ABS FORD F650 2017 13.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F650, Model: FORD F650 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 190 of 382

Note:

The oil consumption of new engines

reaches its normal level after approximately

3,100 mi (5,000 km).

Adding Engine Oil WARNING

Do not remove the filler cap when

the engine is running.

Do not use supplemental engine oil

additives because they are unnecessary

and could lead to engine damage that may

not be covered by the vehicle Warranty.

The American Petroleum Institute (API)

service symbol is used to identify the

proper engine oil for your vehicle's engine.

The API service symbol will be displayed

on the oil container you purchase. The API

service symbol displays the oil

performance category in the top half of

symbol and the viscosity grade in the

center of the symbol.

To top up the engine oil level do the

following:

1. Clean the area surrounding the engine

oil filler cap before you remove it.

2. Remove the engine oil filler cap. See Under Hood Overview

(page 184).

Turn it counterclockwise and remove

it. 3. Add engine oil that meets Ford

specifications. See

Capacities and

Specifications (page 263). You may

have to use a funnel to pour the engine

oil into the opening.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap

correctly.

Note: Soak up any spillage with an

absorbent cloth immediately.

CHANGING THE ENGINE OIL

AND OIL FILTER WARNINGS

Do not handle a hot oil filter with

bare hands.

Continuous contact with used motor

oil has caused cancer in laboratory

mice. Protect your skin by washing

with soap and water. If your vehicle is equipped with a diesel

engine, an Intelligent Oil Life Monitor™

calculates the proper oil change service

interval. When the information display

indicates: OIL CHANGE REQUIRED, change

the engine oil and oil filter. See

Information Displays

(page 62).

The engine oil filter protects your engine

by filtering harmful, abrasive or sludge

particles and particles significantly smaller

than most available will-fit filters. See

Motorcraft Parts

(page 254).

187

F-650/750 (TBC) , enUSA, First Printing MaintenanceE163371

Page 213 of 382

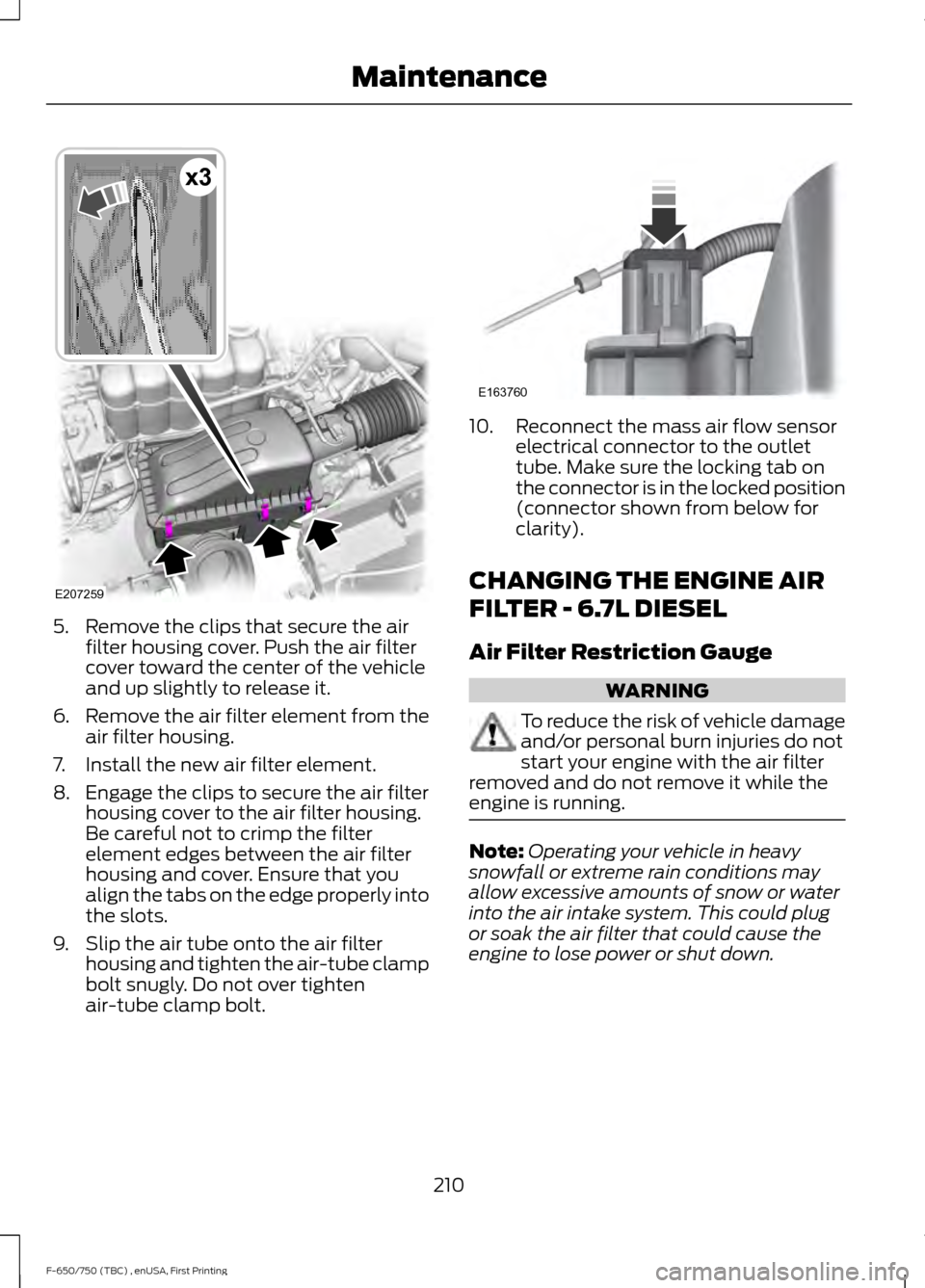

5. Remove the clips that secure the air

filter housing cover. Push the air filter

cover toward the center of the vehicle

and up slightly to release it.

6. Remove the air filter element from the

air filter housing.

7. Install the new air filter element.

8. Engage the clips to secure the air filter housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

9. Slip the air tube onto the air filter housing and tighten the air-tube clamp

bolt snugly. Do not over tighten

air-tube clamp bolt. 10. Reconnect the mass air flow sensor

electrical connector to the outlet

tube. Make sure the locking tab on

the connector is in the locked position

(connector shown from below for

clarity).

CHANGING THE ENGINE AIR

FILTER - 6.7L DIESEL

Air Filter Restriction Gauge WARNING

To reduce the risk of vehicle damage

and/or personal burn injuries do not

start your engine with the air filter

removed and do not remove it while the

engine is running. Note:

Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter that could cause the

engine to lose power or shut down.

210

F-650/750 (TBC) , enUSA, First Printing MaintenanceE207259

x3 E163760

Page 216 of 382

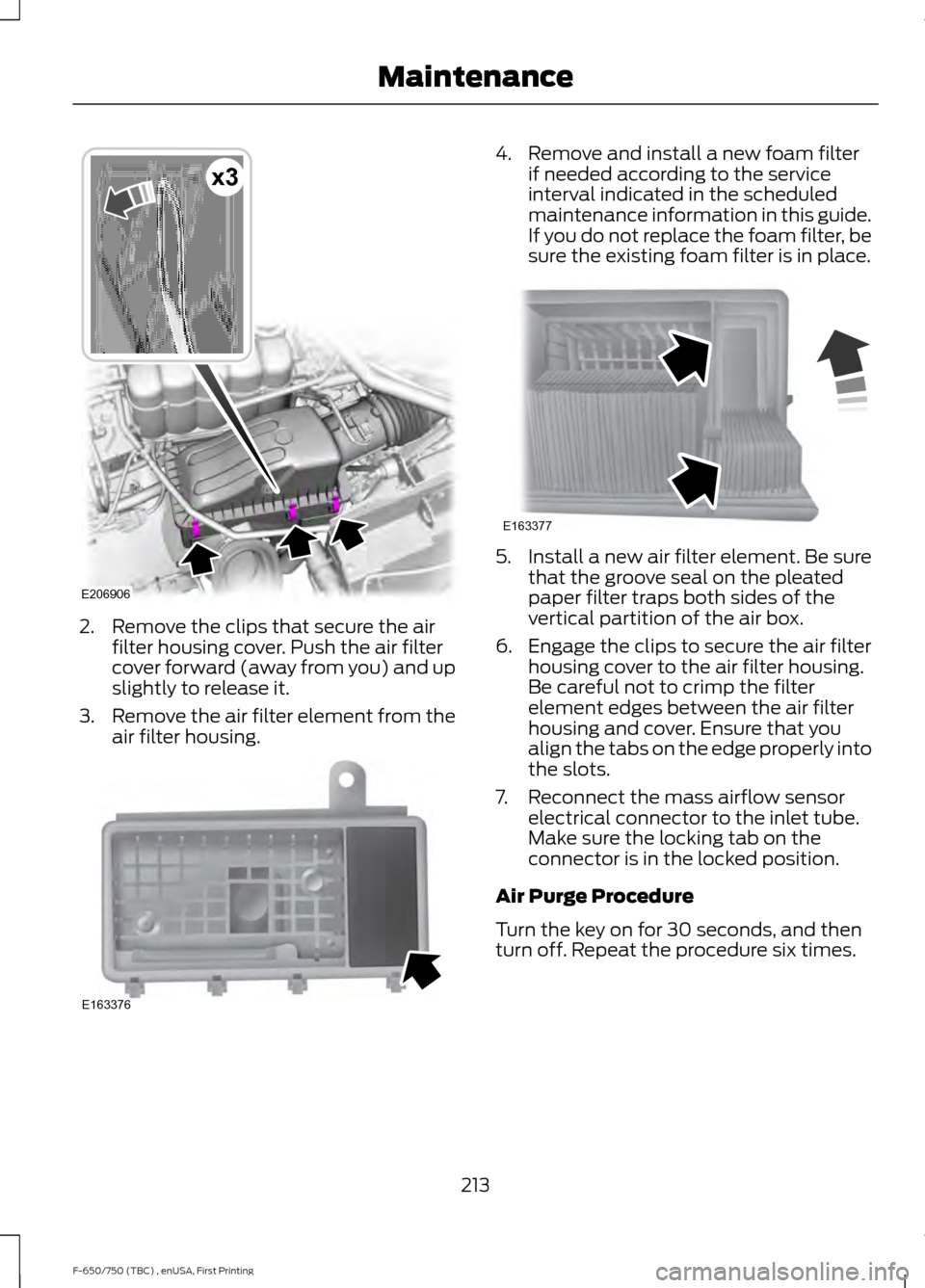

2. Remove the clips that secure the air

filter housing cover. Push the air filter

cover forward (away from you) and up

slightly to release it.

3. Remove the air filter element from the

air filter housing. 4. Remove and install a new foam filter

if needed according to the service

interval indicated in the scheduled

maintenance information in this guide.

If you do not replace the foam filter, be

sure the existing foam filter is in place. 5. Install a new air filter element. Be sure

that the groove seal on the pleated

paper filter traps both sides of the

vertical partition of the air box.

6. Engage the clips to secure the air filter housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

7. Reconnect the mass airflow sensor electrical connector to the inlet tube.

Make sure the locking tab on the

connector is in the locked position.

Air Purge Procedure

Turn the key on for 30 seconds, and then

turn off. Repeat the procedure six times.

213

F-650/750 (TBC) , enUSA, First Printing MaintenanceE206906

x3 E163376 E163377

Page 219 of 382

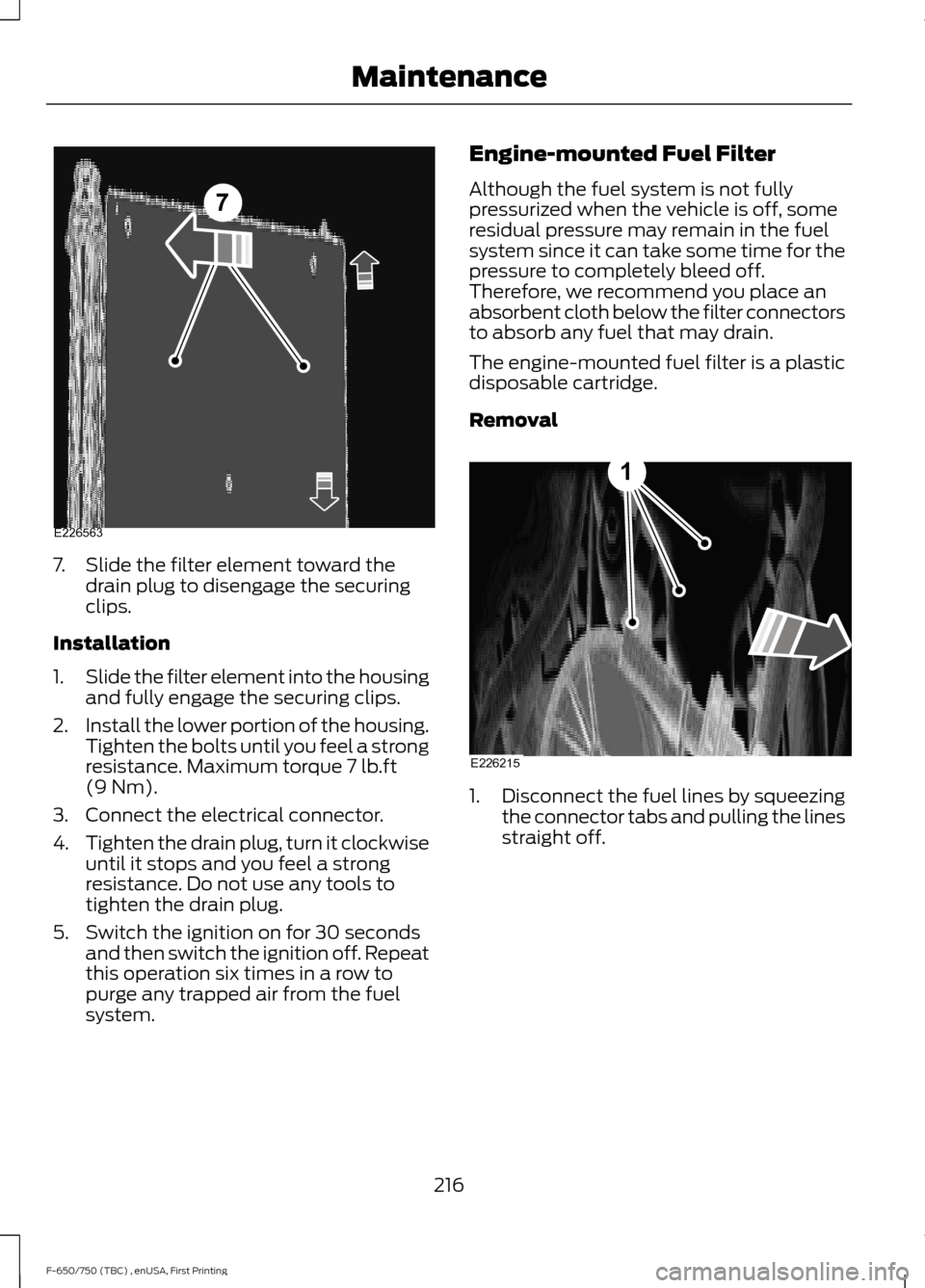

7. Slide the filter element toward the

drain plug to disengage the securing

clips.

Installation

1. Slide the filter element into the housing

and fully engage the securing clips.

2. Install the lower portion of the housing.

Tighten the bolts until you feel a strong

resistance. Maximum torque 7 lb.ft

(9 Nm).

3. Connect the electrical connector.

4. Tighten the drain plug, turn it clockwise

until it stops and you feel a strong

resistance. Do not use any tools to

tighten the drain plug.

5. Switch the ignition on for 30 seconds and then switch the ignition off. Repeat

this operation six times in a row to

purge any trapped air from the fuel

system. Engine-mounted Fuel Filter

Although the fuel system is not fully

pressurized when the vehicle is off, some

residual pressure may remain in the fuel

system since it can take some time for the

pressure to completely bleed off.

Therefore, we recommend you place an

absorbent cloth below the filter connectors

to absorb any fuel that may drain.

The engine-mounted fuel filter is a plastic

disposable cartridge.

Removal

1.

Disconnect the fuel lines by squeezing

the connector tabs and pulling the lines

straight off.

216

F-650/750 (TBC) , enUSA, First Printing Maintenance7

E226563 E226215

1

Page 220 of 382

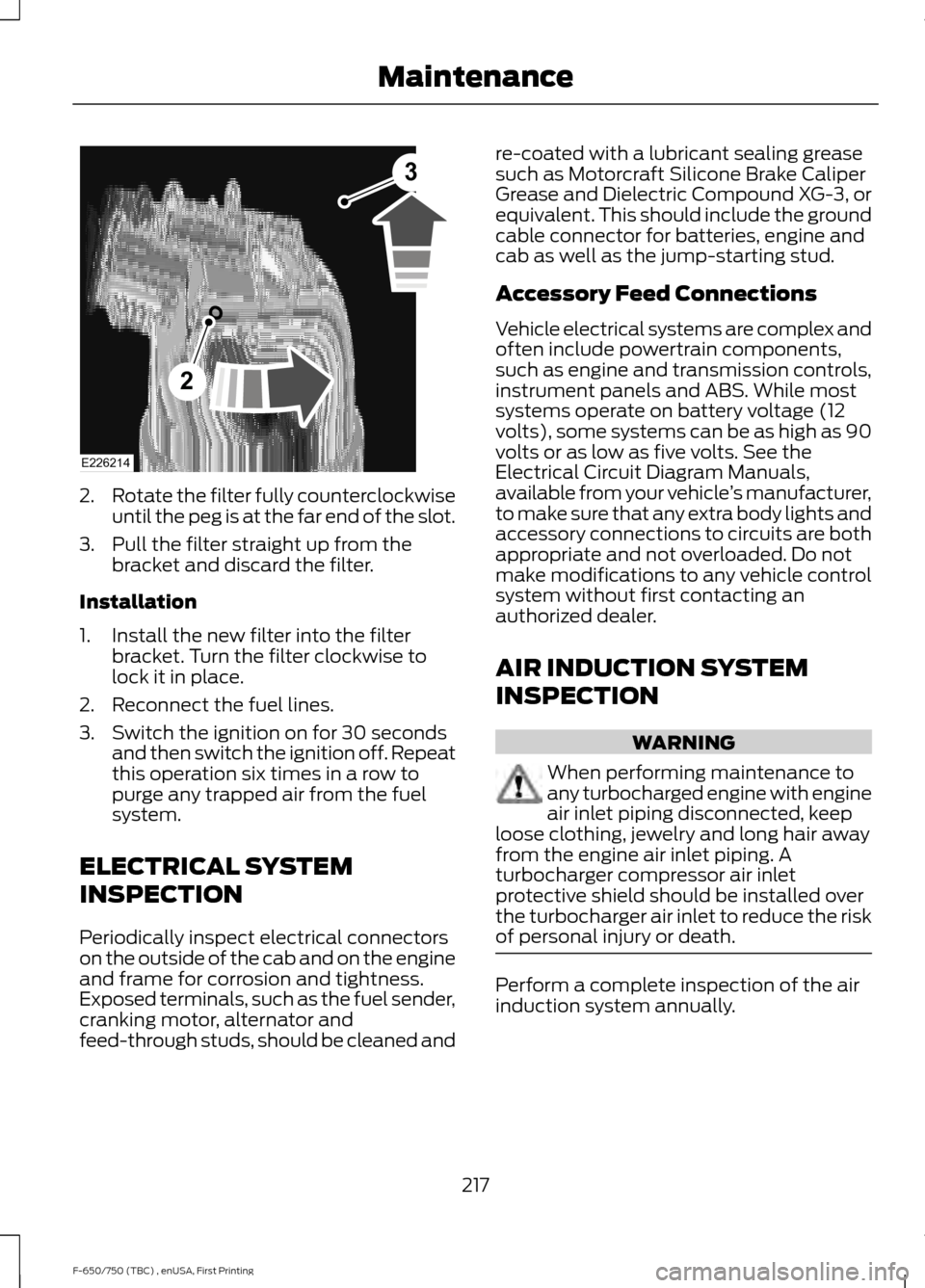

2.

Rotate the filter fully counterclockwise

until the peg is at the far end of the slot.

3. Pull the filter straight up from the bracket and discard the filter.

Installation

1. Install the new filter into the filter bracket. Turn the filter clockwise to

lock it in place.

2. Reconnect the fuel lines.

3. Switch the ignition on for 30 seconds and then switch the ignition off. Repeat

this operation six times in a row to

purge any trapped air from the fuel

system.

ELECTRICAL SYSTEM

INSPECTION

Periodically inspect electrical connectors

on the outside of the cab and on the engine

and frame for corrosion and tightness.

Exposed terminals, such as the fuel sender,

cranking motor, alternator and

feed-through studs, should be cleaned and re-coated with a lubricant sealing grease

such as Motorcraft Silicone Brake Caliper

Grease and Dielectric Compound XG-3, or

equivalent. This should include the ground

cable connector for batteries, engine and

cab as well as the jump-starting stud.

Accessory Feed Connections

Vehicle electrical systems are complex and

often include powertrain components,

such as engine and transmission controls,

instrument panels and ABS. While most

systems operate on battery voltage (12

volts), some systems can be as high as 90

volts or as low as five volts. See the

Electrical Circuit Diagram Manuals,

available from your vehicle

’s manufacturer,

to make sure that any extra body lights and

accessory connections to circuits are both

appropriate and not overloaded. Do not

make modifications to any vehicle control

system without first contacting an

authorized dealer.

AIR INDUCTION SYSTEM

INSPECTION WARNING

When performing maintenance to

any turbocharged engine with engine

air inlet piping disconnected, keep

loose clothing, jewelry and long hair away

from the engine air inlet piping. A

turbocharger compressor air inlet

protective shield should be installed over

the turbocharger air inlet to reduce the risk

of personal injury or death. Perform a complete inspection of the air

induction system annually.

217

F-650/750 (TBC) , enUSA, First Printing MaintenanceE226214

2

3

Page 223 of 382

as a stroke indicator to aid in

adjustment checks. If the push rod is

clean and the brakes are out of

adjustment, you can see the orange

marker protruding from the chamber

when the brakes are applied.

• Checking the brake lining (every service

interval). When brake linings or blocks

wear within 0.063 in (1.6 mm) they

must be replaced.

• Periodic checking (every service

interval) of the air compressor filter.

Check the filter minder and when the

indicator is near or on the red line

marked

Service, replace the filter and

reset the service filter minder.

Do not back off or disconnect the front

brakes so that they are less effective,

letting the rear brakes do all the stopping

of your vehicle. Do not overlook the brakes

on the trailer either. Brake condition on the

trailer is just as important as the tractor.

Proper brake balance on trucks and

tractor-trailers is essential for effective

braking.

Once a year, inspect the entire brake

system:

• Rubber components for deterioration.

A qualified technician should inspect

these components and replace them

as necessary. Replacement intervals

vary according to the severity and

length of vehicle service.

• Condition of brake drums, brake

chambers and slack adjusters.

• System for air leaks.

• Hose or pipes for rust, damage and

deterioration.

• Operation of service and parking

brakes.

Periodically inspect parts such as air brake

chamber diaphragm, air compressor and

air cleaner. Replace any parts if you can

consider them unserviceable. Air Dryer

Climactic conditions affect performance

of desiccant or after-cooler type air dryers.

You must establish a maintenance

schedule for each specific operation.

The use of an air dryer on a vehicle does

not eliminate the need to drain the air

reservoirs periodically.

Inspect for moisture in the air system by

opening reservoirs, draincocks or valves

and checking for presence of water. The

presence of small amounts of water due

to condensation is normal and is not an

indication that the dryer is not functioning

properly.

Replace or rebuild the desiccant cartridge

when you determine that the desiccant is

contaminated and does not have adequate

water absorption capacity. The desiccant

change interval may vary. A general

recommendation is to replace the

desiccant every 12 months (yearly). If

experience has shown that extended or

shortened life has resulted for a particular

installation, then the yearly interval can be

increased or decreased accordingly.

Draining the Air Brake Reservoir

WARNING

Failure to drain air brake reservoirs

can result in a reduction or loss of

braking ability due to fluid

accumulation in the reservoir and/or

possible freeze-up during cold weather. Completely drain all the air brake reservoirs

daily by opening the draincock at the ends

of the tanks. (Where accessible.

Pull-chains are used when the drains are

undercab or otherwise inaccessible.) Close

the draincock after draining. Manually drain

220

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 285 of 382

SYNC Owner Account

Why do I need a SYNC owner account?

•

Essential for keeping up with the latest

software downloads available for

SYNC.

• Access to customer support for any

questions you may have.

Driving Restrictions

For your safety, certain features are

speed-dependent and restricted when your

vehicle is traveling over 3 mph (5 km/h).

Safety Information WARNING

Driving while distracted can result in

loss of vehicle control, crash and

injury. We strongly recommend that

you use extreme caution when using any

device that may take your focus off the

road. Your primary responsibility is the safe

operation of your vehicle. We recommend

against the use of any hand-held device

while driving and encourage the use of

voice-operated systems when possible.

Make sure you are aware of all applicable

local laws that may affect the use of

electronic devices while driving. When using SYNC:

•

Do not operate playing devices if the

power cords or cables are broken, split

or damaged. Place cords and cables

out of the way, so they do not interfere

with the operation of pedals, seats,

compartments or safe driving abilities.

• Do not leave playing devices in your

vehicle during extreme conditions as it

could cause them damage. See your

device's manual for further information.

• Do not attempt to service or repair the

system. See an authorized dealer. Privacy Information

When a cellular phone is connected to

SYNC, the system creates a profile within

your vehicle that is linked to that cellular

phone. This profile is created in order to

offer you more cellular features and to

operate more efficiently. Among other

things, this profile may contain data about

your cellular phone book, text messages

(read and unread), and call history,

including history of calls when your cellular

phone was not connected to the system.

In addition, if you connect a media device,

the system creates and retains an index of

supported media content. The system also

records a short development log of

approximately 10 minutes of all recent

system activity. The log profile and other

system data may be used to improve the

system and help diagnose any problems

that may occur.

The cellular profile, media device index,

and development log will remain in the

vehicle unless you delete them and are

generally accessible only in the vehicle

when the cellular phone or media player

is connected. If you no longer plan to use

the system or the vehicle, we recommend

you perform a Master Reset to erase all

stored information.

System data cannot be accessed without

special equipment and access to the

vehicle's SYNC module. Ford Motor

Company and Ford of Canada will not

access the system data for any purpose

other than as described absent consent, a

court order, or where required by law

enforcement, other government

authorities, or other third parties acting

with lawful authority. Other parties may

seek to access the information

independently of Ford Motor Company and

Ford of Canada.

282

F-650/750 (TBC) , enUSA, First Printing SYNC™

(If Equipped)

Page 318 of 382

•

Brake pads and linings.

• Shock absorbers.

• Struts.

• Engine Belts.

• Engine coolant hoses, clamps and

o-rings.

• Diesel exhaust fluid replenishment.

Interest Free Finance Options

Just a 10% down payment will provide you

with an affordable, no interest, no fee

payment program allowing you all the

security and benefits Ford ESP has to offer

while paying over time. You are

pre-approved with no credit check or

hassles. To learn more, call our Ford

Protect Extended Service Plan specialists

at 800-367-3377.

Ford Protect Extended Service Plan

P.O. Box 321067

Detroit, MI 48232

EXTENDED SERVICE PLAN

(CANADA ONLY)

You can get more protection for your

vehicle by purchasing a Ford Extended

Service Plan. Ford Extended Service Plan

is the only service contract backed by Ford

Motor Company of Canada, Limited.

Depending on the plan you purchase, Ford

Extended Service Plan provides benefits

such as:

• Rental reimbursement.

• Coverage for certain maintenance and

wear items.

• Protection against repair costs after

your New Vehicle Limited Warranty

Coverage expires.

• Roadside Assistance benefits. There are several Ford Extended Service

Plans available in various time, distance

and deductible combinations. Each plan

is tailored to fit your own driving needs,

including reimbursement for towing and

rental. When you purchase Ford Extended

Service Plan, you receive added

peace-of-mind protection throughout

Canada, the United States and Mexico,

provided by a network of participating

authorized Ford Motor Company dealers.

Note:

Repairs performed outside of

Canada, the United States and Mexico are

not eligible for Ford Extended Service Plan

coverage.

This information is subject to change. For

more information, visit your local Ford of

Canada dealer or www.ford.ca to find the

Ford Extended Service Plan that is right for

you.

315

F-650/750 (TBC) , enUSA, First Printing Ford Protect

Page 321 of 382

To make sure the emissions control

systems operate effectively, you should

have the services listed in the maintenance

schedule performed at the specified time

and mileage intervals. You should avoid

running out of fuel or turning off the ignition

when your vehicle is moving, especially at

high speeds.

Do not make unauthorized modifications

to the engine or vehicle. Modifications

causing increased amounts of unburned

fuel to reach the exhaust system can

significantly increase the temperature of

the engine compartment and the exhaust

system.

Avoid driving your vehicle if it does not

operate properly. If the engine diesels

(more than five seconds of engine run-on

after shut-off), misfires, surges, stalls or

backfires, see an authorized dealer. Be alert

for fluid leakage, odor, smoke, loss of oil

pressure, or charge indicator or over

temperature warning.

Vehicles equipped with a diesel engine

cannot use diesel fuel blended with waste

oil if equipped with a catalytic

converter-muffler. Waste lube oil blending

in fuel plugs the catalytic

converter-muffler, resulting in a significant

loss of engine power.

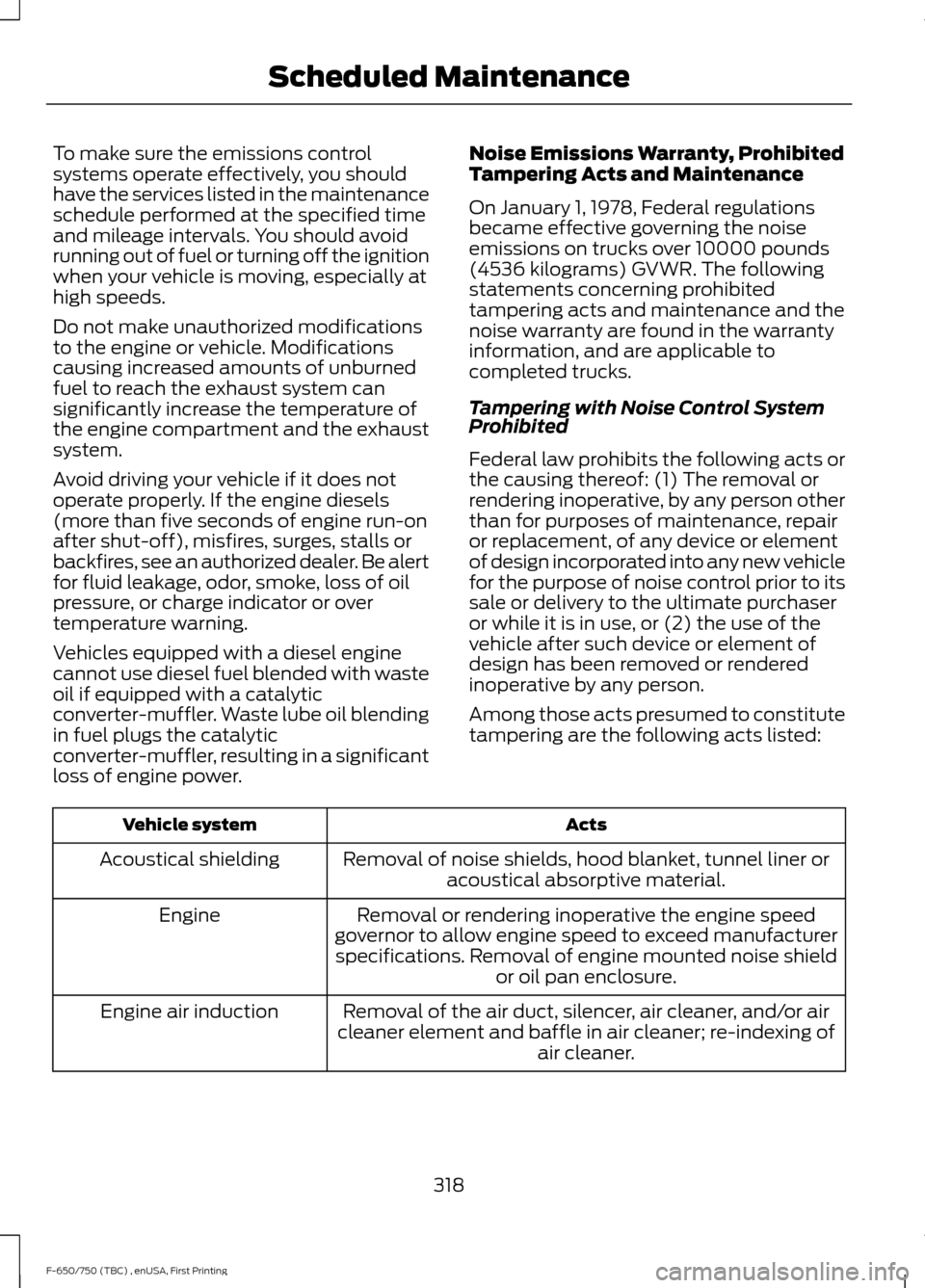

Noise Emissions Warranty, Prohibited

Tampering Acts and Maintenance

On January 1, 1978, Federal regulations

became effective governing the noise

emissions on trucks over 10000 pounds

(4536 kilograms) GVWR. The following

statements concerning prohibited

tampering acts and maintenance and the

noise warranty are found in the warranty

information, and are applicable to

completed trucks.

Tampering with Noise Control System

Prohibited

Federal law prohibits the following acts or

the causing thereof: (1) The removal or

rendering inoperative, by any person other

than for purposes of maintenance, repair

or replacement, of any device or element

of design incorporated into any new vehicle

for the purpose of noise control prior to its

sale or delivery to the ultimate purchaser

or while it is in use, or (2) the use of the

vehicle after such device or element of

design has been removed or rendered

inoperative by any person.

Among those acts presumed to constitute

tampering are the following acts listed:

Acts

Vehicle system

Removal of noise shields, hood blanket, tunnel liner oracoustical absorptive material.

Acoustical shielding

Removal or rendering inoperative the engine speed

governor to allow engine speed to exceed manufacturer specifications. Removal of engine mounted noise shield or oil pan enclosure.

Engine

Removal of the air duct, silencer, air cleaner, and/or air

cleaner element and baffle in air cleaner; re-indexing of air cleaner.

Engine air induction

318

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 324 of 382

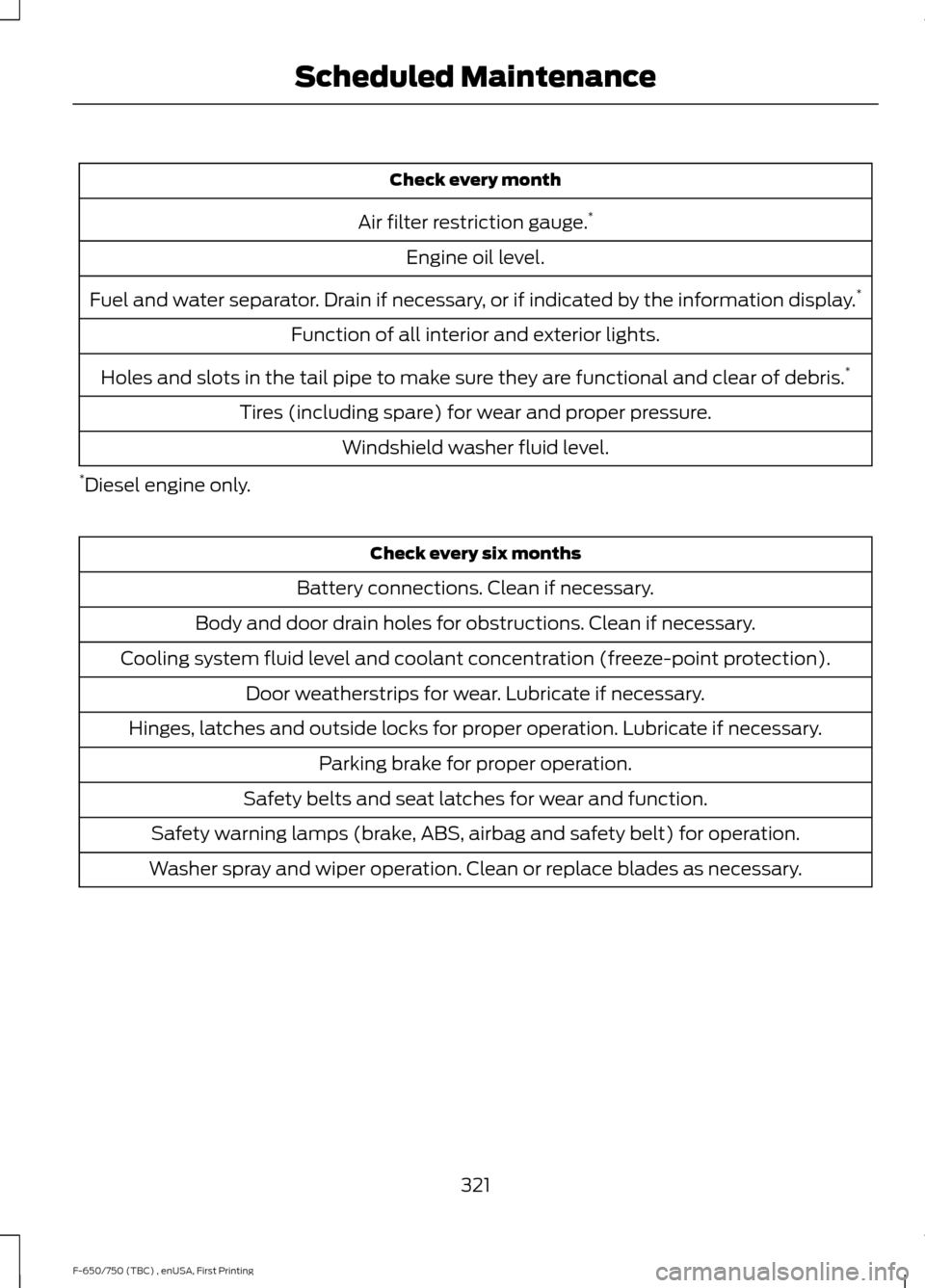

Check every month

Air filter restriction gauge. *

Engine oil level.

Fuel and water separator. Drain if necessary, or if indicated by the information display. *

Function of all interior and exterior lights.

Holes and slots in the tail pipe to make sure they are functional and clear of debris. *

Tires (including spare) for wear and proper pressure. Windshield washer fluid level.

* Diesel engine only. Check every six months

Battery connections. Clean if necessary.

Body and door drain holes for obstructions. Clean if necessary.

Cooling system fluid level and coolant concentration (freeze-point protection). Door weatherstrips for wear. Lubricate if necessary.

Hinges, latches and outside locks for proper operation. Lubricate if necessary. Parking brake for proper operation.

Safety belts and seat latches for wear and function.

Safety warning lamps (brake, ABS, airbag and safety belt) for operation.

Washer spray and wiper operation. Clean or replace blades as necessary.

321

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance