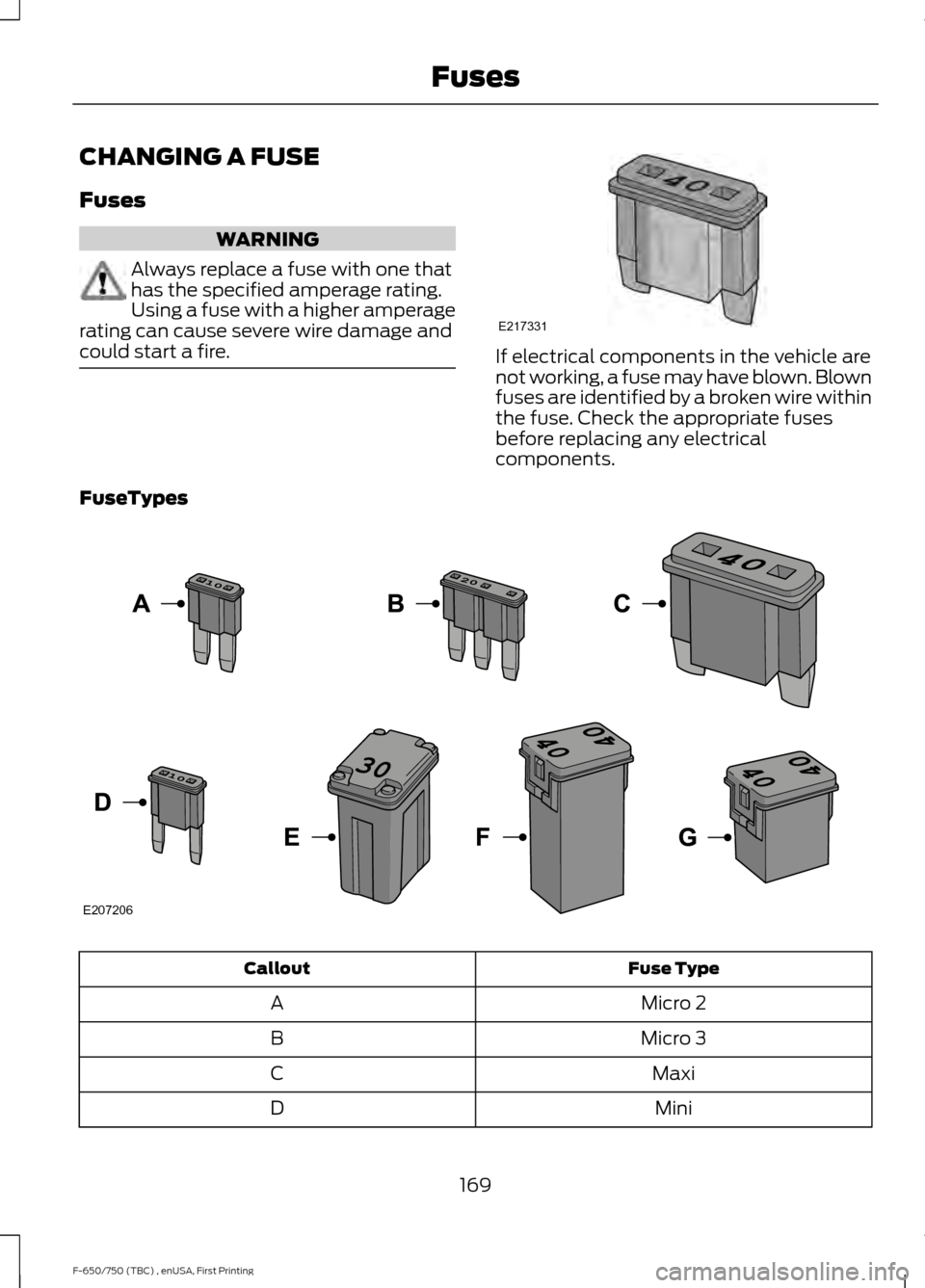

CHANGING A FUSE

Fuses

WARNING

Always replace a fuse with one that

has the specified amperage rating.

Using a fuse with a higher amperage

rating can cause severe wire damage and

could start a fire. If electrical components in the vehicle are

not working, a fuse may have blown. Blown

fuses are identified by a broken wire within

the fuse. Check the appropriate fuses

before replacing any electrical

components.

FuseTypes Fuse Type

Callout

Micro 2

A

Micro 3

B

Maxi

C

Mini

D

169

F-650/750 (TBC) , enUSA, First Printing FusesE217331 E207206

Page 174 of 382

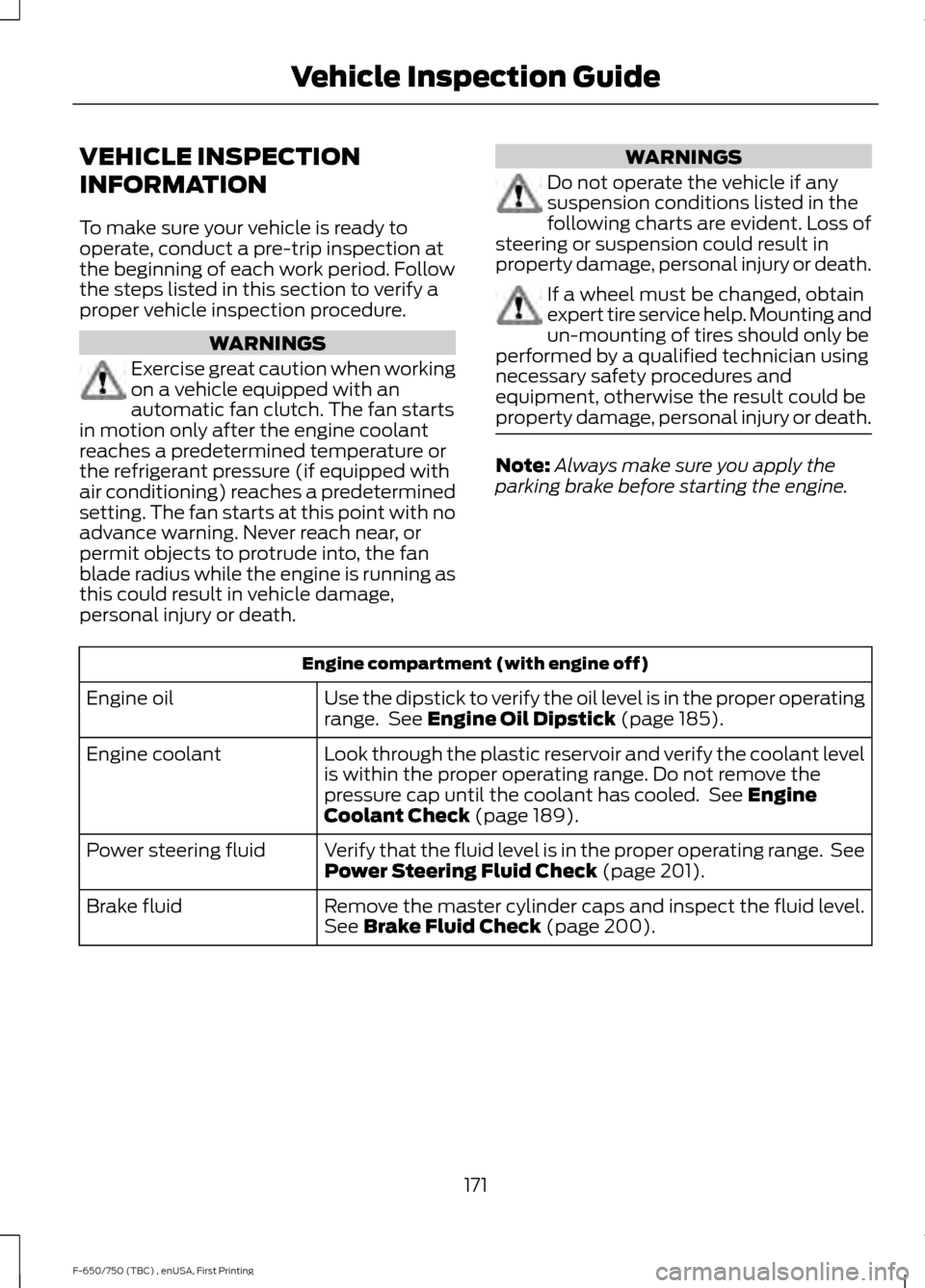

VEHICLE INSPECTION

INFORMATION

To make sure your vehicle is ready to

operate, conduct a pre-trip inspection at

the beginning of each work period. Follow

the steps listed in this section to verify a

proper vehicle inspection procedure.

WARNINGS

Exercise great caution when working

on a vehicle equipped with an

automatic fan clutch. The fan starts

in motion only after the engine coolant

reaches a predetermined temperature or

the refrigerant pressure (if equipped with

air conditioning) reaches a predetermined

setting. The fan starts at this point with no

advance warning. Never reach near, or

permit objects to protrude into, the fan

blade radius while the engine is running as

this could result in vehicle damage,

personal injury or death. WARNINGS

Do not operate the vehicle if any

suspension conditions listed in the

following charts are evident. Loss of

steering or suspension could result in

property damage, personal injury or death. If a wheel must be changed, obtain

expert tire service help. Mounting and

un-mounting of tires should only be

performed by a qualified technician using

necessary safety procedures and

equipment, otherwise the result could be

property damage, personal injury or death. Note:

Always make sure you apply the

parking brake before starting the engine. Engine compartment (with engine off)

Use the dipstick to verify the oil level is in the proper operating

range. See Engine Oil Dipstick (page 185).

Engine oil

Look through the plastic reservoir and verify the coolant level

is within the proper operating range. Do not remove the

pressure cap until the coolant has cooled. See

Engine

Coolant Check (page 189).

Engine coolant

Verify that the fluid level is in the proper operating range. See

Power Steering Fluid Check

(page 201).

Power steering fluid

Remove the master cylinder caps and inspect the fluid level.

See

Brake Fluid Check (page 200).

Brake fluid

171

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide

Page 175 of 382

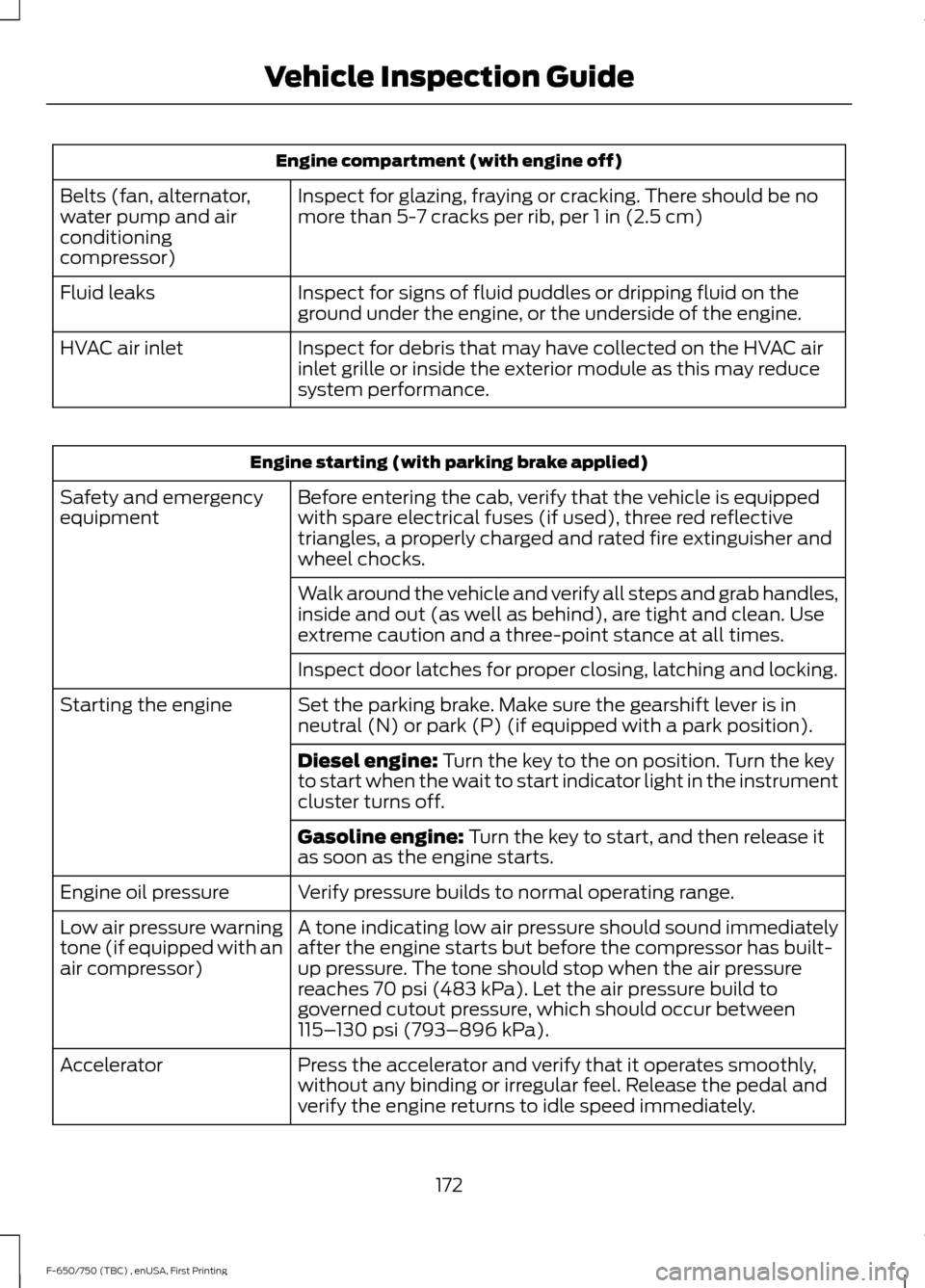

Engine compartment (with engine off)

Inspect for glazing, fraying or cracking. There should be no

more than 5-7 cracks per rib, per 1 in (2.5 cm)

Belts (fan, alternator,

water pump and air

conditioning

compressor)

Inspect for signs of fluid puddles or dripping fluid on the

ground under the engine, or the underside of the engine.

Fluid leaks

Inspect for debris that may have collected on the HVAC air

inlet grille or inside the exterior module as this may reduce

system performance.

HVAC air inlet Engine starting (with parking brake applied)

Before entering the cab, verify that the vehicle is equipped

with spare electrical fuses (if used), three red reflective

triangles, a properly charged and rated fire extinguisher and

wheel chocks.

Safety and emergency

equipment

Walk around the vehicle and verify all steps and grab handles,

inside and out (as well as behind), are tight and clean. Use

extreme caution and a three-point stance at all times.

Inspect door latches for proper closing, latching and locking.

Set the parking brake. Make sure the gearshift lever is in

neutral (N) or park (P) (if equipped with a park position).

Starting the engine

Diesel engine:

Turn the key to the on position. Turn the key

to start when the wait to start indicator light in the instrument

cluster turns off.

Gasoline engine:

Turn the key to start, and then release it

as soon as the engine starts.

Verify pressure builds to normal operating range.

Engine oil pressure

A tone indicating low air pressure should sound immediately

after the engine starts but before the compressor has built-

up pressure. The tone should stop when the air pressure

reaches

70 psi (483 kPa). Let the air pressure build to

governed cutout pressure, which should occur between

115– 130 psi (793–896 kPa)

.

Low air pressure warning

tone (if equipped with an

air compressor)

Press the accelerator and verify that it operates smoothly,

without any binding or irregular feel. Release the pedal and

verify the engine returns to idle speed immediately.

Accelerator

172

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide

Page 176 of 382

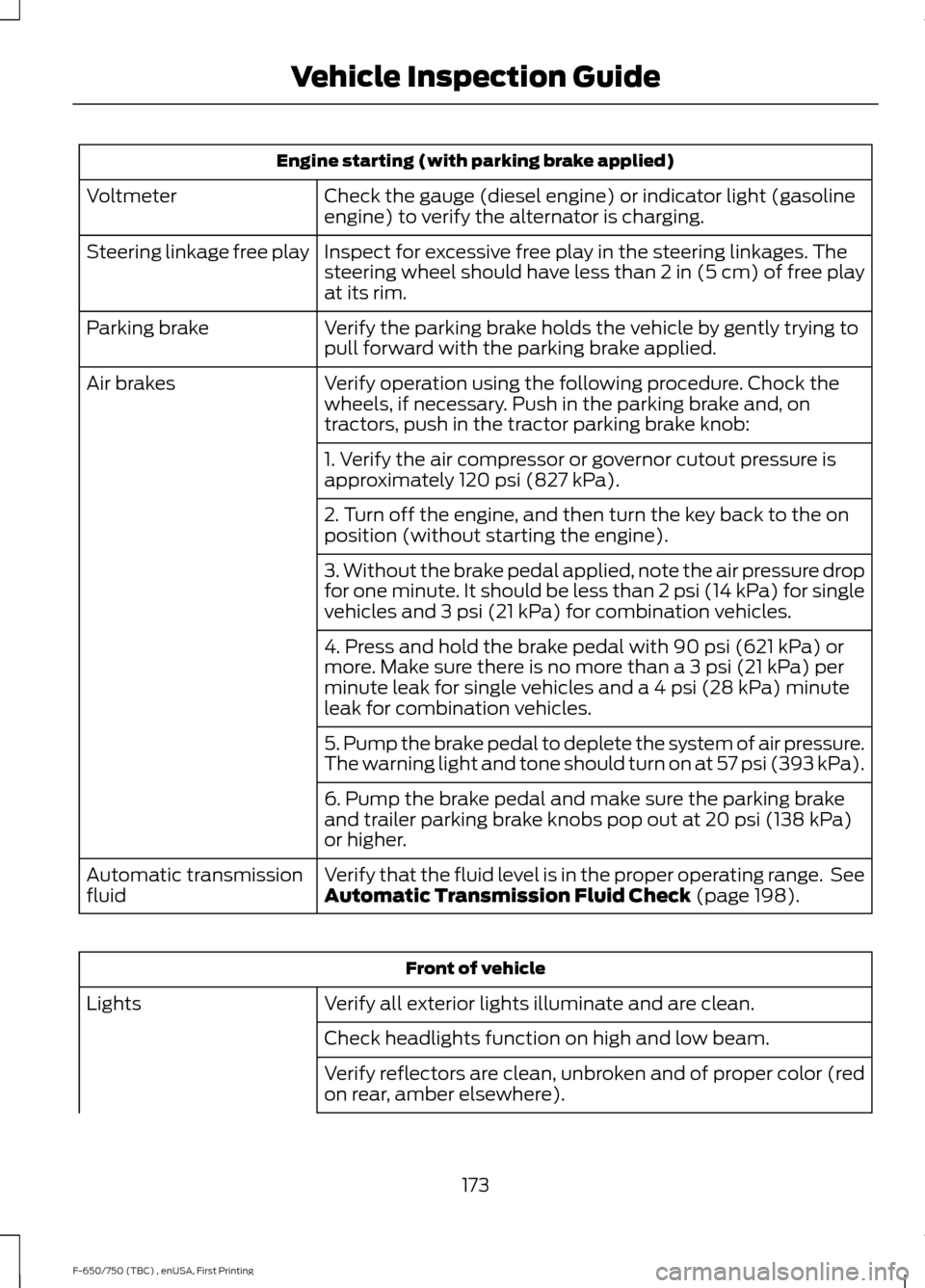

Engine starting (with parking brake applied)

Check the gauge (diesel engine) or indicator light (gasoline

engine) to verify the alternator is charging.

Voltmeter

Inspect for excessive free play in the steering linkages. The

steering wheel should have less than 2 in (5 cm) of free play

at its rim.

Steering linkage free play

Verify the parking brake holds the vehicle by gently trying to

pull forward with the parking brake applied.

Parking brake

Verify operation using the following procedure. Chock the

wheels, if necessary. Push in the parking brake and, on

tractors, push in the tractor parking brake knob:

Air brakes

1. Verify the air compressor or governor cutout pressure is

approximately 120 psi (827 kPa).

2. Turn off the engine, and then turn the key back to the on

position (without starting the engine).

3. Without the brake pedal applied, note the air pressure drop

for one minute. It should be less than 2 psi (14 kPa) for single

vehicles and

3 psi (21 kPa) for combination vehicles.

4. Press and hold the brake pedal with

90 psi (621 kPa) or

more. Make sure there is no more than a 3 psi (21 kPa) per

minute leak for single vehicles and a 4 psi (28 kPa) minute

leak for combination vehicles.

5. Pump the brake pedal to deplete the system of air pressure.

The warning light and tone should turn on at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the parking brake

and trailer parking brake knobs pop out at

20 psi (138 kPa)

or higher.

Verify that the fluid level is in the proper operating range. See

Automatic Transmission Fluid Check

(page 198).

Automatic transmission

fluid Front of vehicle

Verify all exterior lights illuminate and are clean.

Lights

Check headlights function on high and low beam.

Verify reflectors are clean, unbroken and of proper color (red

on rear, amber elsewhere).

173

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide

Page 181 of 382

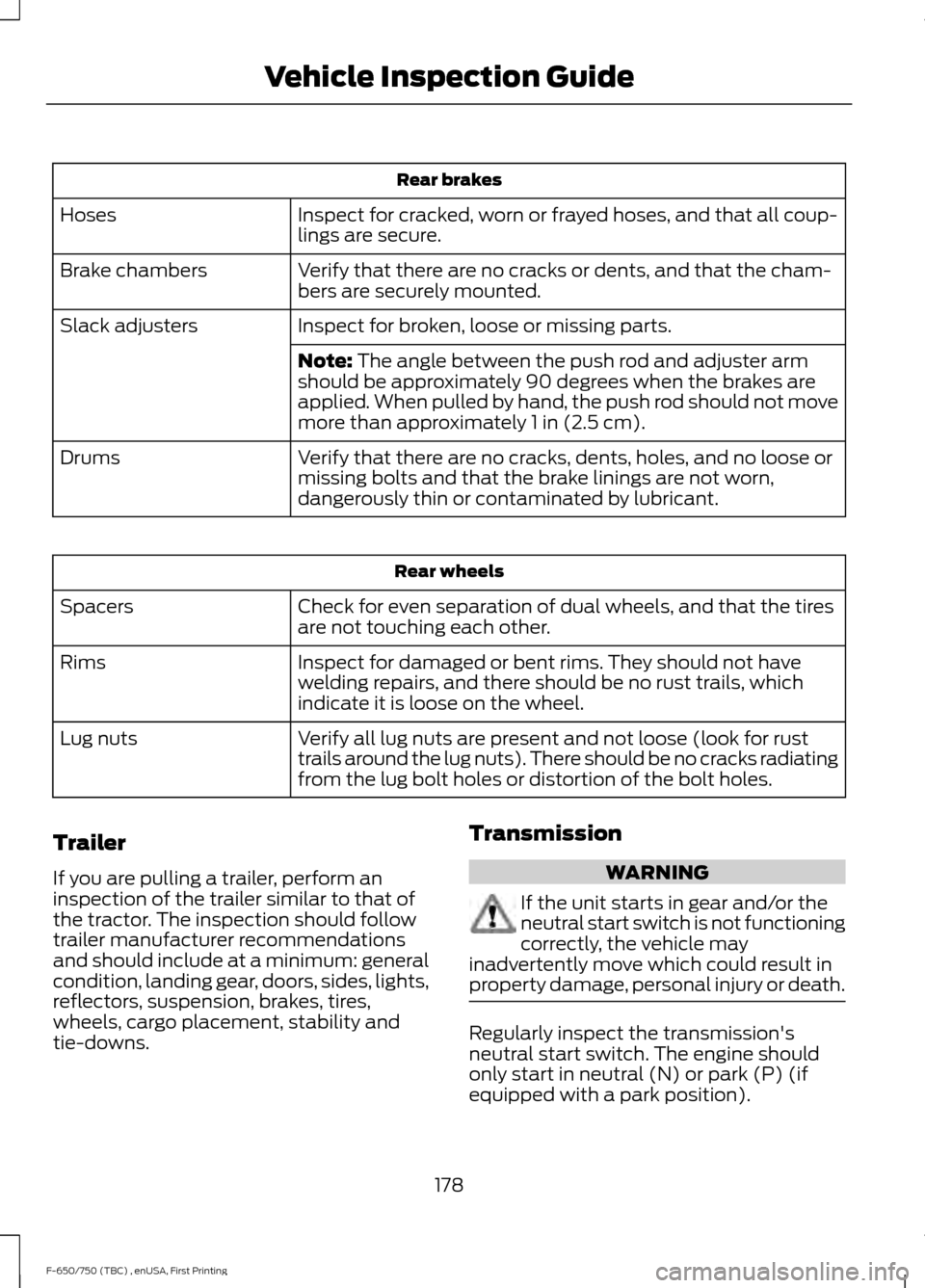

Rear brakes

Inspect for cracked, worn or frayed hoses, and that all coup-

lings are secure.

Hoses

Verify that there are no cracks or dents, and that the cham-

bers are securely mounted.

Brake chambers

Inspect for broken, loose or missing parts.

Slack adjusters

Note: The angle between the push rod and adjuster arm

should be approximately 90 degrees when the brakes are

applied. When pulled by hand, the push rod should not move

more than approximately

1 in (2.5 cm).

Verify that there are no cracks, dents, holes, and no loose or

missing bolts and that the brake linings are not worn,

dangerously thin or contaminated by lubricant.

Drums Rear wheels

Check for even separation of dual wheels, and that the tires

are not touching each other.

Spacers

Inspect for damaged or bent rims. They should not have

welding repairs, and there should be no rust trails, which

indicate it is loose on the wheel.

Rims

Verify all lug nuts are present and not loose (look for rust

trails around the lug nuts). There should be no cracks radiating

from the lug bolt holes or distortion of the bolt holes.

Lug nuts

Trailer

If you are pulling a trailer, perform an

inspection of the trailer similar to that of

the tractor. The inspection should follow

trailer manufacturer recommendations

and should include at a minimum: general

condition, landing gear, doors, sides, lights,

reflectors, suspension, brakes, tires,

wheels, cargo placement, stability and

tie-downs. Transmission WARNING

If the unit starts in gear and/or the

neutral start switch is not functioning

correctly, the vehicle may

inadvertently move which could result in

property damage, personal injury or death. Regularly inspect the transmission's

neutral start switch. The engine should

only start in neutral (N) or park (P) (if

equipped with a park position).

178

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide